Method for producing Ni-Co-Mn ternary hydroxide

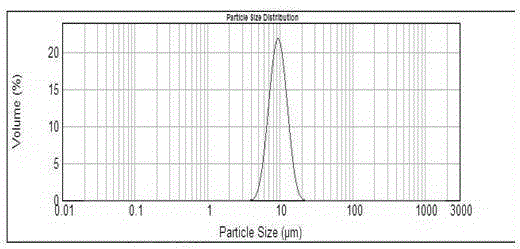

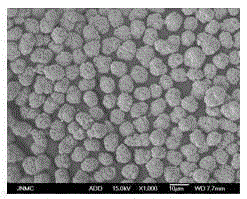

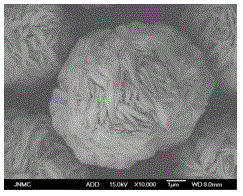

A hydroxide and production method technology, applied in the directions of nickel oxide/nickel hydroxide, manganese oxide/manganese hydroxide, cobalt oxide/cobalt hydroxide, etc. Cobalt manganese hydroxide has problems such as wide particle size distribution and low yield, and achieves the effect of controllable morphology, narrow particle size distribution and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A continuous production method of nickel cobalt manganese hydroxide includes the following steps:

[0040] (1) Add 1.5 mol / L of molten metal (weigh a certain proportion of nickel sulfate, cobalt sulfate, and manganese sulfate crystals into the dissolving kettle, add a certain amount of pure water to prepare a solution), 5.0 mol / L of hydroxide Sodium solution and 5.0mol / L ammonia solution are added into the nucleation reactor according to the flow ratio (10:5:1) through the metering pump at the flow rate of the molten metal (3L / h) for nucleation reaction;

[0041] (2) When the grain size of the nucleation reactor crystal nucleus grows to 4-5μm, the nucleation reaction is over. Use the transfer pump to transfer the crystal nucleus to the intermediate feeding kettle; add the bottom liquid to the crystal nucleus growth reactor (the bottom liquid contains a certain amount of Pure water, ammonia water), turn on the crystal nucleus growth reactor stirring device, and continuously a...

Embodiment 2

[0045] A continuous production method of nickel-cobalt-manganese hydroxide includes the following steps:

[0046] (1) Add 2.0mol / L of molten metal (weigh a certain proportion of nickel sulfate, cobalt sulfate, and manganese sulfate crystals into the dissolving kettle, add a certain amount of pure water to prepare a solution), 5.0mol / L of hydroxide Sodium solution and 5.0 mol / L ammonia solution are added to the nucleation kettle according to the flow ratio (10:5:1) through the metering pump at the flow rate of the molten metal (3L / h);

[0047] (2) When the grain size of the nucleation reactor crystal nucleus grows to 4-5μm, the nucleation reaction is over. Use the transfer pump to transfer the crystal nucleus to the intermediate feeding kettle; add the bottom liquid to the crystal nucleus growth reactor (the bottom liquid contains a certain amount of Pure water, ammonia water), turn on the nucleus growth reactor stirring device, and continuously add the crystal nuclei to be grown fr...

Embodiment 3

[0051] A continuous production method of nickel-cobalt-manganese hydroxide includes the following steps:

[0052] (1) Add 1.0 mol / L of molten metal (weigh a certain proportion of nickel sulfate, cobalt sulfate, and manganese sulfate crystals into the dissolving kettle, add a certain amount of pure water to prepare a solution), 5.0 mol / L of hydroxide Sodium solution and 5.0mol / L ammonia solution are added into the nucleation reactor according to the flow ratio (10:5:1) through the metering pump at the flow rate of the molten metal (3L / h) for nucleation reaction;

[0053] (2) When the grain size of the nucleation reactor crystal nucleus grows to 4-5μm, the nucleation reaction is over. Use the transfer pump to transfer the crystal nucleus to the intermediate feeding kettle; add the bottom liquid to the crystal nucleus growth reactor (the bottom liquid contains a certain amount of Pure water, ammonia water), turn on the nucleus growth reactor stirring device, and continuously add the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com