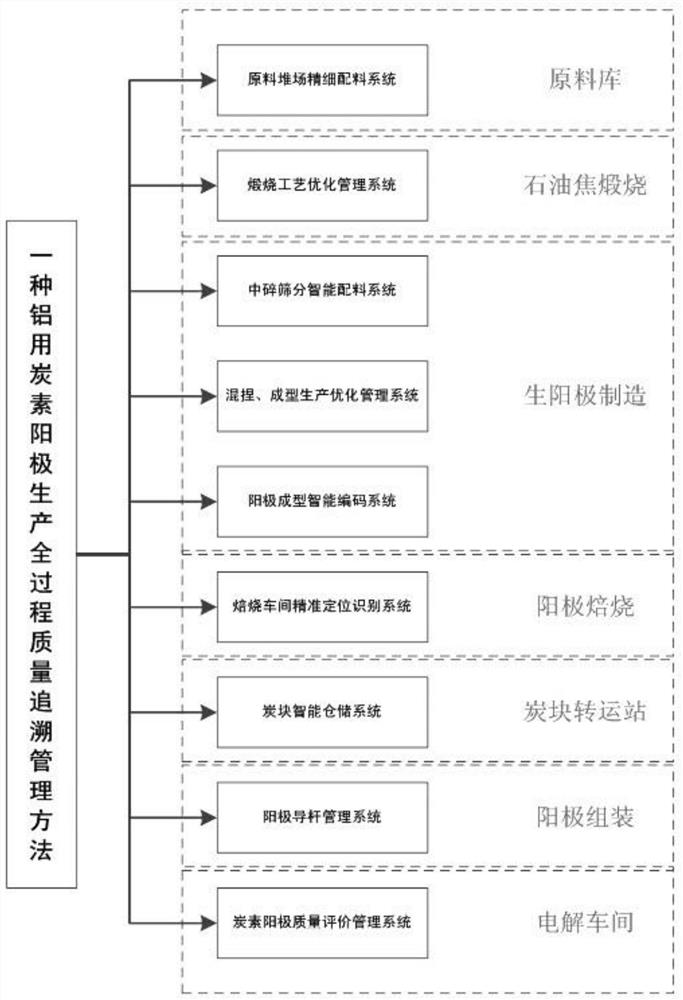

A quality traceability management method for the whole production process of carbon anode for aluminum

A carbon anode and production process technology, applied in the field of aluminum electrolysis, can solve problems such as unreasonable production decision-making, lack of overall quality influencing factors, multi-factor analysis, lack of quality traceability management methods, etc., to reduce human resource costs and achieve fine The effects of streamlined management and solving inventory difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

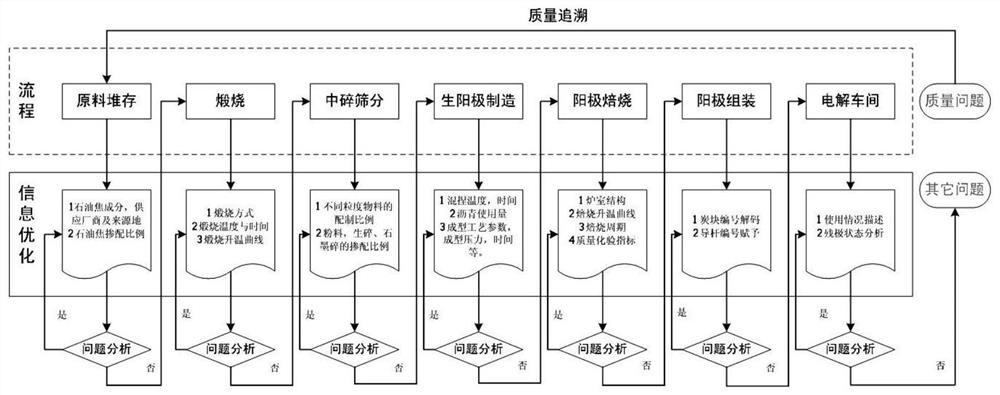

[0029] Petroleum coke raw material warehouse realizes intelligent batching of different types of petroleum coke in different regions through unattended overhead crane and precise weighing system. The prepared petroleum coke raw materials are calcined through optimized and reasonable calcination production process to obtain calcined coke with excellent quality , Calcined coke is batched through an intelligent batching system, and the prepared materials are optimized and reasonable kneading and molding production processes to obtain qualified anode products. Anode products are endowed with physical identity through code spraying or embedded metal encoders, and through the unattended roasting multi-functional overhead crane and roasting management system, the association and matching of carbon block codes, furnace room information, and production process parameters is completed. The roasted anodes are temporarily stored at the carbon block transfer station. Before the anode enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com