High-titanium protection stove pellet ore and preparation thereof

A pellet and high-titanium technology, which is applied in the field of metallurgy, can solve problems such as low melting point, accidents, and no high-titanium furnace protection pellets, etc., and achieves uniform particle size, reduced transportation costs, and good reducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Preparation of high-titanium furnace protection pellets of the present invention

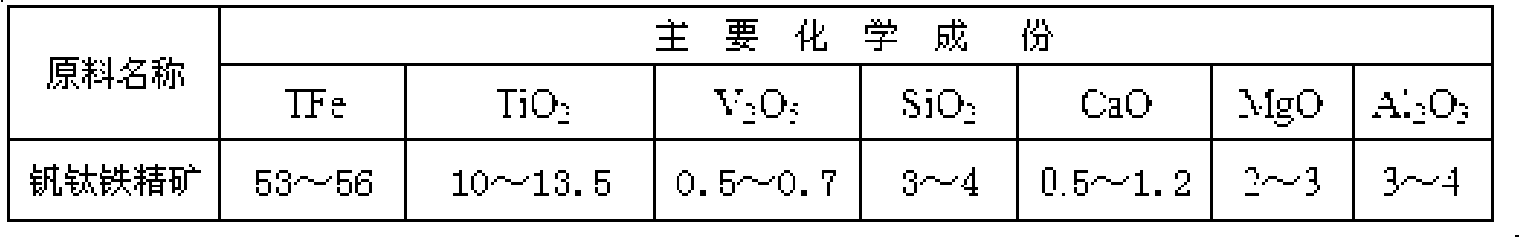

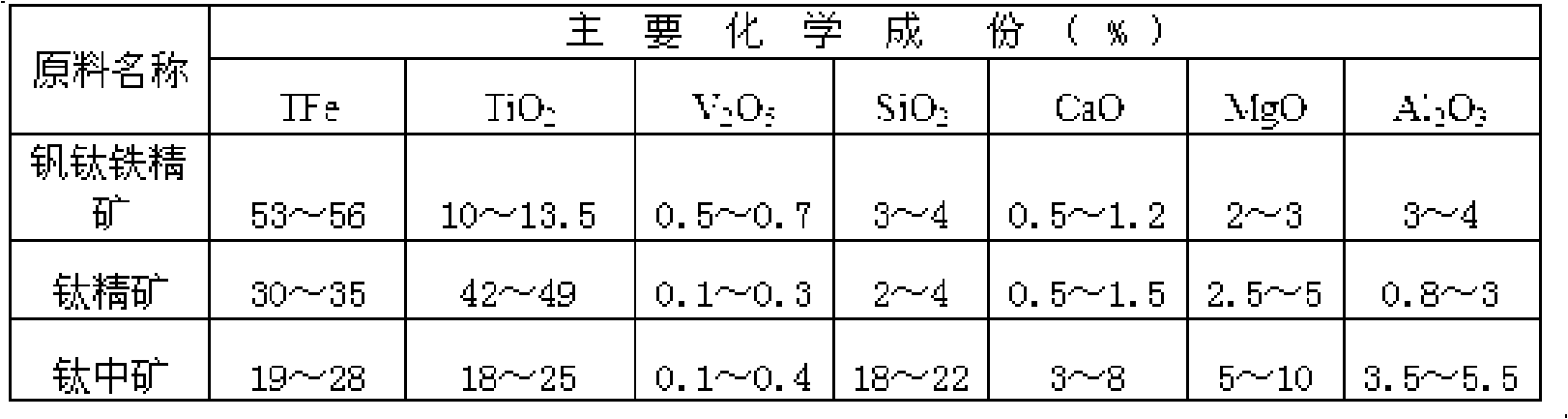

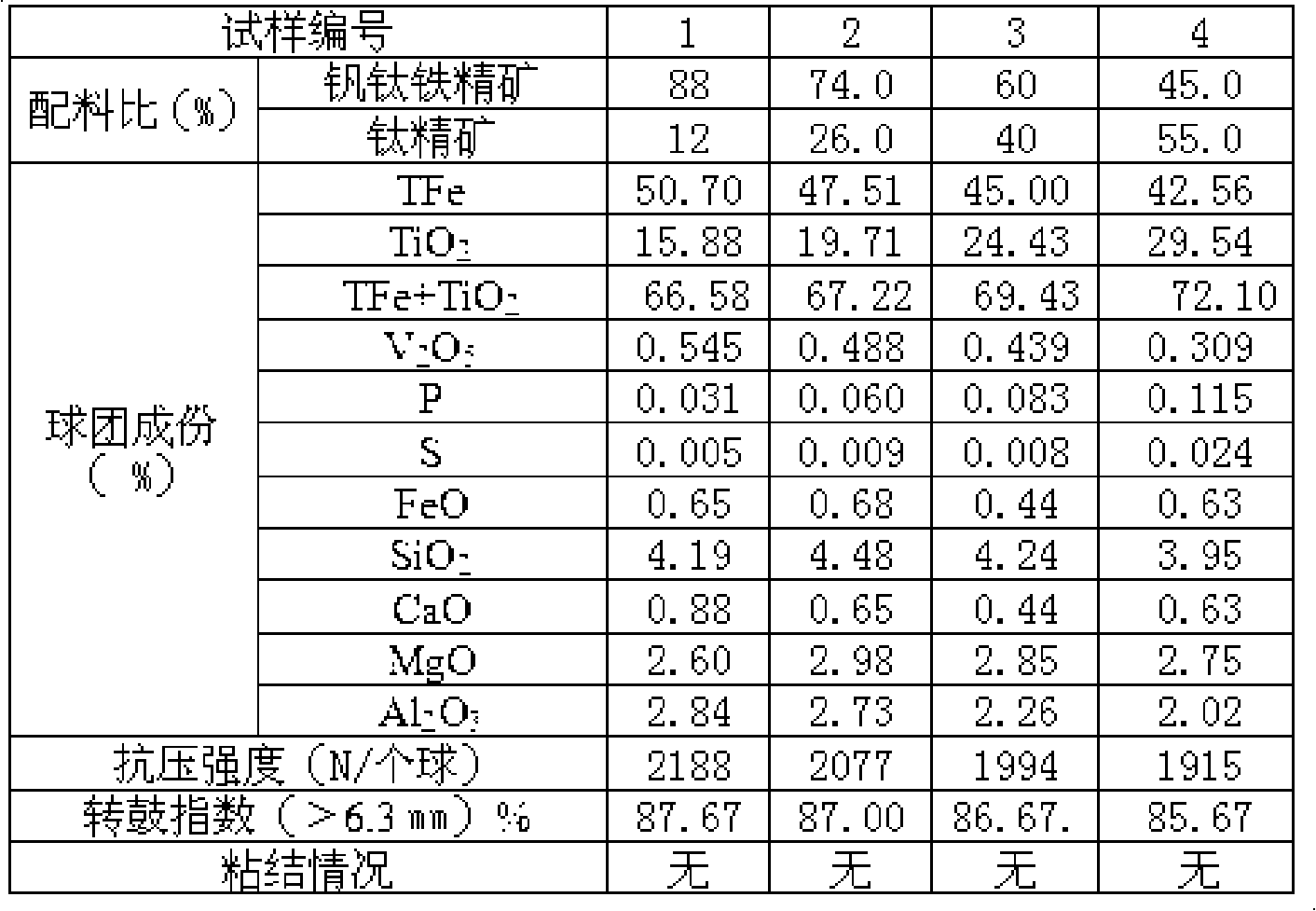

[0035] The vanadium-titanium iron concentrate and titanium concentrate in Table 2 are used as raw materials for batching, and then roasted according to the method of the present invention, and the performance of the prepared high-titanium furnace-protected pellets is measured. See Table 3 for the specific ingredient ratio and performance measurement results of high-titanium furnace protection pellets.

[0036] Table 3 Raw material ratio and performance determination of high-titanium furnace protection pellets

[0037]

Embodiment 2

[0038] Example 2 Preparation of High Titanium Furnace Protecting Pellets of the Present Invention

[0039] The vanadium-titanium iron concentrate, titanium concentrate and titanium medium ore in Table 2 are used as raw materials for batching, and then roasted according to the method of the present invention, and the performance of the prepared high-titanium furnace-protected pellets is measured. See Table 4 for the specific ingredient ratio and performance measurement results of high-titanium furnace protection pellets.

[0040] Table 4 Raw material ratio and performance determination of high titanium furnace pellets (TiO 2 content is about 20%)

[0041]

Embodiment 3

[0042] Example 3 Preparation of High Titanium Furnace Protecting Pellets of the Present Invention

[0043] The vanadium-titanium iron concentrate, titanium concentrate and titanium medium ore in Table 2 are used as raw materials for batching, and then roasted according to the method of the present invention, and the performance of the prepared high-titanium furnace-protected pellets is measured. See Table 5 for the specific ingredient ratio and performance measurement results of high-titanium furnace protection pellets.

[0044] Table 5 Raw material ratio and performance determination of high titanium furnace pellets (TiO 2 content is about 16.5%)

[0045]

[0046] As can be seen from Tables 3, 4, and 5, the drum index (GB8209) of the high-titanium furnace-protected pellets of the present invention can reach more than 85%, the compressive strength is ≥ 1800N / ball, and the furnace does not stick to the furnace during production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com