In-tube paste recovery device

A recovery device and paste technology, which is applied in the field of paste recovery devices in pipes, can solve the problems of no paste collection or recovery equipment or devices in pipes, loss of paste, and inability to collect and utilize paste, achieving excellent recovery effects and easy The effect of simple operation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

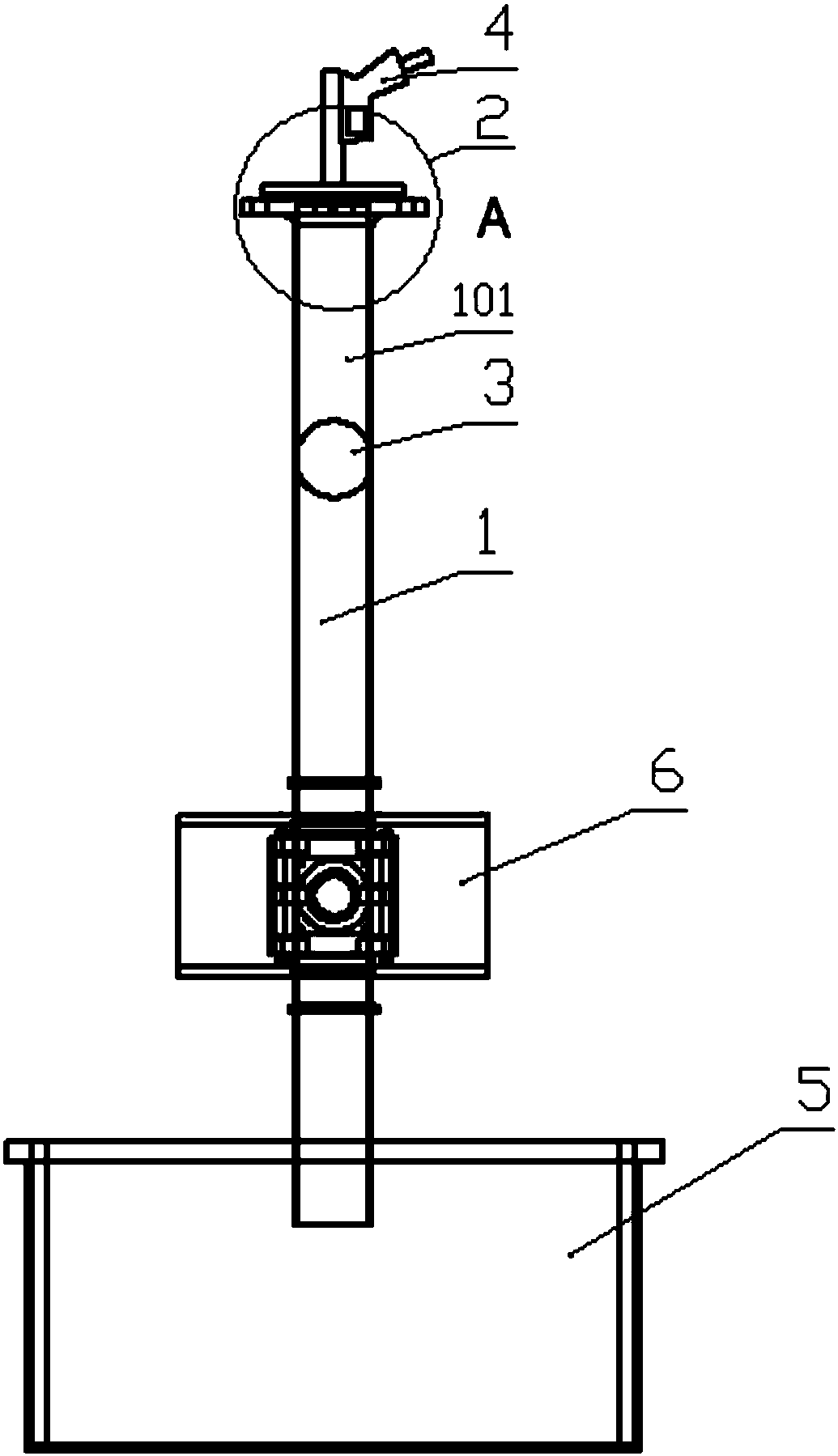

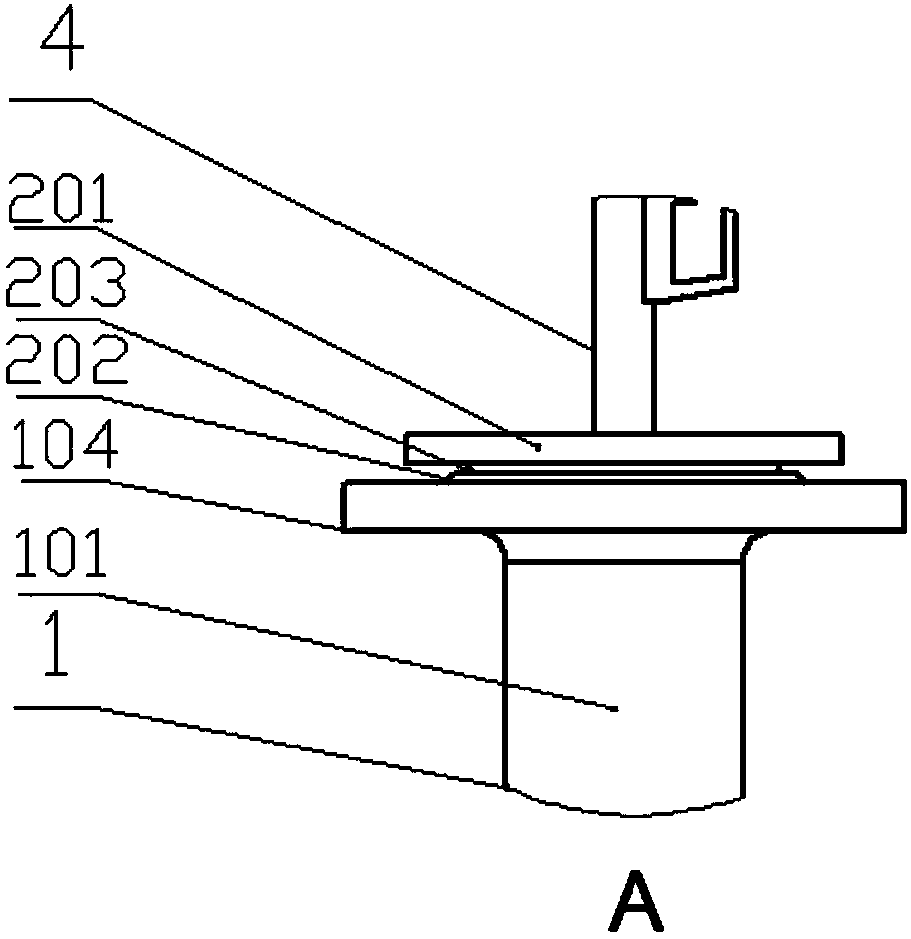

[0023] A kind of paste recovery device in the pipe, such as figure 1 As shown, it includes a pipeline 1 with a ball valve 6, a sealing structure 2 for sealing the pipeline 1 is provided at the pipeline inlet 101, and a flexible extruding part 3 is arranged in the pipeline 1, and the flexible extruding part 3 and the inner wall of the pipeline 1 are seamless. There is clearance fit, and a compressed air source is connected in the pipe section 101 located between the sealing structure 2 and the flexible extrusion part 3 .

[0024] Further, an air pressure gun 4 connected to the pipe section 101 is provided on the sealing structure 2, and the air pressure gun 4 is connected to a compressed air source, and compressed air is injected into the pipe section 101 through the air pressure gun 4 to realize the movement of the flexible extruding part 3. In this embodiment, the air pressure gun is a dust blowing gun.

[0025] Further, the flexible extruding part 3 is a silicone sphere, a ...

Embodiment 2

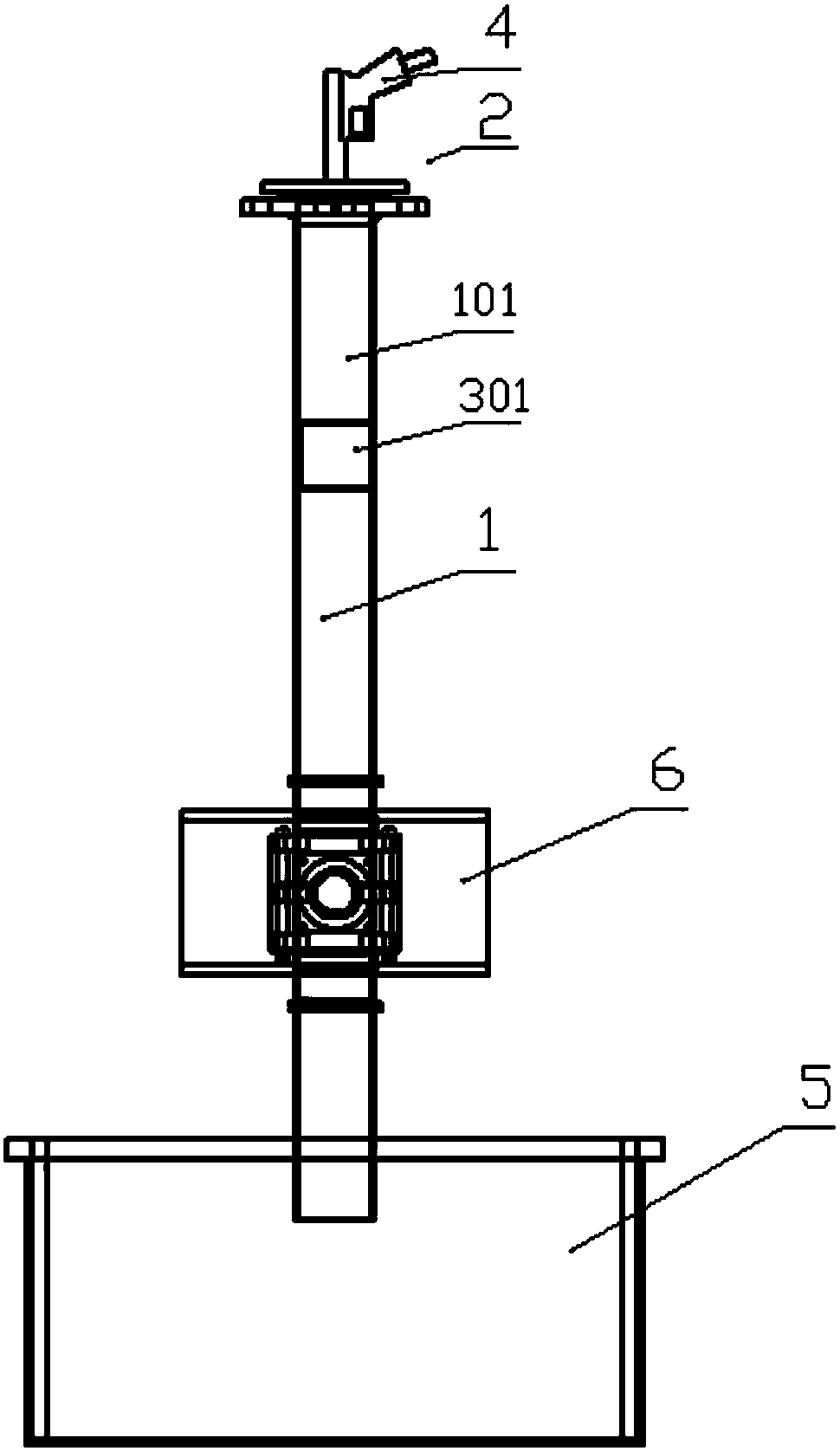

[0034] A kind of paste recovery device in the pipe, such as figure 1 As shown, it includes a pipeline 1 with a pneumatic ball valve, a sealing structure 2 for sealing the pipeline 1 is provided at the pipeline inlet 101, and a flexible extruding part 3 is arranged in the pipeline 1, and the flexible extruding part 3 and the inner wall of the pipeline 1 are seamless. There is clearance fit, and a compressed air source is connected in the pipe section 101 located between the sealing structure 2 and the flexible extrusion part 3 .

[0035] Further, an air pressure gun 4 connected to the pipe section 101 is provided on the sealing structure 2, and the air pressure gun 4 is connected to a compressed air source, and compressed air is injected into the pipe section 101 through the air pressure gun 4 to realize the movement of the flexible extruding part 3. In this embodiment, the air pressure gun 4 is a dust blowing gun.

[0036] Further, the flexible extruding part 3 is a silicone ...

Embodiment 3

[0044] A kind of paste recovery device in the tube, with reference to embodiment 1 and image 3 . Among them, the flexible extruding part is a silicone cylinder that meets hygienic requirements, and the maximum outer diameter of the silicone cylinder is 0.5mm larger than the inner diameter of the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com