Circulation method for recovering organic acid from organic acid lithium waste water

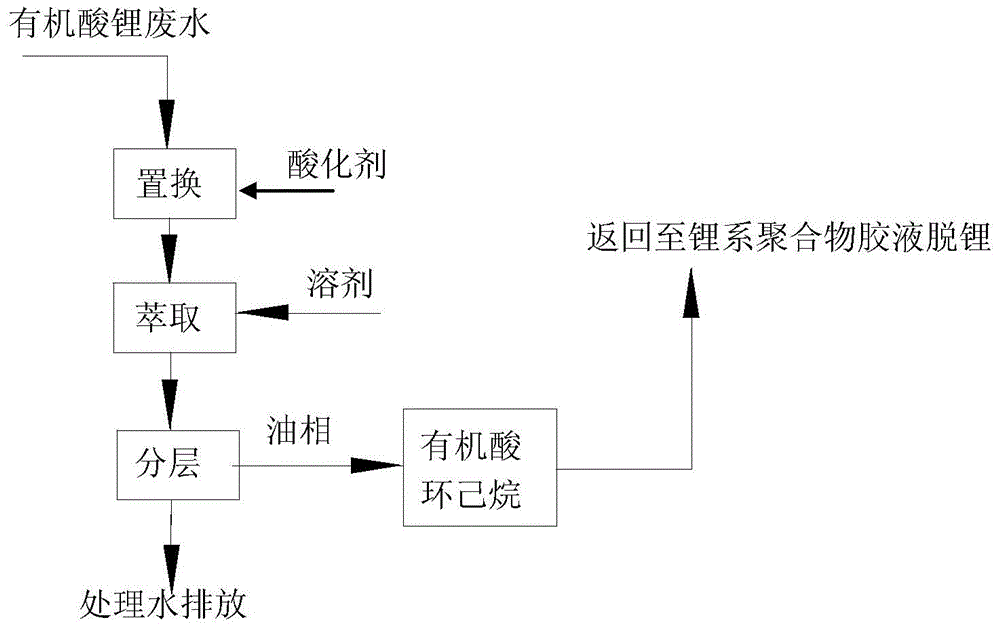

A technology for recycling lithium organic acid and wastewater, applied in the direction of extraction water/sewage treatment, etc., can solve the problems of unenvironmental protection, unseen waste water recycling, uneconomical and other problems, and achieve the effect of ensuring sanitation, environmental protection of treatment methods and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After adding 600ml of waste water containing lithium neodecanoate (where the COD is 2200mg / L) and 200g of 99.5wt% cyclohexane into a 2000ml three-necked flask equipped with a thermometer, start stirring at room temperature at 20°C, and then dropwise add 7.04wt % dilute sulfuric acid solution, until the pH=3.0 of the solution, after stirring for 10min, the pH value remains unchanged, stop adding acid at this time, then use a separatory funnel to stand for stratification for 3min, and divide the lower water phase, at this time the water The COD of phase is 420mg / L; Measure the neodecanoic acid 0.41wt% in the upper layer oil phase solution, separate the cyclohexane solution containing neodecanoic acid and store for standby, wait to be sent into lithium-containing colloid for delithiation.

Embodiment 2

[0028] After adding 600ml of wastewater containing lithium laurate (where the COD is 2300mg / L) and 200g of 99.5wt% cyclohexane into a 2000ml three-necked flask equipped with a thermometer, preheat to 40°C, start stirring, and then dropwise add 6.02wt % dilute hydrochloric acid solution, until the pH of the solution=5.3, after stirring for 10 minutes, the pH value remains unchanged, stop adding acid, then use a separatory funnel to stand for stratification for 5 minutes, and divide the lower water phase, at this time, the water The COD of phase is 430mg / L; Record the 0.44wt% of lauric acid in the upper oil phase solution, separate the cyclohexane solution containing lauric acid and store for standby, to be sent into the lithium-containing colloid for delithiation.

Embodiment 3

[0030]After adding 600ml of waste water containing lithium isooctanoate (where the COD is 2400mg / L) and 150g of 99.5wt% cyclohexane into a 2000ml three-necked flask equipped with a thermometer, preheat to 60°C, start stirring, and then dropwise add 6.60wt % dilute phosphoric acid solution until the pH of the solution is 5.6. After stirring for 10 minutes, the pH value remains unchanged, stop adding acid, then use a separatory funnel to stand for stratification for 4 minutes, and remove the lower water phase. At this time, the water The COD of phase is 450mg / L; Record the isooctanoic acid 0.54wt% in the upper strata oil phase solution, separate the cyclohexane solution containing isooctanoic acid and store for standby, wait to send into the lithium-containing glue solution and carry out delithiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com