Recovery device for waste neodymium iron boron magnetic materials and using method

A recycling device, NdFeB technology, applied in the field of recycling devices for waste NdFeB magnetic materials, can solve the problems that the surface waste cannot be shaken off, clogged, waste NdFeB can not be discharged quickly, etc., and achieve good recycling treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

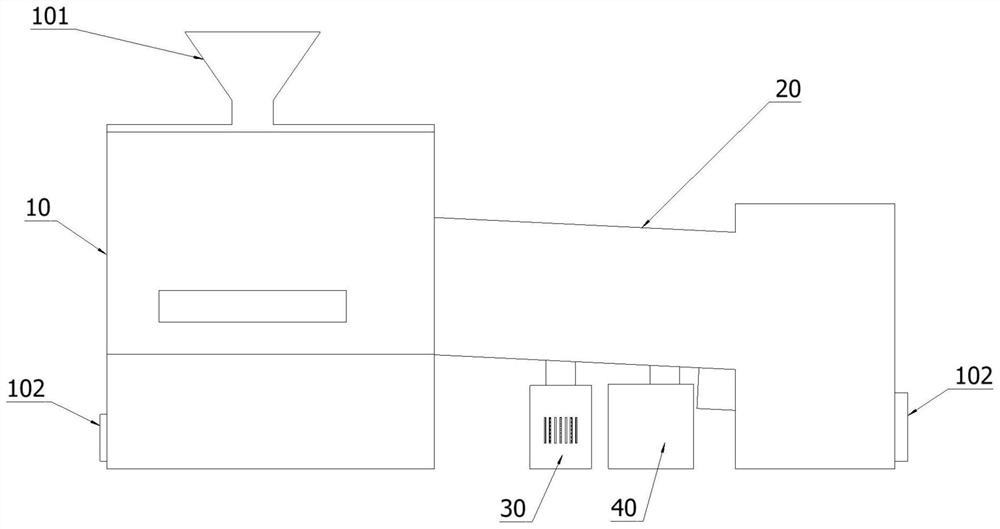

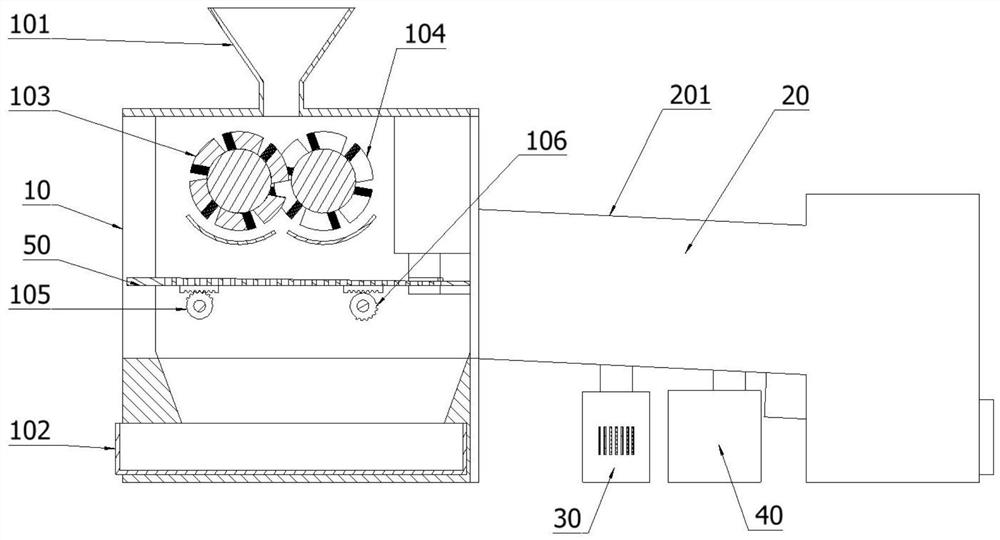

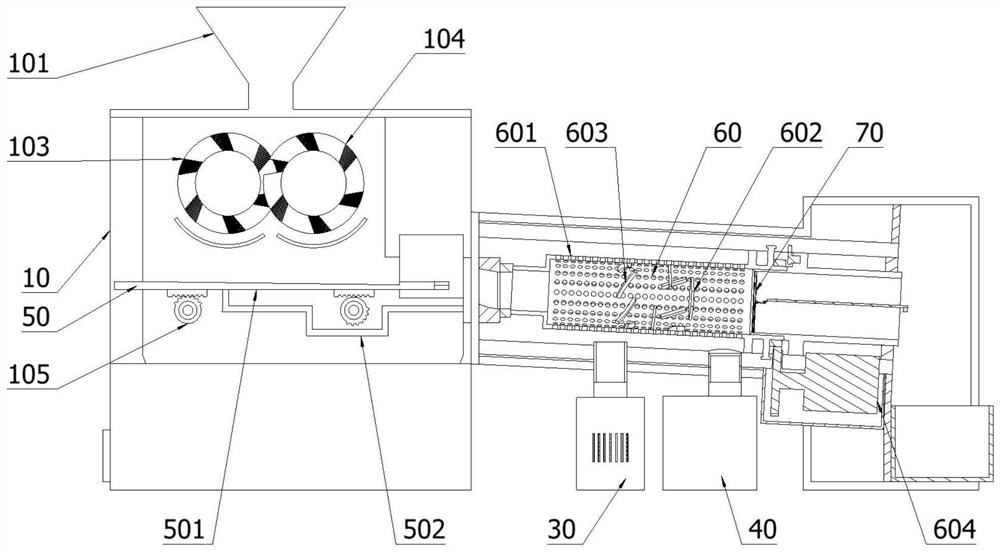

[0054] Such as figure 1 , 2 As shown, this embodiment discloses a recycling device for waste NdFeB magnetic materials, including: a feeding device 10, a feeding device 20, a collecting device 40, a rotating device 60, and a screening device 50. The feeding device 10 includes: The casing, the first crushing roller 103, the second crushing roller 104, the first rotating rod 105, and the second rotating rod 106, the inside of the casing is hollow; the first crushing roller 103 is arranged inside the casing, and the first crushing roller 103 is located above the collection box 102, the first crushing roller 103 is connected to the casing; the second crushing roller 104 is arranged inside the casing, the second crushing roller 104 is located above the collection box 102, and the second crushing roller 104 is connected to the The casing is connected; the first rotating rod 105 is arranged inside the casing, the first rotating rod 105 is located below the first crushing roller 103, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com