Semi-solid forming method of composite pipe

A technology for semi-solid forming and composite material pipes, which is applied in the field of metal semi-solid forming, which can solve the problems of long forming cycle, high product cost, and difficult processing and manufacturing of difficult-to-deform material pipes, and achieve high interface bonding strength and reduce forming Easy to load and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

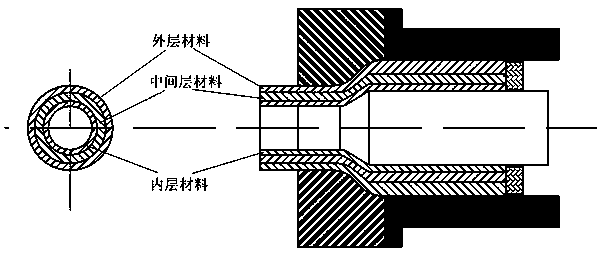

[0023] Taking Q235 carbon steel and high-chromium cast iron as an example to prepare composite material pipes, the hard-to-plastic deformation material of the middle layer is high-chromium cast iron, and the easy-to-plastic deformation material is Q235 carbon steel.

[0024] The composite tube semi-solid forming method, its specific steps are as follows:

[0025] (1) Measure the solidus and liquidus temperatures of the difficult-to-plastically deform material in the middle layer, and use differential scanning calorimetry (DSC) to measure the solidus temperature of high-chromium cast iron to be 1230°C and the liquidus temperature to be 1420°C;

[0026] (2) A three-layer composite material tube blank is obtained by casting with a centrifugal casting machine: first, pour the outer layer of easily plastically deformable material with a thickness of 6 mm, then cast the middle layer of difficultly plastically deformable material, and finally cast the inner layer of easily plastically...

Embodiment 2

[0031] Taking 45# carbon steel and ZCuSn10P1 tin bronze as an example to prepare a composite material pipe, the material of the middle layer that is hard to deform plastically is ZCuSn10P1 tin bronze, and the material that is easily plastically deformable is 45# carbon steel.

[0032] The composite tube semi-solid forming method, its specific steps are as follows:

[0033] (1) Measure the solidus and liquidus temperatures of the hard-to-plastically deformable material in the middle layer, and use differential scanning calorimetry (DSC) to measure the solidus temperature of ZCuSn10P1 tin bronze to be 820°C and the liquidus temperature to be 1003°C;

[0034] (2) A three-layer composite material tube blank is obtained by casting with a centrifugal casting machine: first, pour the outer layer of easily plastically deformable material with a thickness of 5mm, then cast the middle layer of difficultly plastically deformable material, and finally cast the inner layer of easily plastic...

Embodiment 3

[0039] Taking stainless steel and ZCuSn10 tin bronze as an example to prepare a composite material tube, the material of the middle layer that is difficult to deform plastically is ZCuSn10 tin bronze, and the material that is easy to deform plastically is stainless steel.

[0040] The composite tube semi-solid forming method, its specific steps are as follows:

[0041] (1) Measure the solidus and liquidus temperatures of the hard-to-plastic-deformable material in the middle layer, and use differential scanning calorimetry (DSC) to measure the solidus temperature of ZCuSn10 tin bronze to be 830°C and the liquidus temperature to be 1020°C;

[0042] (2) A three-layer composite material tube blank is obtained by casting with a centrifugal casting machine: first, pour the outer layer of easily plastically deformable material with a thickness of 2mm, then cast the middle layer of difficultly plastically deformable material, and finally cast the inner layer of easily plastically defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com