Recovery processing method for discharge water of circulating water system

A circulating water system, recovery and treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost of dosing, heavy maintenance workload, filtration Insufficient material filtration and other problems, to achieve good recycling effect, easy automatic control, high comprehensive utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

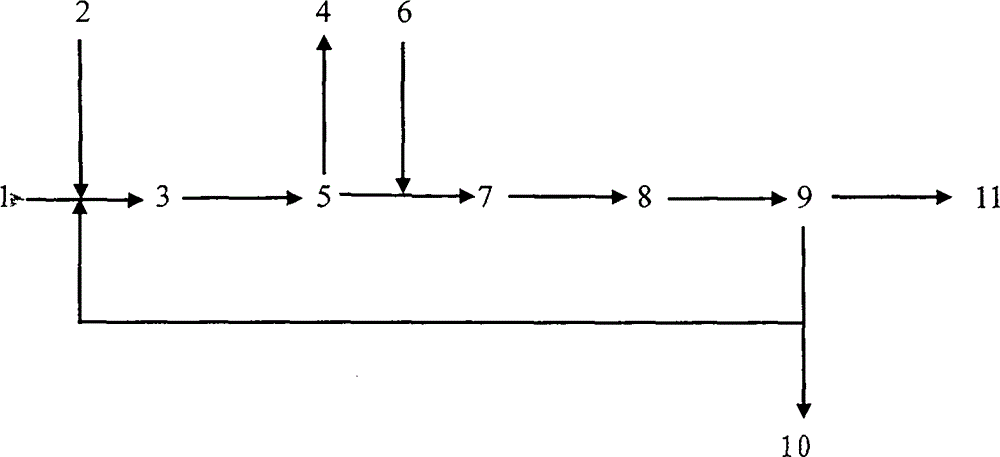

[0018] Describe in detail below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the static mixer [3] is a kind of high-efficiency mixing equipment without moving parts. Its basic working mechanism is to use the mixing unit fixed in the tube to change the flow state of the fluid in the tube, so as to achieve good dispersion and harmony between different fluids. Purpose of mixing well. Static mixer is an advanced unit equipment. Unlike agitator, it has no moving parts inside. It mainly uses fluid flow and internal unit to realize the mixing of various flows and the rational design of special structure. Compared with orifice column, Venturi tube, agitator, homogenizer and other equipment, static mixer has high efficiency, low energy consumption, small volume, low investment and easy continuous production.

[0020] The flocculant automatic dosing device [2] and the pH adjusting device [6] all belong to the dosing device. The dosing device is a comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com