Micro oil content ignition coal powder burner capable of improving initial ignition heat

A pulverized coal combustion and initial ignition technology, which is applied in the field of combustion devices and pulverized coal combustion devices with a small amount of oil, can solve the problems of unstable combustion and difficult ignition of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

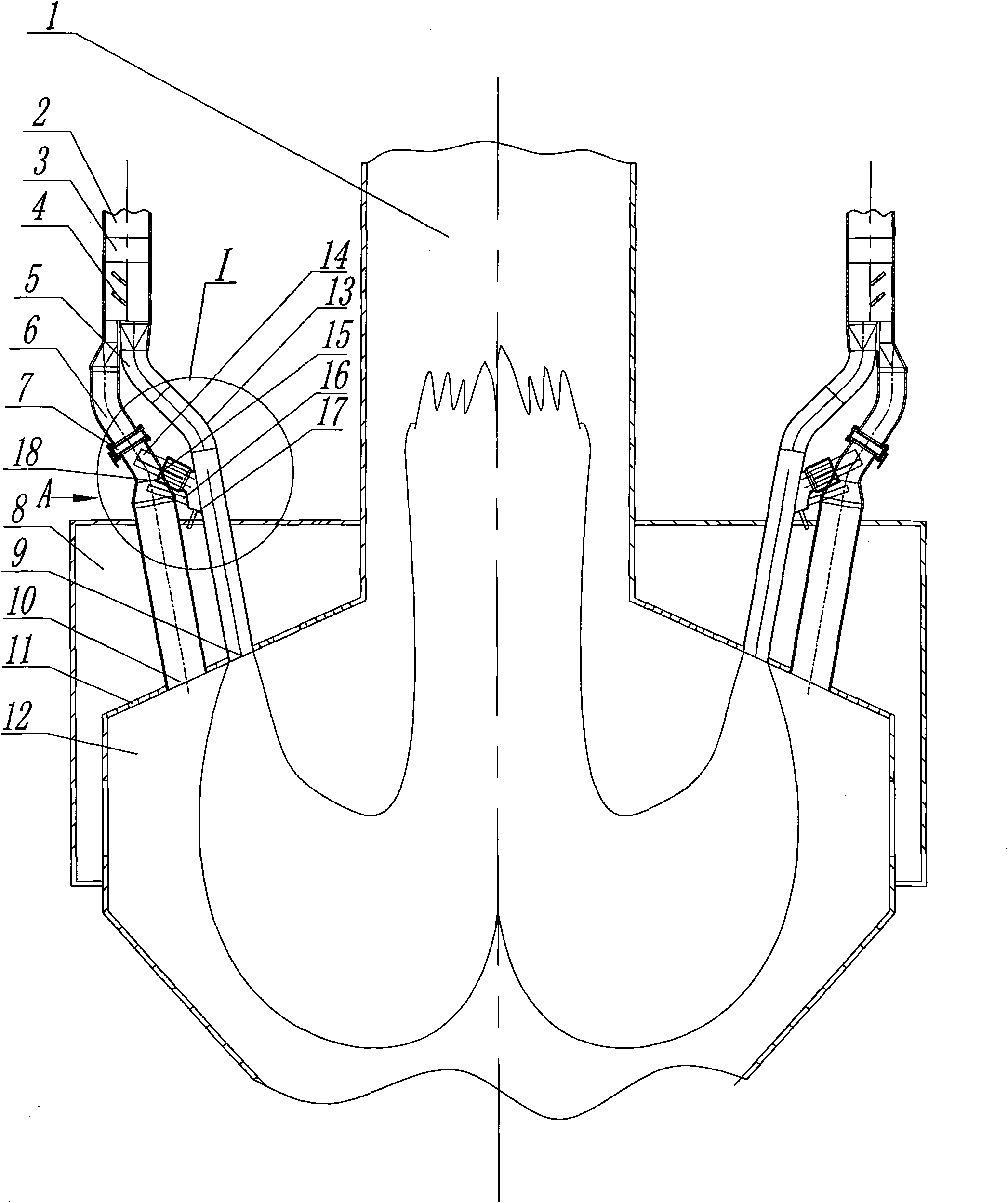

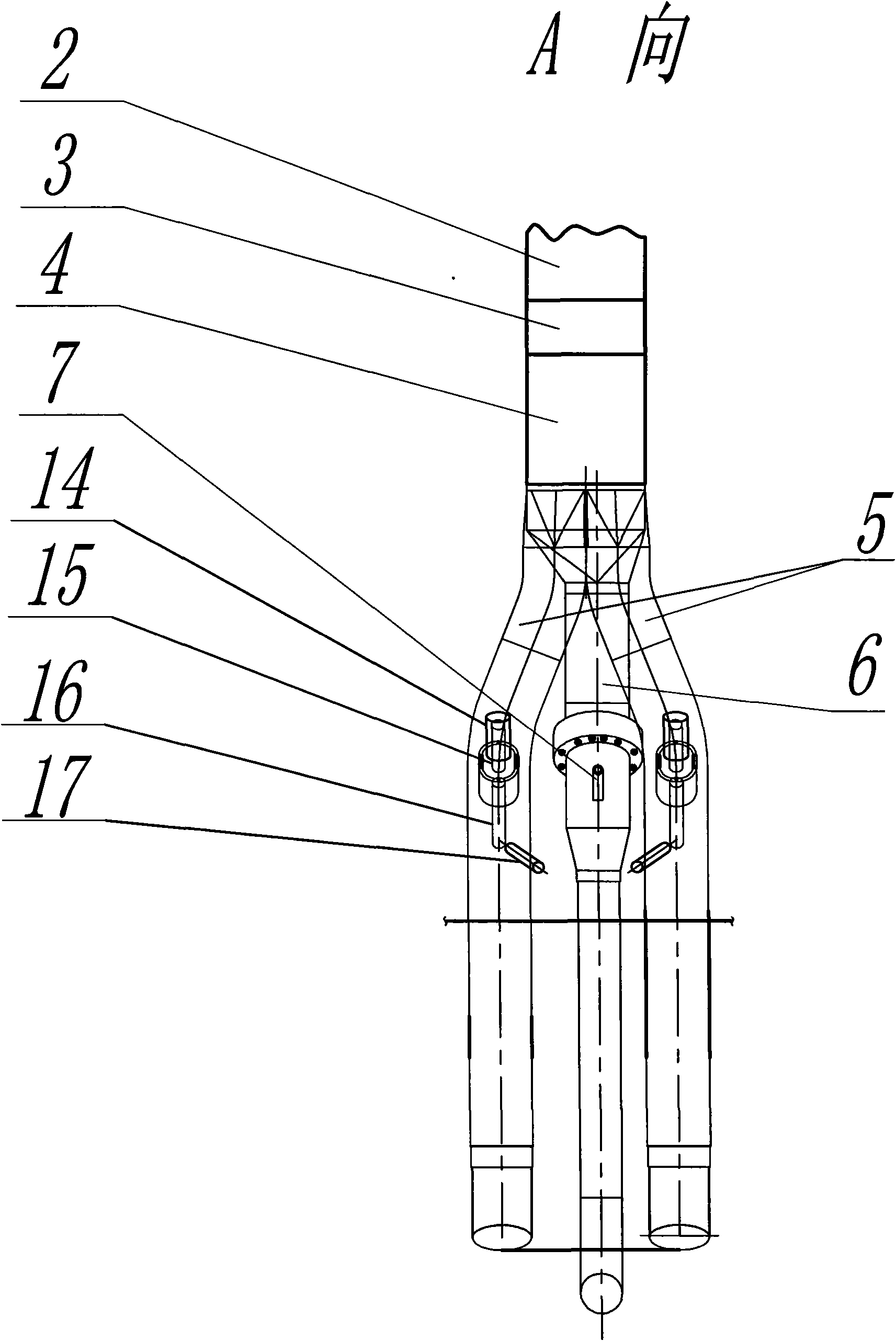

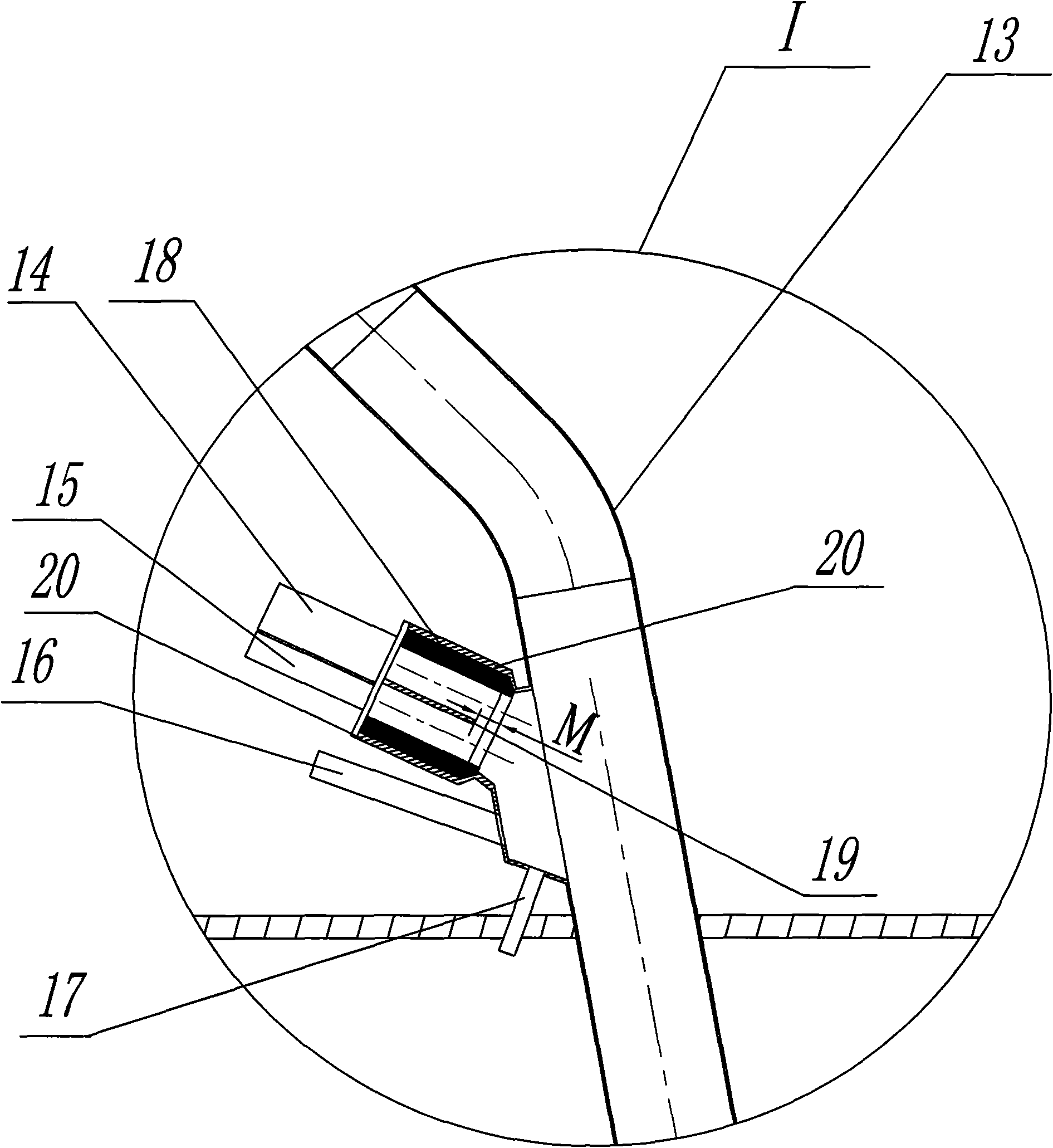

[0009] Specific implementation mode one: combine figure 1 , 2 , 3 illustrate the present embodiment, the micro-oil quantity ignition pulverized coal combustion device that can improve the initial ignition heat described in the present embodiment comprises No. 1 main oil gun 14, No. 2 main oil gun 15 and oil gun installation branch pipe 20; The oil quantity ignites the pulverized coal combustion device also includes adiabatic combustion sleeve 18, and an adiabatic combustion sleeve 18 is installed in the inlet end of oil gun installation branch pipe 20, No. 1 main oil gun 14, No. 2 main oil gun 15 from top to bottom Set in the inlet end of the oil gun installation branch pipe 20 , both the No. 1 main oil gun 14 and the No. 2 main oil gun 15 communicate with the inner cavity of the adiabatic combustion sleeve 18 .

[0010]According to the volatile content of ignited pulverized coal, calorific value, practical factors such as wind speed, one or more auxiliary oil guns can be arr...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, the micro-oil volume ignition pulverized coal combustion device of this embodiment also includes a partition 19, and the partition 19 is inserted in the inner cavity of the heat-insulating combustion sleeve 18 along the axial direction and the heat-insulating combustion sleeve The inner cavity of 18 is divided into upper and lower two parts, No. one main oil gun 14 is communicated with the upper inner cavity of adiabatic combustion sleeve 18, and No. two main oil guns 15 is communicated with the lower inner cavity of adiabatic combustion sleeve 18. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 , 2 , 3 illustrate the present embodiment, the micro-oil quantity ignition pulverized coal combustion device described in the present embodiment also includes auxiliary oil gun 16, and auxiliary oil gun 16 is arranged on the same side as No. 1 main oil gun 14 and No. 2 main oil gun 15. The oil gun 16 is arranged on the shoulder of the lower side wall of the outlet end of the oil gun installation branch pipe 20 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com