Patents

Literature

53results about How to "Solve curing problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

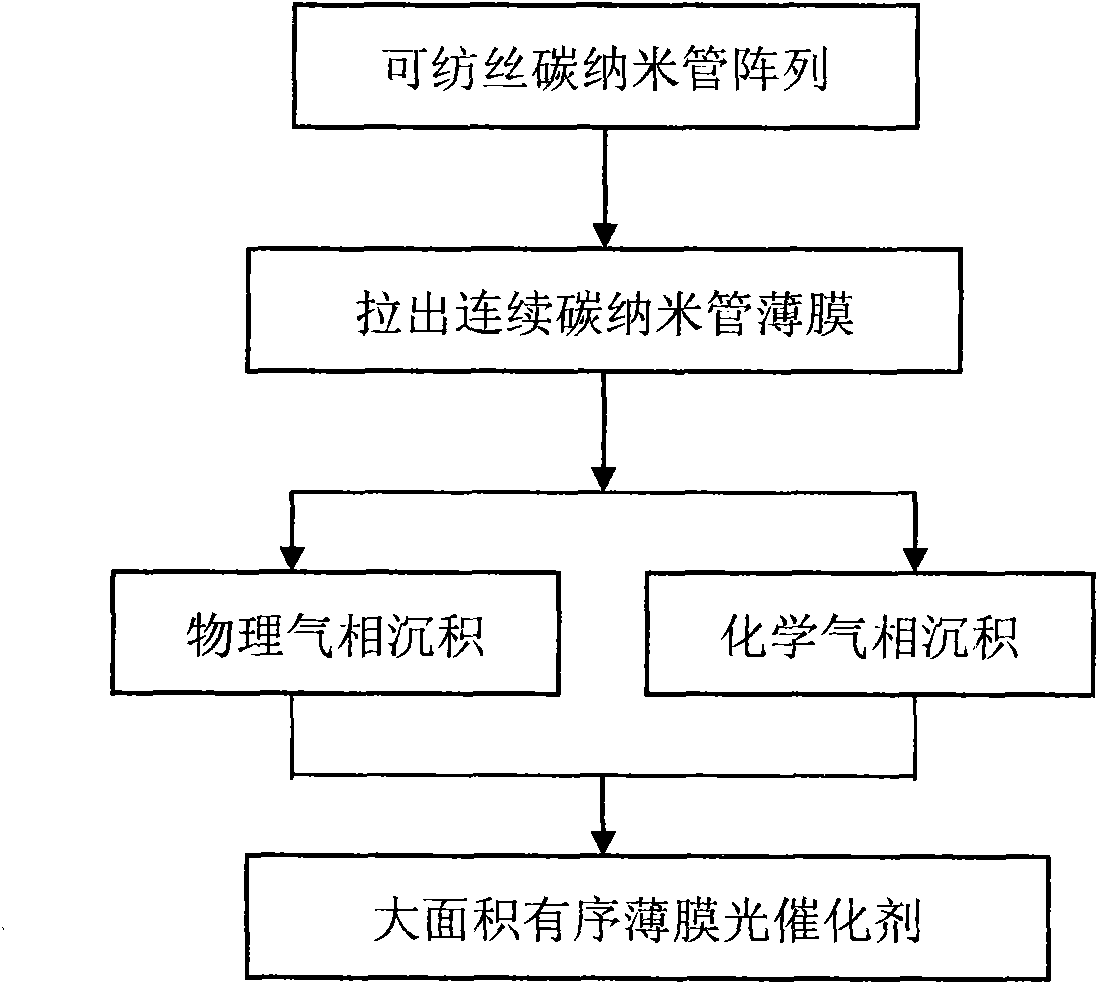

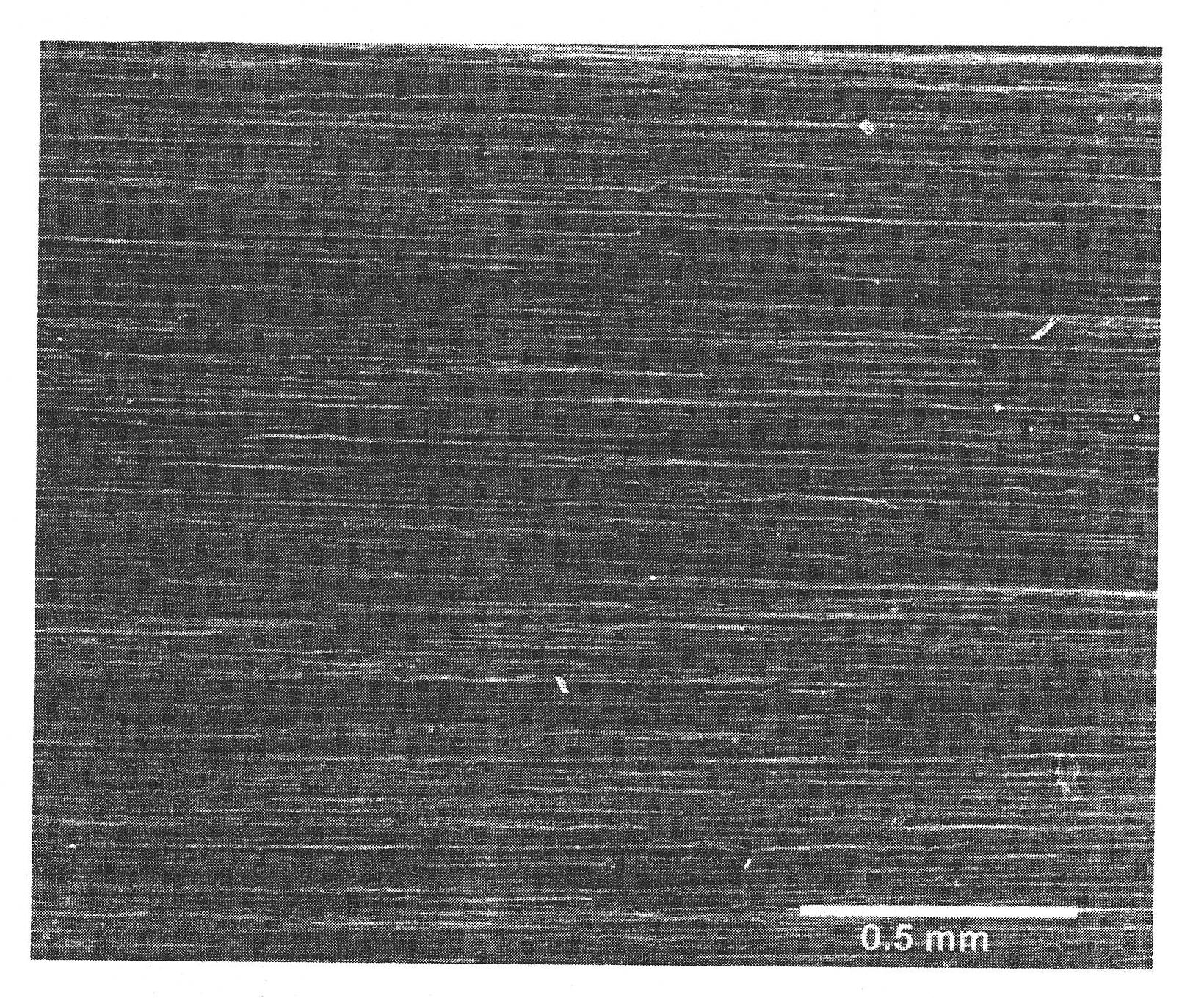

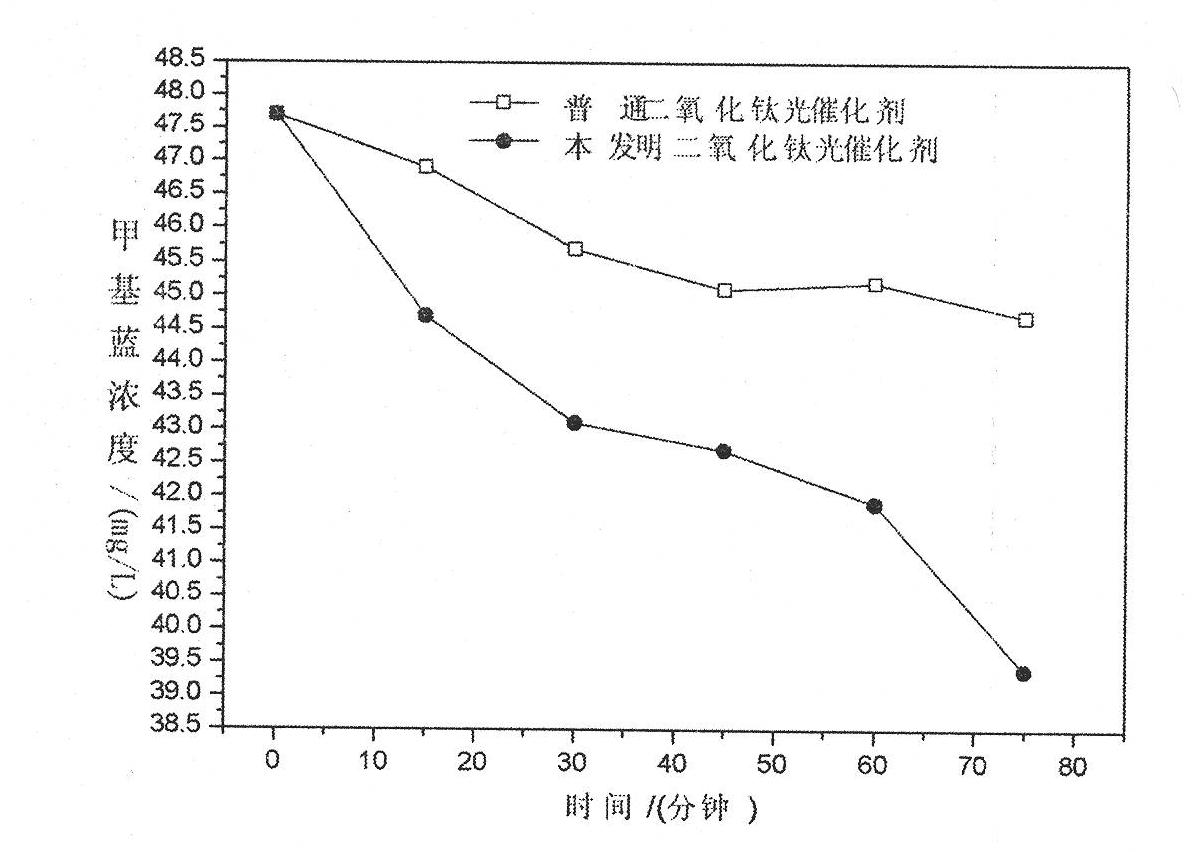

Large-area titanium dioxide nanotube film as well as preparation method and application thereof

InactiveCN101972641AIncrease the areaImprove efficiencyPhysical/chemical process catalystsTio2 nanotubeCatalytic function

The invention relates to a large-area titanium dioxide nanotube film as well as a preparation method and application thereof. The large-area titanium dioxide nanotube film comprises a template formed by a carbon nanotube order film and nano titanium dioxide layers coated on the outer walls of carbon nanotubes forming the template. The carbon nanotube orderly film is used as the template in the preparation method, and the preparation method comprises the step of coating the nano titanium dioxide layers on the carbon nanotubes forming the template to form a titanium dioxide nanotube film. The titanium dioxide nanotube film can be used as a photoelectric integrated catalytic material for application, has adjustable structure and size, the preparation method is simple and easy to apply and has high efficiency and low cost, and meanwhile, the titanium dioxide nanotube film can be applied by adopting various modes, has photoelectric integrated catalytic function and high catalytic activity, and is suitable for being widely applied to the fields of photocatalysis, solar utilization, photoelectric conversion and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

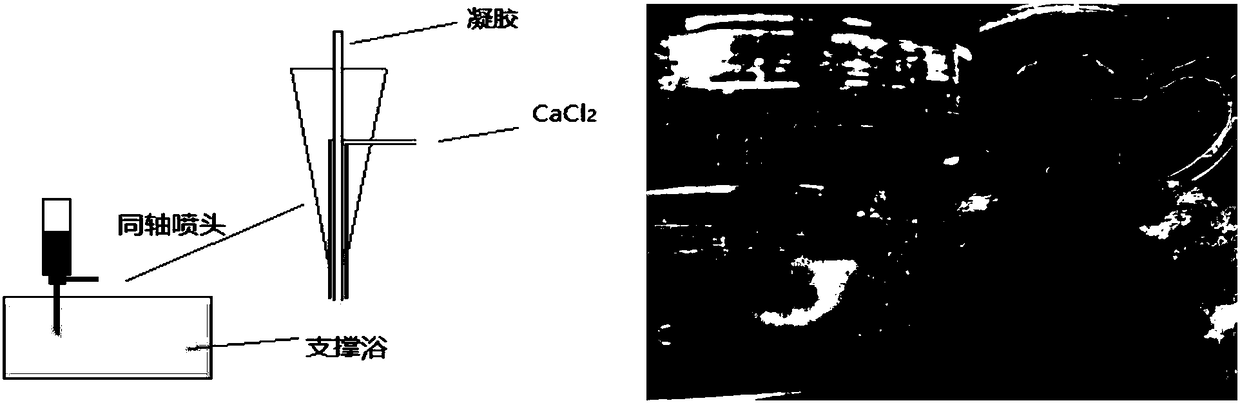

Method for rapid multi-nozzle 3D printing of tumor tissue model using supporting bath

ActiveCN108587903AConvenient researchBuild fastAdditive manufacturing apparatusTissue/virus culture apparatusSterile environmentEngineering

The invention discloses a method for rapid multi-nozzle 3D printing of a tumor tissue model using supporting bath, and relates to the field of biological 3D printing. The method mixes alginate, photocurable gelatin and the like to encapsulate cells and prints rapidly in the supporting bath, and printing of different cells is achieved by rapidly switching nozzles. By printing a normal tissue and atumor tissue in a complete model, the structure of a tumor tissue in vivo is better restored. The closed property of the hydrogel support bath provides a better sterile environment, and at the same time, uncontrolled cell density and species space due to settlement are avoided during printing. The rapid switching of the nozzles reduces the printing time to a certain extent, the decreasing of the activity of the cells is effectively slowed down in the printing process, and the integrity of the printing structure is effectively ensured. The problem of gel curing is effectively solved by printingwith a concentric needle. The tumor model is built faster and can be better used for tumor treatment research.

Owner:JINAN UNIVERSITY

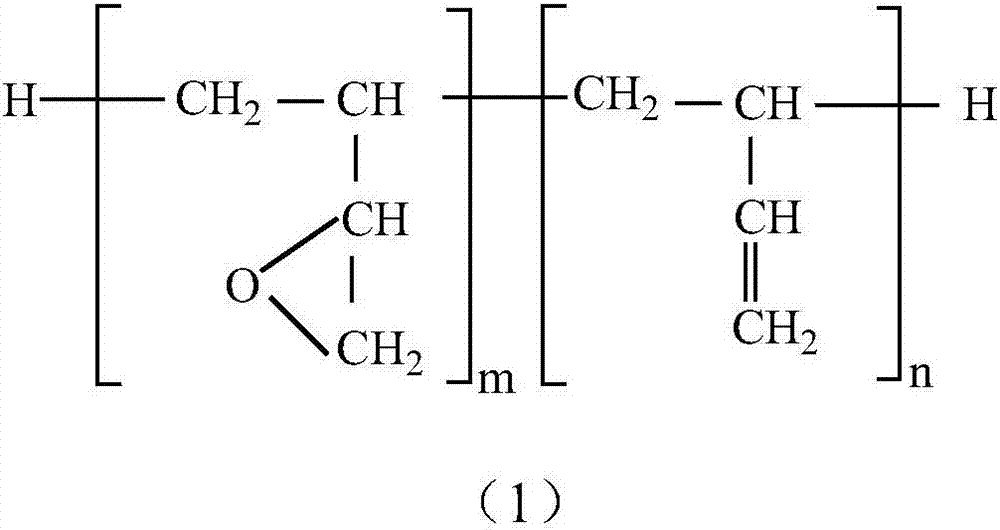

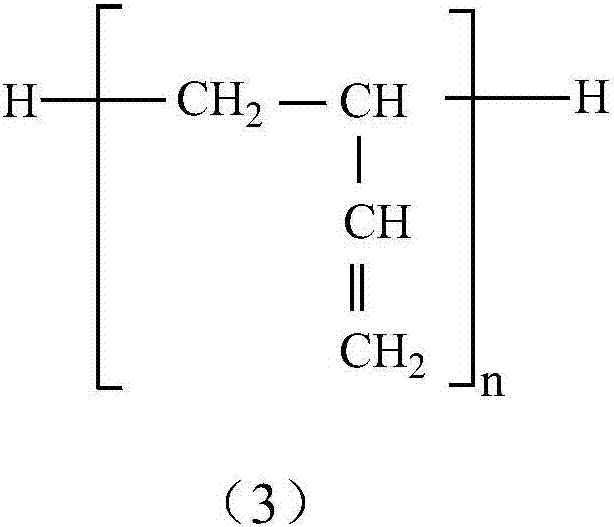

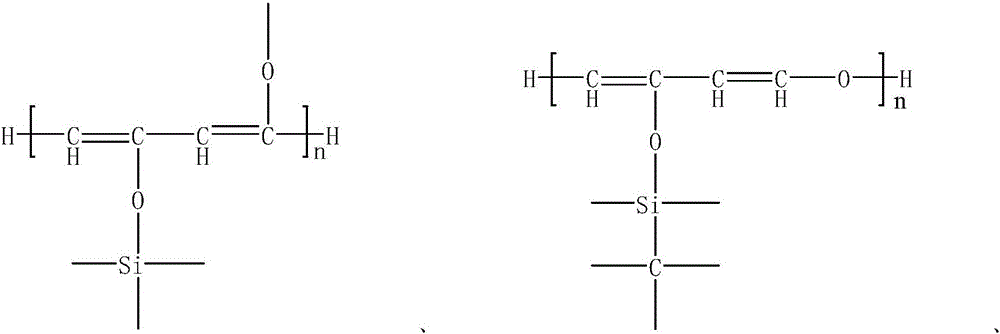

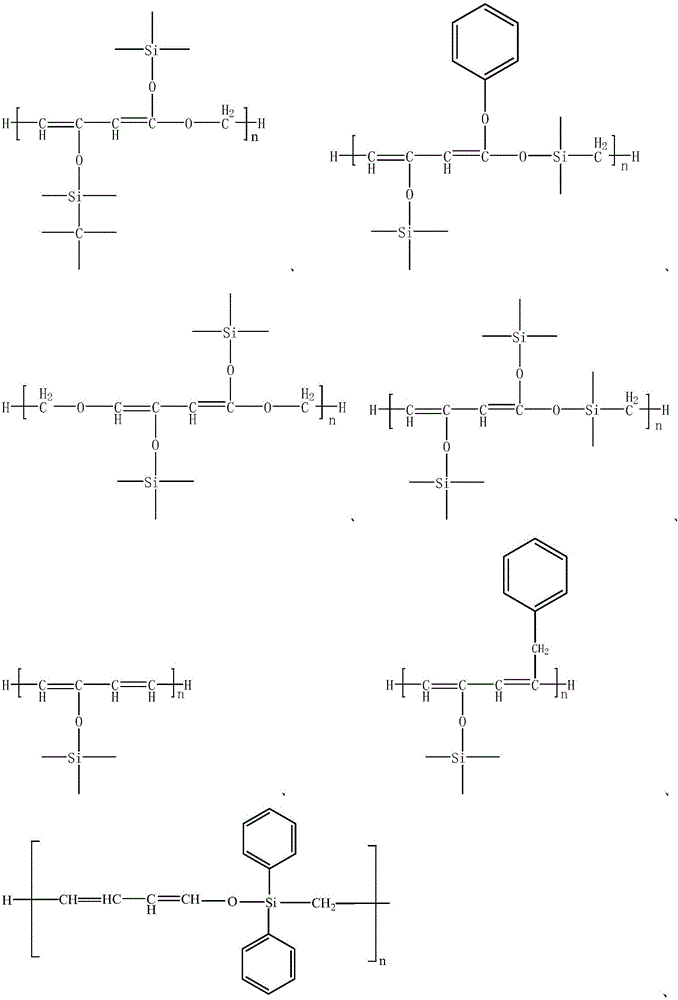

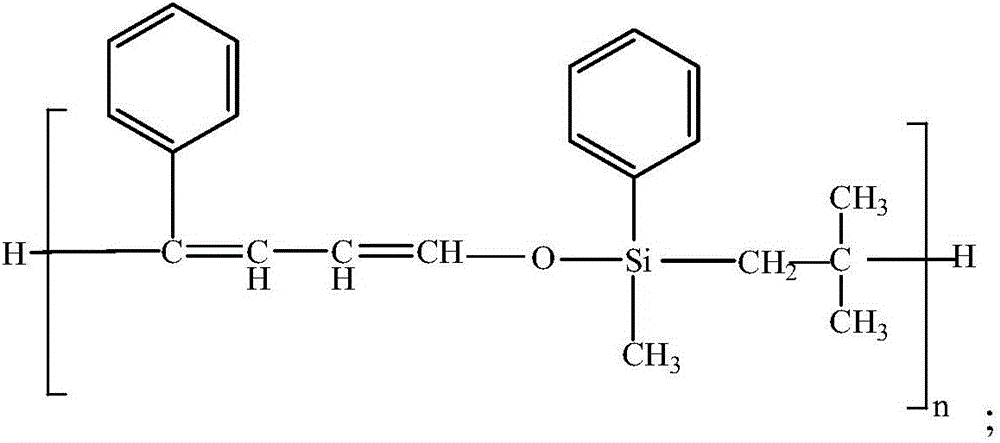

Modified polybutadiene prepolymer as well as preparation method and application thereof

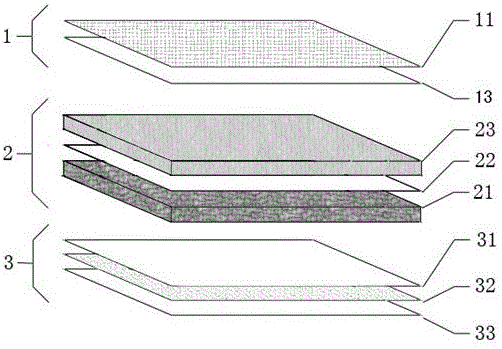

ActiveCN107033517AImprove heat resistanceImprove toughnessSynthetic resin layered productsElectrical equipmentMetal foilCopper foil

The invention relates to a modified polybutadiene prepolymer as well as a preparation method and application thereof, resin composition prepared from the modified polybutadiene prepolymer, a prepreg prepared from the resin composition, a metal foil coated laminated board and a layer insulation film. The modified polybutadiene prepolymer is a prepolymer of an epoxy polybutadiene mixture, bismaleimide resin and cyanate ester in the weight ratio being 100: (10-60): (15-80). The problem that polybutadiene is incompatible with other resin is solved, the adhesion performance of a hydrocarbon resin system is improved, the peel strength between copper foil of the laminated board and the resin layer is improved, and the dielectric performance of the resin system is not affected. The brittleness of a maleimide cured product is improved by the aid of epoxy polybutadiene resin, polybutadiene and silica-containing butadiene.

Owner:SHENGYI TECH SUZHOU

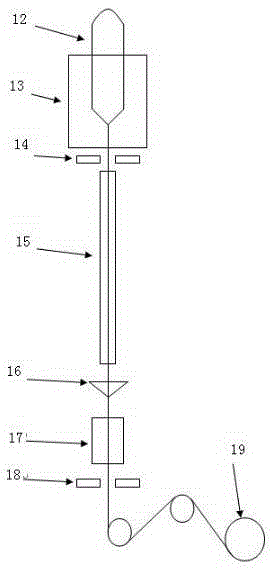

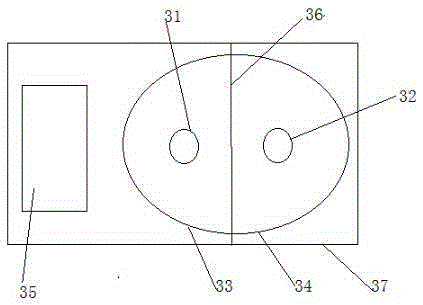

Device for automatically controlling curing degree of optical fiber coating, and optical fiber production equipment

InactiveCN105259625ASolve curing problemsCause jitterGlass optical fibreFibre mechanical structuresPhysical chemistryUltraviolet

The invention relates to a device for automatically controlling the curing degree of an optical fiber coating, and the device is characterized in that the device comprises an ultraviolet curing furnace, connectors, a gas flow sensor, an oxygen concentration measurement instrument, a controller, and an upper computer; the upper and lower sides of the ultraviolet curing furnace are provided with the connectors; the oxygen concentration measurement instrument is connected with the controller through a signal line; the upper computer is connected with the controller through a control line; the device achieves the curing degree of an optical fiber through the control of the internal oxygen concentration in the ultraviolet curing furnace, and simply and effectively solves problems of excessive curing, insufficient curing, pastiness and fiber jittering in a curing process of the optical fiber.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

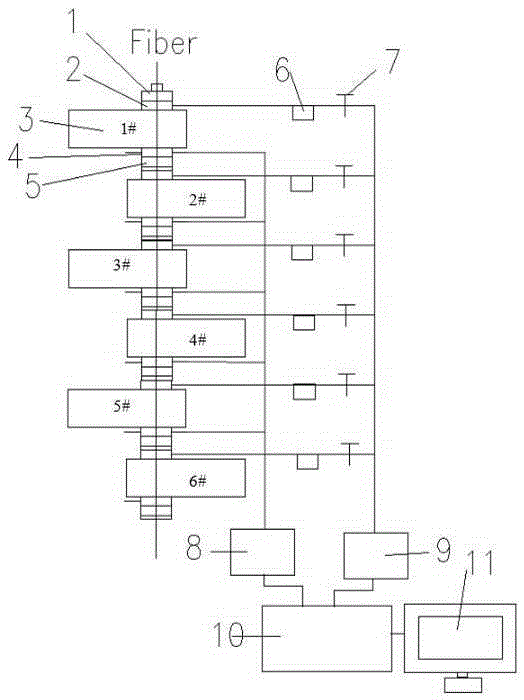

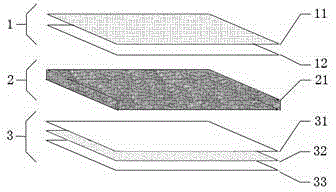

Fragrant warming paste containing plant essential oil and manufacturing method thereof

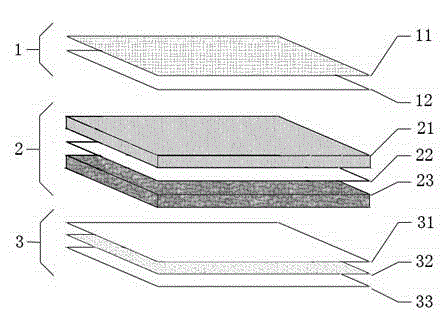

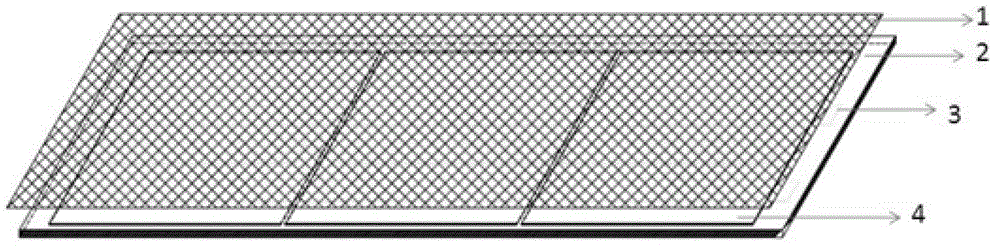

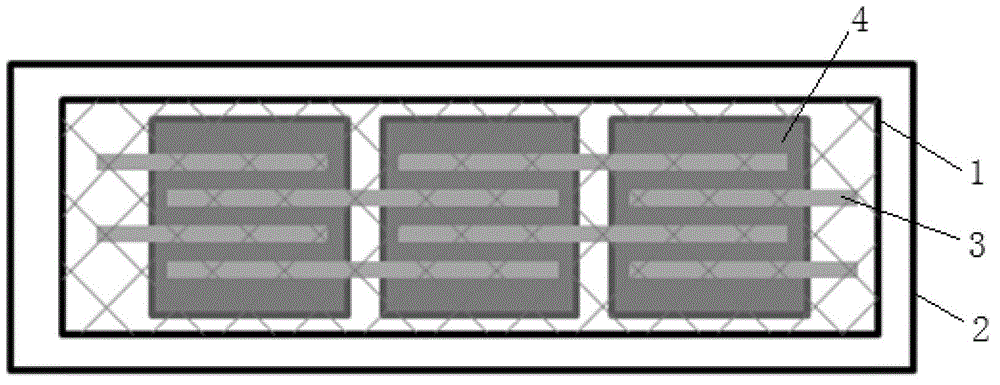

ActiveCN104799996AIncrease profitReduce volatilization and consumptionEssential-oils/perfumesTherapeutic coolingEssence oilEnvironmental geology

The invention discloses a fragrant warming paste containing plant essential oil and a manufacturing method thereof. By changing a raw material layer structure of a common warming paste product, powdered flavor and a heat generating agent are isolated through a micropore air-permeable film, and the single raw material layer is changed into double or three raw material layers. A composite non-woven fabric layer is a non-woven fabric composite high-air-permeability polymer film or a non-woven fabric for avoiding retarded fragrant molecule release and influence on air-permeable performance of the micropore air-permeable film. Plant essential oil is wrapped and cured by cyclodextrin to prepare the powdered flavor, flavor utilization rate is improved, the problems of cutting and slow release of the plant essential oil and other liquid flavors are solved, and the problem that the flavor is directly in contact with the heat generating agent to influence the heating generating stability of the warming paste is solved. The fragrant warming paste containing plant essential oil is advanced in technology, reasonable in scheme design, efficient and capable saving energy, and production technology level of the fragrant warming paste is greatly improved.

Owner:孙松

Back-contact solar battery string and production method thereof

InactiveCN102751361ASolve curing problemsAffect performanceFinal product manufacturePhotovoltaic energy generationSolderingSolar cell

The invention discloses a back-contact solar battery string, which comprises a plurality of back-contact solar cells, solidified conductive glue and a metal soldering belt, wherein the back-contact solar cells are arranged in a linear way at intervals, and the back surfaces of the back-contact solar cells are adhered with the metal soldering belt through the solidified conductive glue. The invention also discloses a production method of the back-contact solar battery string. Due to the adoption of the back-contact solar battery string and the production method thereof, the adhering and solidification problem of the back-contact solar cells and the soldering belt can be solved, and the situation that the solar cells and the soldering belt shift before the conductive glue is solidified to influence the performance of the back-contact solar battery string is prevented.

Owner:HEFEI HAREON SOLAR TECH

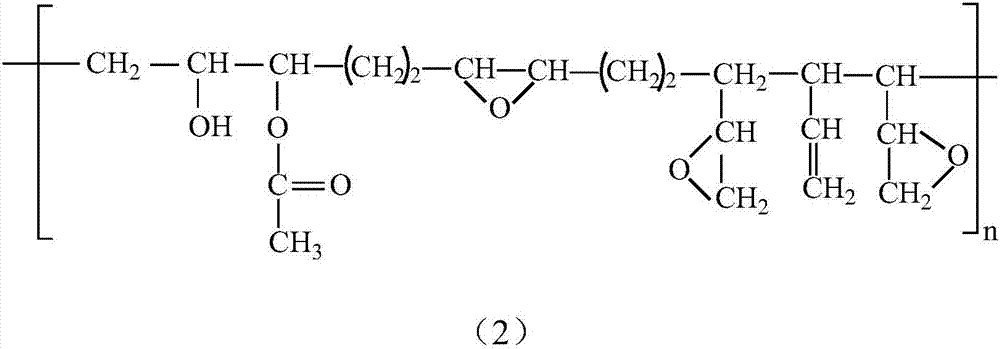

Resin composition and prepreg, laminated board and interlayer insulating film manufactured thereby

ActiveCN106749952ASolve curing problemsLow dielectric constantLaminationLamination apparatusChemistryFire retardant

The invention discloses a resin composition. The resin composition comprises the following solids in parts by weight: (a) 10-80 parts of maleimide resin, (b) 10-80 parts of a silica crosslinking agent, (c) 0.01-5 parts of an initiator, (d) 0-60 parts of inorganic filler and (e) 0-30 parts of a flame retardant. By adopting the silica crosslinking agent, the problems that in the prior art, hydrocarbon resin such as polybutadiene is poor in adhesiveness, poor in thermal expansion, insufficient in heat resistance, poor in compatibility with other resin and the like are further solved on the basis of providing an excellent dielectric property for the maleimide resin.

Owner:SHENGYI TECH SUZHOU

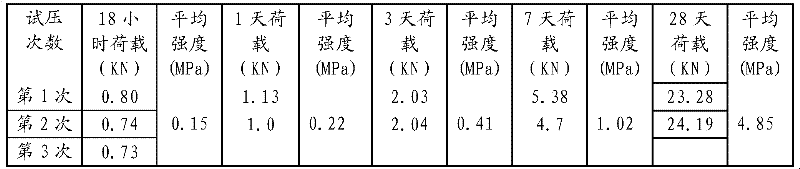

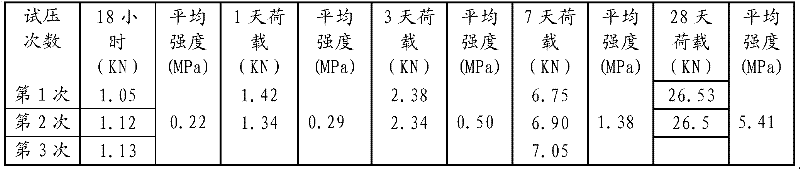

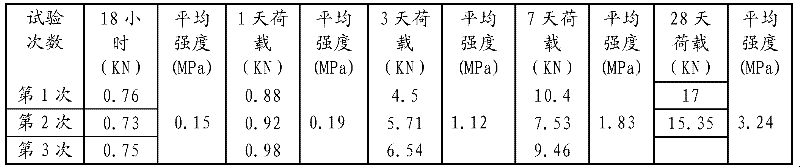

Coal ash gangue filling activity-stimulating rubber solid material and preparation method thereof

The invention discloses a coal ash gangue filling activity-stimulating rubber solid material which comprises the following components in parts by weight: 34-60 parts of base material, 15-45 parts of calcium source compound, 7-21 parts of gypsum, 10-42 parts of slag fine powder and 1.5-10 parts of stimulating material, wherein the base material is cement clinker or cement; the calcium source compound is calcined lime and / or calcium magnesium powder; and the stimulating material is chloride and / or sulfate. As Ca(OH)2 is key material for generating hydrated silicate and hydrated aluminum silicate, the coal ash gangue filling activity-stimulating rubber solid material takes the chloride and / or the sulfate as the stimulating material, so that the dissolution of Ca(OH)2 generated by the base material, the calcined lime or the calcium magnesium powder can be promoted, the alkalinity of solution can be improved, the covalent bond of SiO4<4-> in the coal ash can be opened, so that the depolymerization of silica tetrahedron can be promoted, the activity stimulation of the coal ash and the gangue powder can be accelerated, early solidifying and early strengthening when the coarse coal ash and the gangue powder are filled with each other in a mixing way can be realized, and the later strengthening intensity can be improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

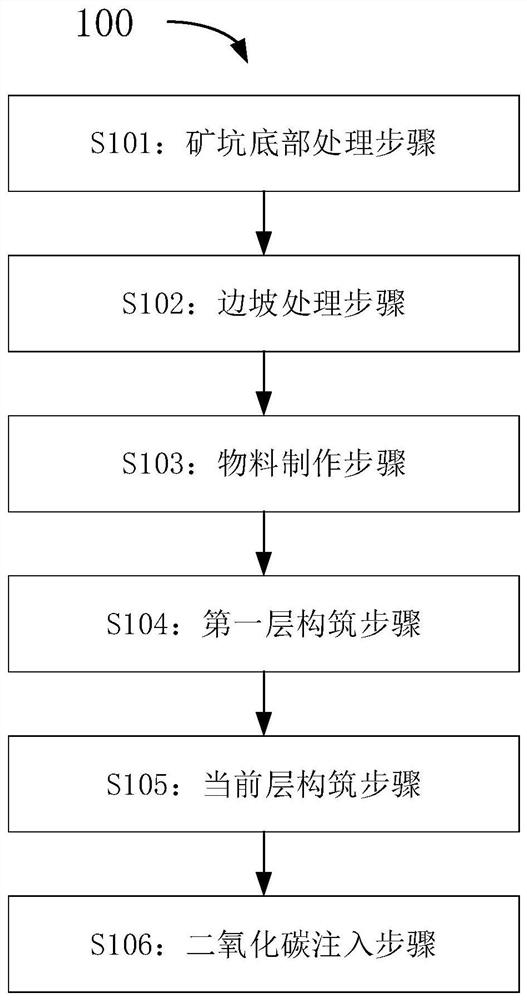

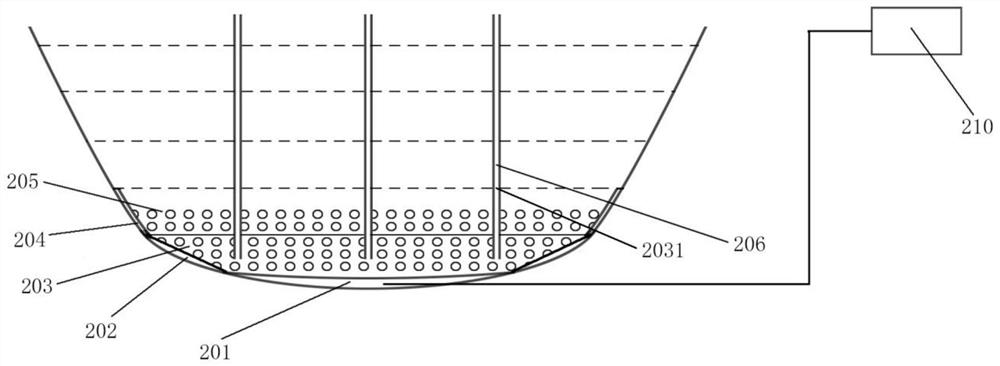

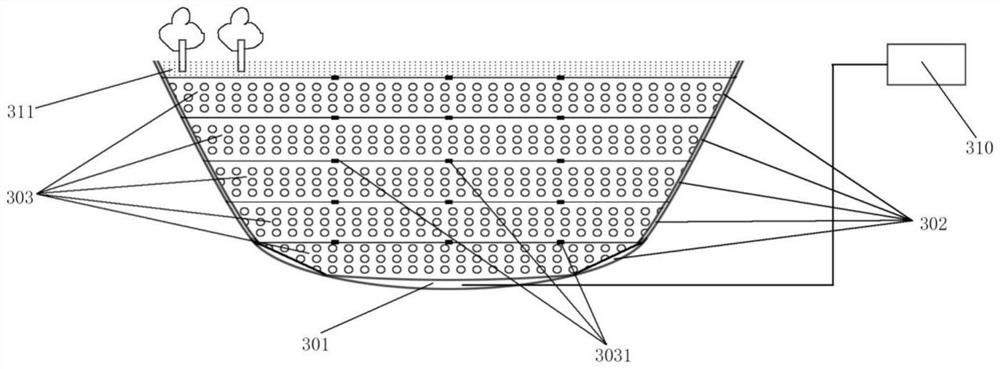

Method and structure for sealing and storing carbon dioxide by using strip mine pit and mining method

ActiveCN113101789AResolve disposal issuesSolve curing problemsGas treatmentDispersed particle separationMining engineeringProcess engineering

The invention provides a method and a structure for sealing and storing carbon dioxide by using a strip mine pit and a mining method. The method for sealing and storing carbon dioxide by using the strip mine pit comprises the steps: a step of treating the bottom of the mine pit; a slope treatment step; a material manufacturing step; a first layer construction step; a current layer construction step; and a carbon dioxide injection step, wherein according to the sealing and storage requirements, the slope treatment step, the material manufacturing step, the current layer construction step or the carbon dioxide injection step are executed one or more times. According to the invention, co-processing of various industrial solid wastes can be realized, reduction, resource utilization and safe processing of the wastes are realized, carbon dioxide is synchronously added for sealing and storage, the utilization value of the mine pit is greatly improved, secondary benefits are generated, a carbon sequestration engineering technology is realized, and a solution is provided for early carbon neutralization.

Owner:珞珈环讯环境科技(北京)有限公司

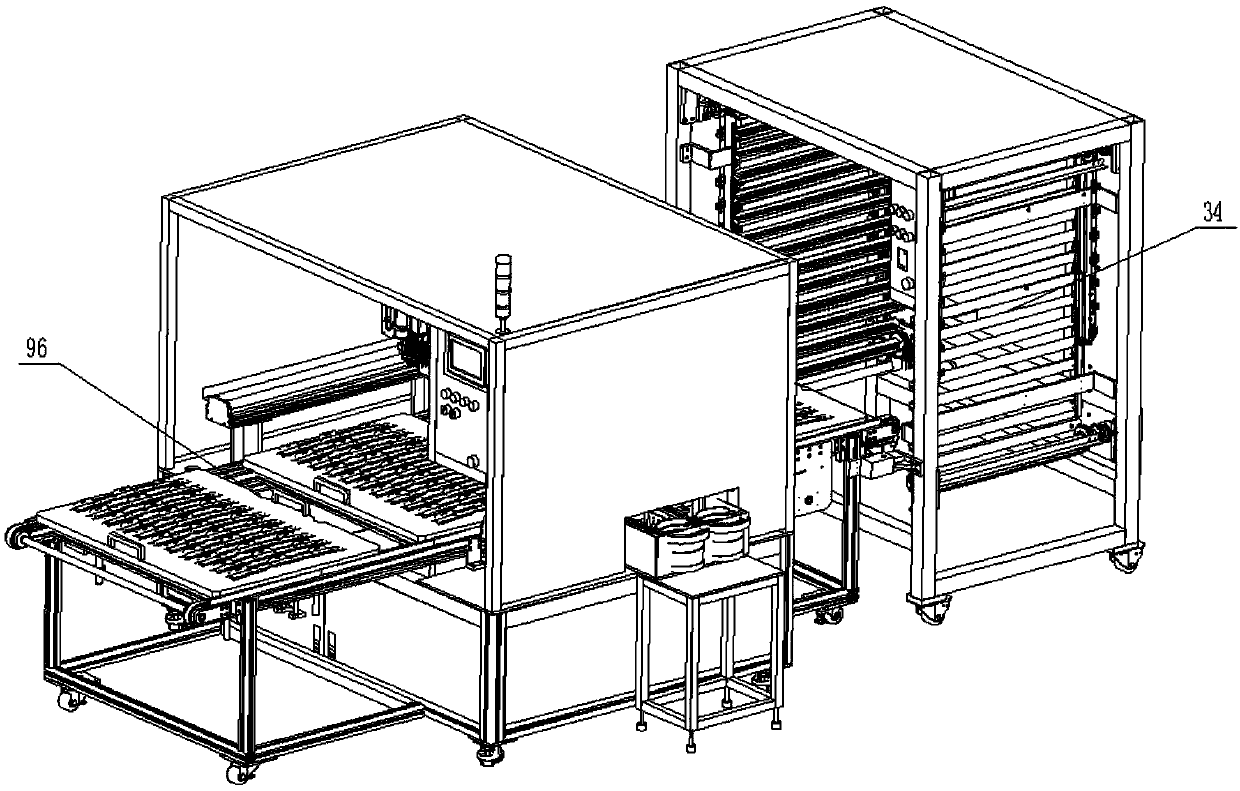

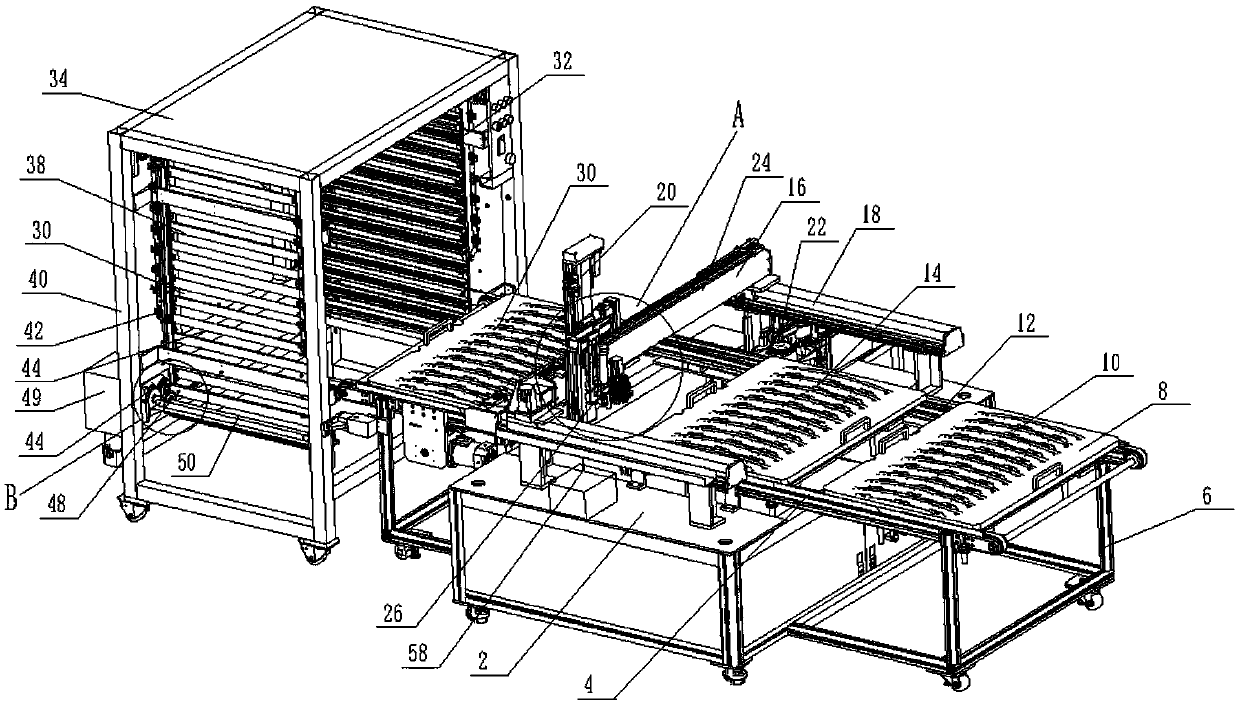

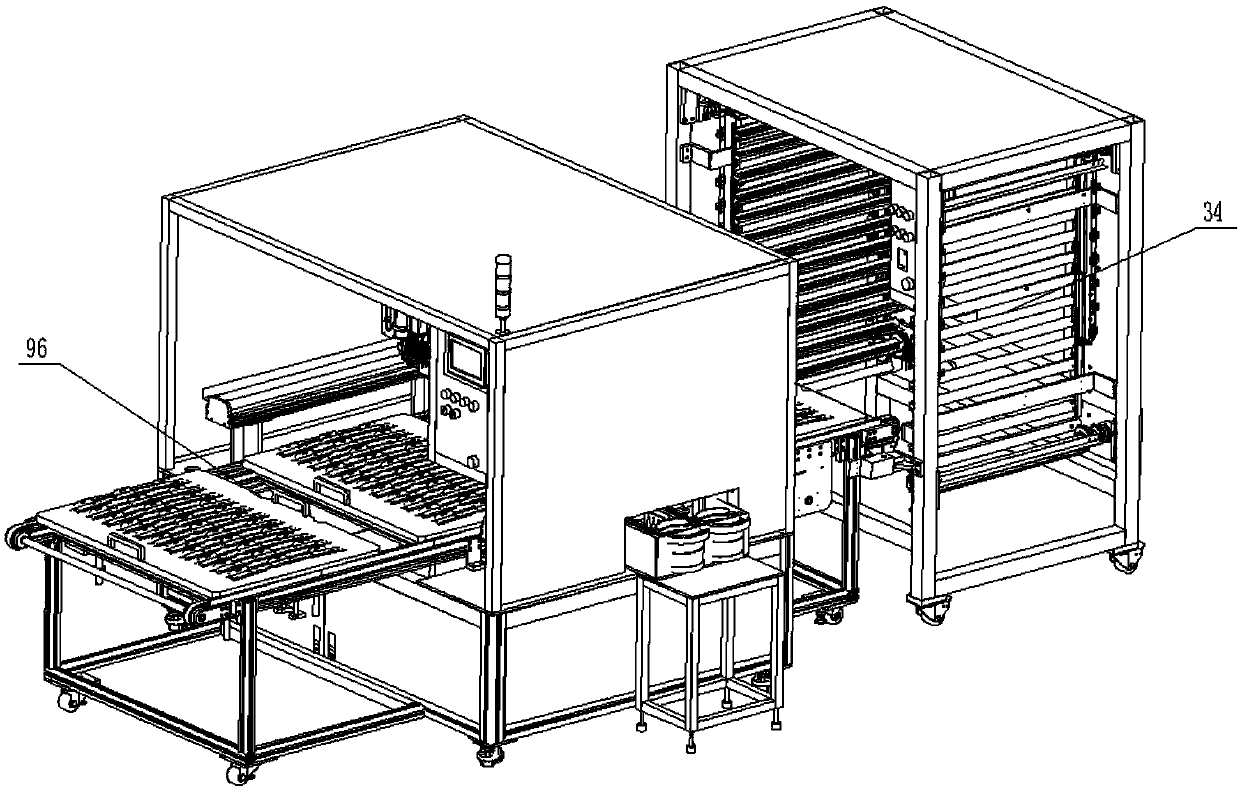

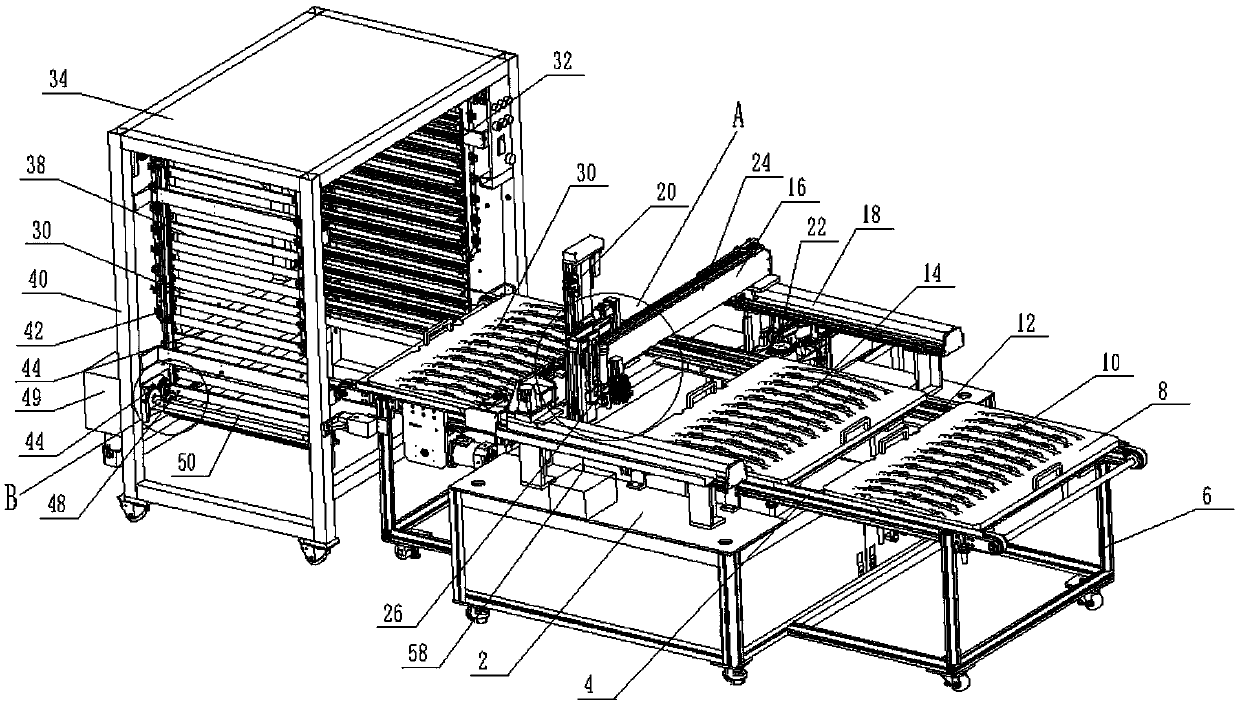

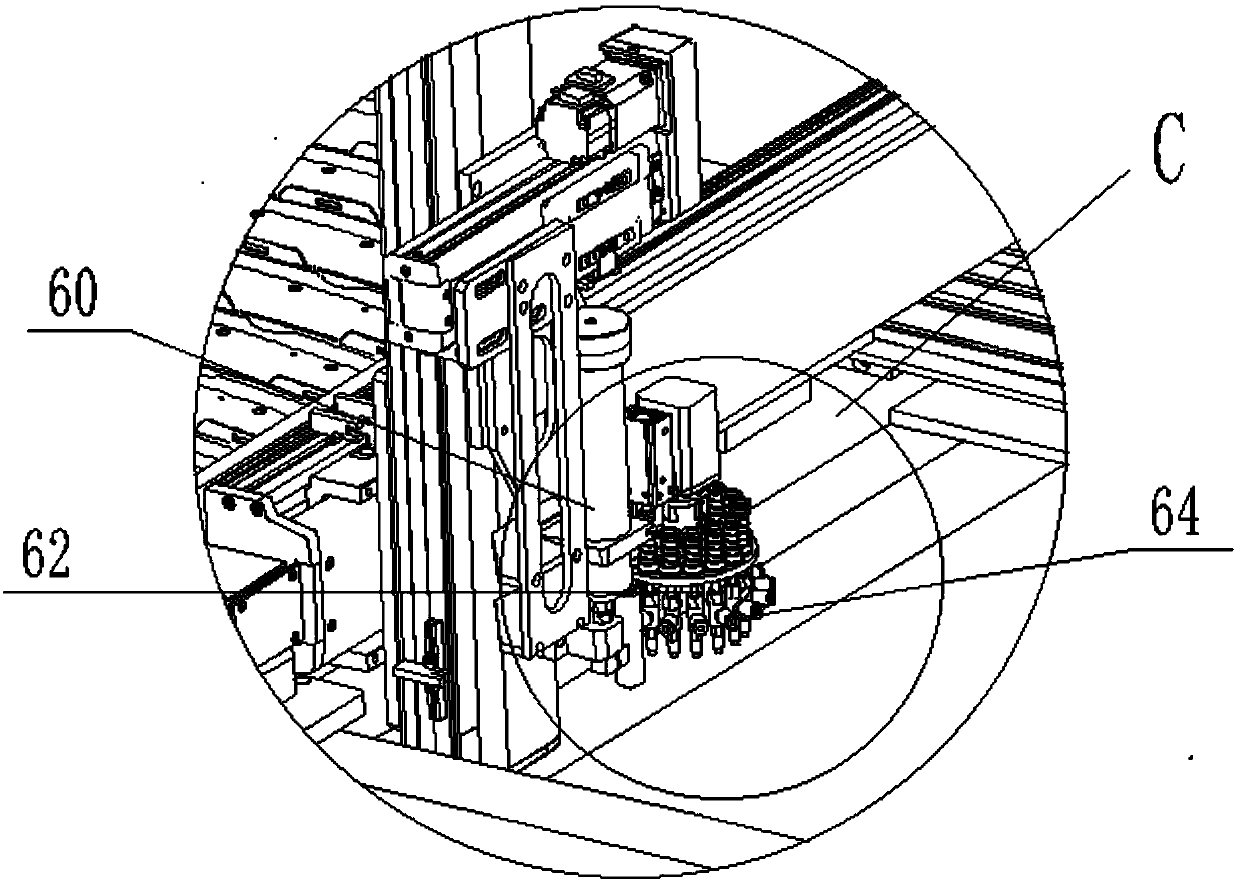

Gasket gluing equipment

The invention discloses gasket gluing equipment. The gasket gluing equipment comprises a tray and a conveying mechanism for conveying products; the products are placed on the tray; the conveying mechanism is provided with a loading station, a glue dispensing station and an unloading station in a conveying direction; a laminator for bearing the tray is arranged on the side near the unloading station; the laminator comprises a laminating frame, and a first shelf set and a second shelf set arranged on the laminating frame; the first shelf set and the second shelf set are oppositely arranged, andrespectively comprise multiple support units; the support units on the first shelf set and the support units on the second shelf set are correspondingly arranged for supporting the same tray; each support unit comprises an U-shaped groove and multiple strips arranged in the U-shaped groove; and the strips are arranged in the conveying direction of the conveying mechanism. The gasket gluing equipment can realize glue dispensing to improve the working efficiency.

Owner:苏州工业园区多司电子科技有限公司

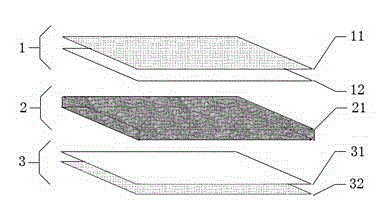

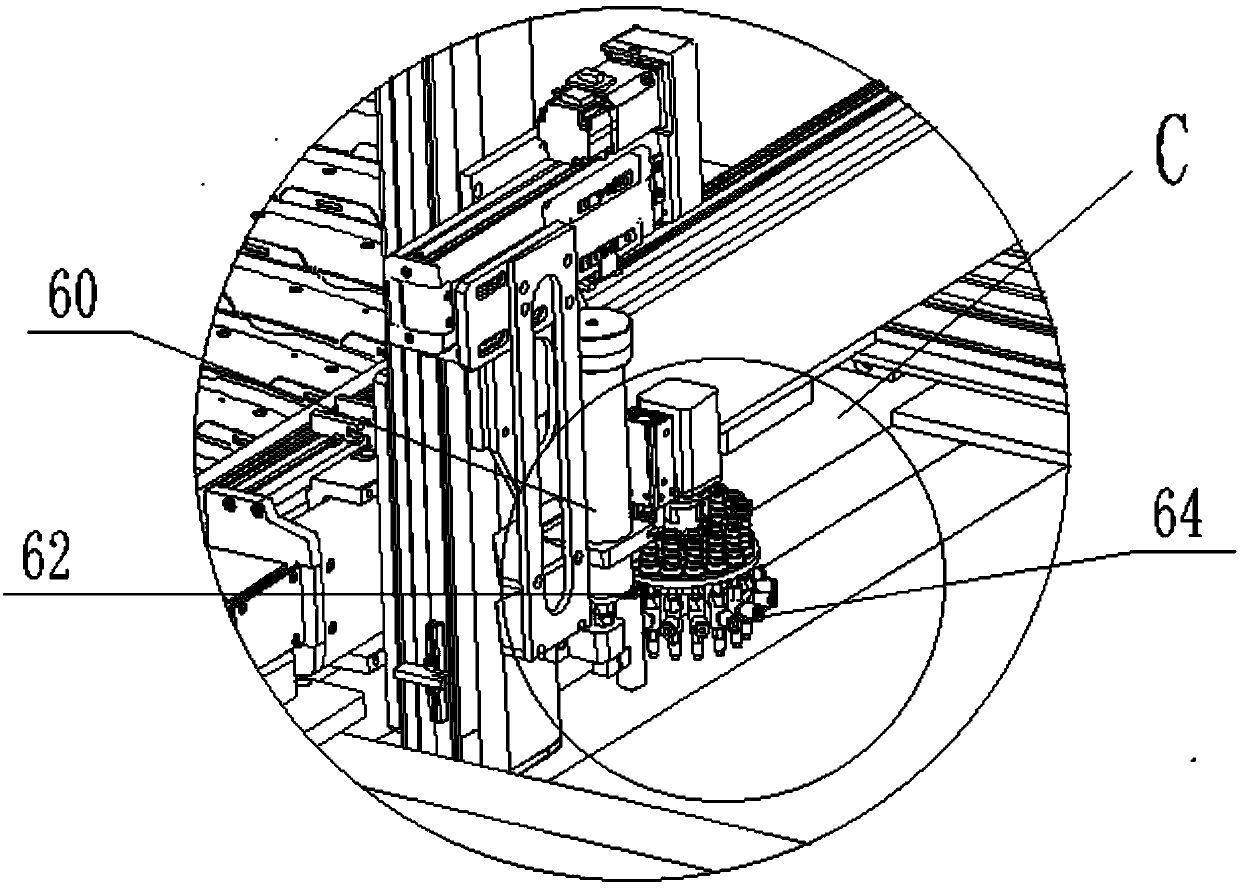

Automatic dispensing mechanism

PendingCN109550646ALabor savingSave energyLiquid surface applicatorsCoatingsEngineeringAutomatic Dispensing

The invention discloses an automatic dispensing mechanism. The mechanism comprises a workbench; a feeding mechanism and a material taking and placing mechanism are arranged on the workbench, the material taking and placing mechanism is arranged on a moving assembly, the moving assembly drives the material taking and placing mechanism to move, and the feeding mechanism comprises a stock bin and atleast one vibrating disc; and the stock bin comprises a material distributing disc and a first driving mechanism for driving the material distributing disc to rotate, the material distributing disc isprovided with a plurality of object placing tables used for containing gaskets, each containing table is provided with a notch allowing the gasket to pass through, and the material distributing discis provided with feeding positions which are used for receiving materials from discharge ends of the vibrating discs. The dispensing can be realized, and the working efficiency is improved.

Owner:苏州工业园区多司电子科技有限公司

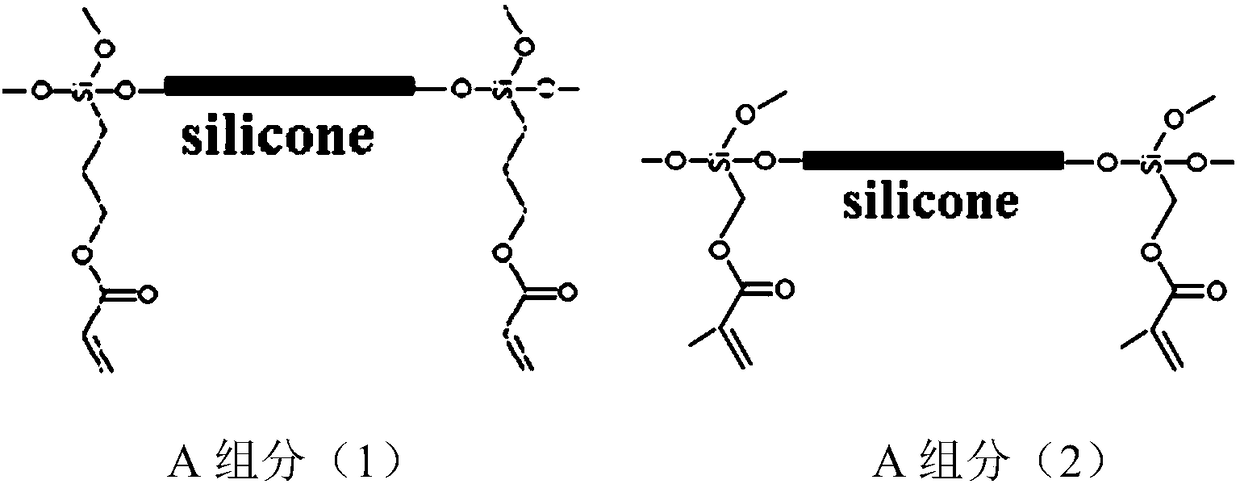

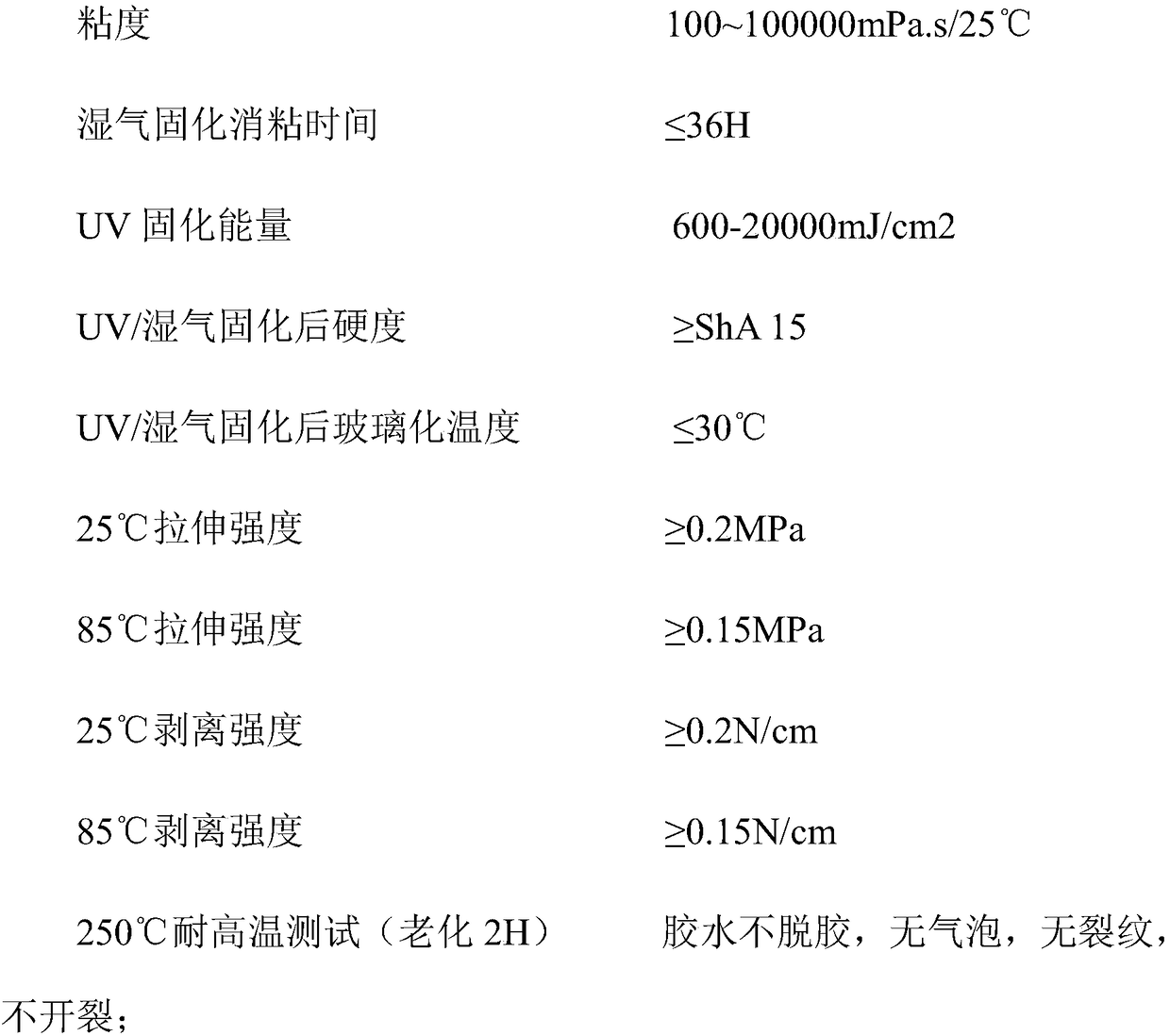

High-temperature-resistant dual-curing three-proof glue composition and application thereof

InactiveCN108913088AImprove high temperature resistanceLower glass transition temperatureAdhesivesBond propertiesElectron

The invention relates to high-temperature-resistant dual-curing three-proof glue. Based on 100 parts by weight of adhesive composition, the high-temperature-resistant dual-curing three-proof glue mainly comprises the following components in parts by weight: component A: 60-99 parts of one or more polydimethylsiloxane with the terminal group containing bialkoxy groups and mono(methyl) acrylate groups simultaneously; component B: 0.5-10 parts of one or more silane coupling agent; component C: 0.5-8 parts of one or more cracking type photoinitiator; component D: 0.01-3.0 parts of organic-tin or organic-titanium condensation catalyst. The adhesive composition is especially applicable to three-proof application of the electronic industry, i.e., water proof, dust-proof and shock-proof, and has excellent bonding property for PCB plastic substrates; in a formula, an organic-silicon structure is designed as the main body, and has excellent heat resistance, and the heat-resistant temperature canreach 250 DEG C in a short time.

Owner:江苏科琪高分子材料研究院有限公司

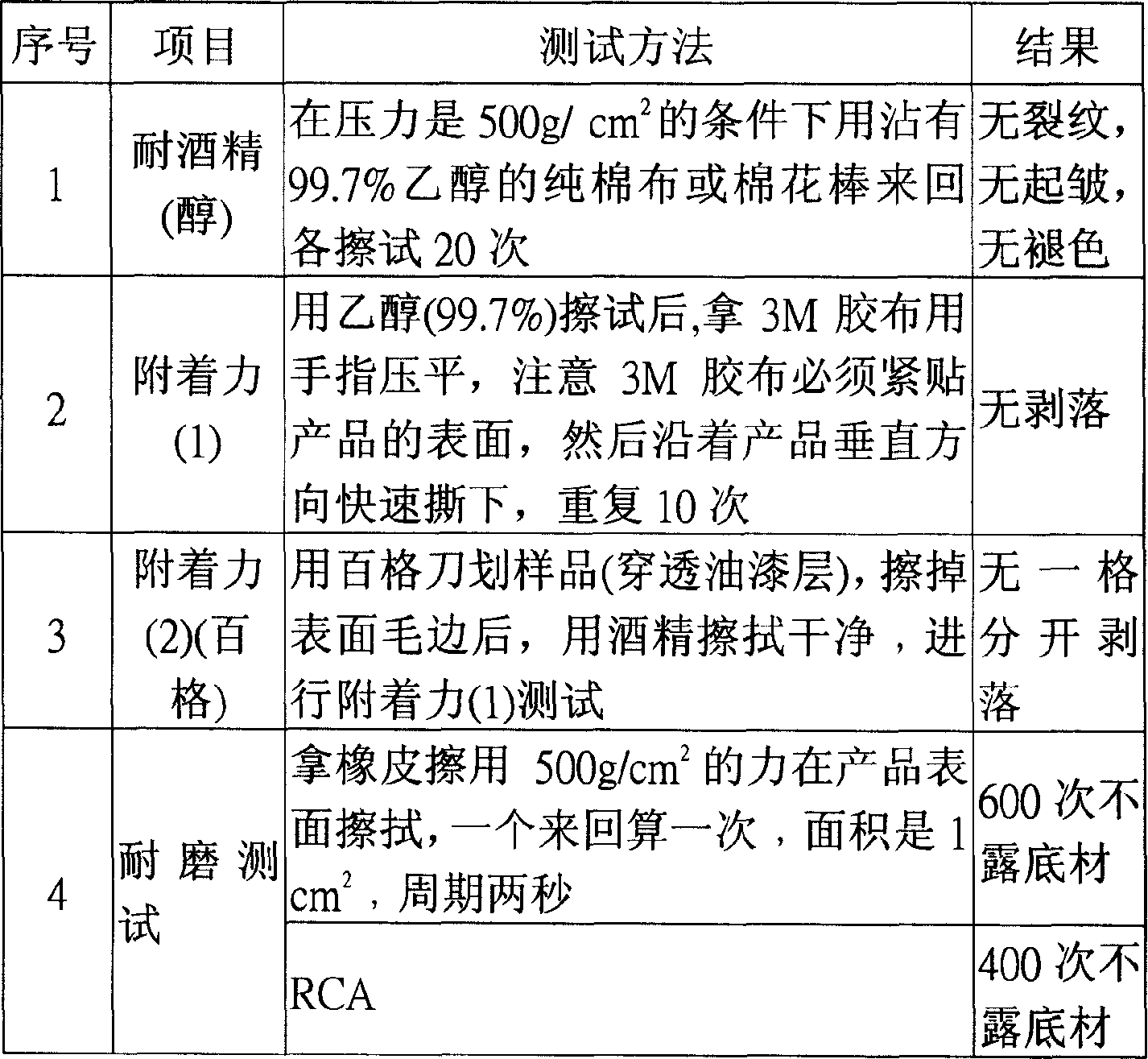

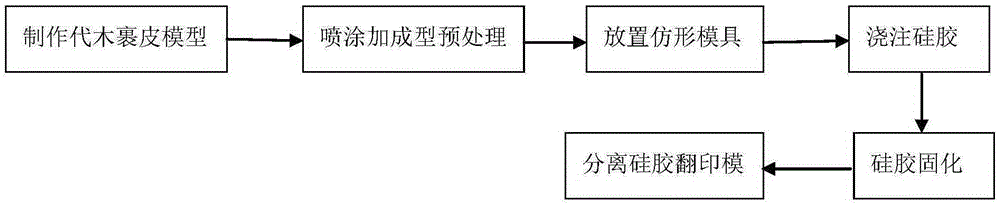

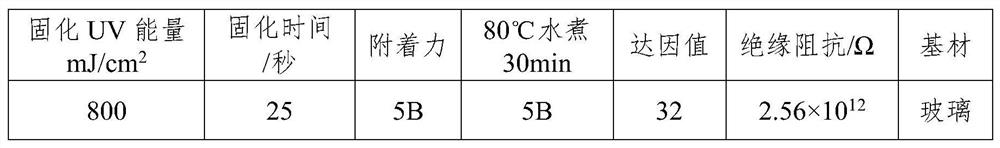

UV lacquer suitable for black plastics base material

InactiveCN101173148ASolve curing problemsHigh hardnessPolyurea/polyurethane coatingsTripropylene glycolPolymer science

The invention provides a UV varnish for black plastic substrates, comprising a plurality of components in weight percentage: tripropylene glycol diacrylate 20 to 30 percent, diepentaerythritol hexaacrylate 10 to 20 percent, tri-functional aliphatic polyurethane acrylate 20 to 30 percent, hexa-functional aliphatic polyurethane acrylate 30 to 40 percent, acylphosphine oxide photoinitiators 3 to 5 percent, alpha hydroxyacetone photoinitiators 4 to 6 percent, reaction type organic siloxane flow agent 0.4 to 0.6 percent, and non-reaction type organic siloxane flow agent 0.05 to 0.1 percent. Since resins with high hardness and resistance to abrasion are matched with reactive diluents with high hardness, as well as slipping flow agent is added, the invention has the advantages of high hardness and resistance to abrasion, solving the curing of the UV varnish for black plastic substrates, and at the same time conforming to the high hardness and resistance to abrasion in the coating of the black plastic substrates.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

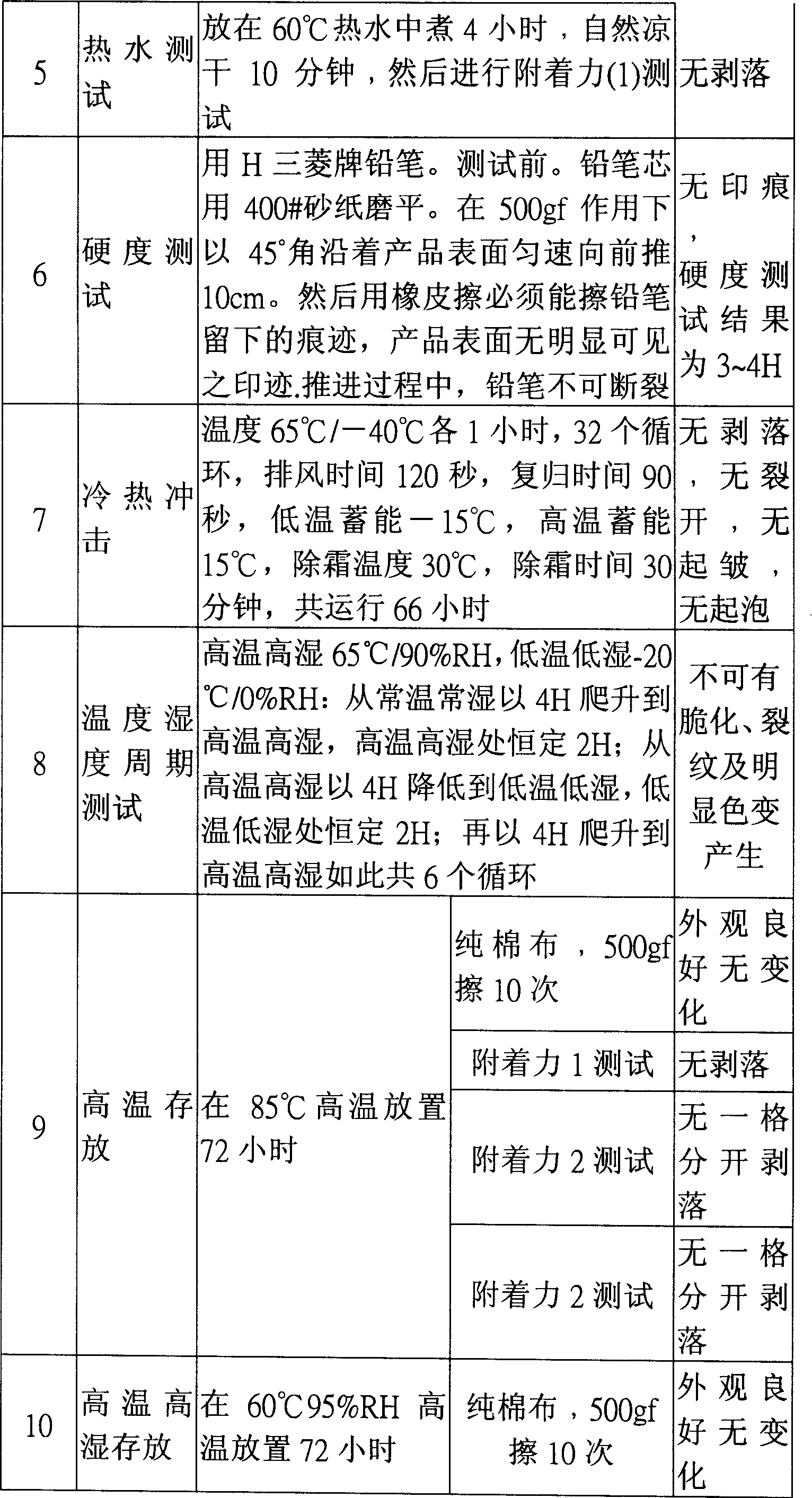

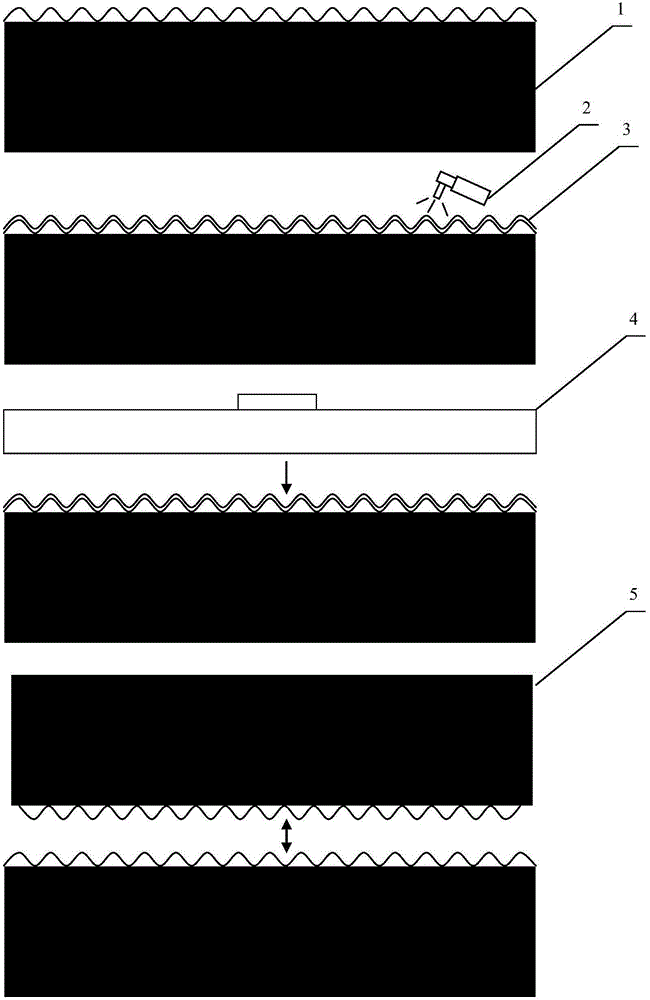

Method for manufacturing silica gel reprinting model of automotive instrument board slush mold

InactiveCN105345963AReduce loss rateSolve curing problemsManufacturing technologyPulp and paper industry

The invention belongs to the technical field of manufacturing of slush molds for automotive trim products and discloses a method for manufacturing a silica gel reprinting model of an automotive instrument board slush mold. The method for manufacturing the silica gel reprinting model comprises the following steps that 1, a wood skin-wrapped model provided with automotive instrument board pattern skin is prepared; 2, an addition-cure pretreatment agent is sprayed to the surface of the pattern skin; 3, the pattern skin is placed under the indoor temperature condition till the surface with the addition-cure pretreatment agent is dried; 4, addition-cure silica gel is poured into a profile modeling mold after the profile modeling mold is additionally arranged above the wood skin-wrapped model; and 5, after the addition-cure silica gel is cured, the addition-cure silica gel is separated from the wood skin-wrapped model, and the silica gel reprinting model is obtained. The method is simple and low in cost, and the problem that curing of the addition-cure silica gel is affected by metal elements in the pattern skin can be effectively solved; the method has the advantages that the curing effect of the silica gel reprinting model is good, and the pattern lose rate is low.

Owner:JILIN UNIV +1

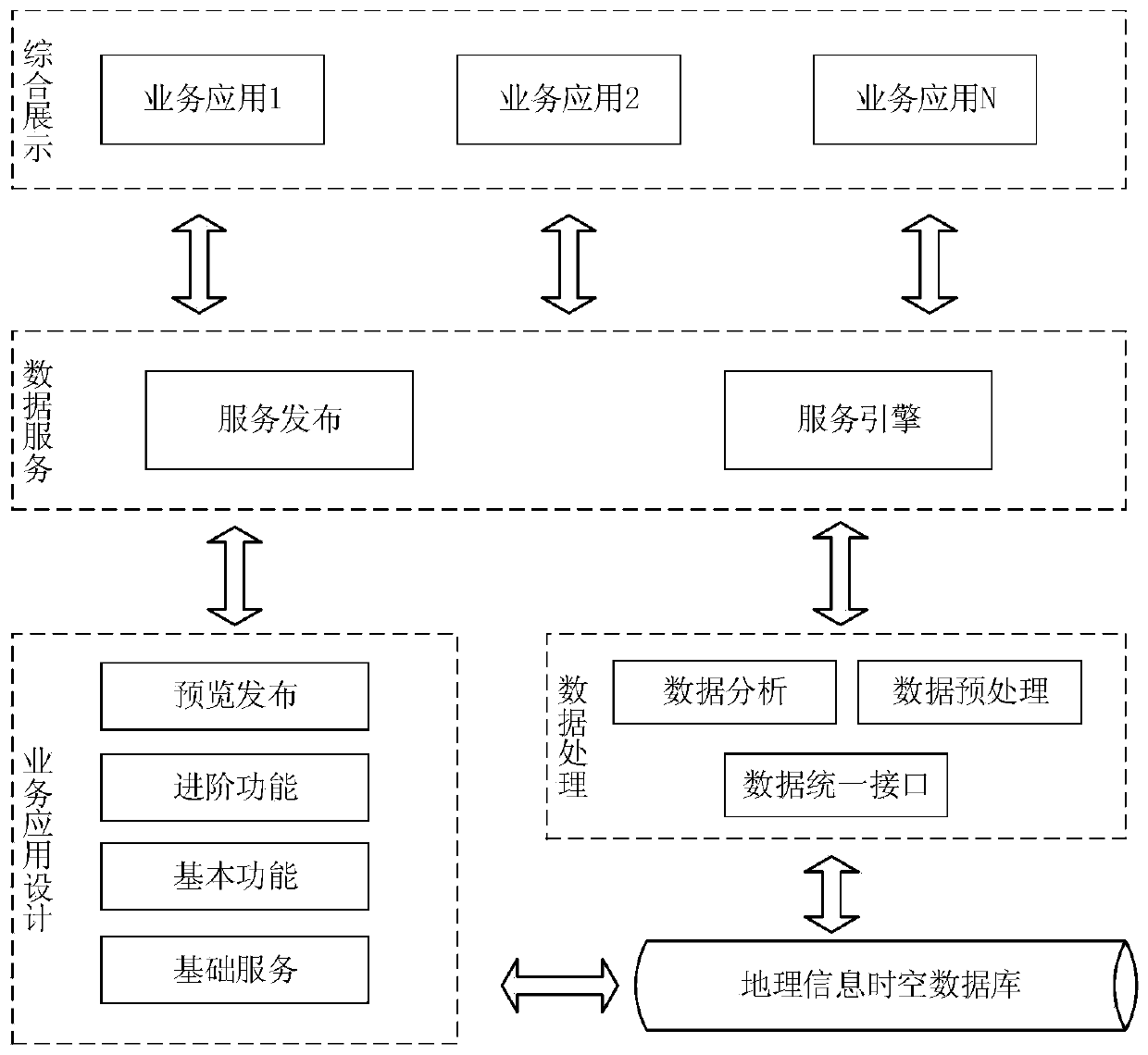

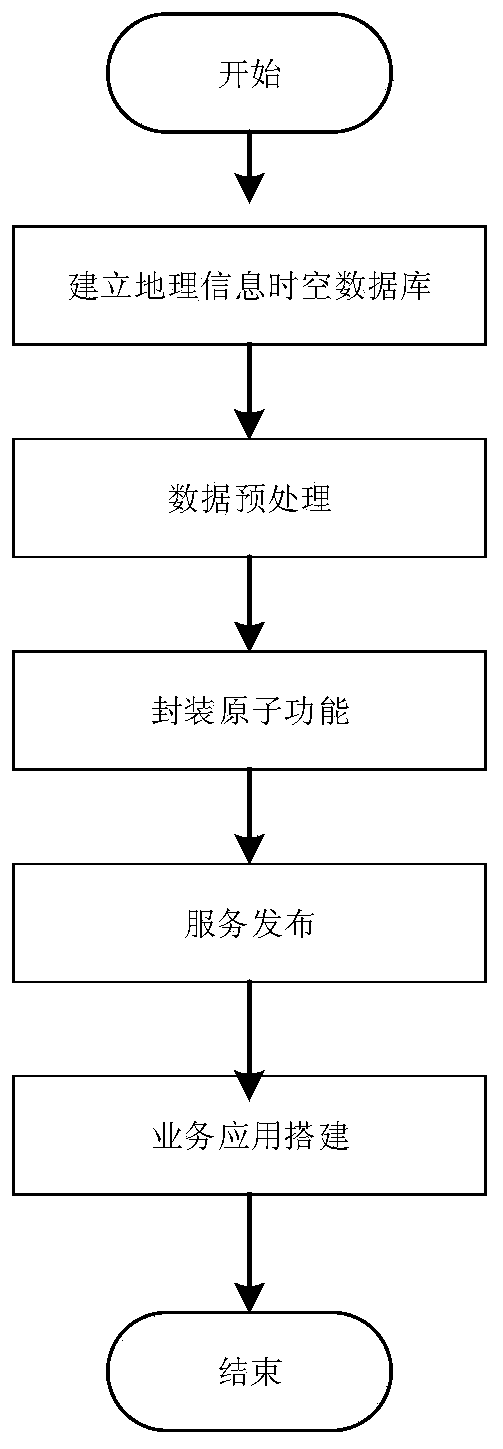

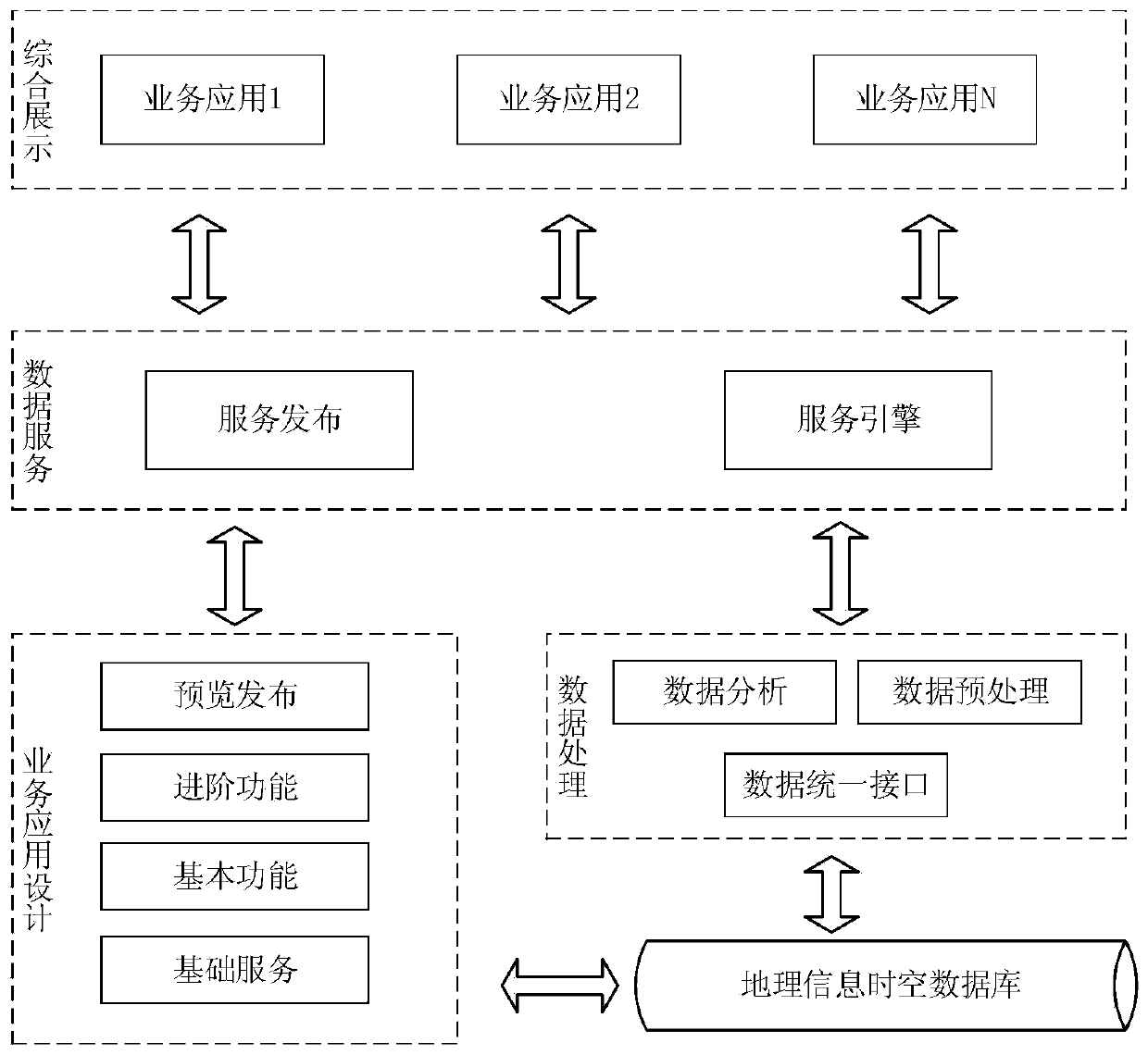

System and method for quickly establishing geographic information data application

ActiveCN110008296AStrong designabilitySolve curing problemsDatabase management systemsGeographical information databasesInformation spaceData display

The invention discloses a system and a method for quickly establishing a geographic information data application, and belongs to the field of geographic information data analysis and application. Theinvention designs a universal and configurable data application framework. The framework mainly comprises a geographic information space-time database, a data processing module, a data service module,a business application design module and a comprehensive display module. According to the system and the method, various processing, rendering and other processes required by geographic information data application and analysis are split into independent function modules. According to a data transmission protocol defined by a system, an input / output interface is packaged, a service application design module sequentially selects basic services, basic functions and advanced functions in a guide mode, and required application display functions and user interfaces are configured according to service requirements, so that the requirements of different services and users on data display are met.

Owner:贵州图智信息技术有限公司

Production technology for solid-liquid phase combined rice wine

InactiveCN103614271ASolve curing problemsConsistent qualityAlcoholic beverage preparationYeastFood flavor

The invention discloses a food production technology, and particularly relates to a production technology for solid-liquid phase combined rice wine, which effectively solves the problem of solidification of rice wine, and guarantees that the flavor, nutrition and color of the produced rice wine are relatively consistent with the quality of the original taste and flavor rice wine. The production technology also comprises post processes mainly comprising steps of filtering, namely, filtering the original taste and flavor rice wine so as to obtain rice water and rice dregs; processing rice water, namely, heating up the rice water so as to obtain at most 65 DEG C inactivated yeast, filling, then sterilizing for at least 18 minutes at 88-92 DEG C; processing rice dregs, namely, desaccharifying the rice dregs, freezing for at least 18-20 hours at below 40 DEG C-below 30 DEG C, then drying for 20-40 hours in a 40-50 DEG C vacuum drying chamber; and packaging, namely, respectively packaging the processed rice water and rice dregs, then packaging for the second time so as to obtain the solid-liquid phase combined rice wine.

Owner:李俊平

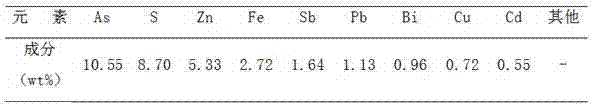

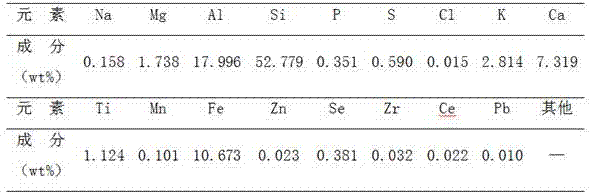

Method for co-processing arsenic-containing sludge and lake sediment

InactiveCN106927657ASolve stacking problemsSolve curing problemsSludge treatment by de-watering/drying/thickeningWater contaminantsSteam pressureDry weight

The invention relates to a method for co-processing arsenic-containing sludge and lake sediment and belongs to the technical field of solid waste resource utilization in environmental engineering. The method comprises the following steps: firstly, controlling the moisture content of the acquired arsenic-containing sludge to be below 15% after treating the arsenic acid wastewater and lime according to a ferric salt method; controlling the moisture content of the lake sediment containing more than 50% of SiO2 and Al2O3 in dry weight to be above 50%; ball-milling and uniformly mixing the pre-processed arsenic-containing sludge, lake sediment, cement, lime, excitant and additive, thereby acquiring a dry base; adding water into the acquired dry base, uniformly stirring and then pressing into a cured building block; placing the cured building block and standing by for 4-6h; maintaining for 6-12h under 0.8-2.0Mpa steam pressure; safely storing the standard cured building block or applying to industrial buildings. The method provided by the invention not only can solve the problem of stockpiling of the lake sediment but also can solve the problem of curing of the arsenic-containing sludge and the problem of secondary pollution to the environment.

Owner:KUNMING UNIV OF SCI & TECH

High-humic-acid soil curing agent and preparation method thereof

The invention belongs to the technical field of curing agents, and particularly relates to a high-humic-acid soil curing agent and a preparation method thereof. The high-humic-acid soil curing agent comprises substances in percentage by mass: 25%-40% of steel slag, 15%-25% of fly ash, 10%-15% of quick lime, 10%-20% of ordinary Portland cement, 6%-10% of an exciting agent, 1%-5% of an ion replacing agent, 1%-3% of a water repellent, 4%-6% of a retarder, 1%-2% of an early strength agent, 1%-3% of a filling agent, 1%-3% of a stabilizer, 1%-2% of an air entraining agent, 0.5%-1% of a water reducing agent and 0.5%-2% of a humic acid modifier. The high-humic-acid soil curing agent has the effects and advantages that the influence of humic acid on soil can be effectively reduced, the shear strength, the compressibility and the water stability of the soil are improved, the pore size, the compressibility and the permeability of the soil are reduced, and good economic and environmental benefits are achieved.

Owner:吉林建筑科技学院

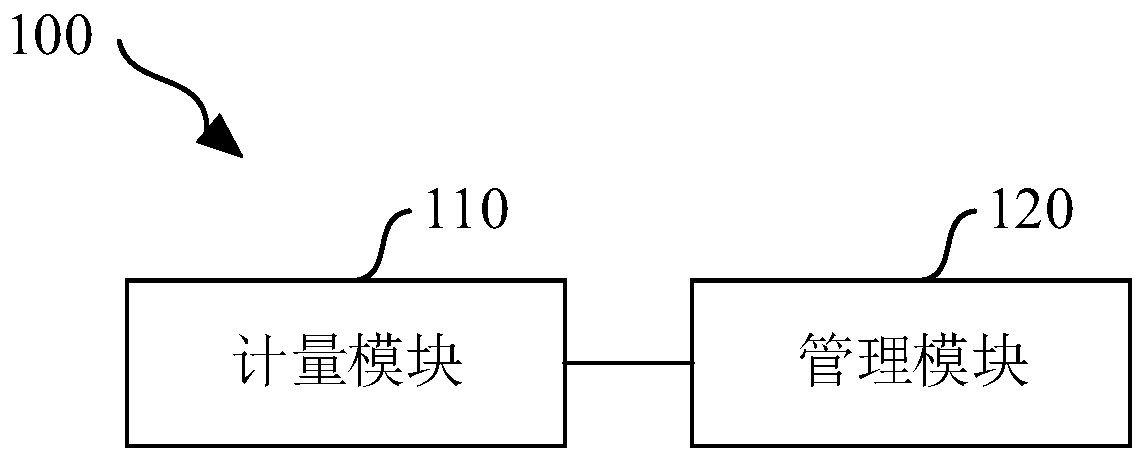

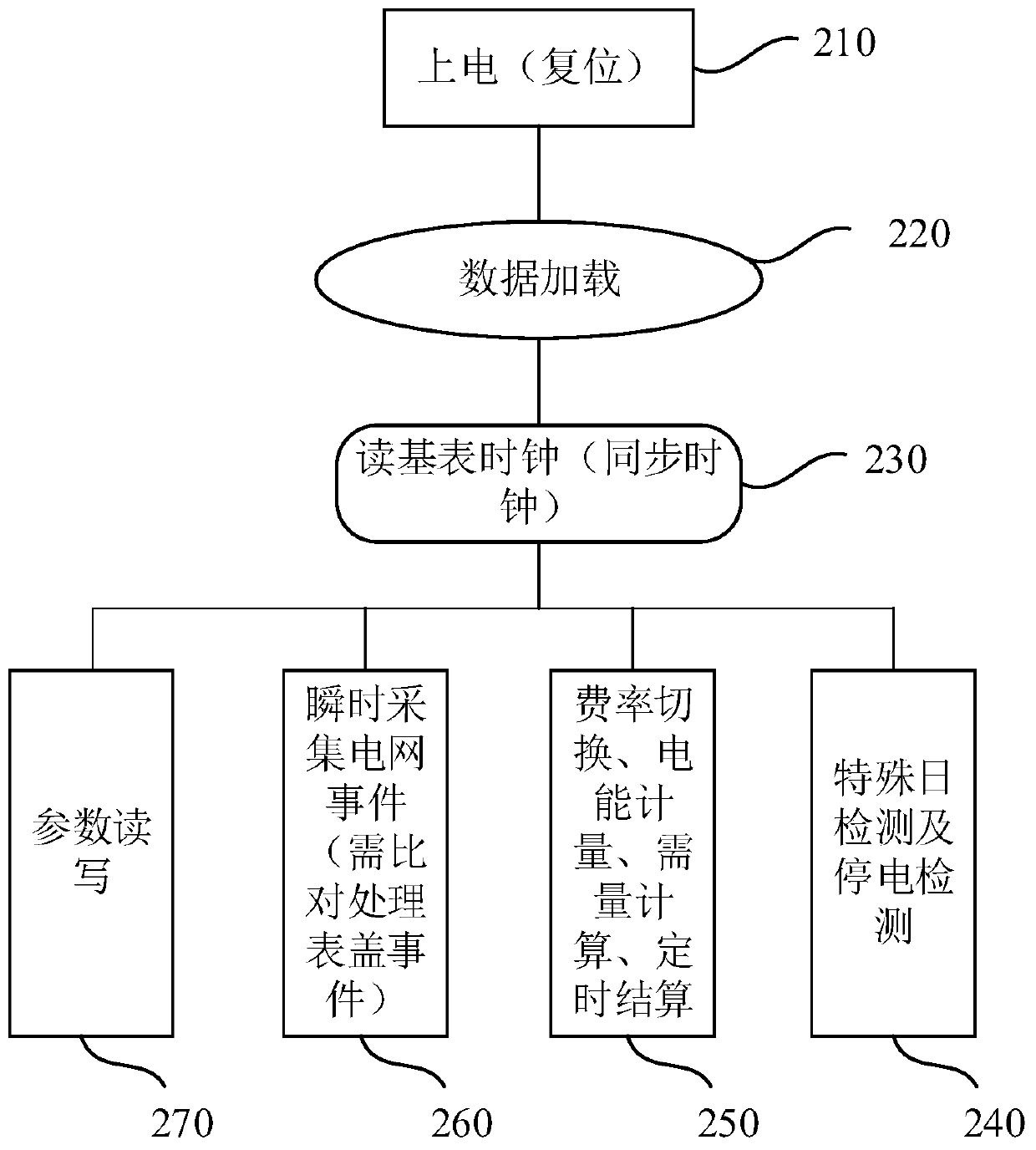

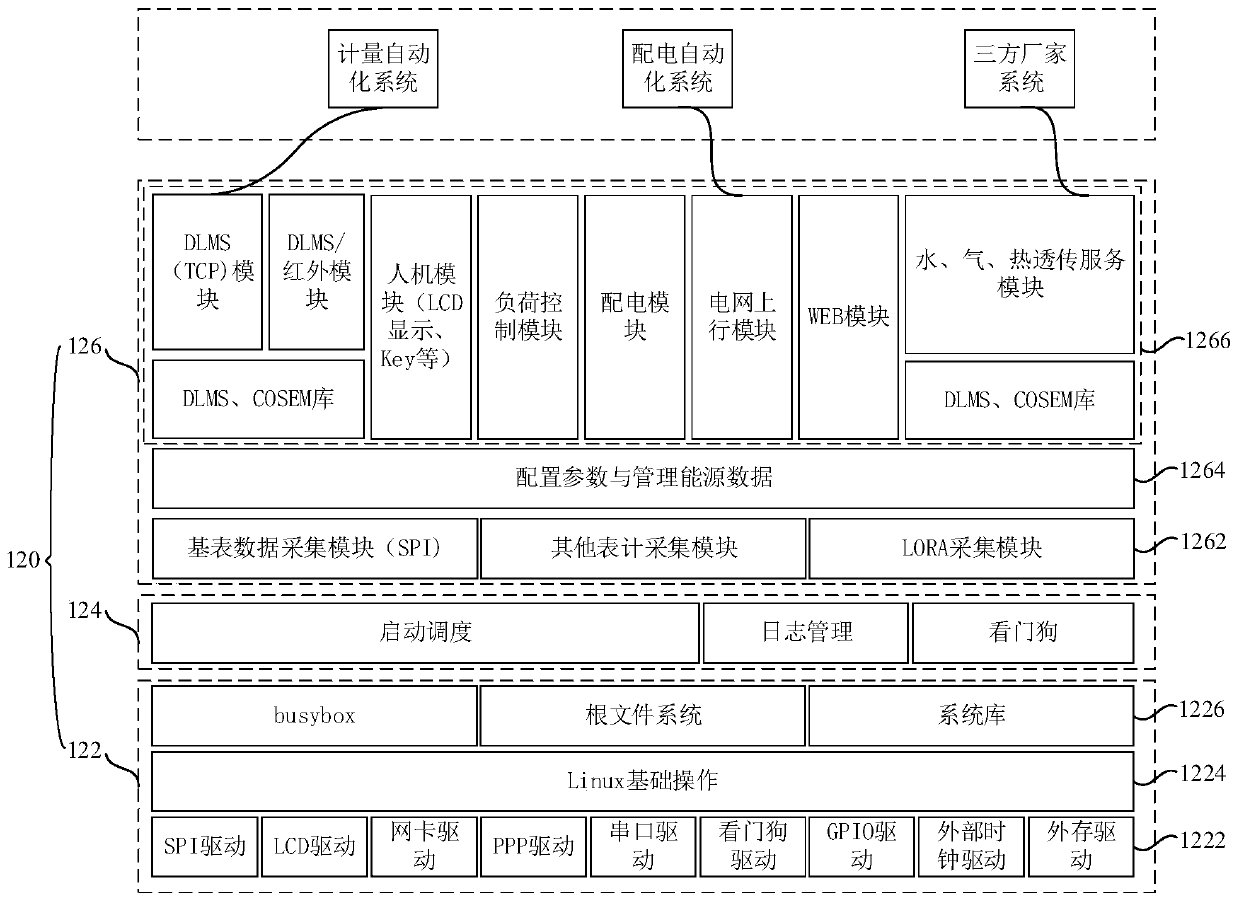

Energy gateway for accurate metering

The invention relates to an energy gateway for accurate metering. The energy gateway used for accurate metering comprises a metering module used for collecting and outputting energy data; a managementmodule in communication connection with the metering module and used for generating service data according to the energy data; wherein the metering module and the management module are independently arranged on a physical layer. The metering module in the energy gateway for accurate metering is used for collecting and outputting energy data. The management module is used for generating servicedata according to the energy data; the metering module and the management module are independently arranged on the physical layer, so that the metering module is not influenced by abnormal work of themanagement chip; the metering module provides basic energy data for the management module; and the management chip generates the service data, so that the problem of program solidification of the metering module is solved, personalized and diversified customization requirements of a user can be met by upgrading the program of the management module, and the work of the metering module is not influenced while the management module is upgraded.

Owner:SHENZHEN POWER SUPPLY BUREAU

Curing method of soluble semi-solid waste salt

InactiveCN111744926ASolve curing problemsSolve the use problemSolid waste disposalTransportation and packagingPhysical chemistryEnvironmental engineering

The invention discloses a curing method of soluble semi-solid waste salt. The curing method comprises the following steps of: step 01. draining the soluble semi-solid waste salt, to be specific, draining the saturated soluble semi-solid waste salt to reduce the moisture content of the semi-solid waste salt; step 02. curing the soluble semi-solid waste salt, to be specific, adding the drained semi-solid waste salt, incineration fly ash, and a curing agent in proportion to a container, uniformly mixing the drained semi-solid waste salt, the incineration fly ash, and the curing agent, and fully chelating, wherein the mass ration of the soluble semi-solid waste salt to the incineration fly ash to the curing agent is 79.36 to 87.72: 7.94 to 8.77: 3.51 to 12.70, and the curing agent is one or more of cement, lime and asphalt; and step 03. putting the uniformly mixed chelated waste salt in a mold and maintaining for 1 to 7 days to obtain the chelated waste salt solidified body. By chelating and curing the soluble semi-solid waste salt, the curing agent and the incineration fly ash in proportion, the problem of solidification of the semi-solid waste salt is solved, and the problem of comprehensive utilization of the incineration fly ash is also solved; the treatment method is relatively environmentally-friendly; and the resource integration utilization rate is relatively high.

Owner:中节能(连云港)清洁技术发展有限公司

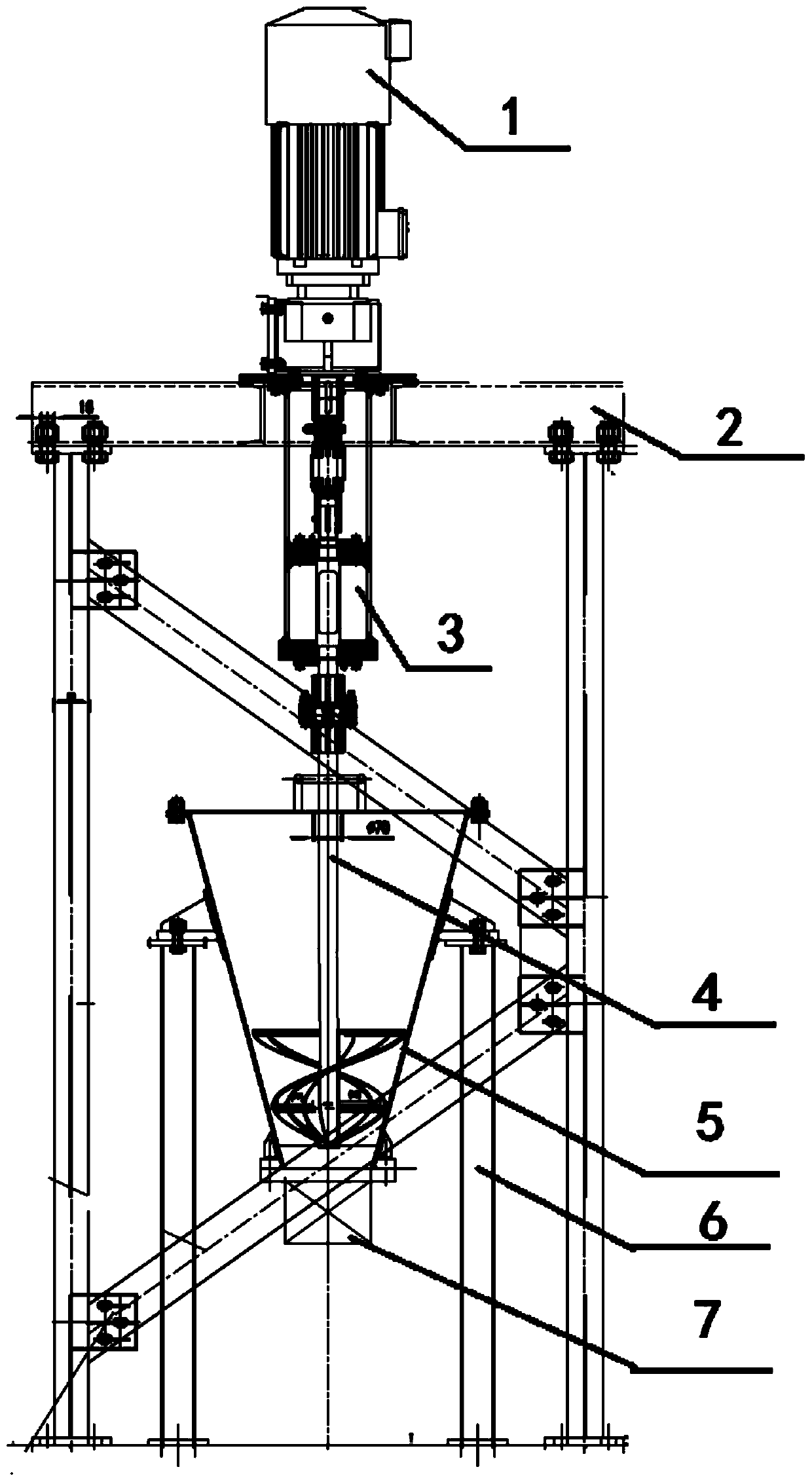

Radioactive organic waste liquid solidification device and method

PendingCN111354499AImprove structural stabilityCompact structureRadioactive decontaminationElectric machineryChemistry

The invention relates to a radioactive organic waste liquid solidification device and method. The device comprises a motor, a bracket, a stirring shaft, a stirring paddle, a solidification kettle, a fixing frame and a discharging valve. The method comprises the following steps: 1, adding a certain amount of radioactive organic waste liquid into a solidification kettle at room temperature; and 2, under the condition of continuous mechanical stirring, adding a thickening agent, wherein the stirring speed is 45-55 rpm, the stirring time is 45-60 min, and the organic waste liquid becomes dark in color, is not clear any more, but still has good fluidity. According to the invention, the problem of radioactive organic waste liquid solidification is solved, and the device has the advantages of compact structure, stable operation, convenient operation, good product solidification effect and the like.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

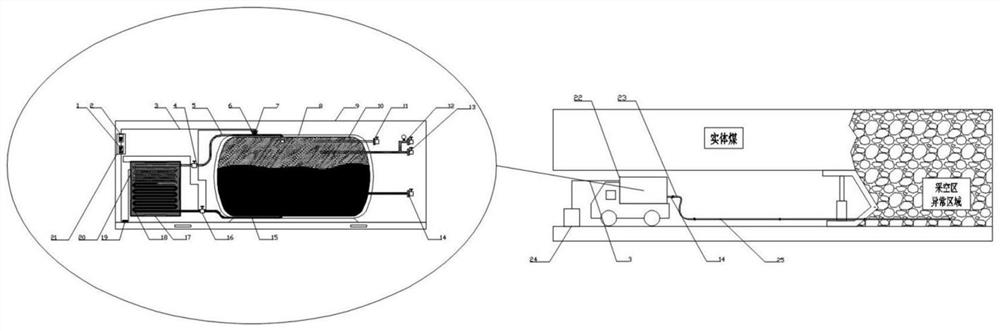

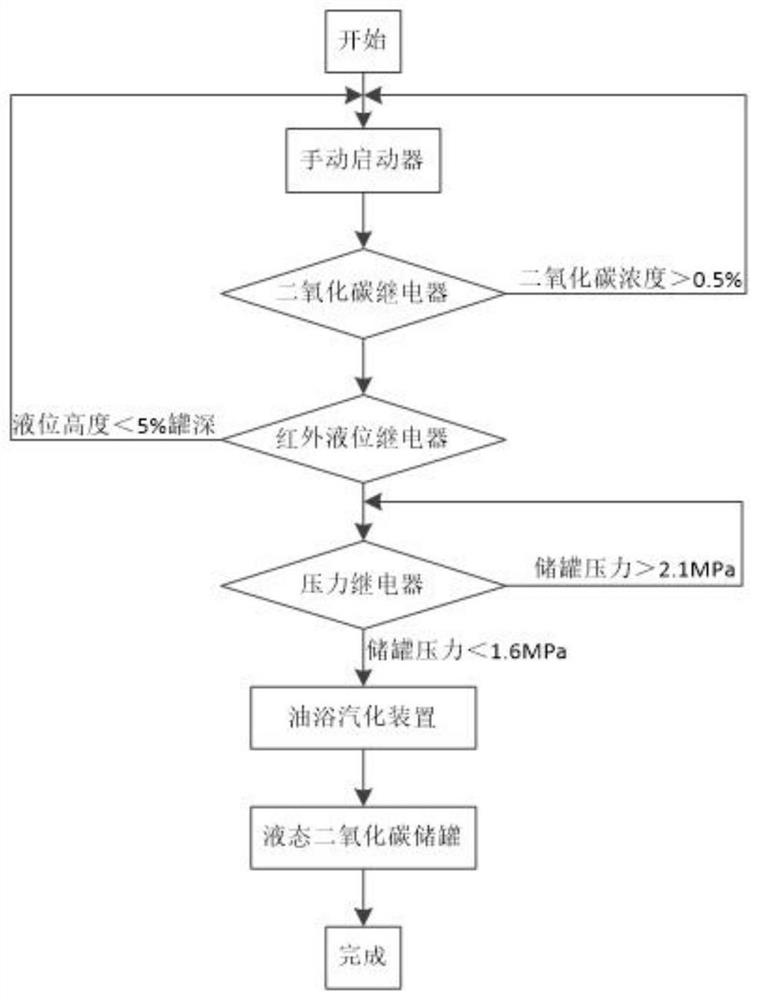

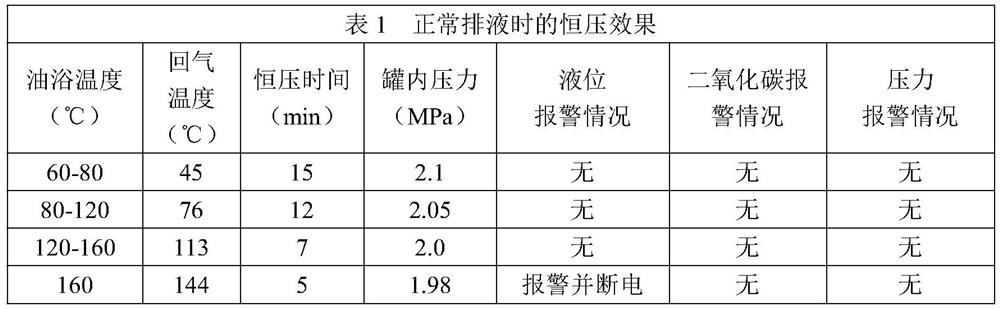

Mining constant-pressure liquid carbon dioxide fire preventing and extinguishing device and method

PendingCN113509657AImprove fire extinguishing efficiencyGuarantee the safety of lifeDust removalFire preventionLiquid storage tankSafety valve

The invention discloses a mining constant-pressure liquid carbon dioxide fire preventing and extinguishing device and method. The mining constant-pressure liquid carbon dioxide fire preventing and extinguishing device comprises a low-temperature liquid storage tank, wherein the low-temperature liquid storage tank communicates with gas inlet and return pipelines and valves, liquid inlet and return pipeline valves, an overflow pipe and a valve, gas inlet and return pipelines on the gas inlet and return pipeline valves are provided with pressure gauges and safety valves, the low-temperature liquid storage tank communicates with a pressurizing gas pipe and a pressurizing liquid pipe, the pressurizing liquid pipe communicates with a stainless steel heat exchange pipe arranged on an oil bath box, and an exhaust port of the stainless steel heat exchange pipe is connected through the pressurizing air pipe. The liquid carbon dioxide fire extinguishing efficiency is improved.

Owner:XIAN UNIV OF SCI & TECH +1

High-humic-acid soft soil curing agent adopting solid waste inorganic binder and preparation method of high-humic-acid soft soil curing agent

PendingCN114106848ASimple construction processEasy to operateBuilding constructionsOrganic fertilisersFirming agentEconomic benefits

The invention relates to a high-humic-acid soft soil curing agent adopting a solid waste inorganic binder and a preparation method of the high-humic-acid soft soil curing agent, and belongs to the technical field of curing agents. Comprising the following raw materials in parts by weight: 40-50 parts of an inorganic binding material, 6-8 parts of an exciting agent, 6-10 parts of an ion replacing agent, 8-10 parts of a humic acid modifier, 8-10 parts of a water repellent, 5-8 parts of an early strength agent, 6-10 parts of a water reducing agent, 5-8 parts of a filling agent and 5-8 parts of an air entraining agent. The invention has the following effects and advantages: when the soil containing humic acid is cured, the traditional cement is often low in strength due to the existence of humic acid. According to the invention, the influence of humic acid on soil solidification is especially solved, good economic benefits and environmental benefits are achieved, and the aspects of strength, durability, waterproofness and the like are also powerfully guaranteed.

Owner:吉林建筑科技学院

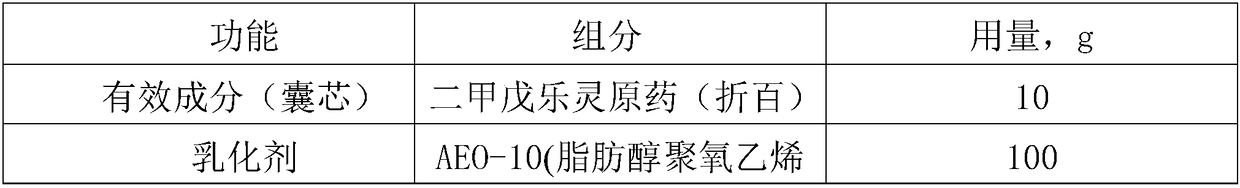

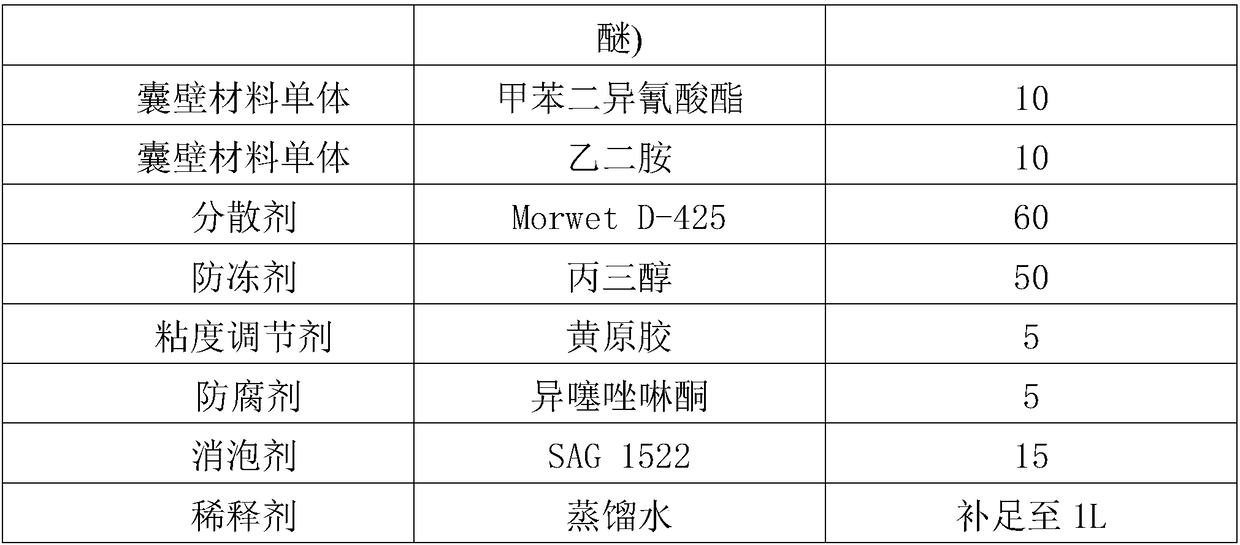

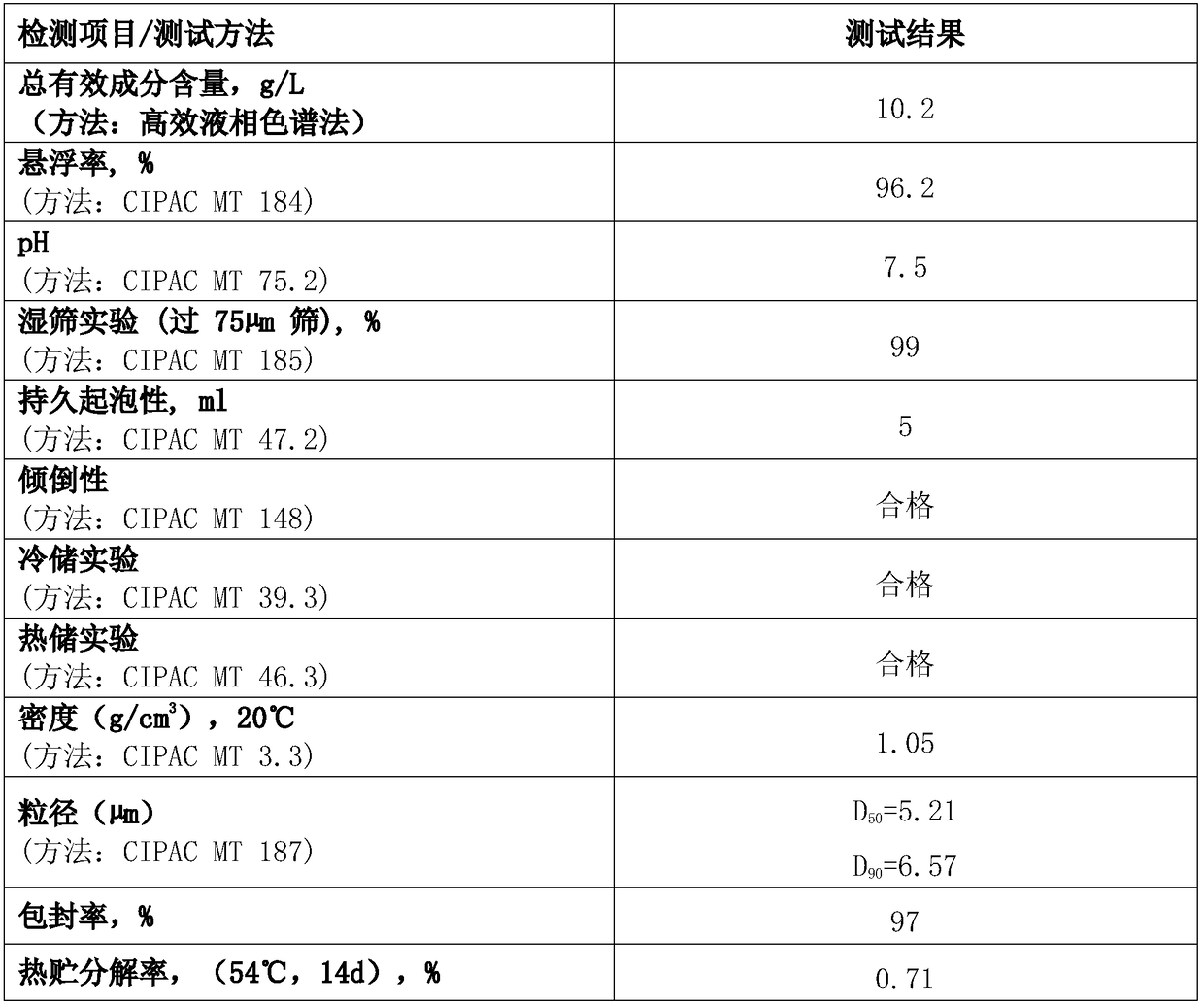

A kind of pendimethalin microcapsule suspension and preparation method thereof

ActiveCN105875607BAvoid gatheringSolve curing problemsBiocideDead animal preservationTemperature controlSuspending Agents

The invention relates to a pendimethalin micro-capsule suspending agent and a preparation method thereof. The pendimethalin is taken as the micro-capsule core of the pendimethalin micro-capsule suspending agent and the content thereof is 10-450g / L; polyuria or polyurethane is taken as a micro-capsule wall of the pendimethalin micro-capsule suspending agent and the content thereof is 20-100g / L; the pendimethalin micro-capsule suspending agent also contains 20-100g / L emulsifier, 20-60g / L dispersing agent, 30-100g / L antifreezing agent, 1-10g / L viscosity modifier and 2-15g / L antifoaming agents and the balance of water. The pendimethalin micro-capsule suspending agent can solve the problem that the liquid preparation is easy to color and pollute the drug applying equipment; the agent does not contain the solvent and is environment-friendly; the compound of dispersing agent and emulsifier adopted by the invention can solve the problem of system creaming caused by coarse crystal easily generated by the low melting point compound following the temperature fluctuation; according to the preparation method provided by the invention, the temperature control is adopted, the operation is performed under normal pressure, no catalyst is used, the process is simple, no special equipment is required and the cost is low.

Owner:CHINA AGRI UNIV

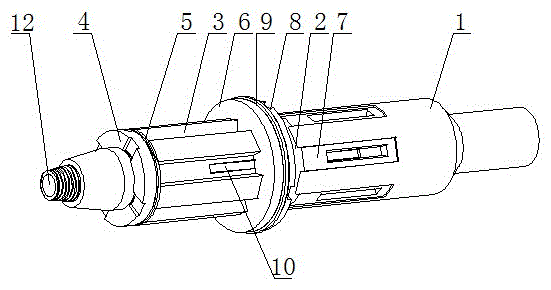

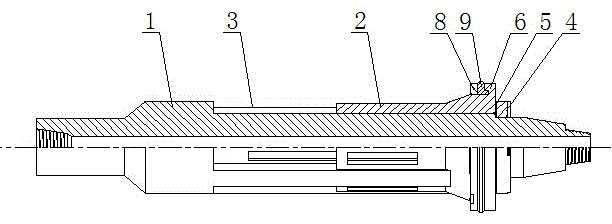

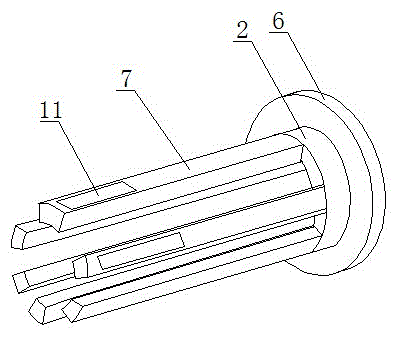

Axial sliding type marine riser cleaning device

InactiveCN105114036ASimple structureImprove securityCleaning apparatusHigh probabilityEconomic benefits

The invention relates to an axial sliding type marine riser cleaning device, and belongs to the field of downhole tools for an offshore oil and gas well. The cleaning device comprises a central pipe and a sleeve, wherein central pipe sliding chutes are uniformly distributed on the central pipe, the sleeve is glidingly mounted on the central pipe, and a cleaning brush is mounted on the sleeve through a fixing ring; central pipe channel slots are formed in the central pipe sliding chutes of the central pipe, and sleeve channel ports are formed in the sleeve and glidingly communicated with the central pipe channel slots. The cleaning device is simple in structure, convenient to dismount, mount and maintain and high in safety performance, and the problems of low efficiency, incomplete cleaning and high probability of damage to the inner wall of a marine riser caused by a traditional method for cleaning solidified and adhered fluids in the marine riser are solved. The cleaning brush can be prevented from damaging the inner wall of the marine riser in a working process, and the axial sliding type marine riser cleaning device has good economic benefits and popularization significance.

Owner:YANGTZE UNIVERSITY

Cover plate ink based on cationic photoinitiator and preparation method thereof

The invention relates to cover plate ink based on a cationic photoinitiator. The cover plate ink comprises the following components: 40-65% of liquid epoxy resin, 20-40% of a reactive diluent, 2-4% of a cationic photoinitiator, 6-12% of a black pigment, 2-8% of matting powder, 3-10% of a dispersant, 1-3% of a thixotropic agent, 0.1-1% of an anti-foaming agent and 0.1-1% of a leveling agent. The components are metered in percentage by mass. The liquid epoxy resin is a combination of at least two liquid epoxy resins. According to the cover plate ink, the cationic photoinitiator is adopted, the problem of curing of the inner layer of the ink can be well solved, and the cationic photoinitiator is not affected by oxygen in air, and the problem of free radical loss caused by free radical collision and the like is solved. The ultraviolet curing cover plate ink can be used on cover plates of electronic equipment such as mobile phones, televisions and tablet personal computers, and is simple in processing technology, high in efficiency, low in energy consumption and free of pollution to the environment.

Owner:厦门三德信科技股份有限公司

Aroma warming patch containing plant essential oil and preparation method thereof

ActiveCN104799996BSolve curing problemsSolve the adsorption problemEssential-oils/perfumesTherapeutic coolingFlavorWoven fabric composite

The invention discloses a fragrant warming paste containing plant essential oil and a manufacturing method thereof. By changing a raw material layer structure of a common warming paste product, powdered flavor and a heat generating agent are isolated through a micropore air-permeable film, and the single raw material layer is changed into double or three raw material layers. A composite non-woven fabric layer is a non-woven fabric composite high-air-permeability polymer film or a non-woven fabric for avoiding retarded fragrant molecule release and influence on air-permeable performance of the micropore air-permeable film. Plant essential oil is wrapped and cured by cyclodextrin to prepare the powdered flavor, flavor utilization rate is improved, the problems of cutting and slow release of the plant essential oil and other liquid flavors are solved, and the problem that the flavor is directly in contact with the heat generating agent to influence the heating generating stability of the warming paste is solved. The fragrant warming paste containing plant essential oil is advanced in technology, reasonable in scheme design, efficient and capable saving energy, and production technology level of the fragrant warming paste is greatly improved.

Owner:孙松

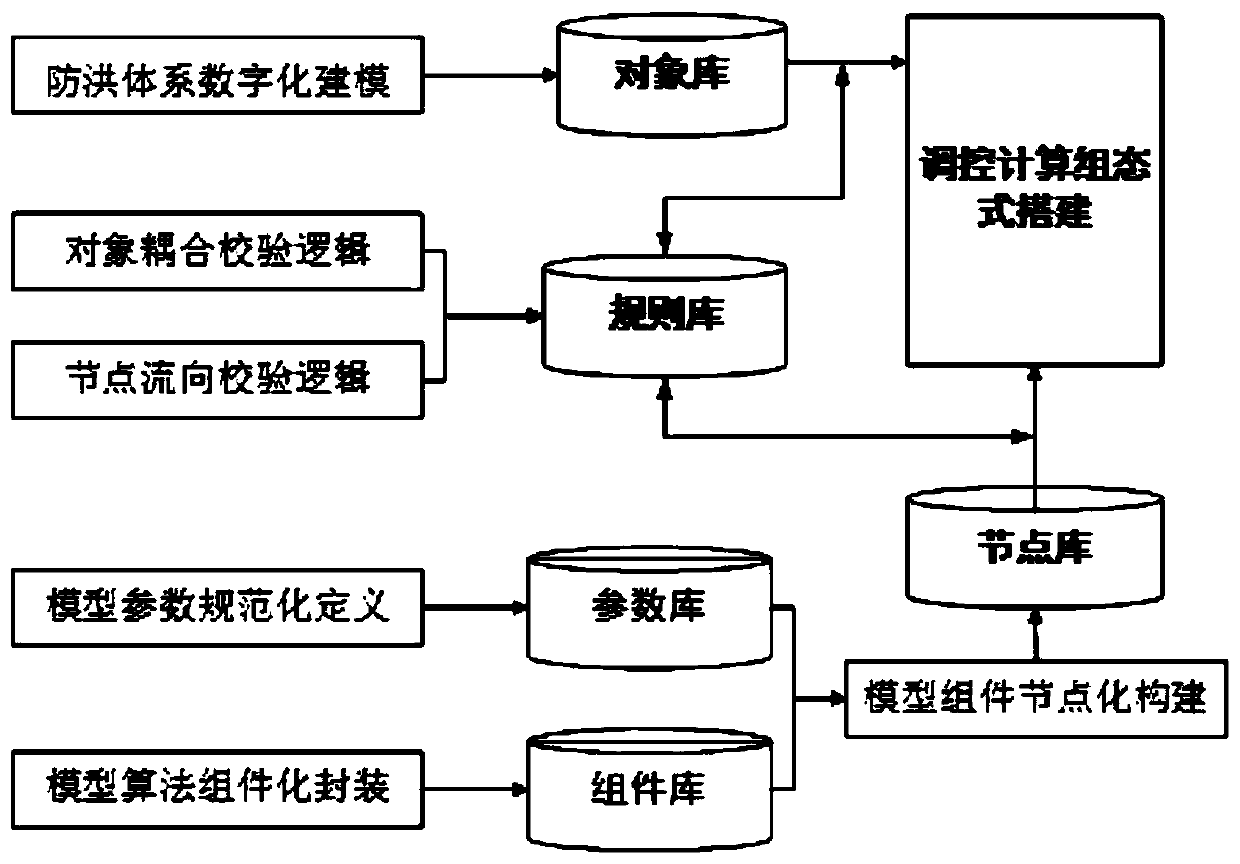

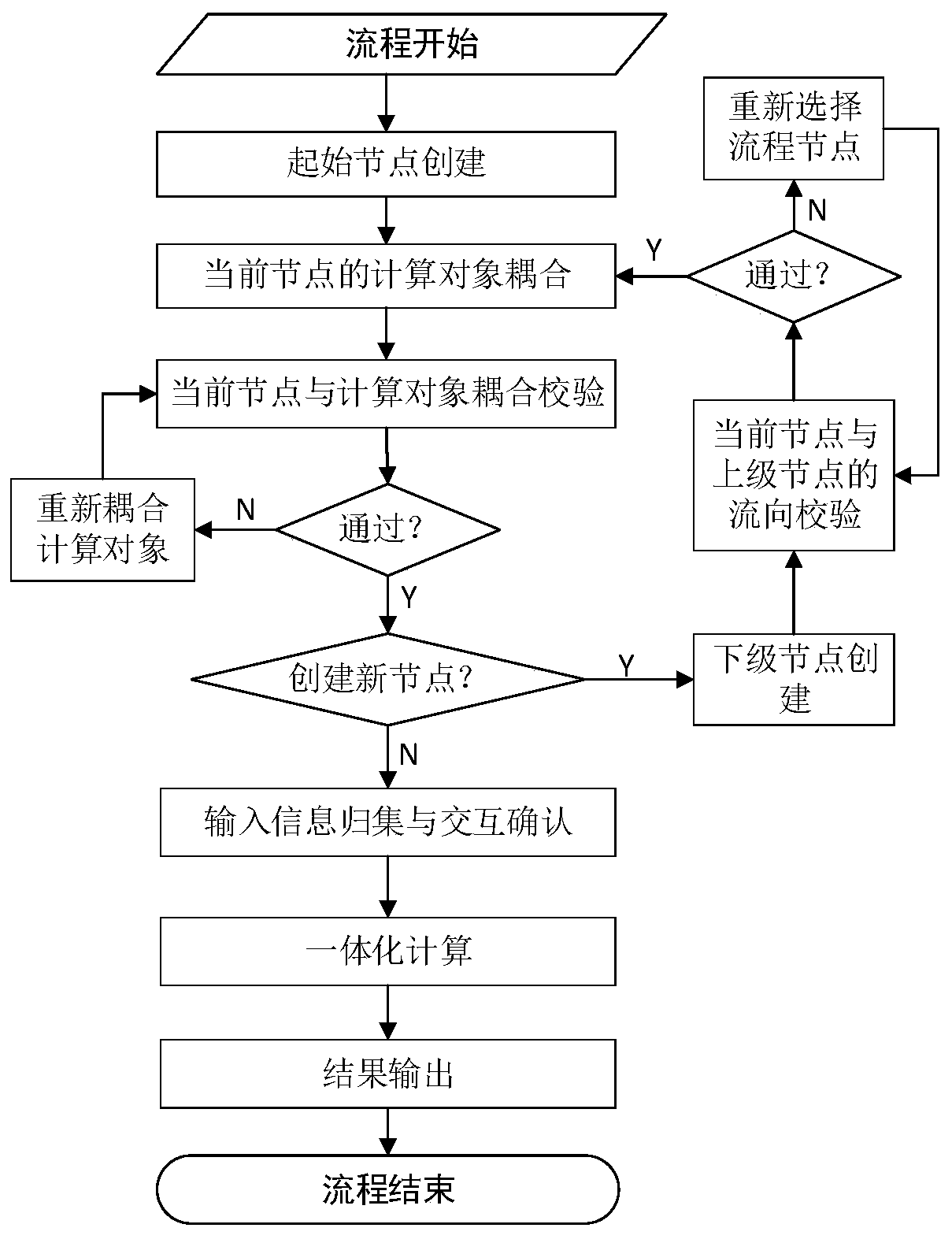

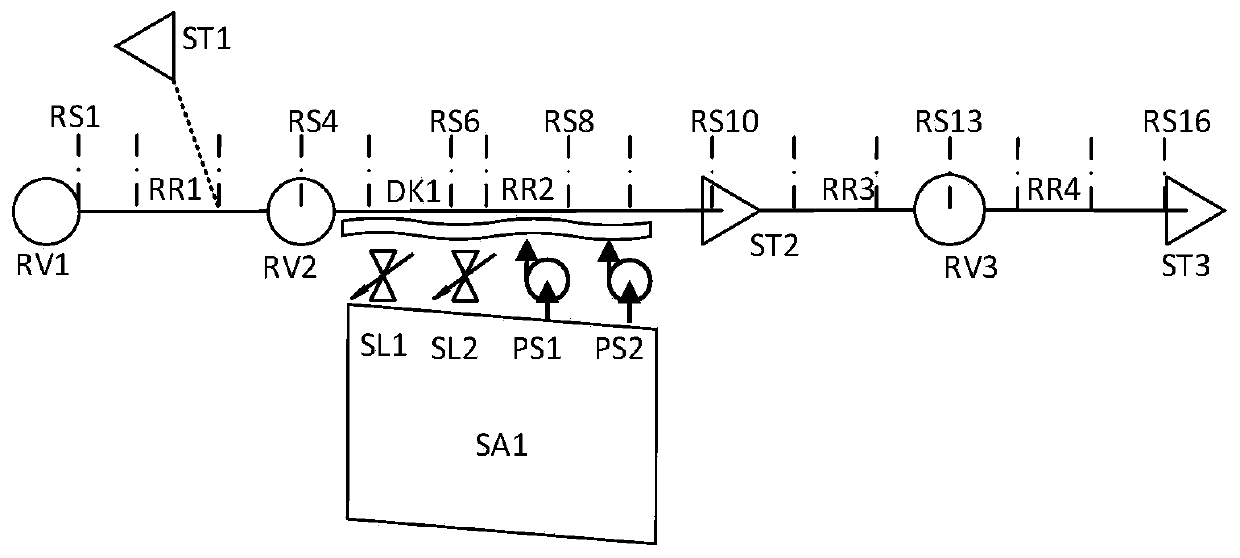

Agile configuration method for multi-combination regulation and calculation of superstandard flood

ActiveCN110377993BEnhanced convertibilityEffectively respond to uncertain combination control computing needsData processing applicationsClimate change adaptationAlgorithmTheoretical computer science

The invention introduces componentization, configuration and flow engine technology into the field of river basin flood dispatching and control. The present invention provides an agile configuration method for super-standard flood multi-combination control and calculation, which includes the following steps: packaging various model algorithm components into a node library; selecting a node from the node library as the starting node of the process; Node coupling computing objects, and verify whether the coupling between the current node and the object is valid according to the rule base; create lower-level nodes according to the combination requirements; couple computing objects for the lower-level nodes; according to the combination computing requirements, repeat steps to create new lower-level nodes and complete the correspondence Check the node flow direction and object coupling until the node is created; gather all the input information of the node flow, start the calculation task, and output the summary result.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

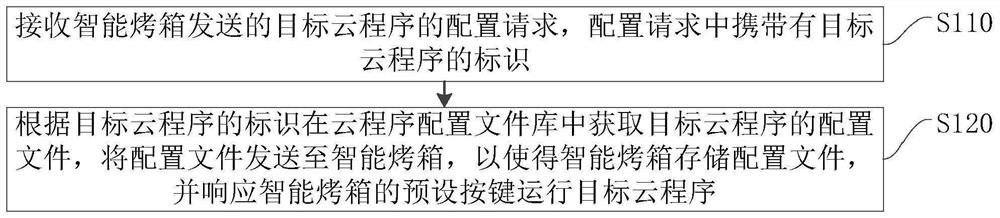

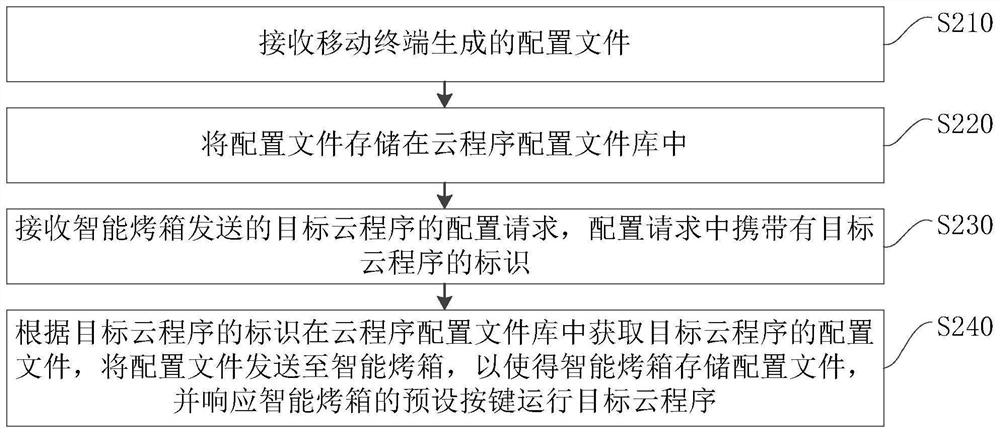

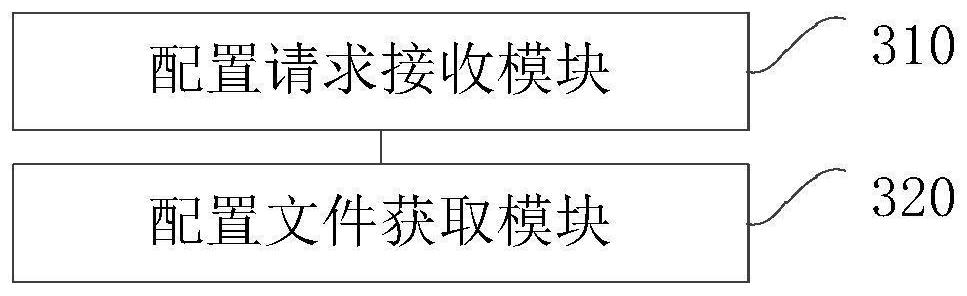

Cloud program configuration method and device, electronic equipment and storage medium

PendingCN114840266AImprove user experienceSolve curing problemsProgram loading/initiatingPersonalizationSoftware engineering

The embodiment of the invention discloses a cloud program configuration method and device, electronic equipment and a storage medium, and relates to the technical field of smart home, the cloud program configuration method comprises the steps that a configuration request of a target cloud program sent by a smart oven is received, and the configuration request carries an identifier of the target cloud program; and obtaining a configuration file of the target cloud program in a cloud program configuration file library according to the identifier of the target cloud program, sending the configuration file to the intelligent oven so that the intelligent oven stores the configuration file, and responding to a preset key of the intelligent oven to run the target cloud program. The configuration file of the target cloud program in the embodiment of the invention is generated on the mobile terminal according to the personalized demand of the customer. The configuration file is sent to the intelligent terminal through the cloud server, and then the target cloud program is operated by responding to the preset key of the intelligent oven, so that the beneficial effects of meeting diversified requirements of users and improving user experience are achieved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

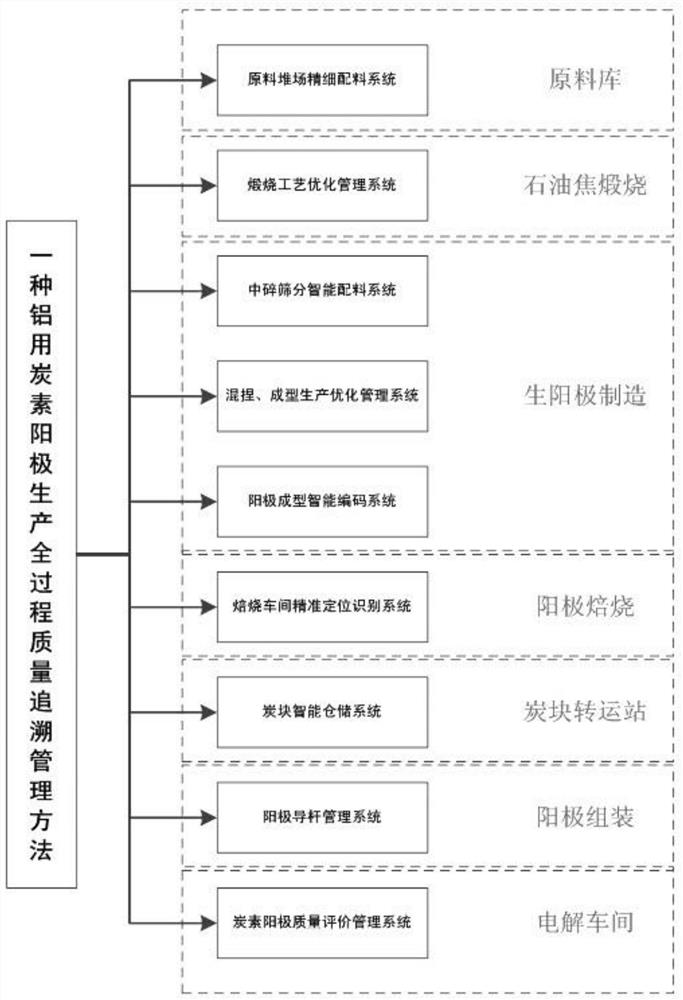

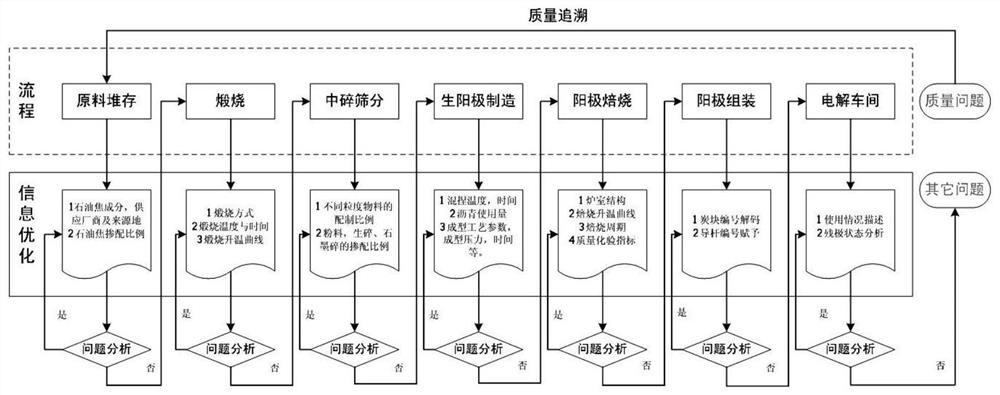

A quality traceability management method for the whole production process of carbon anode for aluminum

ActiveCN110738434BSolve the problem of single curing production process parametersRealize unattendedForecastingResourcesMachine visionProcess engineering

The invention discloses a quality traceability management method for the whole production process of carbon anodes for aluminum. By assigning physical identity attributes to carbon anodes, the matching and correlation of information including process parameters in the production and use of carbon anodes and time correspondence are realized; through the development of identity Endow physical attributes with machine vision recognition equipment to realize the tracking of physical attributes; through the means of developing system software, complete the storage, conversion and preprocessing of production process information data; finally, through data mining and machine learning, establish the quality of carbon anode production process system prediction model. Through the development of the above-mentioned related devices and system development, the present invention can optimize the technical parameters of the production process, realize the precise correspondence and association between the process data and the anode production batches, and find out the cause of the problem if there is an anode and quality problem, and solve the problem. Adjust in time to improve the quality of anode production, reduce the unqualified rate, and increase the rate of first-class products.

Owner:GUIYANG AL-MG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com