Molding sand dust-free treatment and recovery device for molding sand casting

A recovery device and collection device technology, which is applied to casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc., can solve the problems of poor winnowing effect, dust escaping, fast falling speed, etc., and achieve Realize dust-free recycling, avoid filter clogging, and slow down the effect of falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

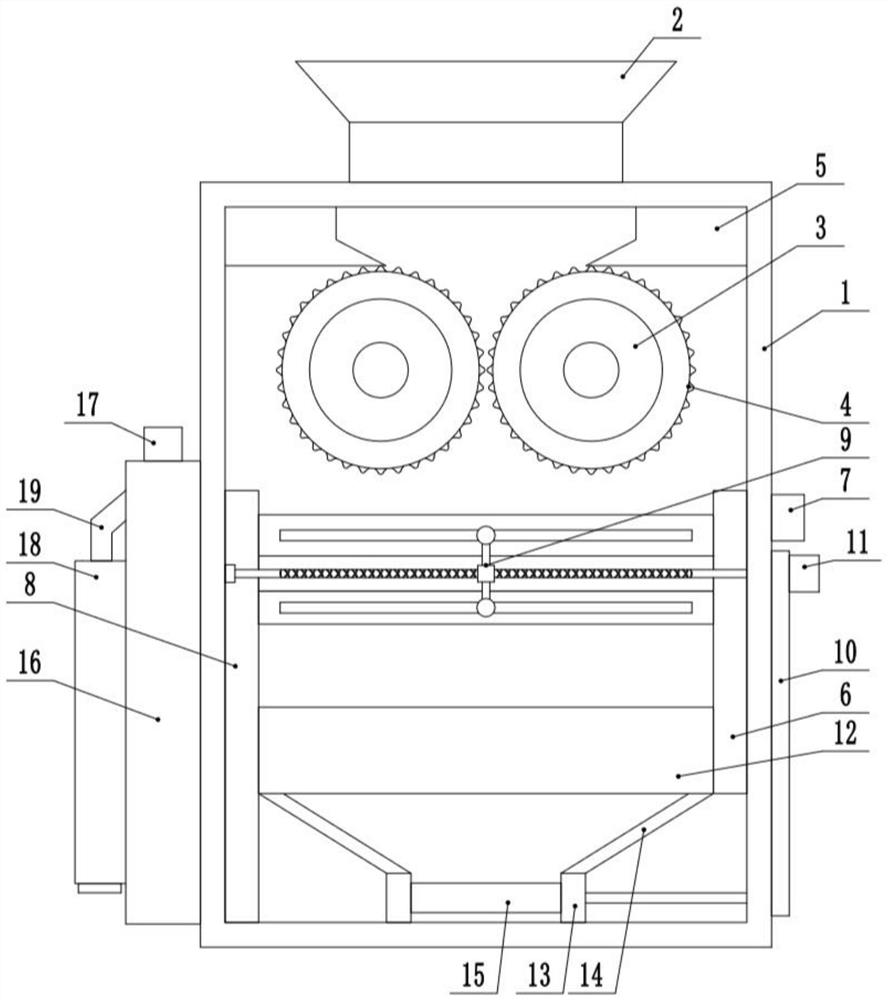

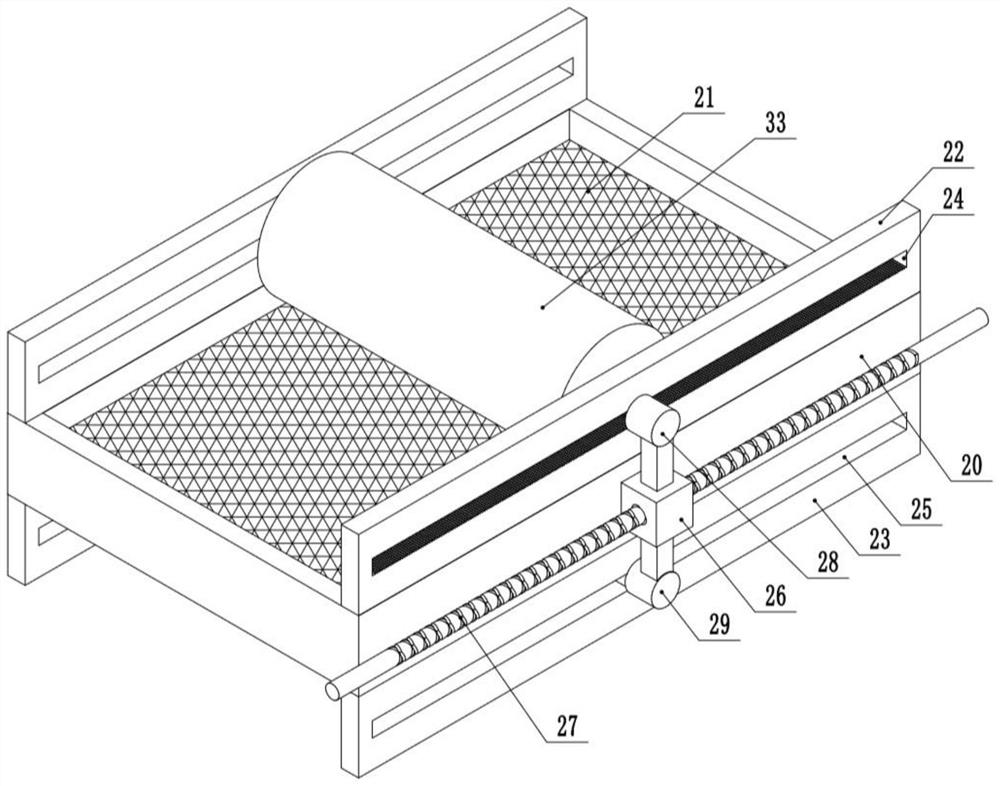

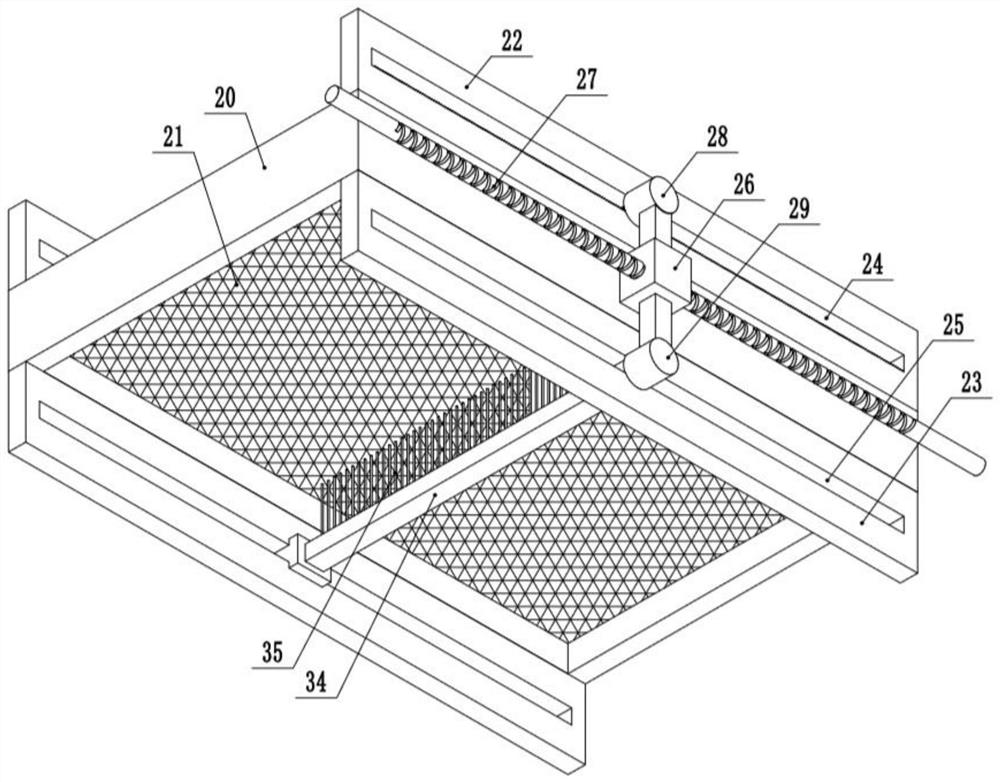

[0028] see figure 1 , a molding sand dust-free treatment recovery device for molding sand casting, comprising a recovery box 1, the top of the recovery box 1 is fixedly connected to the feed hopper 2, the upper part of the recovery box 1 is provided with a primary crushing device, the primary crushing device includes a rotating connection On the two rollers 3 on the inner wall of the recovery box 1, the outer fixed sleeve of the rollers 3 is provided with a rolling sleeve 4, and both sides of the recovery box 1 above the rolling sleeve 4 are fixedly connected with a stopper 5. The bottom of the crushing device is provided with a screening device 9, and the recovery box 1 inner wall on both sides of the screening device 9 is fixedly connected with an air intake cover 6 and an exhaust cover 8 respectively, and the outside of the recovery box 1 is fixedly provided with a blower 7, and the blower 7 The output end is fixedly connected with the air intake cover 6, and a buffer cover...

Embodiment 2

[0037] see Figure 1-7 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the outside of the recovery box 1 is fixedly connected to the transmission cover 10, the drive motor 11 is fixedly arranged on the transmission cover 10, and the discharge conveyor belt 15 is connected to the drive shaft , one end of the drive shaft is located in the transmission housing 10 and is connected to the output shaft of the drive motor 11 through transmission.

[0038] In the implementation process of the present invention, first pour the molding sand block from the feed hopper 2, crush it into small pieces after being crushed by the rolling sleeve 4 and drop it on the filter screen 21, and then start the drive motor 11, Negative pressure fan 17 and blower 7, driving motor 11 drives the reciprocating screw rod 27 to rotate to make the side slider 26 move back and forth, drives the rolling roller 33 to rotate back and forth and moves to repeatedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com