Cutting fluid recovery device for machining

A technology of mechanical processing and recycling device, applied in the field of mechanical processing, can solve the problems of clogging of mesh holes, affecting the effectiveness of long-term recycling operations, etc., and achieve the effect of improving adsorption effect and enhancing the effect of treatment and reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

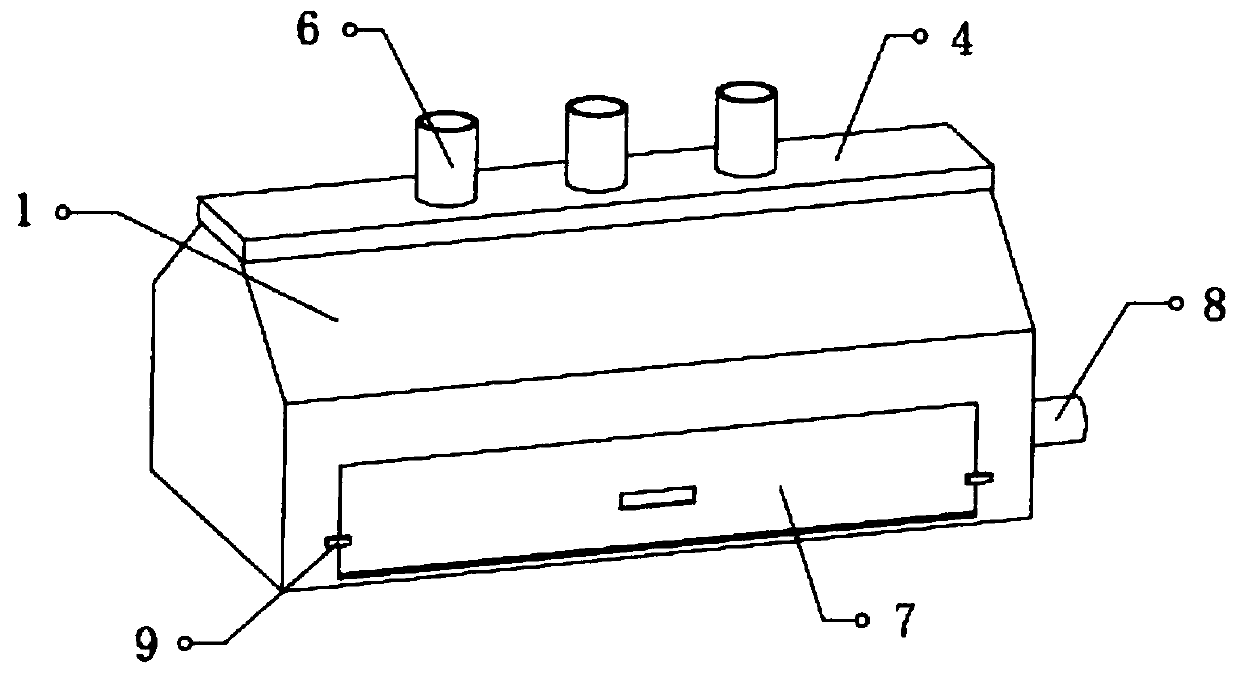

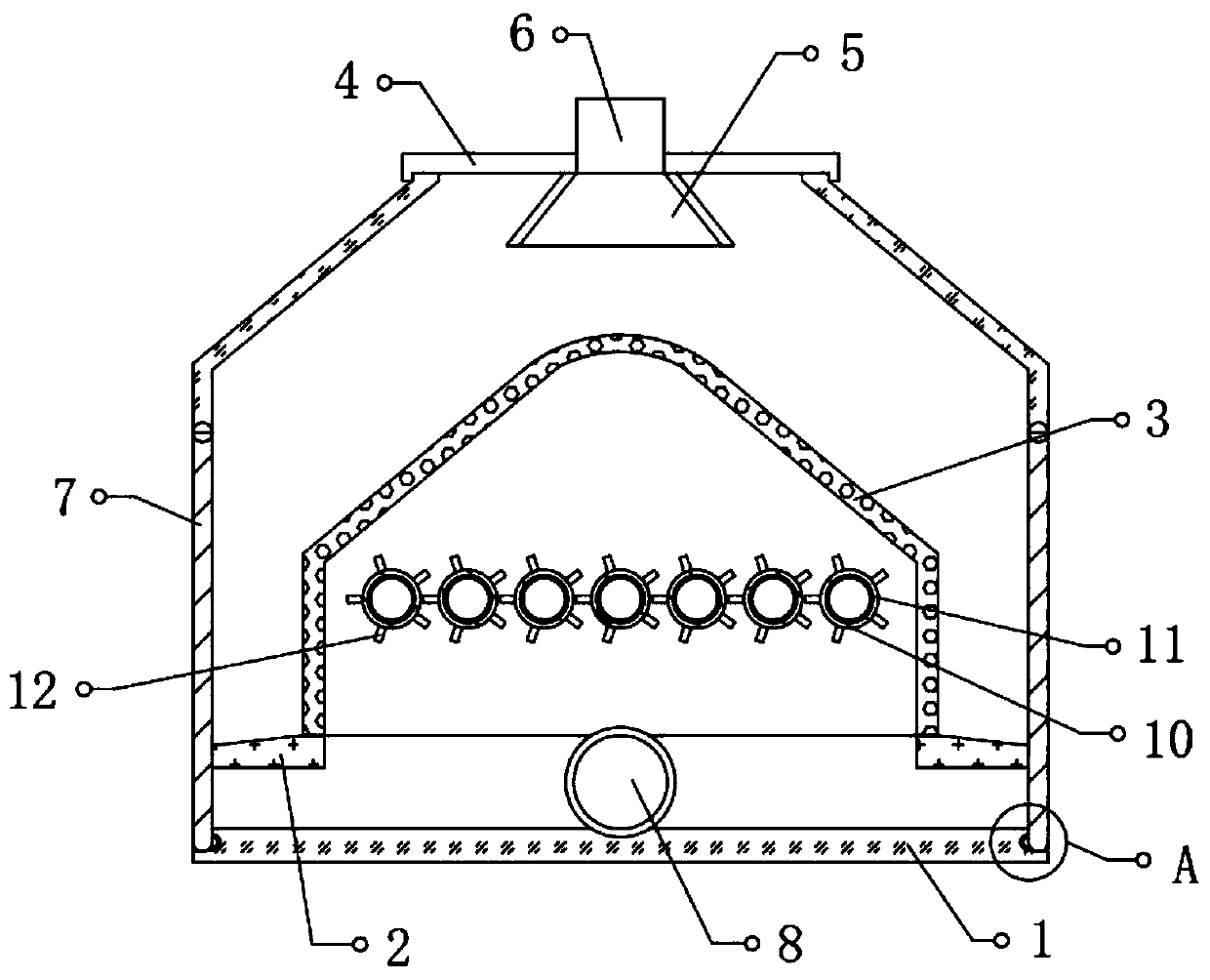

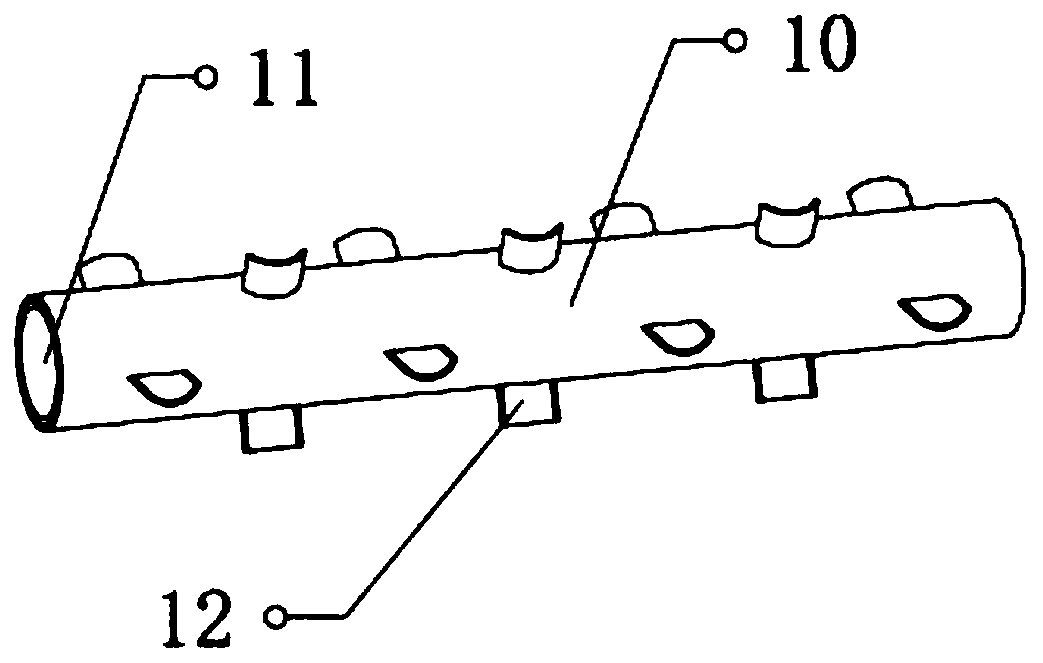

[0028] refer to Figure 1-4 , a cutting fluid recovery device for mechanical processing, including a box body 1, fixing pieces 2 are fixed at the bottom of both ends between the inner walls on both sides of the box body 1, and a filter screen is fixed between the top outer walls of the two fixing pieces 2 Plate 3, the filter screen plate 3 is set as a box-like structure with an open bottom, and the middle position of the top outer wall of the filter screen plate 3 is set as an upwardly protruding arc structure, and both ends of the top outer wall of the filter screen plate 3 are set to be inclined downward The inclined surface, and a storage cavity is formed between the two ends of the filter screen plate 3 and the inner walls of both ends of the box body 1, the top of the box body 1 is open, and the bottom end of the outer wall of the box body 1 is fixed with a liquid outlet pipe 8. The outer walls of both ends of the box body 1 are provided with fixing grooves, and the top o...

Embodiment 2

[0035] refer to Figure 5 , a cutting fluid recovery device for mechanical processing, the top of the inner wall at both ends of the box body 1 is set as an inclined surface, and the inclined surface at the top of the inner wall at both ends of the box body 1 is parallel to the inclined surface at both ends of the top end of the filter screen plate 3, the box body 1 The tops of the inner walls at both ends are provided with installation grooves, and the inner walls of the installation grooves are fixed with electric guide rails 15, and the bottom of the electric guide rails 15 is connected with a connecting plate 16 placed obliquely, and the bottom of the connecting plate 16 is fixed with bristles 17, and the bottom of the bristles 17 In contact with the top of the filter screen plate 3 , an electric telescopic rod 18 is fixedly connected between the bottom of the electric guide rail 15 and the top of the connecting plate 16 .

[0036] During use, during normal filtration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com