Nonanisotropic magnesium alloy bar extrusion forming mold

An anisotropic, extrusion forming technology, applied in the direction of metal extrusion dies, can solve problems such as restricting the extensiveness of the extrusion process, cracking, product scrapping, etc., to achieve significant economic benefits, high mechanical properties, and improved mold effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without paying creative labor. Please refer to Figure 1-10 .

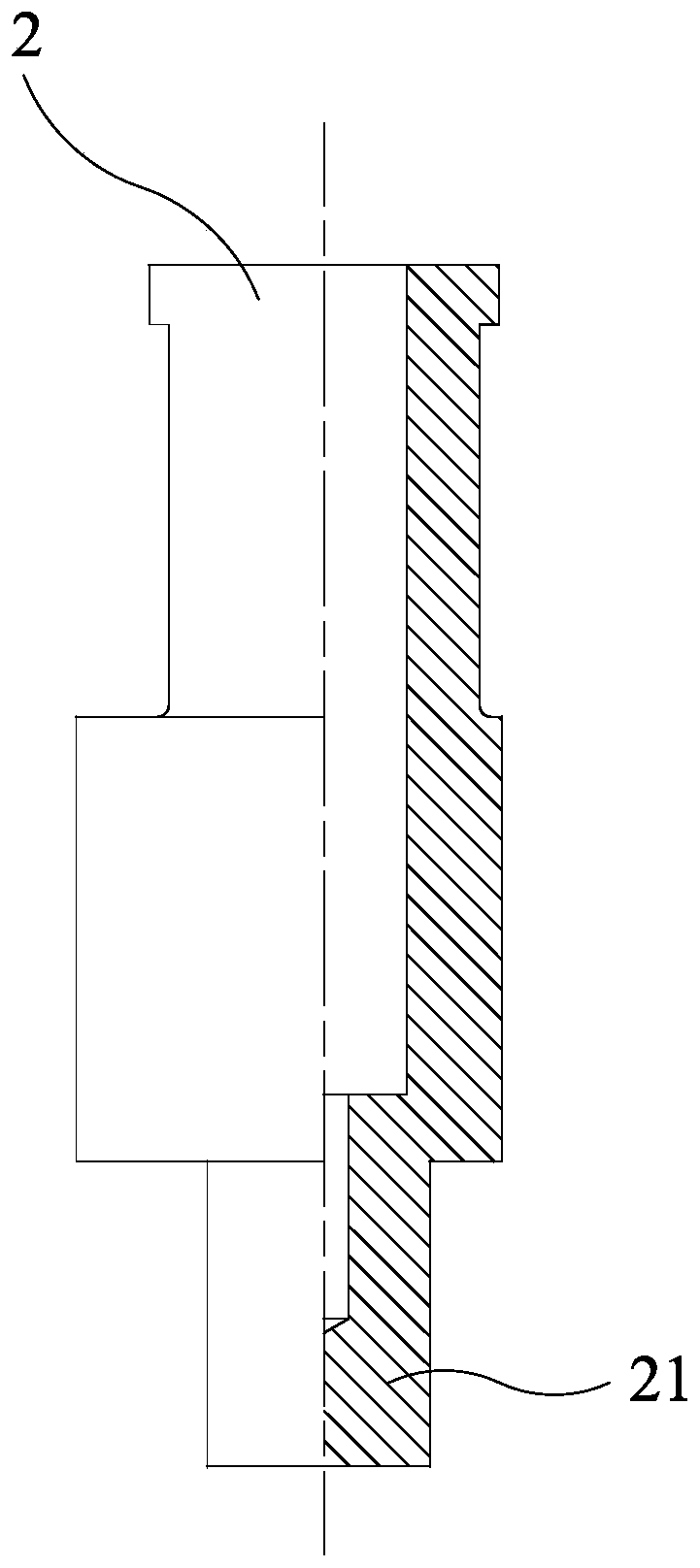

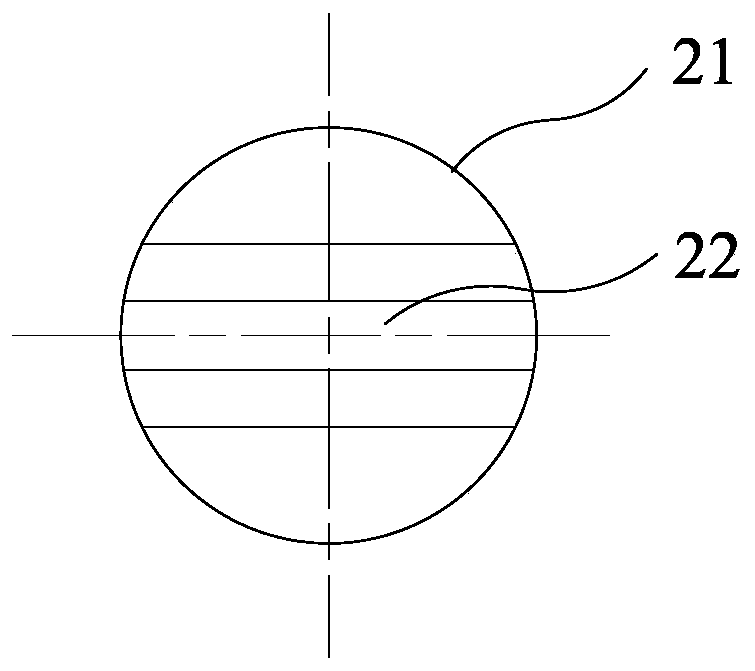

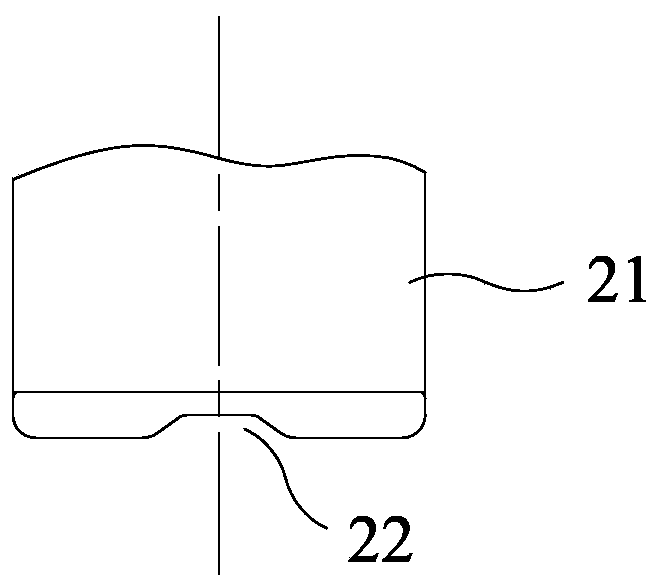

[0028] A non-anisotropic extrusion die for magnesium alloy rods, please refer to figure 1 , figure 2 , Figure 7 and Figure 9 , including an insert 1, a punch 2 connected to a press (not shown in the figure), a die 3 connected to a rotating mechanism (not shown in the figure), and an ejection mechanism (not shown in the figure), so The punch 2 is connected to a press to move axially, and the die 3 is connected to a rotating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com