Porous membrane for secondary battery, slurry for secondary battery porous membrane and secondary battery

一种二次电池、多孔膜的技术,应用在多孔膜领域,能够解决爆炸、正极及负极短路等问题,达到高速涂装、滑动性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

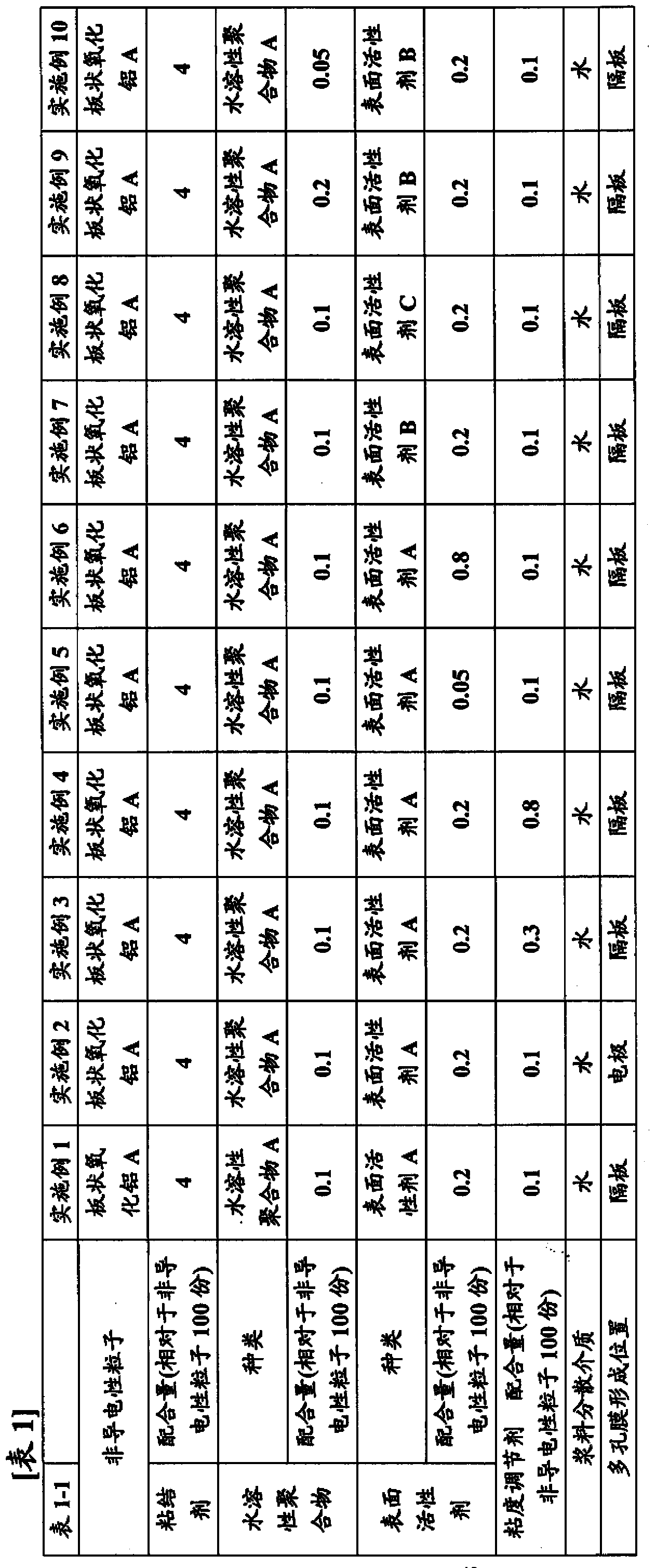

[0341] (Preparation of samples)

[0342] As non-conductive particles, L / b was 1.5, b / t was 50, L was 5 micrometers, and the plate-shaped alumina particle A whose volume average particle diameter was 0.6 micrometers was prepared.

[0343] As a viscosity modifier, carboxymethylcellulose (manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., trade name BSH-12) having an average degree of polymerization of 1600 to 1800 and a degree of etherification of 0.65 to 0.75 was used. Moreover, the viscosity of the 1% aqueous solution of a viscosity modifier is 6000-8000 mPa*s.

[0344] (Manufacture of slurry for porous membrane)

[0345] 100 parts of platy alumina particles A, 0.1 part of water-soluble polymer A, and 0.1 part of a viscosity modifier were mixed, and water was mixed so that the solid content concentration became 40% by mass, and dispersed using a bead mill. Then, 4 parts of binder-containing aqueous dispersions and 0.2 parts of surfactant A were added in terms of solid c...

Embodiment 2

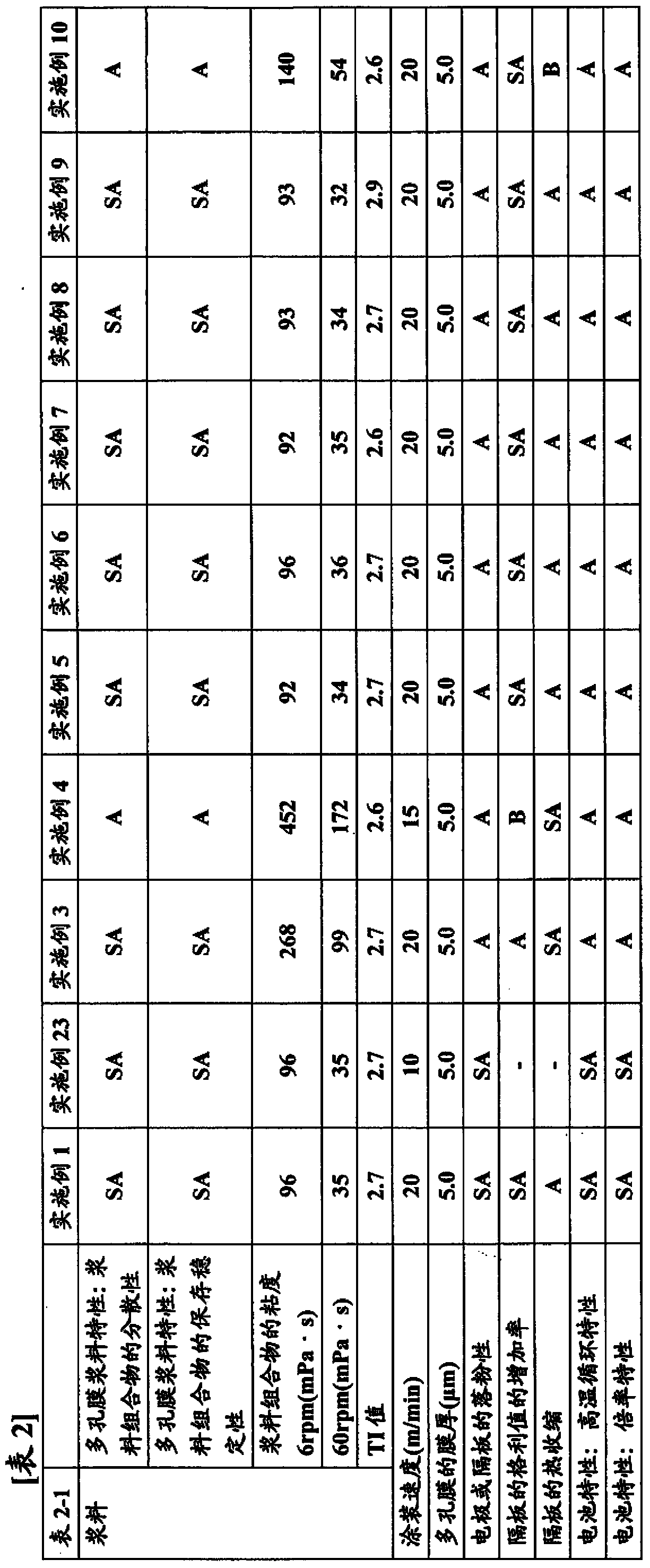

[0359] (Fabrication of Electrode with Porous Membrane)

[0360] Use a gravure coater to coat the above-mentioned slurry 1 for a porous membrane on the negative electrode obtained in the same manner as in Example 1 at a speed of 10 m / min, and completely cover the negative electrode mixture layer and make the thickness after drying be 5 μm, then The electrode 1 with a porous membrane was obtained by drying at 10°C and winding. The flexibility and powder falling properties of the obtained electrode 1 with a porous membrane were evaluated. The results are shown in Table 2.

[0361] The positive electrode obtained in Example 1 was cut into a circle with a diameter of 13 mm to obtain a circular positive electrode. The negative electrode with a porous membrane obtained above was cut into a circular shape with a diameter of 14 mm to obtain a circular negative electrode. In addition, the single-layer polyethylene separator used in Example 1 was cut into a circle with a diameter of 1...

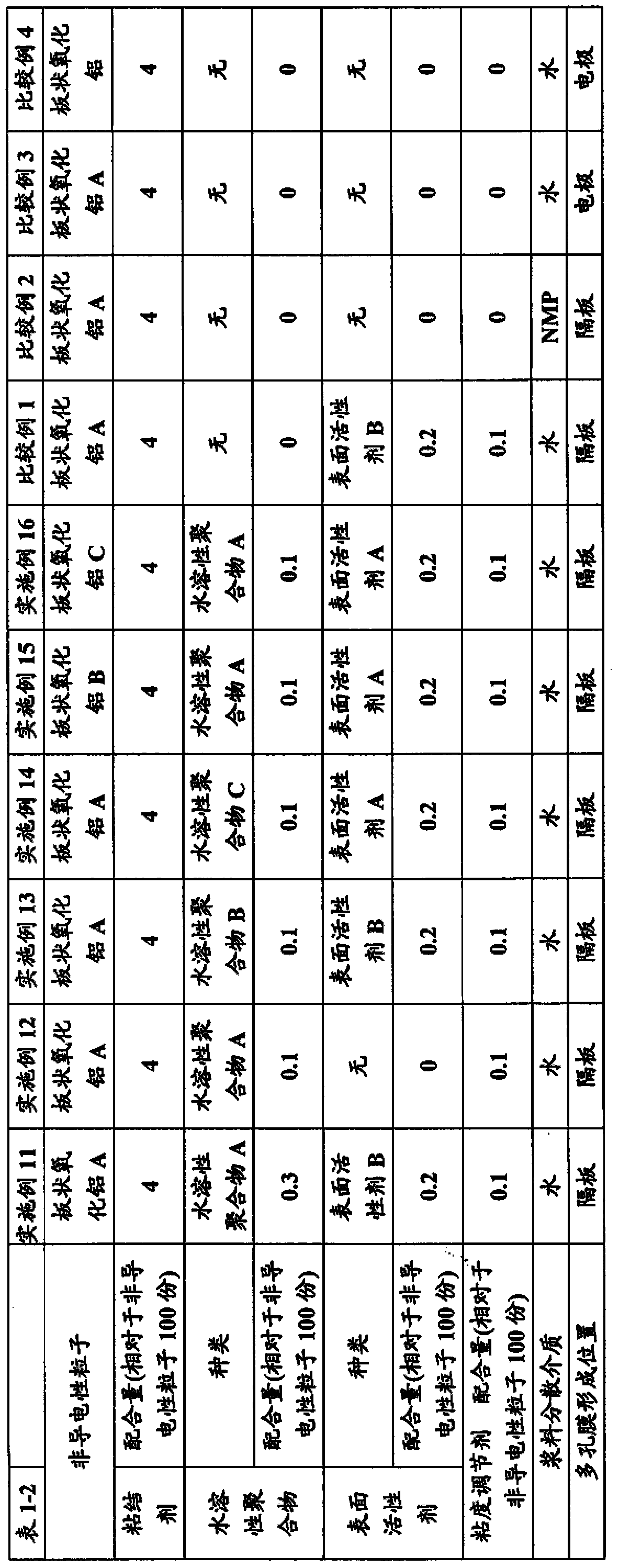

Embodiment 3、4

[0365] The compounding amount of the viscosity modifier is as follows Table 1 It was the same as Example 1 except that it was changed as described in . show the result in Table 2 . In addition, in Example 4, the coating speed was set to 15 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com