Hoisting and transferring device for barrel-shaped skin panel components

A technology of transfer device and wall plate group, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inability to lift barrel-shaped skin wall plate parts, damage products, etc., to improve the efficiency of hoisting and transfer, and force balance , Reduce the effect of dynamic load impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

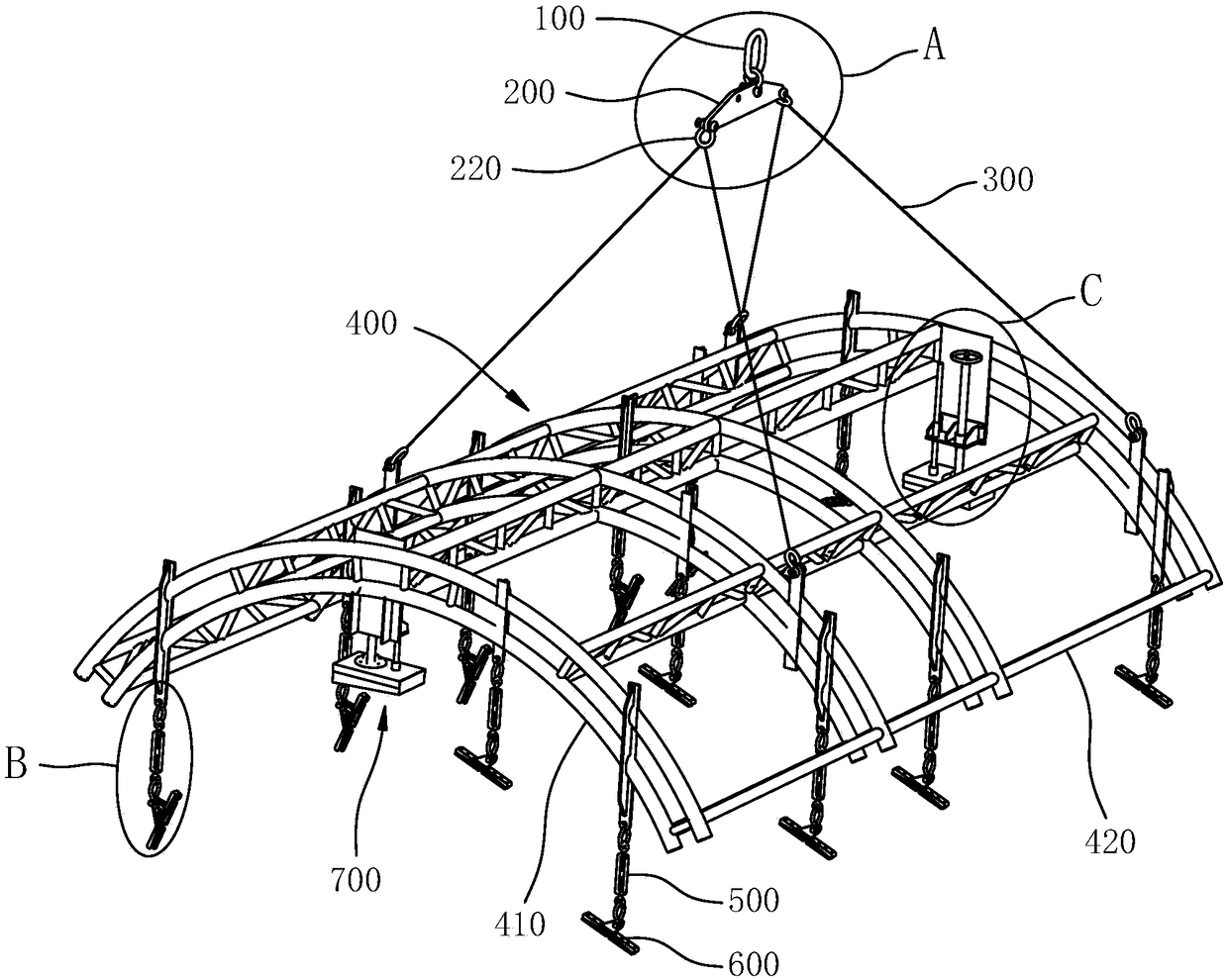

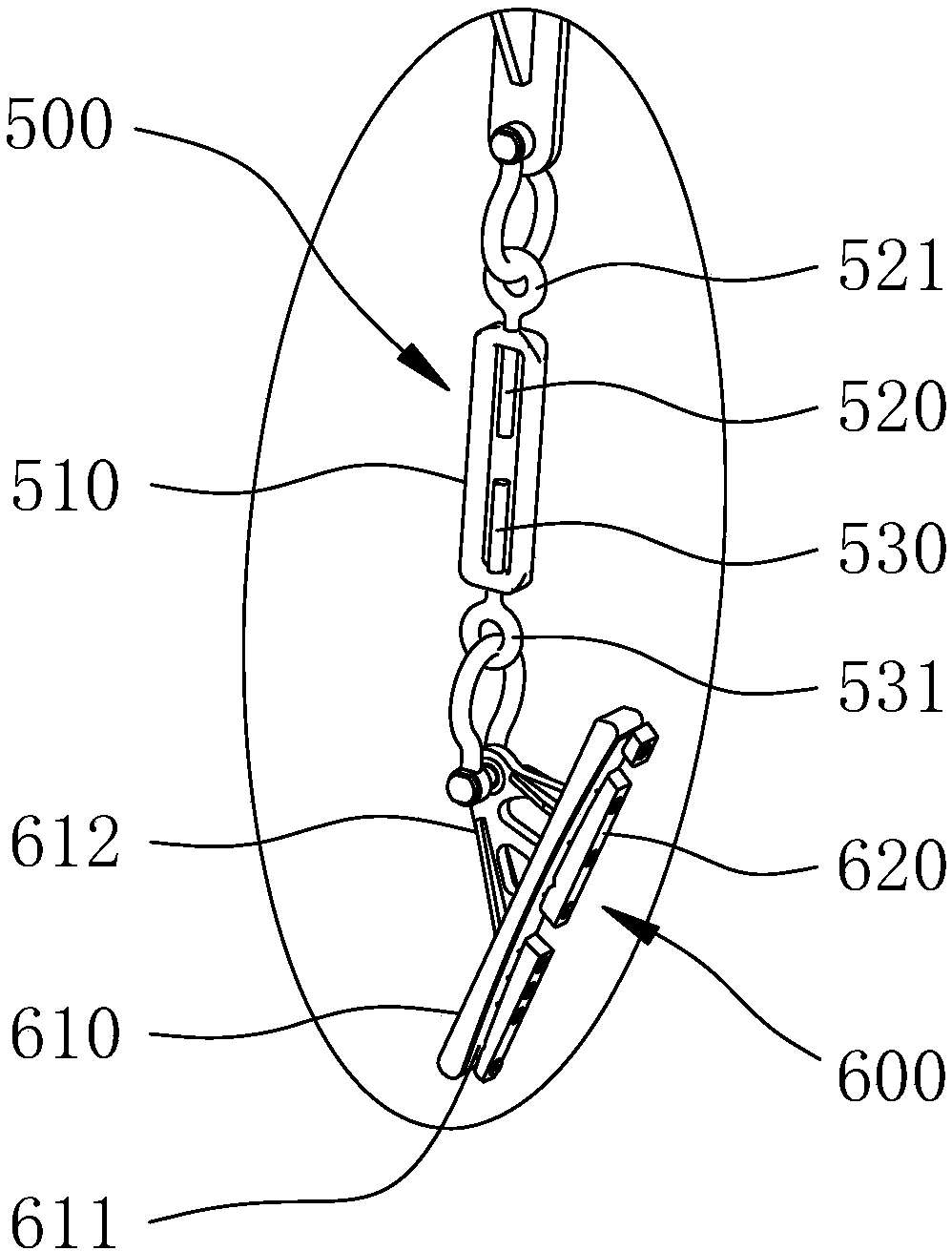

[0035] like figure 1 and figure 2 As shown, the hoisting and transferring device for barrel-shaped skin panel components includes a hoisting ring 100, a hoisting point adjustment block 200, a hoisting rope 300, a rigid skeleton 400, a rigid adjustable linkage mechanism 500, and a hoisting joint 600;

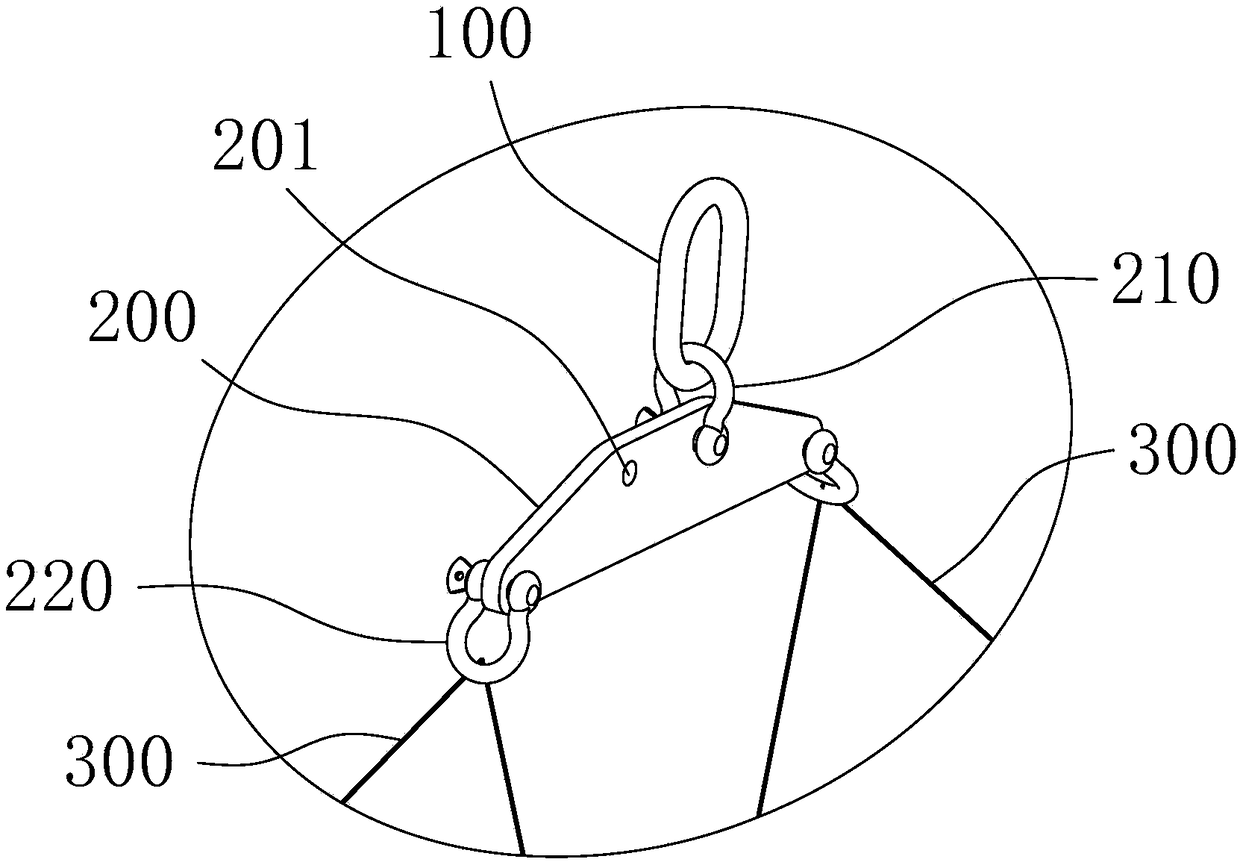

[0036] The upper side of the lifting point adjustment block 200 is provided with at least two lifting ring connecting holes 201 at intervals, and at least one lifting ring connecting hole 201 is detachably provided with a lifting ring connecting buckle 210, and the lifting ring 100 is connected to the lifting ring connecting buckle 210; Both ends of the lower side of the point adjustment block 200 are provided with hanging rope connecting buckles 220, and each hanging rope connecting buckle 220 is connected with at least two hanging ropes 300;

[0037] The rigid frame 400 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com