Method for manufacturing silica gel reprinting model of automotive instrument board slush mold

A technology for automobile instrument panels and manufacturing methods, which is applied in the field of slush molding mold manufacturing for automobile interior products, and achieves the effects of good curing effect, simple method, and low pattern loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

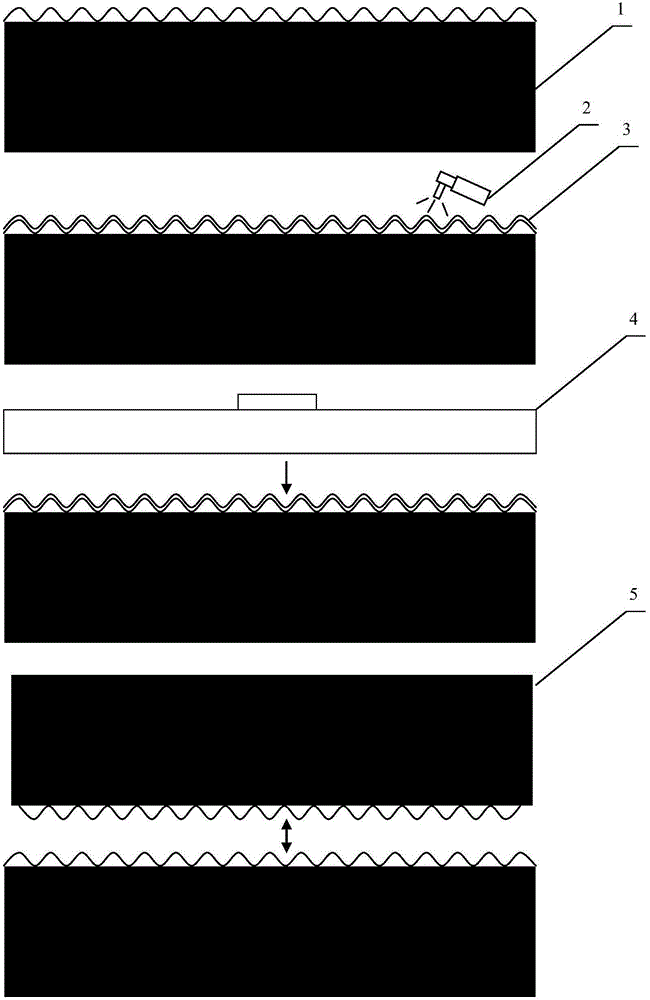

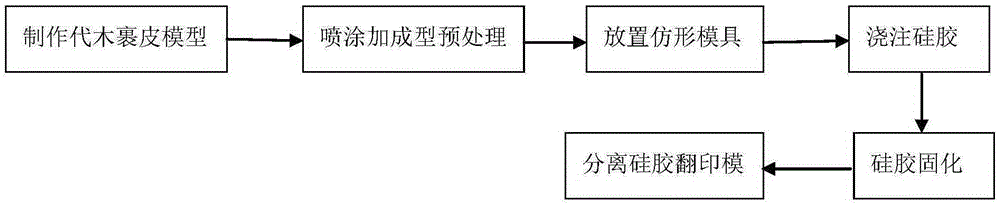

Method used

Image

Examples

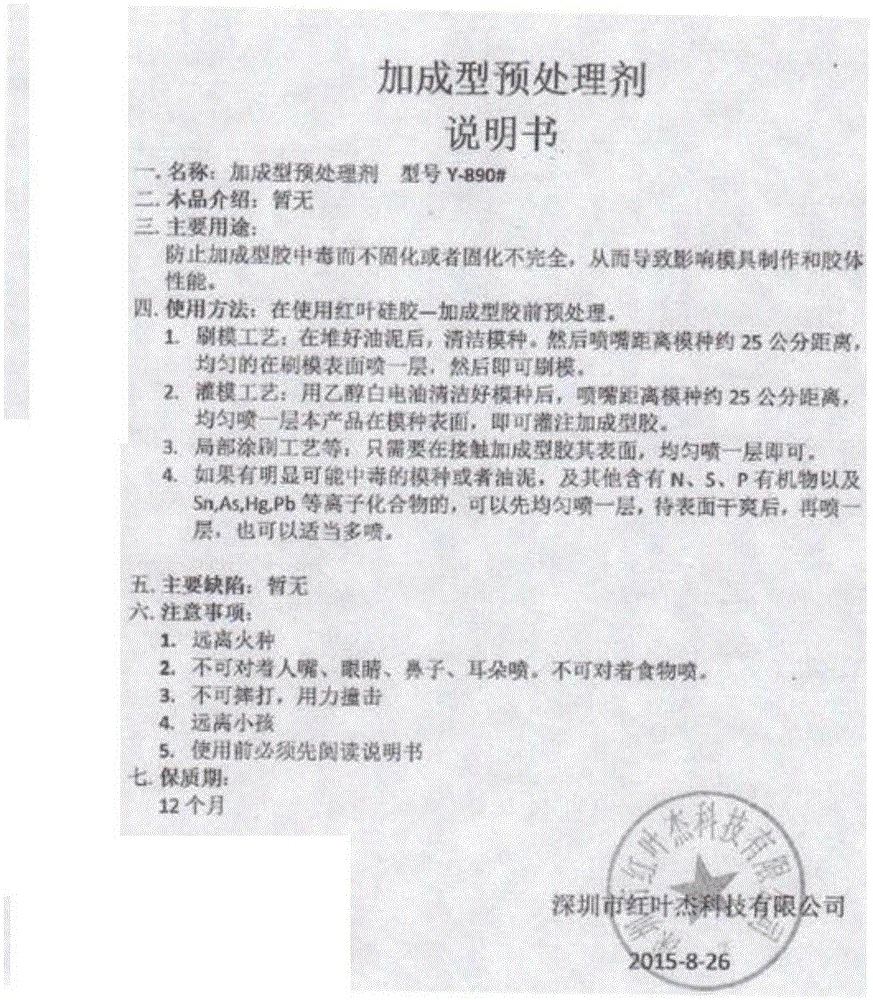

Embodiment 1

[0033] Spray the addition-forming pretreatment agent on the surface of the pattern area of the wrapped leather substitute wooden mold with pattern that has been prepared in advance. The number of sprays is 1 time, the distance is 24cm perpendicular to the surface of the pattern area, and the moving speed is 30mm / s. After the surface of the treatment agent is dry, apply silica gel profiling on the surface of the substitute wood model, pour addition-type silica gel into the profiling, and after curing for 6 hours at 25°C, separate the silica gel model from the skin-wrapped mold to obtain a fully cured model with patterns. Silicone replica mold.

Embodiment 2

[0035] Spray the addition forming pretreatment agent on the surface of the pattern area of the wrapped leather substitute wood mold with pattern that has been made in advance, the number of sprays is 2 times, the distance is 25cm from the surface of the pattern area, and the moving speed is 32mm / s. After the surface of the treatment agent is dry, apply silica gel profiling on the surface of the substitute wood model, pour addition-type silica gel into the profiling, and after curing for 7 hours at 25°C, separate the silica gel model from the skin-wrapped mold to obtain a fully cured model with patterns. Silicone replica mold.

Embodiment 3

[0037] Spray the additive pretreatment agent on the surface of the pattern area of the wrapped leather substitute wood mold with pattern that has been prepared in advance. The number of sprays is 3 times, the distance is 26cm from the surface of the pattern area, and the moving speed is 35mm / s. After the surface of the treatment agent is dry, apply silica gel profiling on the surface of the substitute wood model, pour addition-type silica gel into the profiling, and after curing for 8 hours at 25°C, separate the silica gel model from the skin-wrapped mold to obtain a fully cured model with patterns. Silicone replica mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com