Large-area titanium dioxide nanotube film as well as preparation method and application thereof

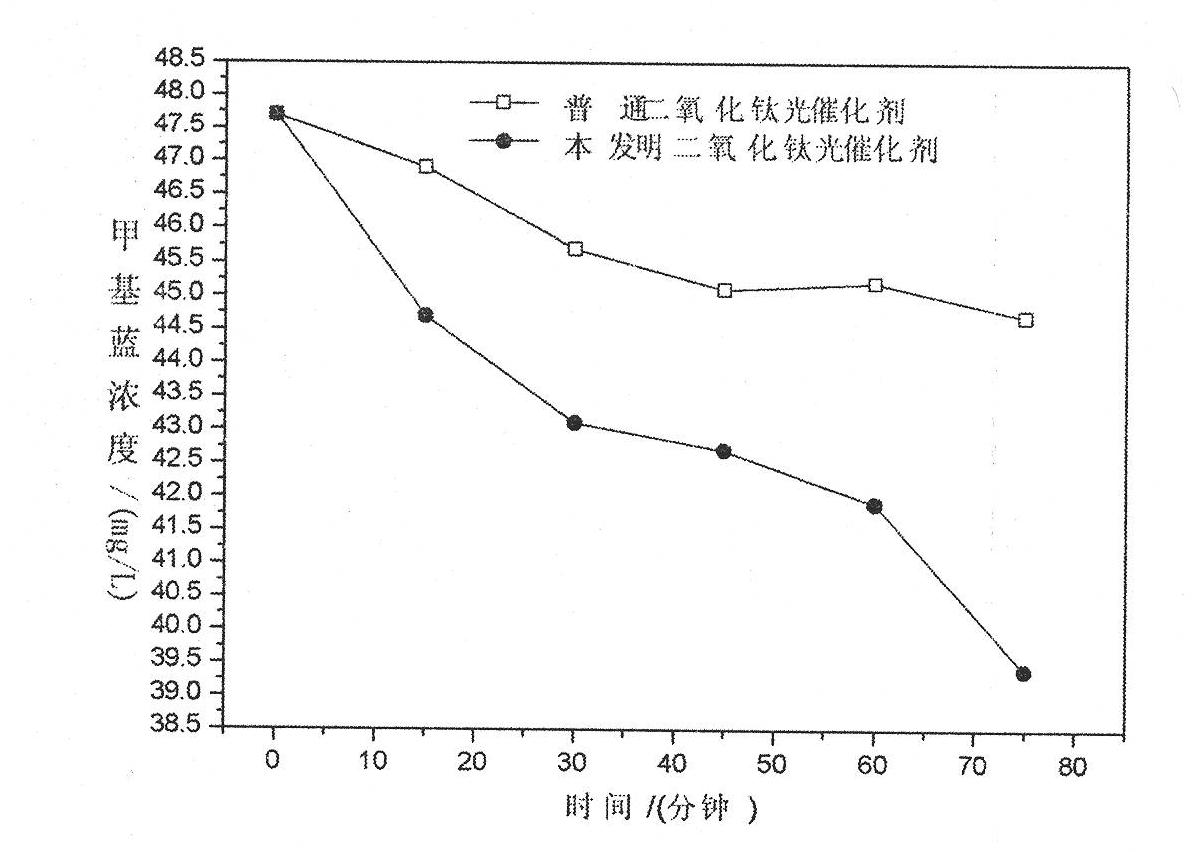

A titanium oxide nanotube and large-area technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem that the structure and performance of photocatalyst materials are difficult to further modulate, and the structure and size of materials can be controlled In order to achieve the effect of photoelectric integrated catalysis, good electrocatalytic activity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

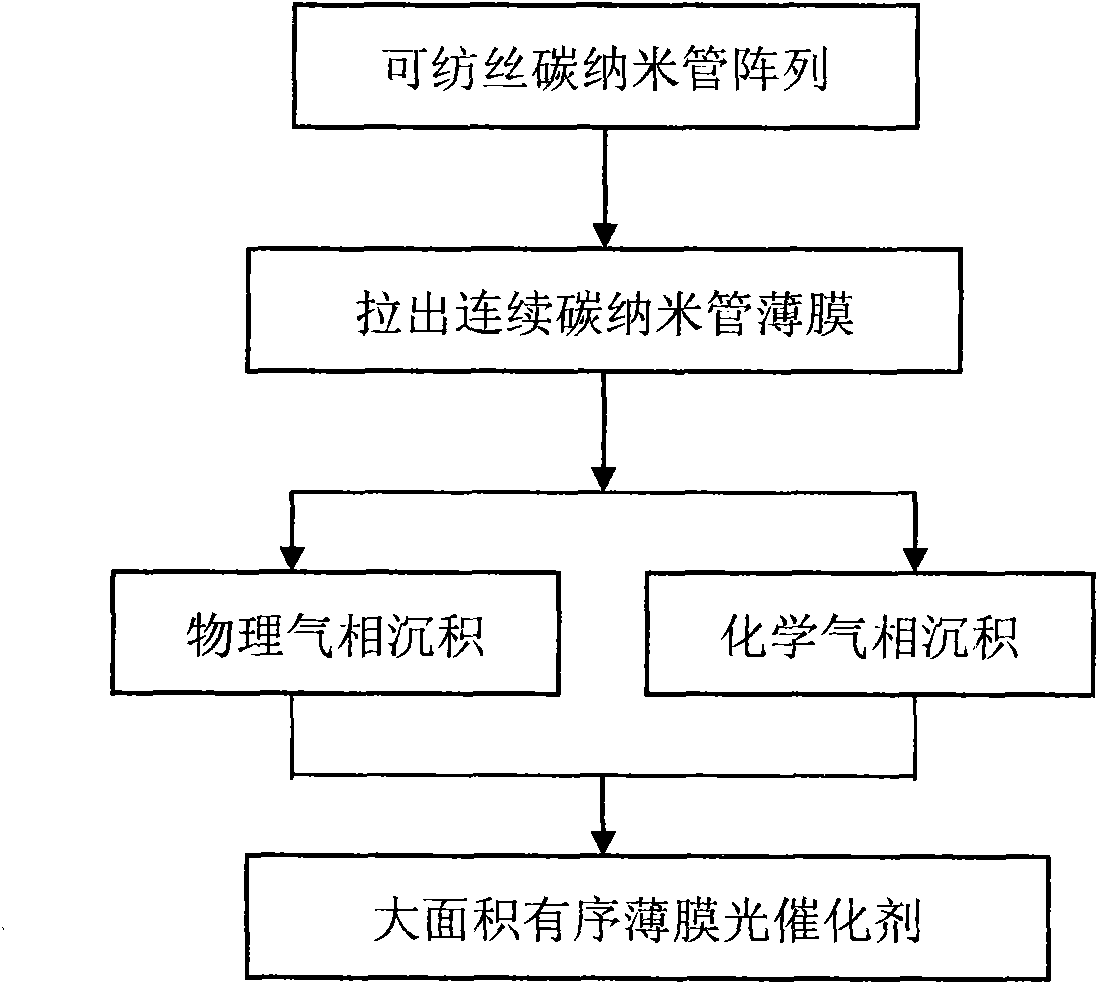

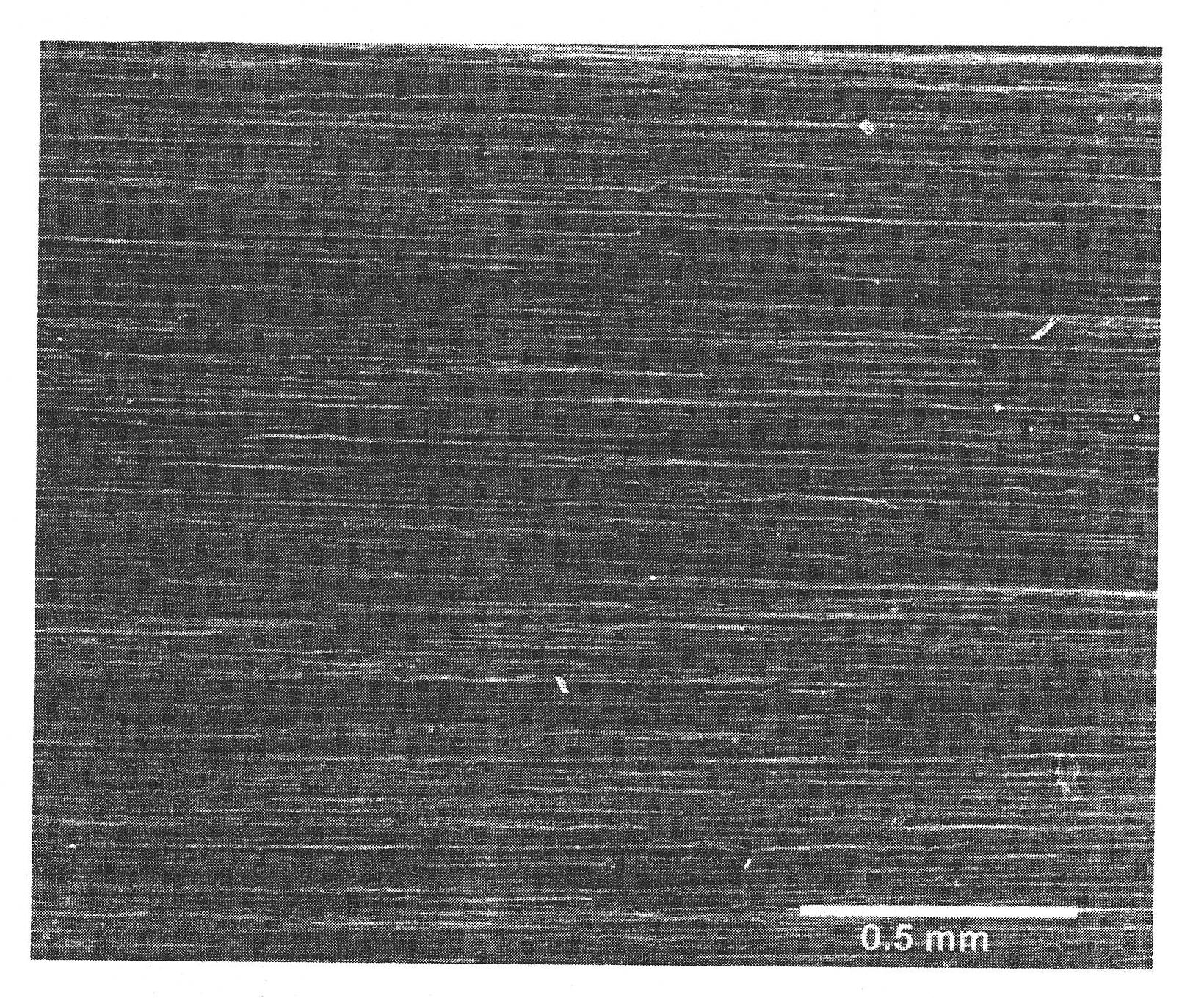

[0058] Pull out ordered transparent films of carbon nanotubes from carbon nanotube arrays in pullable films;

[0059] Spread carbon nanotube films with different directions on a single crystal silicon wafer with a size of 2cm×5cm, and the thickness of the silicon wafer is 500 microns;

[0060] Put the silicon wafer covered with the carbon nanotube film in the middle of a 1-inch horizontal tube furnace, feed argon gas with a flow rate of 300 standard cubic centimeters per minute, and exhaust for 10 minutes;

[0061] Start to heat the furnace. When the temperature of the furnace rose to 300°C, the carrier gas containing titanium tetraisopropoxide was passed into the furnace. The main component of the carrier gas was argon, and the flow rate was 300 standard cubic centimeters per minute. The time is 10 minutes. After the reaction is over, first turn off the carrier gas, keep the argon flow at 300 standard cubic centimeters per minute, let the furnace cool down naturally, and take...

Embodiment 2

[0065] Pull out ordered transparent films of carbon nanotubes from carbon nanotube arrays in pullable films;

[0066] Spread carbon nanotube films with different directions on a single crystal silicon wafer with a size of 2cm×5cm, and the thickness of the silicon wafer is 500 microns;

[0067] Put the silicon wafer covered with the carbon nanotube film in the middle of a 1-inch horizontal tube furnace, feed argon gas with a flow rate of 300 standard cubic centimeters per minute, and exhaust for 10 minutes;

[0068] Start to heat the furnace. When the temperature of the furnace rose to 300°C, the carrier gas containing titanium tetraisopropoxide was passed into the furnace. The main component of the carrier gas was argon, and the flow rate was 300 standard cubic centimeters per minute. The time is 10 minutes. After the reaction is over, first turn off the carrier gas, keep the argon flow at 300 standard cubic centimeters per minute, let the furnace cool down naturally, and take...

Embodiment 3

[0071] Pull out the ordered continuous film of carbon nanotubes from the carbon nanotube array of the pullable film, suspend the carbon nanotube film with a metal support, and then put the suspended carbon nanotube film into a 1-inch double-temperature zone horizontal tube furnace Right in the middle of the second temperature zone; a quartz boat is placed in the middle of the first temperature zone of the double temperature zone horizontal tube furnace, and the inside is filled with tetraisopropoxide titanium solution, with a volume of 10 milliliters. Argon gas with a flow rate of 300 standard cubic centimeters per minute was introduced and exhausted for 10 minutes. Then, the temperature of the first temperature zone (the area where the titanium tetraisopropoxide solution is placed) is controlled to be 120°C, and the temperature of the second temperature zone (the place where the silicon wafer is placed) is 300°C. In the subsequent process, the argon flow rate was kept constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com