Straw carbonization system

A carbonization system and straw carbonization technology, which are applied in stationary carbonization furnaces, chemical instruments and methods, special forms of dry distillation, etc., can solve the problems of low condensation efficiency, heat loss, and unsatisfactory carbonization effect, so as to prolong residence time and save energy. Ideal effect of energy consumption and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

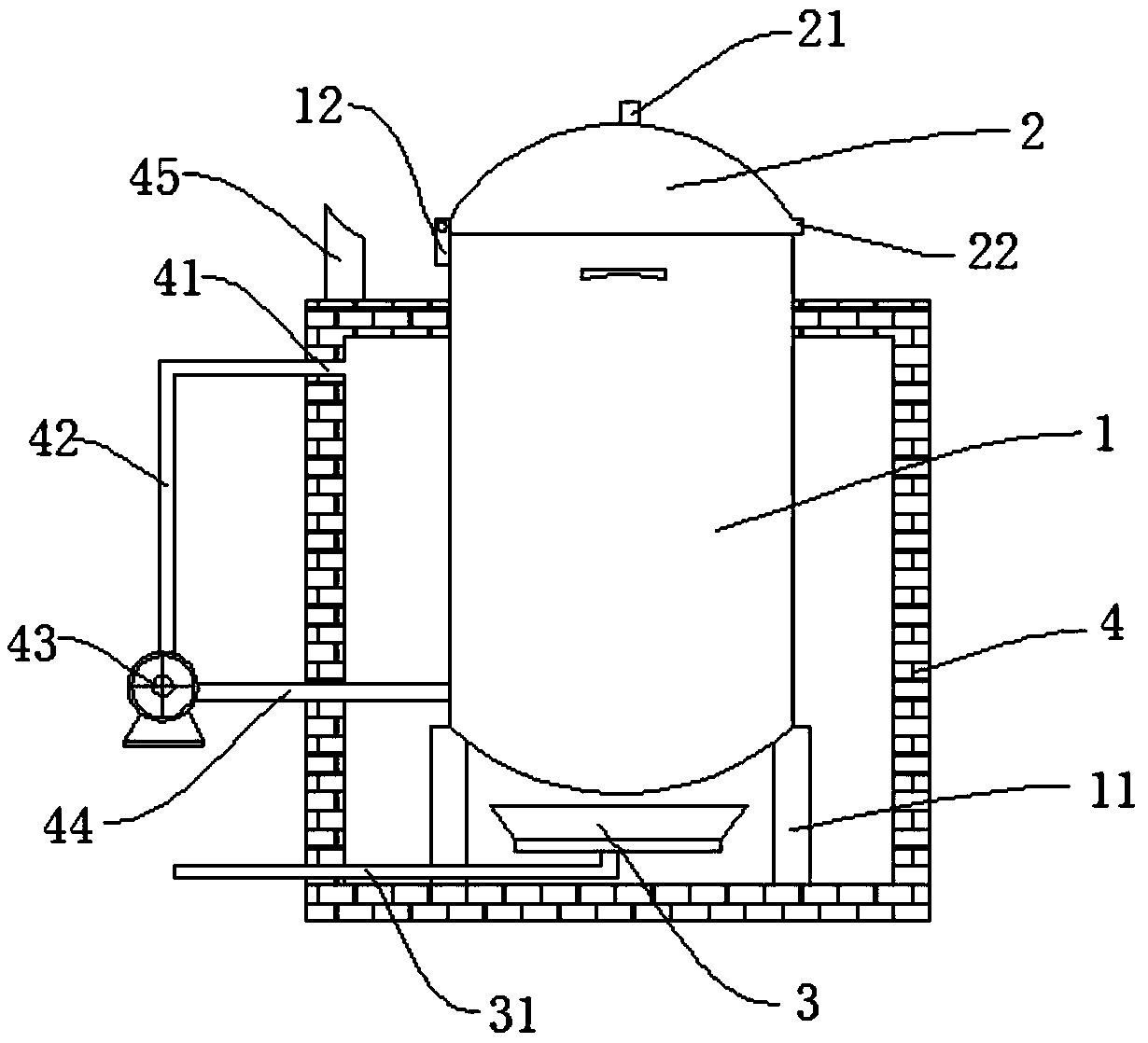

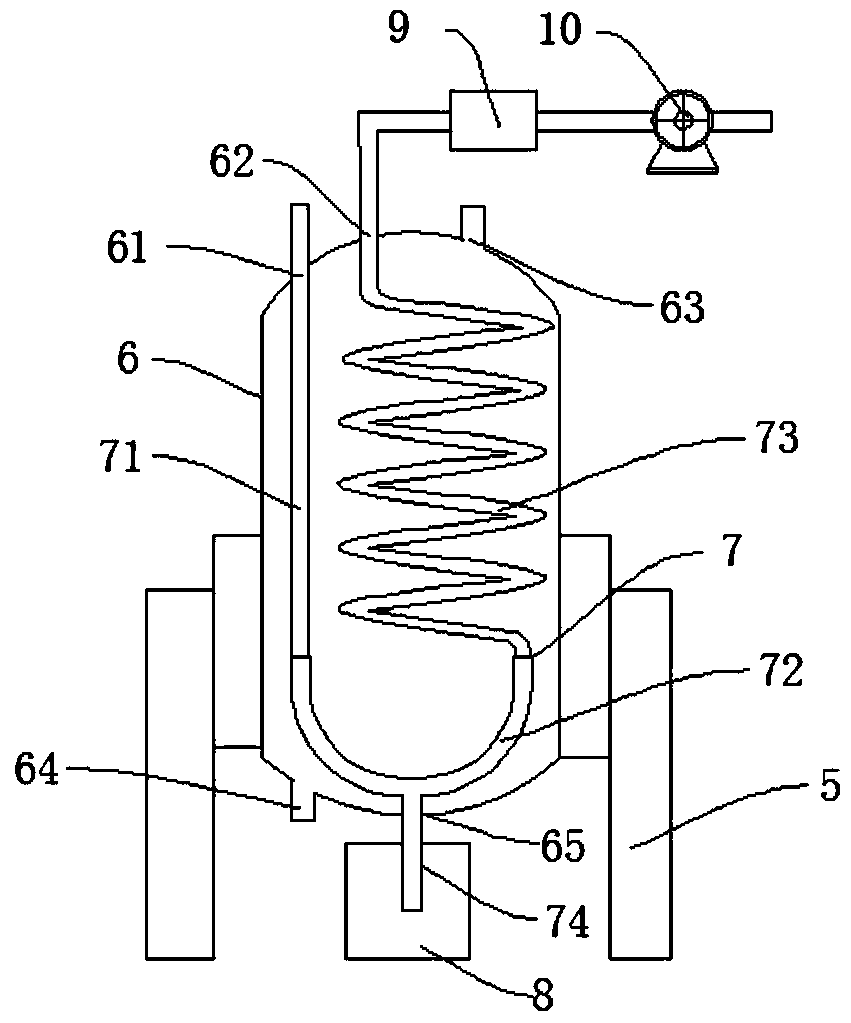

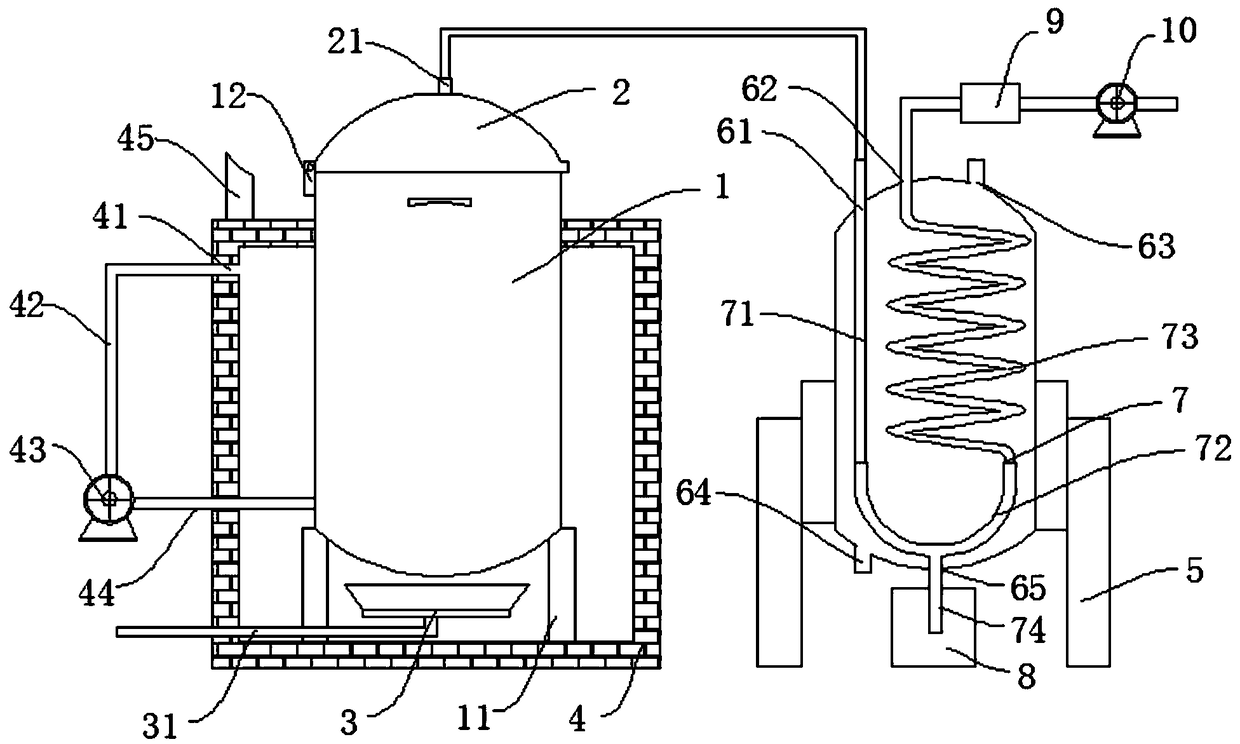

[0027] Please refer to Figure 1~3 As shown, a straw carbonization system includes a straw carbonization furnace and a flue gas recovery treatment device. The straw carbonization furnace communicates with the flue gas recovery and treatment device through a pipe. Specifically, one end of the pipe is connected to the gas outlet pipe 21 of the straw carbonization furnace, and the other end is connected to the air guide pipe 71 of the flue gas recovery and treatment device.

[0028] The straw carbonization furnace includes a heat preservation shell 4 , a carbonization furnace body 1 , a carbonization furnace cover 2 and a burner 3 .

[0029] The heat-insulating shell 4 is made of heat-insulating bricks. The inner bottom of the thermal insulation shell 4 is provided with a carbonization furnace frame 11 , and the top of the thermal insulation shell 4 is provided with an opening.

[0030] The bottom of the carbonization furnace body 1 is arranged on the carbonization furnace fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com