Waste water comprehensive treatment and recycling system and method adopting tungsten smelting ion-exchange method

An ion exchange method and comprehensive treatment technology, which is applied in the field of comprehensive treatment and recovery system of wastewater from tungsten smelting by ion exchange method, can solve the problems that multiple components cannot be realized at the same time, the treatment effect is not good, and the effect is single, so as to achieve good treatment and recovery effect , simple design, good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

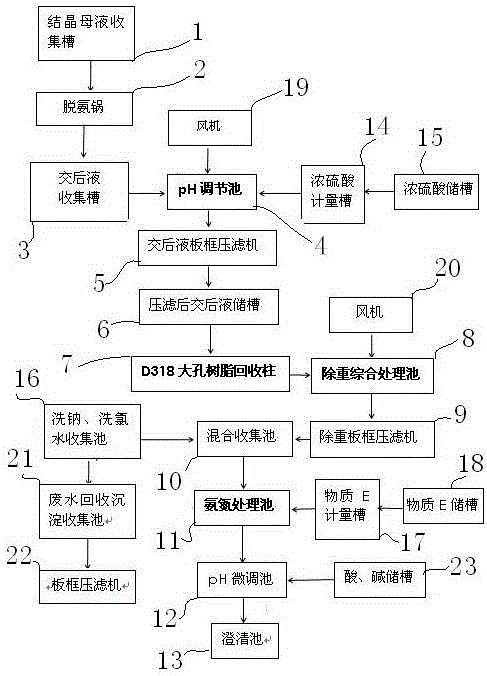

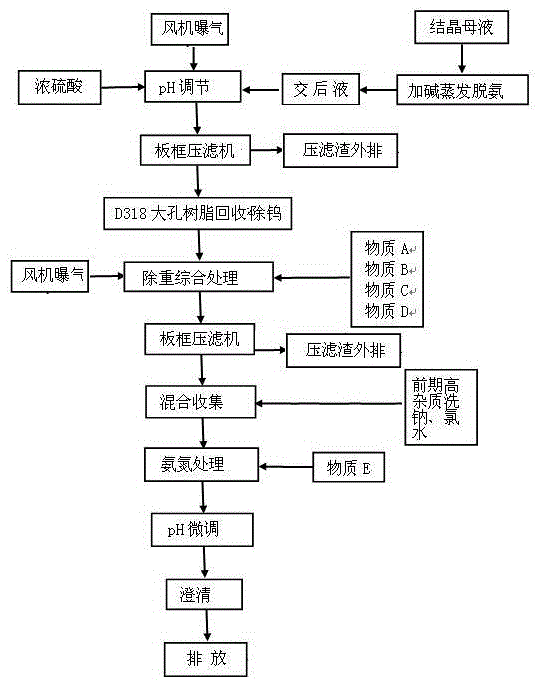

[0030] Tungsten smelting ion exchange waste water comprehensive treatment and recovery system mainly includes crystallization mother liquid collection tank 1, deammonization pot 2, post-transaction liquid collection tank 3, pH adjustment pool 4, post-transition liquid plate and frame filter press 5, Liquid storage tank after press filtration 6, D318 macroporous resin recovery column 7, weight removal comprehensive treatment pool 8, weight removal plate and frame filter press 9, mixing collection pool 10, ammonia nitrogen treatment pool 11, pH fine-tuning pool 12, clarification The pool 13 also includes a sodium washing and chlorine washing water collection pool 16, and the sodium washing and chlorine washing water collection pool 16 is connected with the mixing collection pool 10. The pH adjustment tank 4 is also connected to the concentrated sulfuric acid metering tank 14 at the same time, and the concentrated sulfuric acid storage tank 15 is connected to the concentrated sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com