Material additive manufacturing device and method of high-degree-of-freedom complex structural part

A complex structure, additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of reducing forming efficiency, increasing powder consumption, twisting deformation, etc., to achieve the effect of improving forming efficiency, avoiding rebound deformation, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

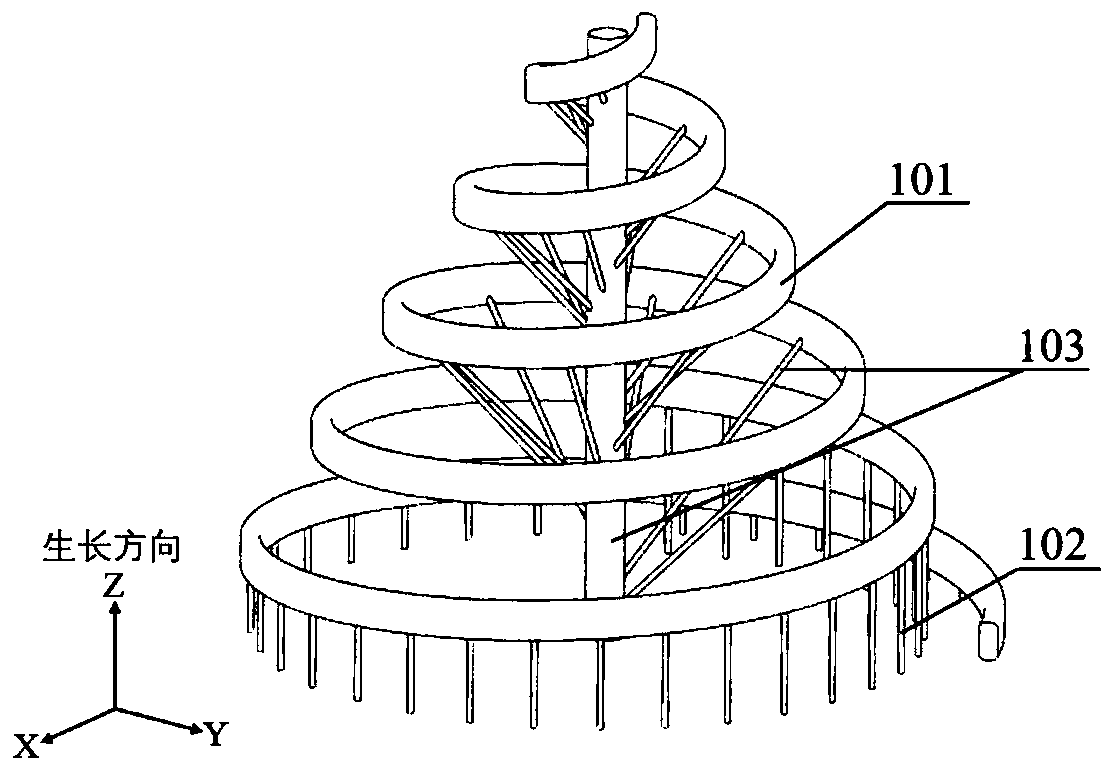

[0052] This embodiment 1 is to explain the three-dimensional spatial positioning conformal tree-shaped support structure used for additive manufacturing of high-degree-of-freedom and complex-structure 60Mn steel parts, and the structural shape of the 60Mn steel parts is similar to a cone-shaped spring.

[0053] Include the following steps:

[0054] Step 1: Design and optimize the 60Mn steel part structure 101, and generate a corresponding three-dimensional solid model;

[0055] Step 2: Determine the placement form and position of the three-dimensional solid model of the 60Mn steel part structure 101, the axis of the 60Mn steel part structure 101 is parallel to the growth direction;

[0056] Step 3: for the structure and shape of the 60Mn steel part structure 101, select the three-dimensional space positioning follow-the-shaped tree-shaped support structure, add a small amount of conventional support structures 102 and the three-dimensional space positioning follow-the-shaped t...

Embodiment 2

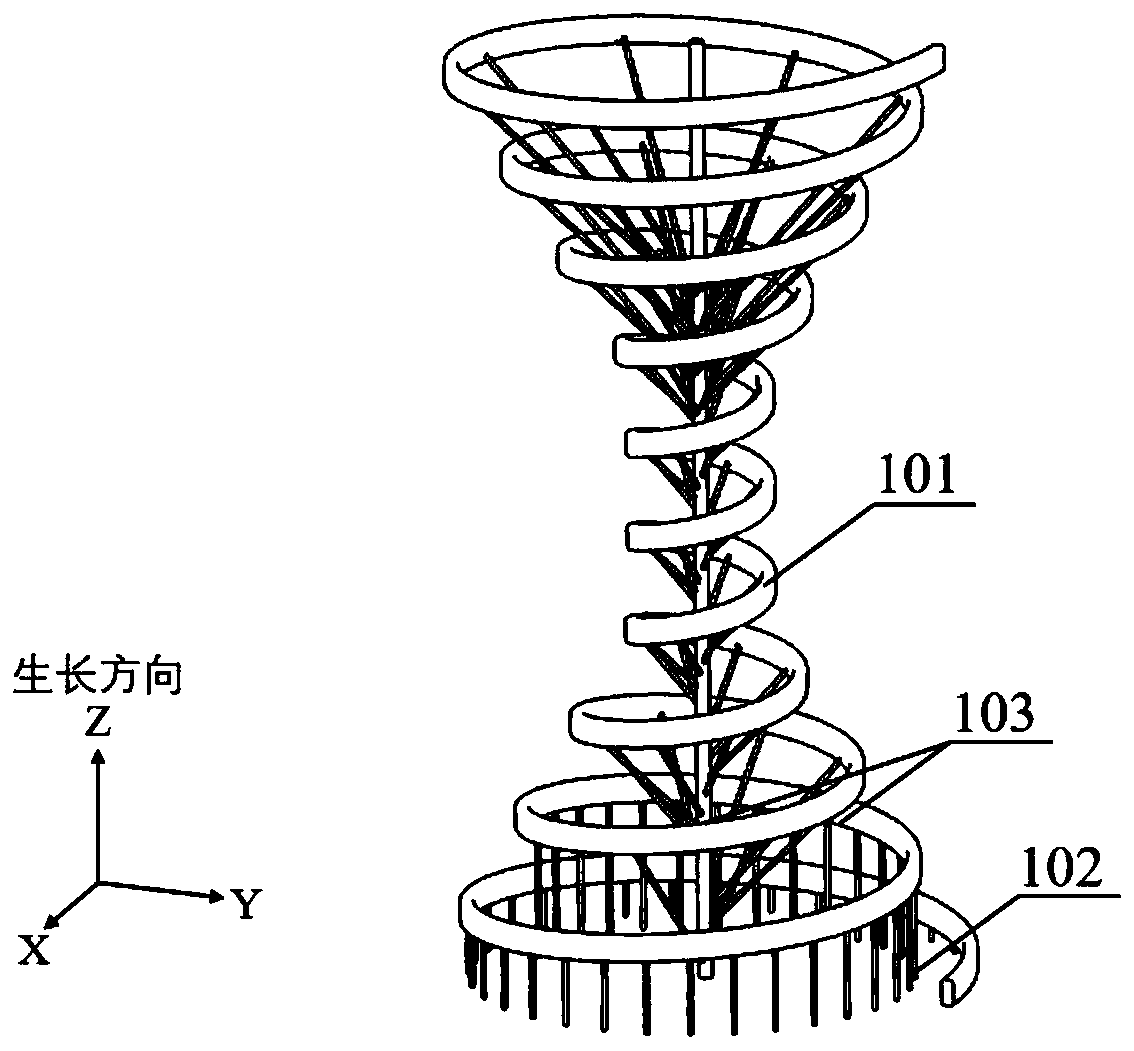

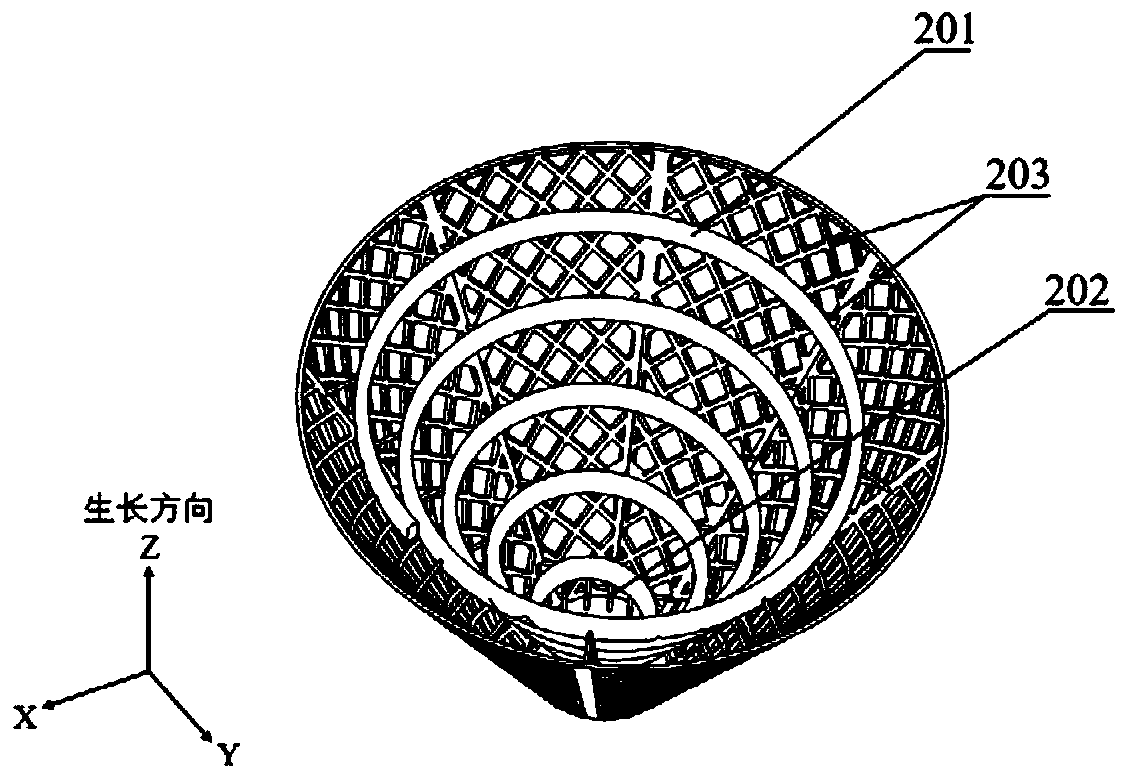

[0060] This embodiment 2 is to explain the three-dimensional space positioning conformal grid support structure used for additive manufacturing of high-degree-of-freedom and complex-structure 304 stainless steel parts. The structure of 304 stainless steel parts is similar to an inverted cone spring.

[0061] Include the following steps:

[0062] Step 1: Design and optimize the 304 stainless steel part structure 201, and generate a corresponding three-dimensional solid model;

[0063] Step 2: Determine the placement form and position of the three-dimensional solid model of the 304 stainless steel part structure 201, the axis of the 304 stainless steel part structure 201 is parallel to the growth direction;

[0064] Step 3: For the structure and shape of the 304 stainless steel part structure 201, select the three-dimensional space positioning conformal grid support structure, add a small amount of conventional support structure 202 and three-dimensional space positioning grid s...

Embodiment 3

[0068] This embodiment 3 is to explain the three-dimensional spatial positioning conformal truss support structure used for additive manufacturing of high-degree-of-freedom and complex-structure NiTi alloy parts. structure has the broadest applicability.

[0069] Include the following steps:

[0070] Step 1: Design and optimize the NiTi alloy part structure 301, and generate a corresponding three-dimensional solid model;

[0071] Step 2: Determine the placement position of the three-dimensional solid model of the NiTi alloy part structure 301. Any placement form can be selected to ensure a lower processing height as much as possible, so as to reduce the time required for powder spreading and improve processing efficiency;

[0072] Step 3: Select the three-dimensional space positioning conformal truss support structure, according to the structure and shape of the NiTi alloy part structure 301, construct a three-dimensional space positioning conformal truss support structure 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com