Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

The technology of wire and cable and polyphenylene ether is applied in the field of flexible halogen-free flame retardant polyphenylene ether wire and cable sheath material and its preparation, and can solve the problems of short elongation at break, reduced processing flow performance, low flame retardant efficiency, etc. Achieve excellent mechanical properties, take into account mechanical properties, and improve the effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

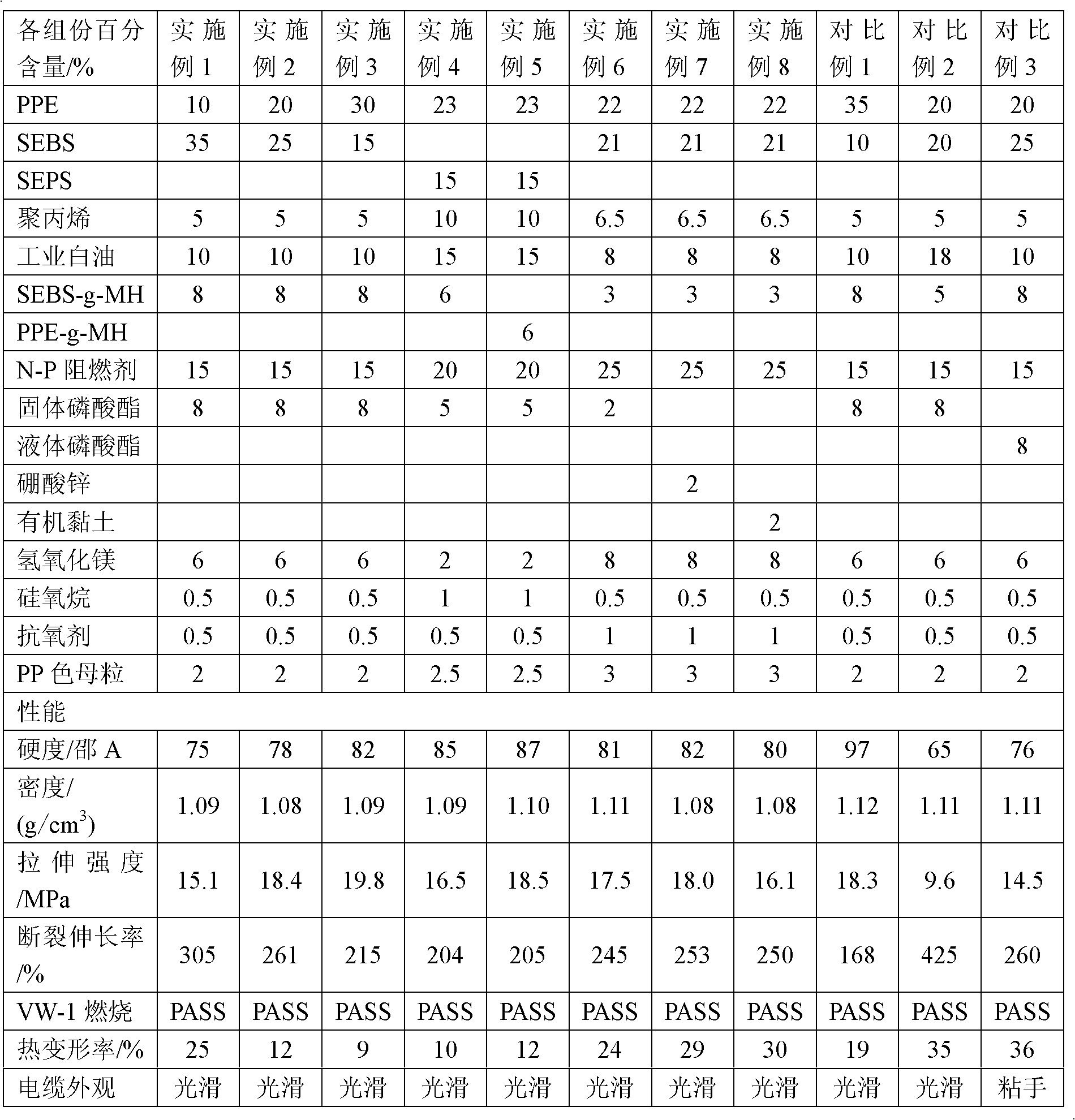

[0063] The ratio of the raw material components in the formula is carried out with reference to Example 1 in Table 1.

[0064] The preparation method is as follows: Weigh each component according to the raw material formula, first add styrene-based elastomer (SEBS) into the mixer, spray plasticizer (industrial white oil), and stir for 30 minutes, then PPE, SEBS-g- Add MH, PP, N-P flame retardant, solid phosphate, magnesium hydroxide, siloxane, antioxidant 1010 and PP masterbatch into the mixer and stir for 30 minutes, and mix well. Put the mixed raw materials into the twin-screw extruder, the feeding speed is 80rpm / min, the screw speed is 600rpm / min, the length-to-diameter ratio of the screw is 25, and the processing temperature of the twin-screw: the first stage is 210°C, the second The second stage is 220°C, the third stage is 230°C, the fourth stage is 240°C, the fifth stage is 250°C, and the sixth stage is 250°C. After water-cooling and granulation, flexible halogen-free f...

Embodiment 2

[0068] The ratio of the raw material components in the formula is carried out with reference to Example 2 in Table 1.

[0069] Preparation method and test method are all the same as embodiment 1.

[0070] Compared with Example 1, in the present example, the content of PPE is increased to 20%, the content of SEBS is reduced to 25%, and the contents of all other components are unchanged. The test results are as shown in Example 2 of Table 1, and the results show that : After the content of PPE increases, the tensile strength of the prepared cable material increases, the elongation at break decreases, the flame retardancy is good, the heat resistance is high, the cable is soft and elastic, the surface is smooth, and there is no flame retardant migration after a period of time. Suitable for use as electrical and electronic wires.

Embodiment 3

[0072] The ratio of the raw material components in the formula is carried out with reference to Example 3 in Table 1.

[0073] Preparation method and test method are all the same as embodiment 1.

[0074] Compared with Example 2, in the present example, the content of PPE is increased to 30%, the content of SEBS is reduced to 15%, and the contents of all other components are unchanged. The test results are as shown in Example 3 of Table 1, and the results show that : After the PPE content increases to 30%, the tensile strength of the prepared cable material increases more obviously, and the elongation at break decreases, indicating that the increase of the PPE content has a great effect on the improvement of the mechanical properties, and the flame retardancy and heat resistance are high. , feel good, smooth surface, no flame retardant migration after a period of time, suitable for use as electrical and electronic wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com