Spraying system for spraying room workpiece height automatic identification

An automatic identification and workpiece technology, applied in the direction of spraying device, can solve the problems of re-spraying, the workpiece is not completely sprayed with powder, powder waste, etc., and achieves the effect of reducing production cost, reducing workpiece scrap, and reducing rework rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

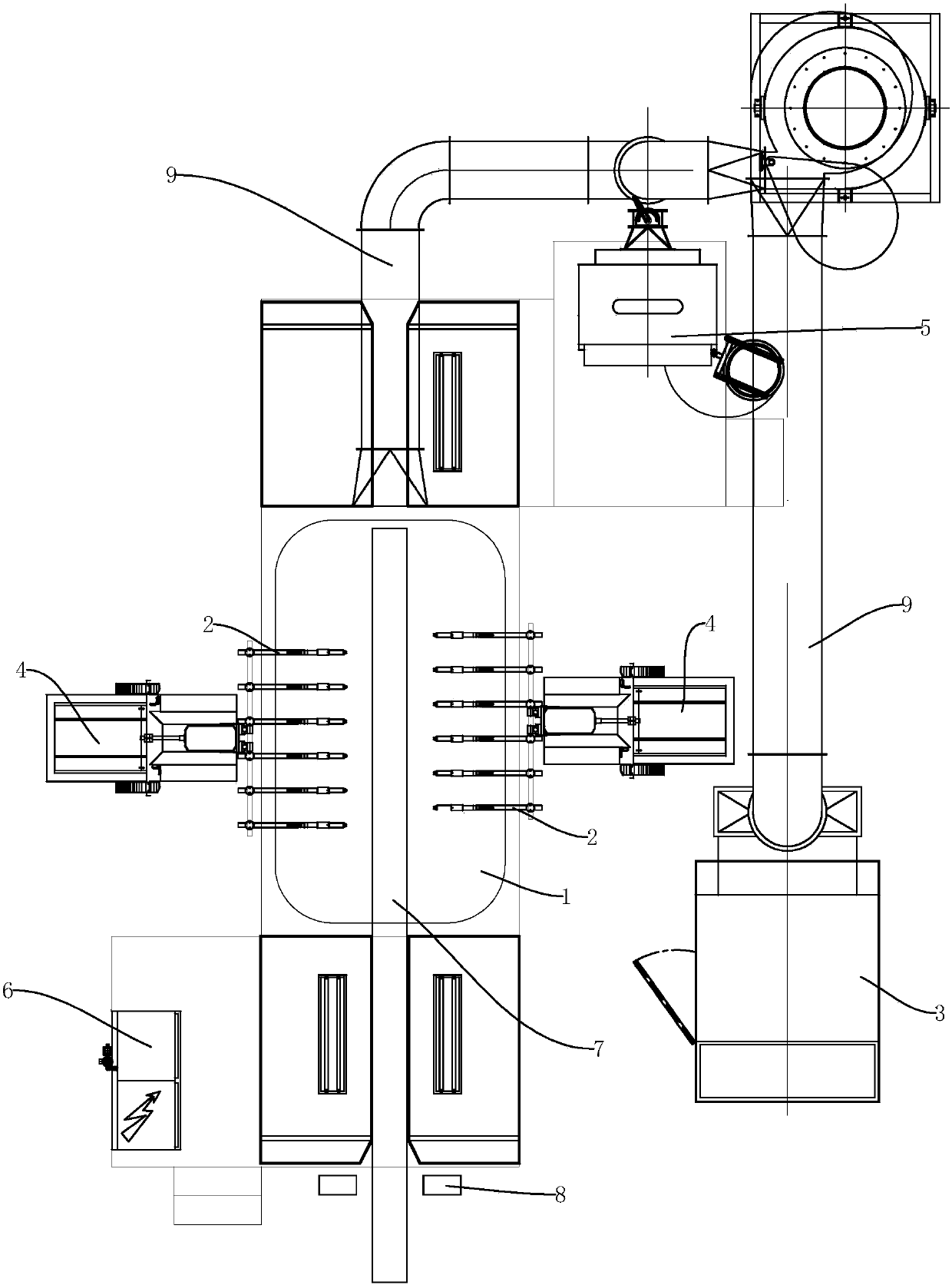

[0022] like figure 1 As shown, a spraying system for automatic recognition of workpiece height in a spray booth includes a conveying device 7, a first encoder, a measuring grating 8, a reciprocating machine 4, a limit mechanism and a main control module 6, and the conveying device 7 is used to transfer the workpiece from The entrance of the spray booth 1 is transmitted into the interior of the spray booth 1 for spraying operations. The first encoder is arranged on the conveying device 7 to detect the transmission speed information of the conveying device 7. The measuring grating 8 is arranged at the entrance of the spray booth 1. For detecting whether there is a workpiece passing through and detecting the height information of the workpiece, the reciprocating machine 4 is located on one side of the conveying device 7, and the reciprocating machine 4 is provided with a spray gun 2 for pushing the spray gun 2 to reciprocate up and down and detecting the height information of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com