Method for producing fragrant and fruity persimmon leaf tea

A production method and technology of flower and fruit fragrance, applied in the direction of tea substitutes and other directions, can solve the problems that affect the development of persimmon industry, the green smell and bitterness of persimmon leaf tea are serious, and achieve accurate and reliable data, high aroma and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: stacking fermentation single factor optimization:

[0026] The fresh young leaves of picking persimmon tree require fresh leaves to be green without disease and pests, and are operated by kneading and cutting, stacking and fermenting, and drying (see "Invention Contents" of this manual). The kneading and cutting is carried out in the 6CRQ-20 rotor kneading and cutting machine (Zhejiang Fuyang Tea Machinery Factory), the speed is 34r / min, the time is 0.5min, and the kneading and cutting are repeated twice. : 60cm*40cm*30cm), drying is carried out in a 6CH-1.3 continuous dryer (product of Zhejiang Lufeng Machinery Co., Ltd.) (drying twice, the first temperature is 100-120°C, so that the persimmon leaves water content to 10-15%; the second baking temperature is 80-90°C to make the water content of persimmon leaves to 3-5%), and finally packaged for delivery. In order to realize the optimization of products and processes, different fermentation temperature te...

Embodiment 2

[0046] Embodiment 2: Orthogonal optimization of stacking fermentation conditions:

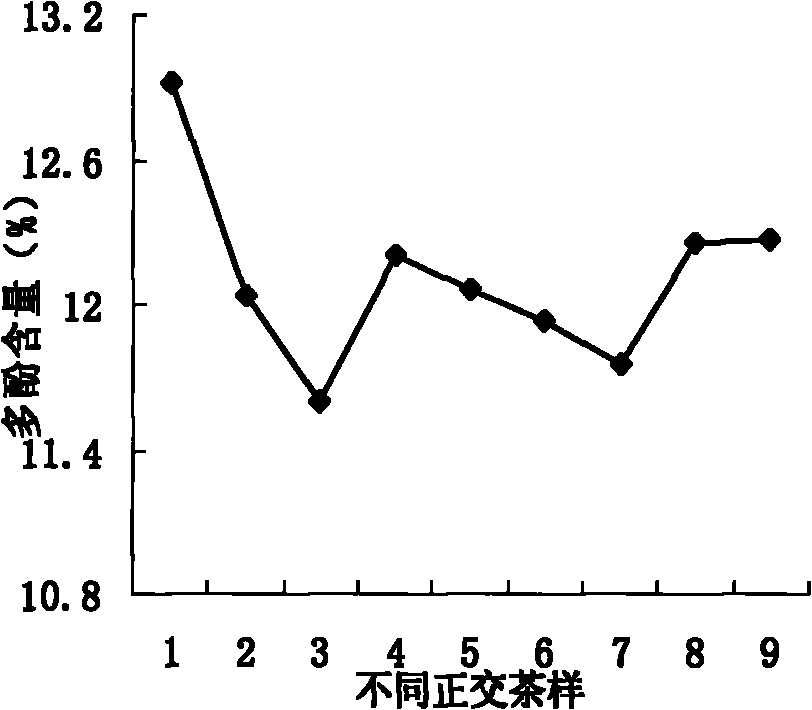

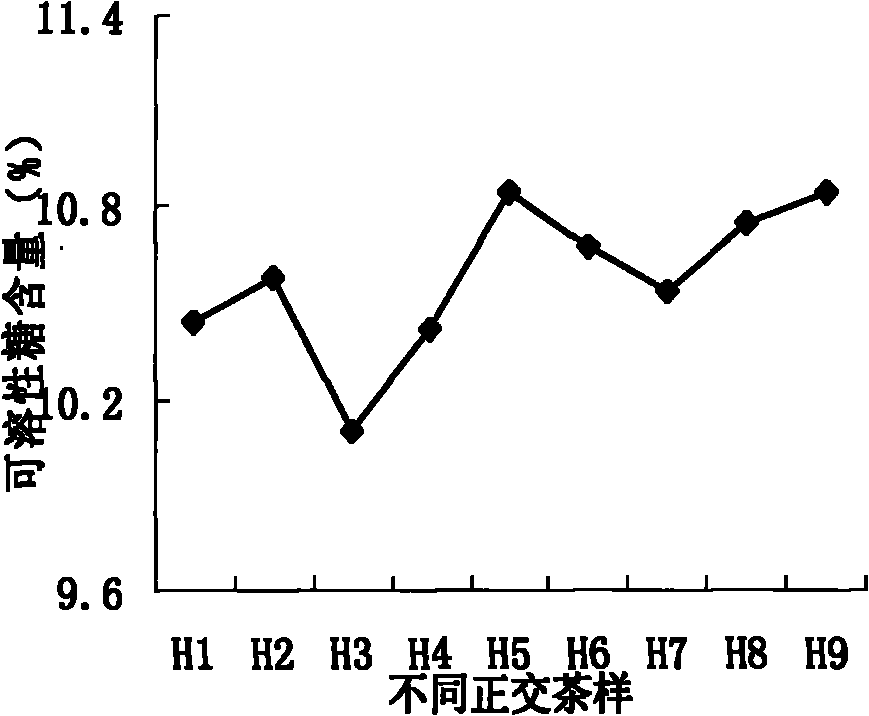

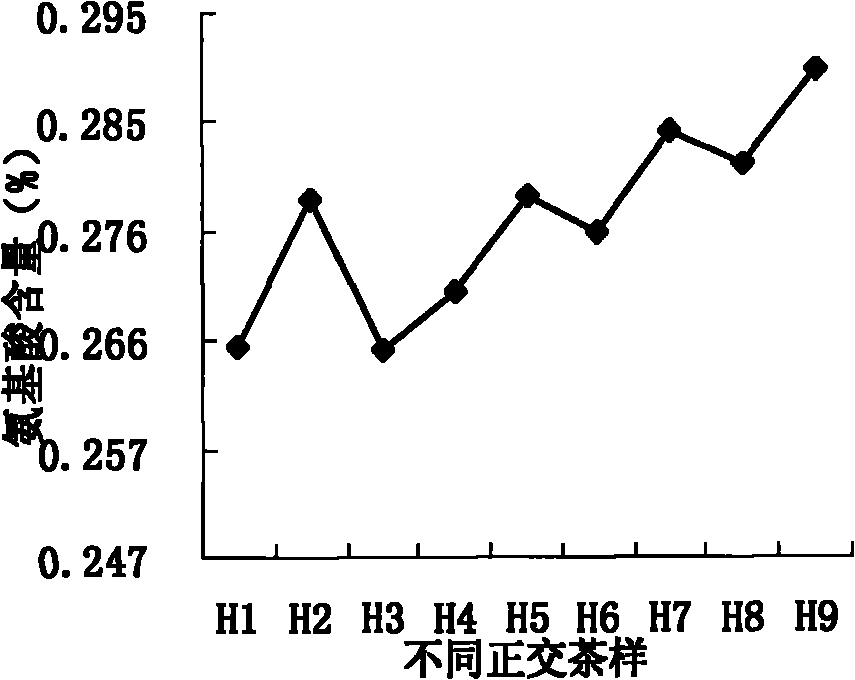

[0047] Pick the fresh young leaves of the persimmon tree, require fresh leaves to be green, and have no disease and insect leaves, and operate according to the process of embodiment 1. The kneading and cutting are carried out in the 6CRQ-20 rotor kneading and cutting machine (Zhejiang Fuyang Tea Machinery Factory), and the kneading and cutting are repeated twice. Carry out in 6CH-1.3 type continuous dryer (Zhejiang Lvfeng Machinery Co., Ltd.) (drying 2 times, the first temperature is 100-120 ℃, so that the moisture content of persimmon leaves reaches 10-15%; the second drying Temperature is 80~90 ℃, make the water content of persimmon leaves reach 3~5%), finally pack and leave the factory. Set fermentation temperature (25°C, 30°C, 35°C), fermentation time (8h, 10h, 12h), relative humidity of fermentation (55%, 70%, 85%) three-factor three-level orthogonal experiment (see Table 7) , the results ...

Embodiment 3

[0079] Embodiment 3: the comparison of technique of the present invention and traditional technique

[0080] The process of the present invention: picking fresh young leaves, green fresh leaves, leaves free of disease and insects, and operating according to the technological process of kneading and cutting, stacking and fermenting, and drying. Kneading and cutting is carried out in a 6CRQ-20 rotor kneading and cutting machine (product of Zhejiang Fuyang Tea Machinery Factory), repeated twice, stacking and fermenting on a self-made fermentation plate (length*width*height: 60cm*40cm*30cm, leaf thickness 15cm~20cm , the temperature is controlled at 30°C-35°C, the humidity is controlled at 50%-70%, and the time is 12h), and the drying is carried out in a 6CH-1.3 continuous dryer (product of Zhejiang Lvfeng Machinery Co., Ltd.) (drying 2 times, The temperature for the first time is 100°C-120°C, the water content of the persimmon leaves is 10%-15%; the temperature for the second tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com