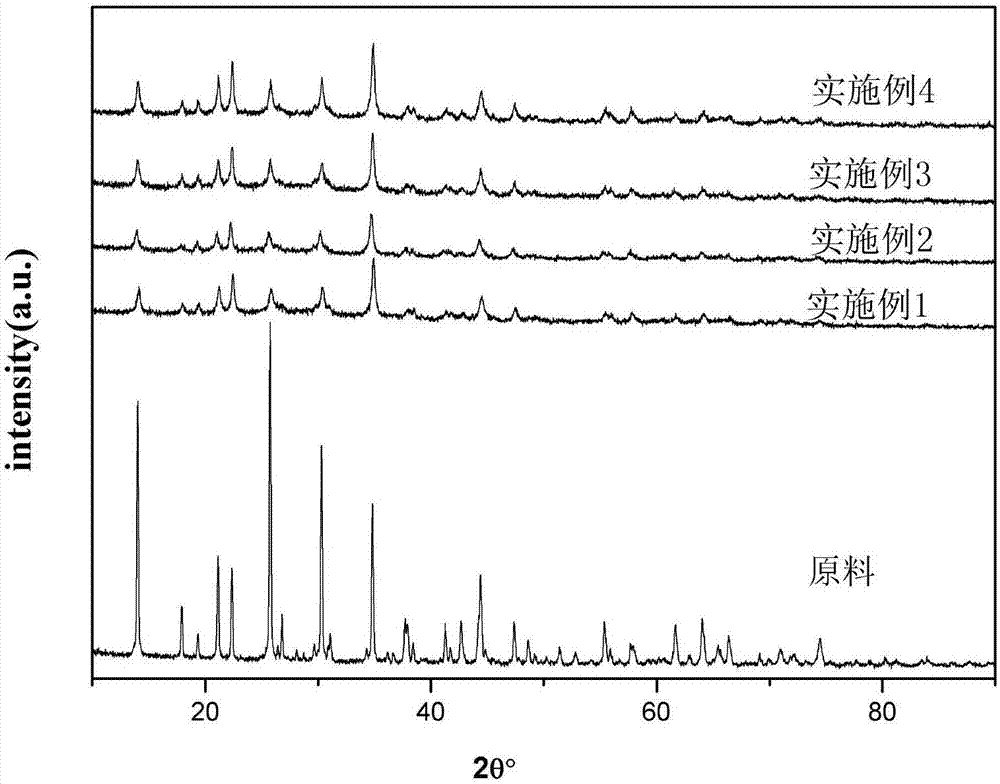

Preparation method for nanometer tourmalinite powder

A tourmaline powder and nano-scale technology, which is applied in the field of preparation of nano-scale tourmaline powder, can solve the problems of high processing conditions, complex process flow, high temperature environment, etc., to shorten the grinding time, simplify the process, and increase the amount of dissolved oxygen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

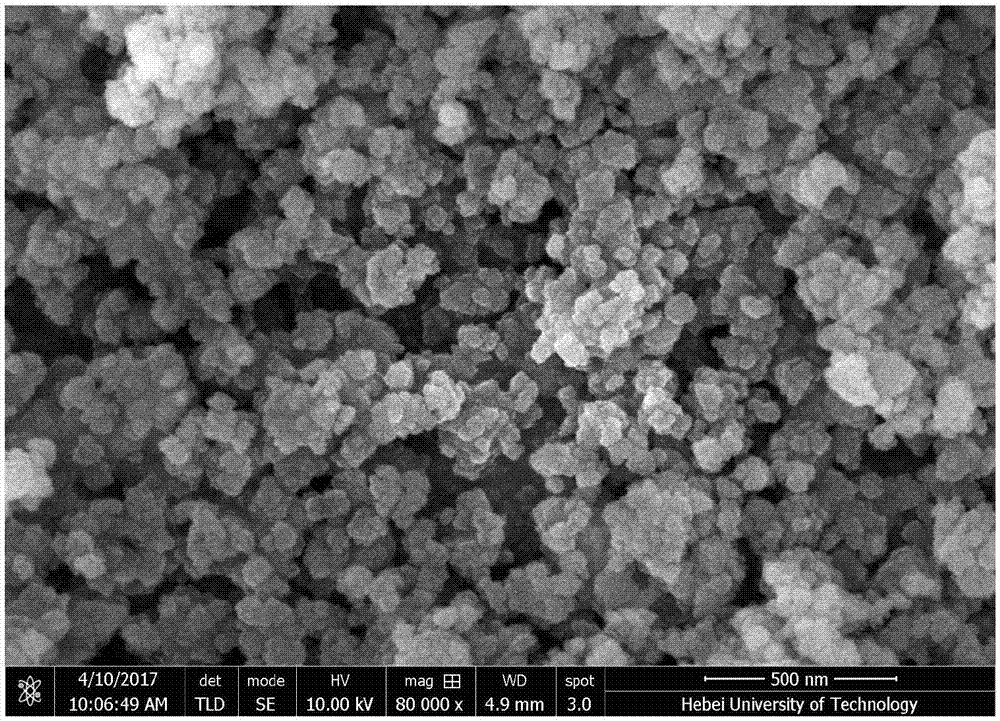

Embodiment 1

[0033]The present embodiment prepares the method for nanoscale tourmaline powder, comprises the following steps:

[0034] (1) Wet high-speed coarse grinding: Using ferrite tourmaline with a particle size of 15 μm as raw material, add 18g of zirconia grinding beads, 6g of ferrite and 9mL of water into the ball mill tank in turn for coarse grinding, micron-sized tourmaline powder The mass ratio of body and rough grinding medium material is 1:3, the mass ratio of micron-sized tourmaline powder to water is 1:1.5, the rough grinding speed is 1100r / min, and the rough grinding time is 1h, so that the tourmaline particles reach 1 to 5 μm to obtain tourmaline rough grinding slurry; the rough grinding material is zirconia grinding beads with a particle size of 2 mm;

[0035] (2) Wet high-speed fine grinding: After the tourmaline coarse grinding slurry prepared in step (1) is separated from the coarse grinding material, it is mixed with the fine grinding material and then diluted with wa...

Embodiment 2

[0039] The specific steps of the method for preparing nano-tourmaline powder in this embodiment are the same as in Example 1, except that the rough grinding material in this embodiment is zirconia grinding beads with a particle size of 1 mm and a mass of 35 g; 10g particle size is ferrite tourmaline of 20 μm, add 15mL water in the process of wet high-speed coarse grinding; h.

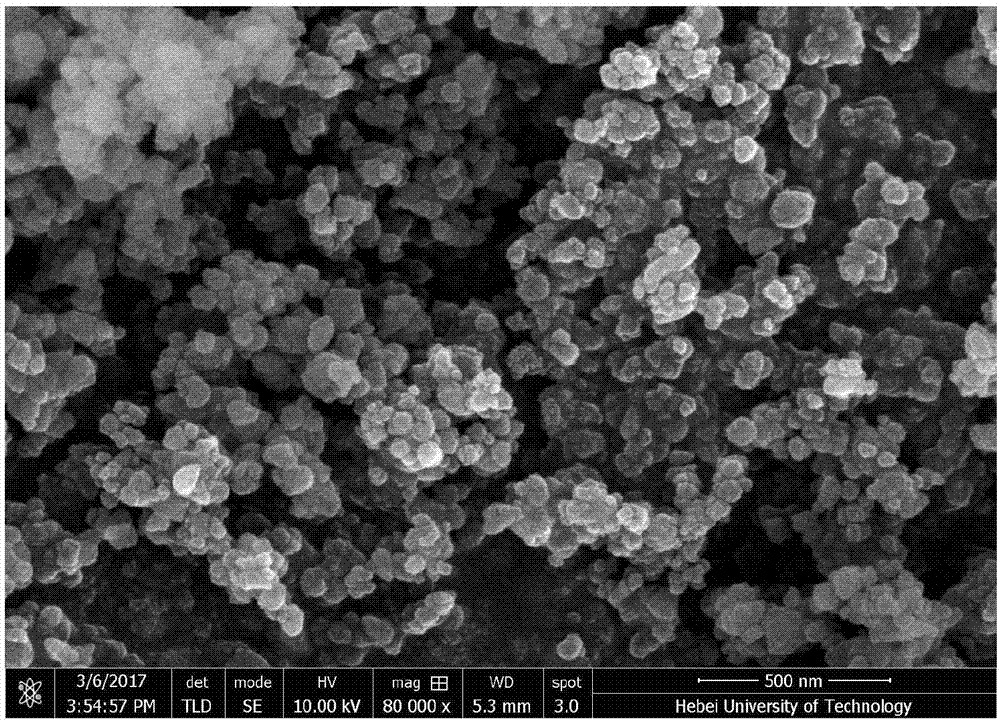

Embodiment 3

[0041] The specific steps of the method for preparing nano-tourmaline powder in this embodiment are the same as in Example 1, except that the rough grinding medium material in this embodiment is zirconia grinding beads with a particle size of 1 mm and 3 mm; wet method Add 6mL of water during the high-speed fine grinding process, the fine grinding time is 2h, and the rough grinding time is 2.5h.

[0042] In this embodiment, the nano-tourmaline slurry obtained in step (2) is packed in a container and placed in a freeze dryer, dried at a vacuum of 50 Pa and at a temperature of -60°C, and dried for 8 hours to obtain nano-tourmaline powder body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com