Far infrared water heating radiator and preparation method thereof

A far-infrared radiator technology, applied in the field of far-infrared water heating radiators and its preparation, can solve the problems of metal radiators with short service life, corrosion, failure to reach the 15-year target, waste of national resources, etc., and achieve ingenious structural design, Long service life, good acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

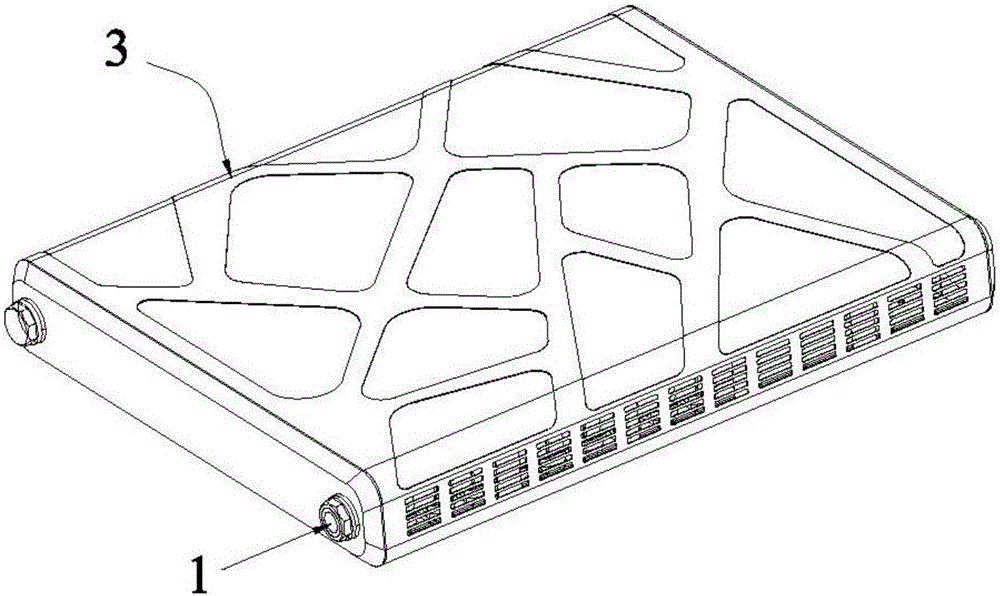

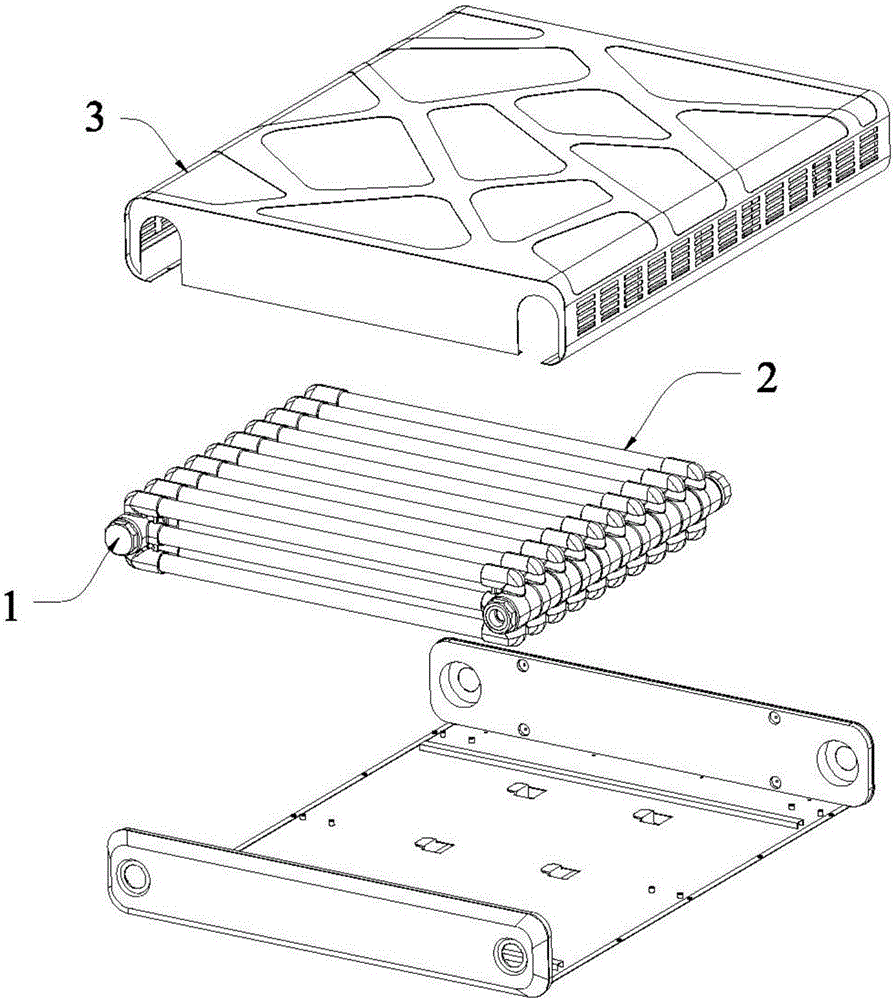

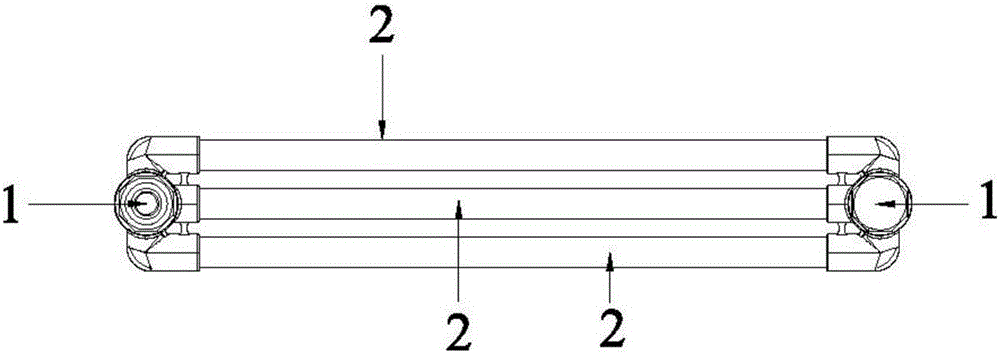

[0031] Example 1: see Figure 1 to Figure 5 , the present embodiment provides a far-infrared water heating radiator, which includes a heat-dissipating pipe 1 and a main water pipe 2 made of far-infrared composite materials through extrusion or injection molding processes. The pipeline 1 is horizontally arranged between two main water pipelines 2 and communicates with the main water pipelines 2 . In this embodiment, the heat dissipation pipe 1 is linear, simple in structure, and easy to implement; in other embodiments, the heat dissipation pipe 1 can also be in the shape of a coil, that is, coiled to meet different heat dissipation requirements.

[0032] Preferably, the radiating pipes at the same level form a radiating pipe row group. In this embodiment, refer to figure 2 and image 3 , the number of the heat pipe rows is 3 groups. see Figure 4 , the number of heat pipe rows is 2 groups; see Figure 5 , the number of the heat pipe row is 1 group. Of course, in other em...

Embodiment 2

[0046] Embodiment 2, this embodiment provides a kind of far-infrared plumbing radiator and preparation method thereof, and it is basically the same as embodiment 1, difference is: described far-infrared composite material is made up of the raw material of following weight fraction ratio: main base material 10 parts, 2 parts flake graphite powder, 5 parts carbon fiber, 1 part ceramic, 6 parts silicon carbide.

Embodiment 3

[0047]Embodiment 3, this embodiment provides a kind of far-infrared plumbing radiator and its preparation method, and it is basically the same as embodiment 1, difference is: described far-infrared composite material is made up of the raw material of following weight fraction ratio: main base 10 parts of raw materials, 10 parts of main base material, 6 parts of flake graphite powder, 1 part of carbon fiber, 4 parts of ceramics, and 1 part of silicon carbide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com