Method for treating sulfate in wastewater

A treatment method, sulfate technology, applied in the field of water treatment, can solve environmental pollution and other problems, and achieve the effect of low investment and operation costs, simple method, and environmentally friendly treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A kind of treatment method of sulfate in waste water, its steps are as follows: 50g oil shale waste residue obtains 130mLAl after high temperature and multiple leaching treatments 3+ Leachate, Al measured by 3+ The concentration was 2.42g / L, that is, 0.3146g Al was extracted in total. Al in oil shale residue 2 O 3 The content accounts for 28% of the total mass, and the extraction rate of Al element is calculated to be about 4.25%.

Embodiment 2

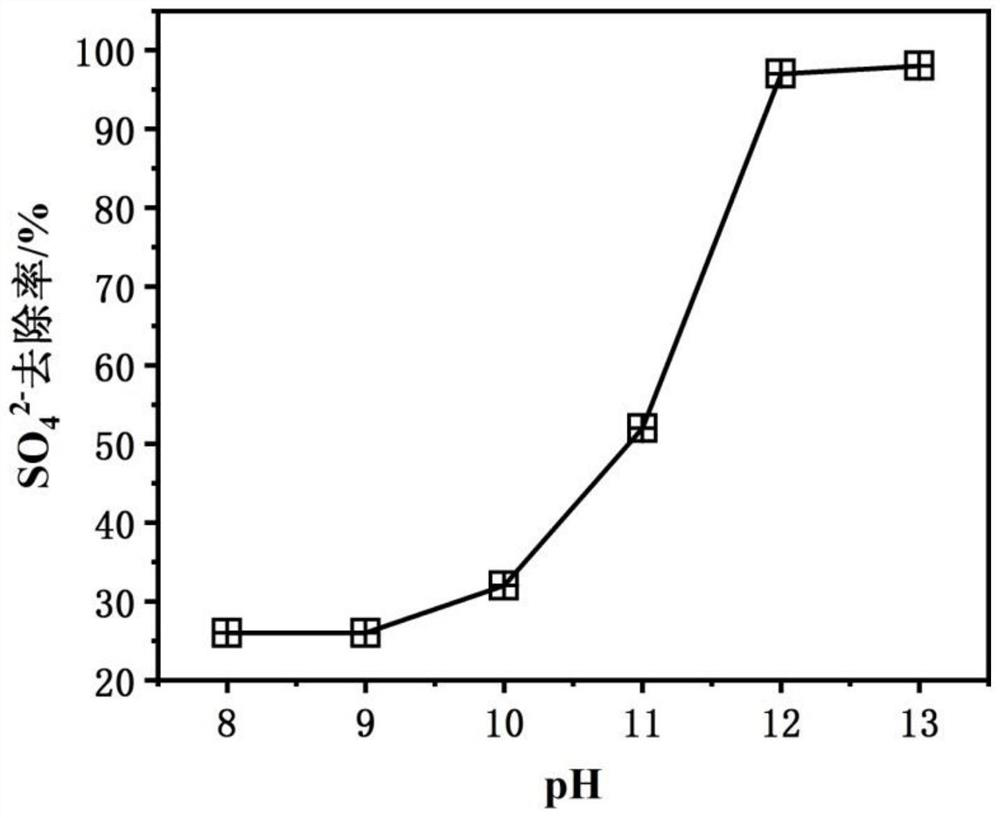

[0067] figure 1 shows that it contains Al 3+ The effect of pH of the acid leaching solution and the sulfate reaction system in the wastewater on the sulfate removal rate in the wastewater. When pH=8 or 9 in the reaction system, SO 4 2- The removal rate is only 26%, less than 30%; when pH=11, SO 4 2- The removal rate reached 52%, and the treatment effect was significantly improved; when pH=12, SO 4 2- The removal effect is the best, and the removal rate reaches more than 95%, and when the pH continues to increase, the SO 4 2- The removal rate did not change much. This shows that the pH of SO 4 2- The removal effect has a great influence on the pH value, and it is more likely to generate aluminum calcium sulfate complex or ettringite precipitation when the pH value is higher. When the pH reaches 12, SO 4 2- The removal rate is close to the peak value.

Embodiment 3

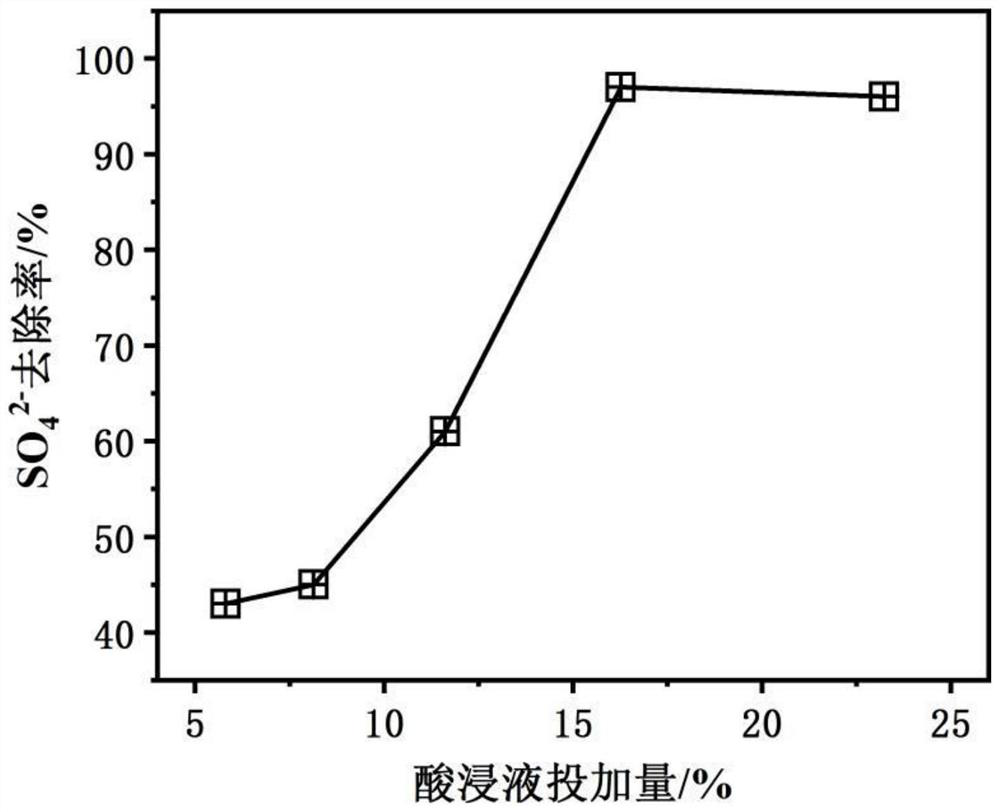

[0069] figure 2 shows that contain Al 3+ The effect of acid leaching solution dosage on sulfate removal rate in wastewater. while keeping SO 4 2- Under the condition of 1.0g / L of acid leaching solution, the removal rate gradually increases with the increase of acid leaching solution dosage. When the acid leaching solution dosage is 16.27%, the removal rate reaches the maximum value. To consider, the acid leaching solution dosage of 16.27% is the most suitable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com