Refill recycling platform based on environmental protection concept

A pen refill and concept technology, applied in the field of stationery recycling machinery, can solve the problems of uneven ink discharge, waste of resources, and inability to discharge ink from the refill, and achieve the effect of saving resources, wide application and good recycling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

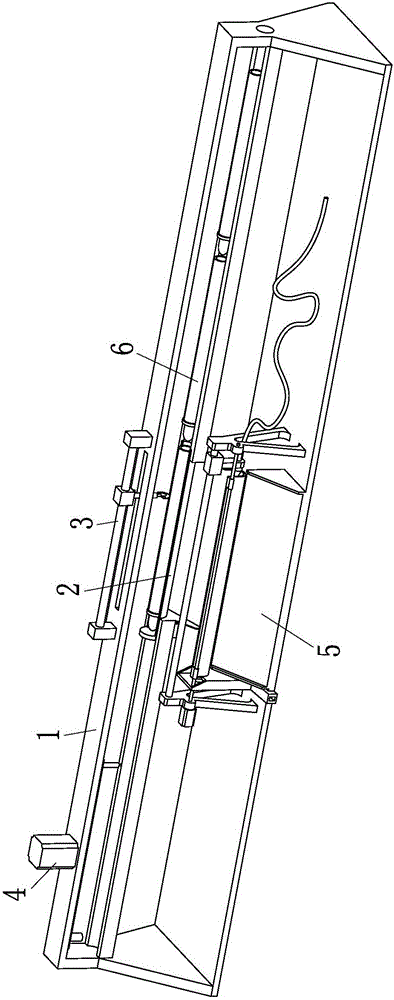

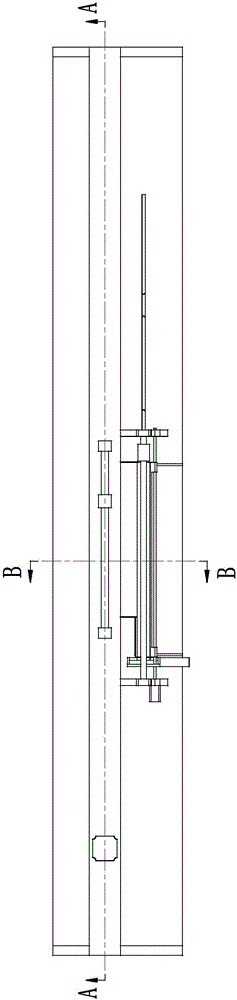

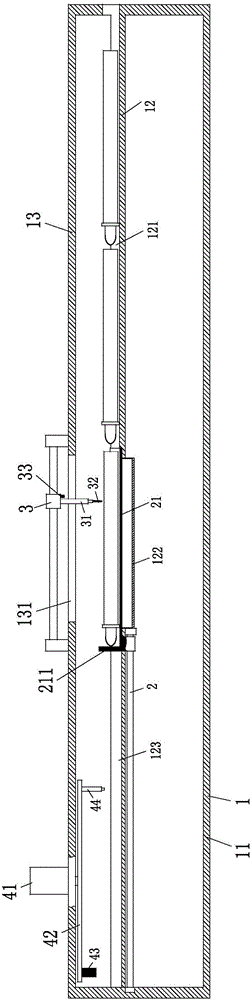

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a kind of refill recovery platform based on the environmental protection concept of the present invention includes a frame 1, a core movement device 2, a core cutting device 3, a head feeding device 4 and an oil blowing device 5; the core movement device 2 is located on the left part of the frame 1, the core cutting device 3 is located above the right part of the core moving device 2, the head feeding device 4 is located above the left part of the core moving device 2, and the oil blowing device 5 is located at the front of the frame 1.

[0029] Described frame 1 comprises base plate 11, middle frame 12 and top frame 13; PLC controller is installed on the base plate 11, and PLC controller is used for controlling the automatic operation of all electric elements of the present invention, pneumatic element, hydraulic element and sensor etc. , the right part of the middle frame 12 i...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is only that: the color recognition sensor 33 recognizes the boundary line between the ink and the nib in the pen core 6, and the electric heating knife 32 divides the pen core into two from the ink and the nib; thus blowing oil The device mixes the sealing oil and ink and recycles them into the oil storage tank; this design is used when the requirements for the recycled ink are not high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com