Axial sliding type marine riser cleaning device

A technology of axial sliding and cleaning devices, which is applied in the direction of cleaning tools, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of drilling operation time and cost waste, and achieve low cost, good economic benefits and promotion significance. The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

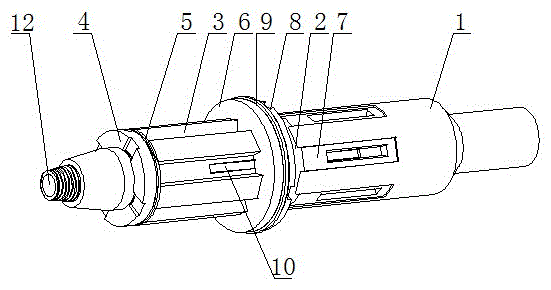

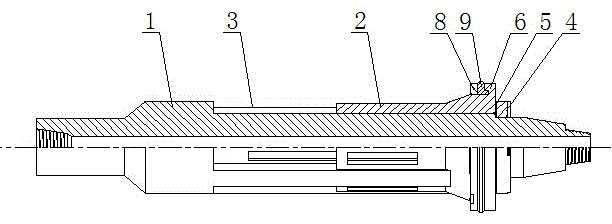

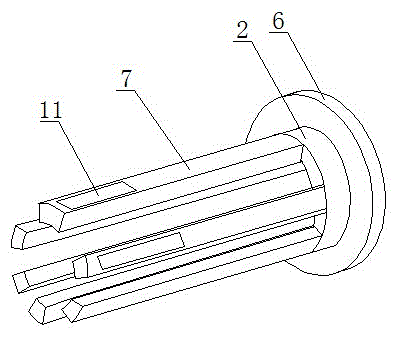

[0017] The axially sliding riser cleaning device includes a center pipe 1 and a sleeve 2; six center pipe chutes 3 are evenly distributed on the circumference of one side of the center pipe 1 . A flange 6 is arranged on the port at one end of the sleeve 2 , and a sleeve rib 7 is arranged on the circumference of the sleeve 2 on one side of the flange 6 corresponding to the center pipe chute 3 . The sleeve 2 is slidably installed on the central tube 1 through the cooperation of the sleeve edge 7 and the central tube chute 3 . An annular cleaning brush 9 is installed on the sleeve 2 between the flange 6 and the sleeve edge 7 through a fixing ring 8;

[0018] The central pipe runner 3 of the central pipe 1 is respectively provided with a central pipe runner groove 10, and the sleeve edge 7 of the sleeve 2 is respectively provided with a sleeve runner mouth 11, and the sleeve runner mouth 11 is connected with the central pipe runner groove 10. Swipe to connect. A spacer 5 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com