Feeding device

A technology of feeding device and conveying device, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of not being able to reduce the moisture of materials well, the volume of the feeding device is large, and the conveying device is easy to block, etc., to achieve the effect of heat dissipation Good, improve production efficiency, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

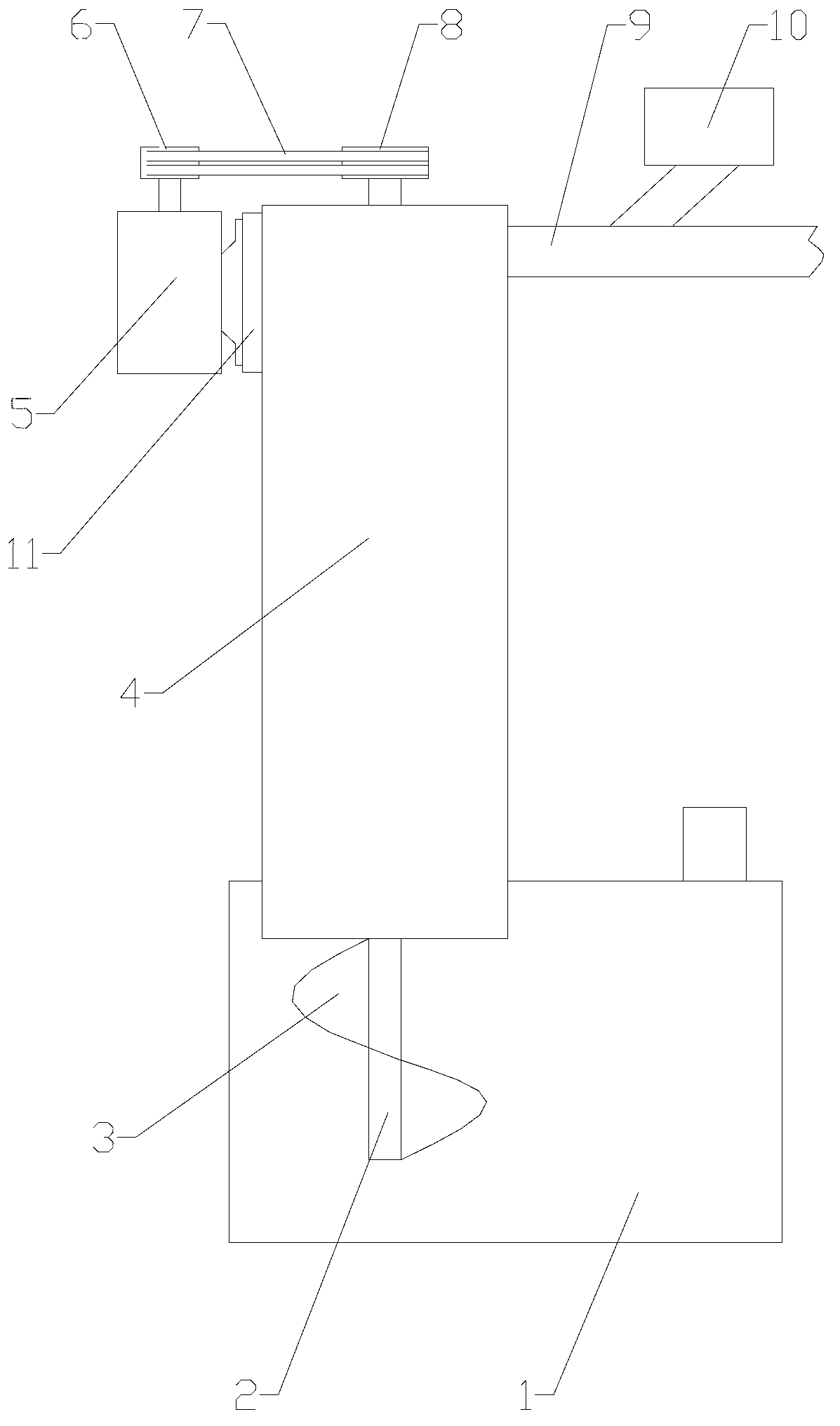

[0021] Embodiment: As shown in the drawings, a feeding device includes a storage tank 1, the storage tank 3 is connected with a conveying device, and the conveying device includes a feeding cylinder 4, and a rotating shaft 2 is arranged in the feeding cylinder 4 , the rotating shaft 2 is provided with a helical blade 3 , and the feeding cylinder 4 is provided with a discharge pipe 9 , and the discharge pipe 9 is connected with an induced draft fan 10 .

[0022] The rotating shaft 2 passes through the two ends of the feeding cylinder 4 .

[0023] One end of the rotating shaft 2 close to the discharge pipe 9 is connected with a motor 5 , and the other end of the rotating shaft 2 is located in the storage tank 3 .

[0024] The motor 5 is connected to the rotating shaft 2 through a belt transmission, and other transmissions, such as chain transmission, gear transmission, etc., can also be used as required.

[0025] The belt transmission includes a first pulley 6 arranged on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com