Optical fiber optofluidic dye laser

A dye laser and optical fluid technology, applied in the optical field, can solve the problems affecting the use range and application flexibility of the light source, the laser output beam mode is not adjustable, the optical resonator structure is not adjustable, etc. Flexibility, output beam pattern controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

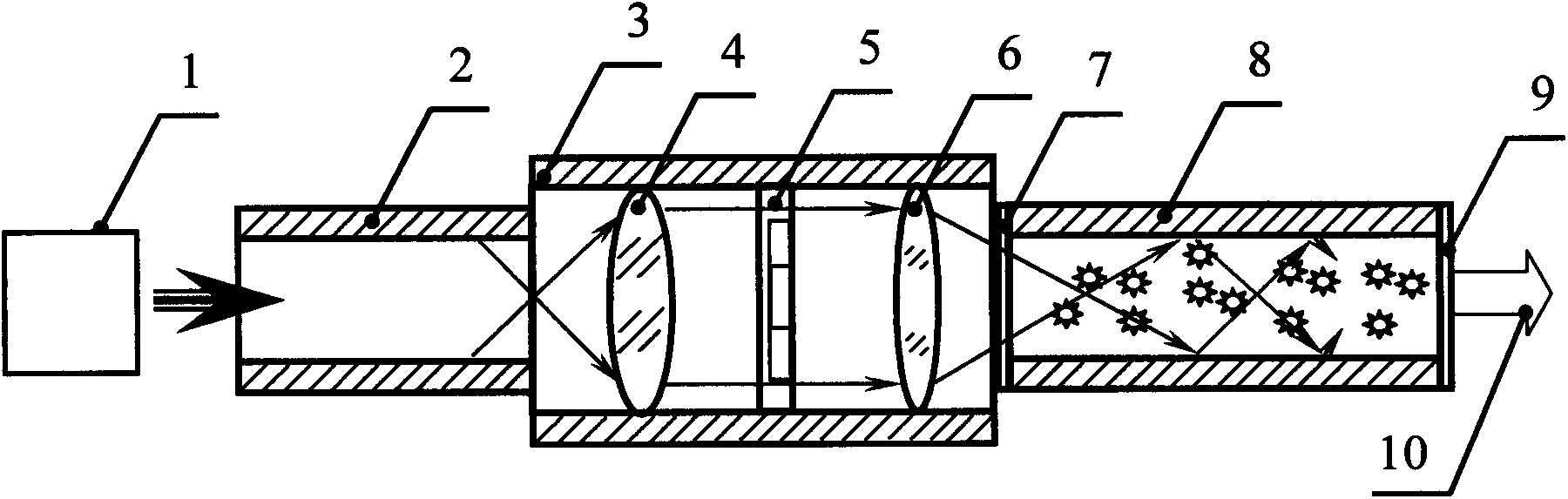

[0019] like figure 1 Shown is a schematic diagram of the structure of a fiber optofluidic dye laser according to an embodiment of the present invention, which is a rotationally symmetrical structure, and a pumping light source 1, a pumping fiber 2, and a light beam are sequentially arranged on the optical path of the incident pumping beam on the same optical axis. Shaping device 3, first reflector 7, dye hollow-core fiber 8, second reflector 9; first reflector 7, dye hollow-core fiber 8 and second reflector 9 form a resonant cavity, and the resonant cavity is provided with laser The dye of the gain medium; the beam shaping device 3 is sequentially provided with a collimating lens 4, a phase adjuster 5 and a converging lens 6 in the direction of propagation of the pumping beam, and the collimating lens 4 collimates the outgoing beam of the pumping optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com