Cover plate ink based on cationic photoinitiator and preparation method thereof

A cationic photo-initiation and photo-initiator technology, which is applied in inks, household utensils, applications, etc., can solve the problems that the polymerization reaction cannot continue, the inner layer ink is difficult to completely cure, and cannot generate enough free radicals, so as to improve the brittleness problem , fast curing speed, and the effect of improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

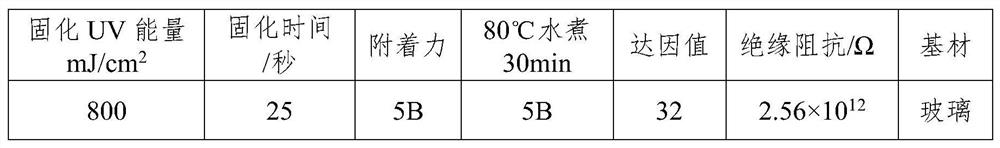

Embodiment 1

[0034] The ink composition raw material of the present embodiment is as follows (below all are mass percent):

[0035] Diglycidyl tetrahydrophthalate 30% (liquid epoxy resin), bis((3,4-epoxycyclohexyl)methyl) adipate 25% (liquid epoxy resin), diethyl ether Glycol divinyl ether 12% (reactive diluent), N-butyl glycidyl ether 10% (reactive diluent), 4-(phenylmercapto)phenyldiphenylthione hexafluorophosphate 3% (cation Photoinitiator), Mitsubishi carbon black MA-100R7% (black pigment), silica matting powder 5%, Lubo-20000 5% (dispersant), fumed silica (thixotropic agent) 2%, BYK- 066N (defoamer) 0.5%, BYK-354 (leveling agent) 0.5%.

[0036] The preparation method of above-mentioned printing ink is as follows:

[0037] (1) Put Mitsubishi carbon black into a high-speed stirred tank at 80°C, with a stirring speed of 400rpm, and take it out after stirring for 10 hours, so as to achieve relative insulating surface modification.

[0038] (2) Add at least two liquid epoxy resins into ...

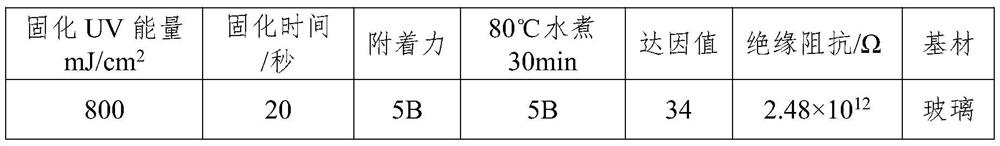

Embodiment 2

[0052] The ink composition raw material of the present embodiment is as follows (below all are mass percent):

[0053] Diglycidyl tetrahydrophthalate 28% (liquid epoxy resin), bis((3,4-epoxycyclohexyl)methyl) adipate 28% (liquid epoxy resin), diethyl ether Glycol divinyl ether 14% (reactive diluent), N-butyl glycidyl ether 10% (reactive diluent), 4-(phenylmercapto) phenyl diphenylsulfonium hexafluorophosphate 4% (cation Photoinitiator), Mitsubishi carbon black MA-100R7% (black pigment), silica matting powder 3%, Lubo-20000 4%, fumed silica (thixotropic agent) 1%, BYK-066N (defoaming agent) 0.5%, BYK-354 (leveling agent) 0.5%.

[0054] Using the same preparation method as above, the cover ink was prepared.

[0055] Coat the cover plate ink prepared in this example on the surface of sodium silicate glass to obtain an ink coating with a thickness of 15 μm, and then use 1000 mJ / cm 2 Irradiated by a high-pressure mercury lamp. The results are as follows:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com