UV lacquer suitable for black plastics base material

A technology for plastics and substrates, applied in the field of UV varnish, can solve the problems of difficulty in varnish hardness and the hardness of UV varnish cannot meet the requirements, and achieve the effect of meeting the requirements of high hardness and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

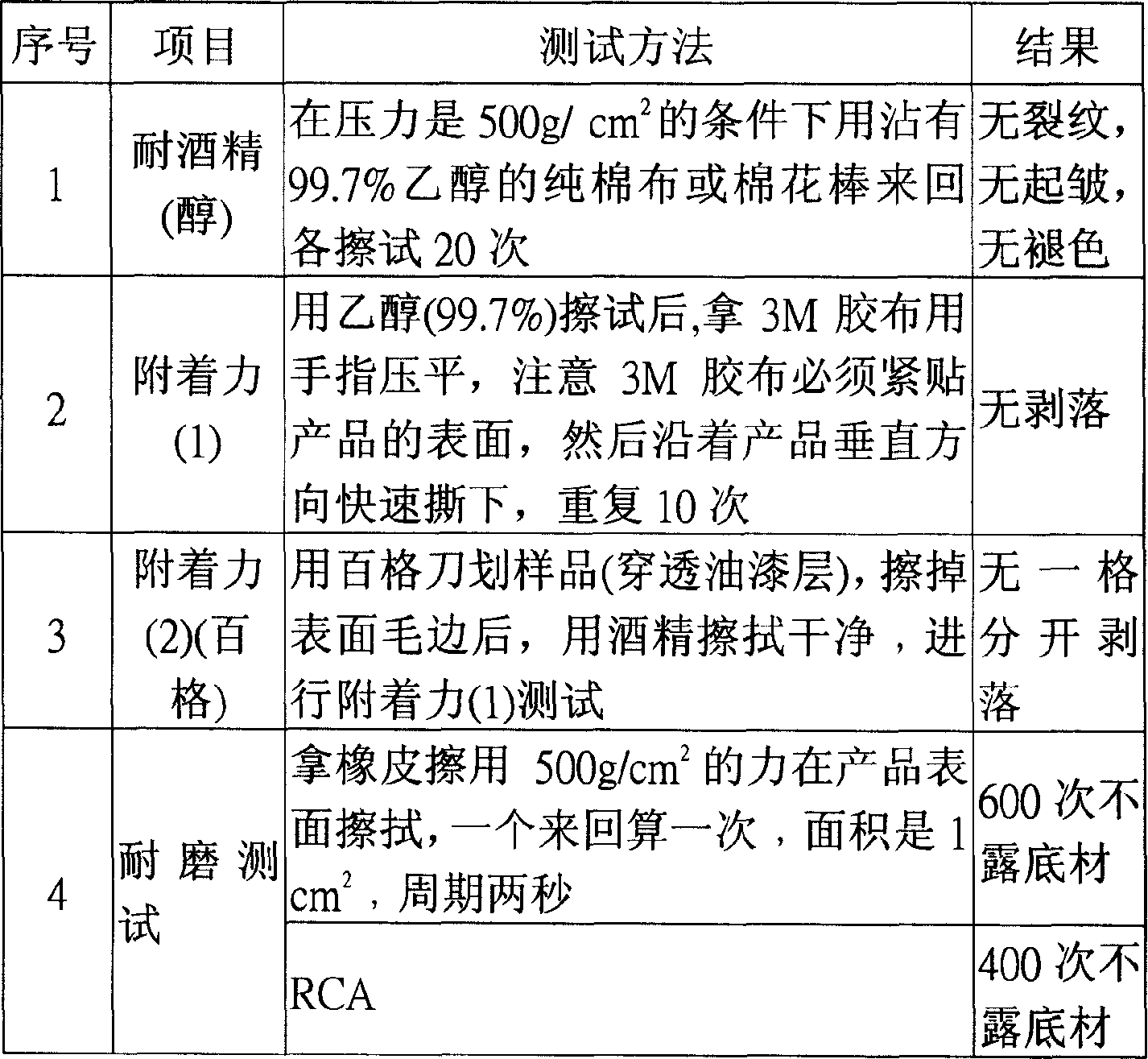

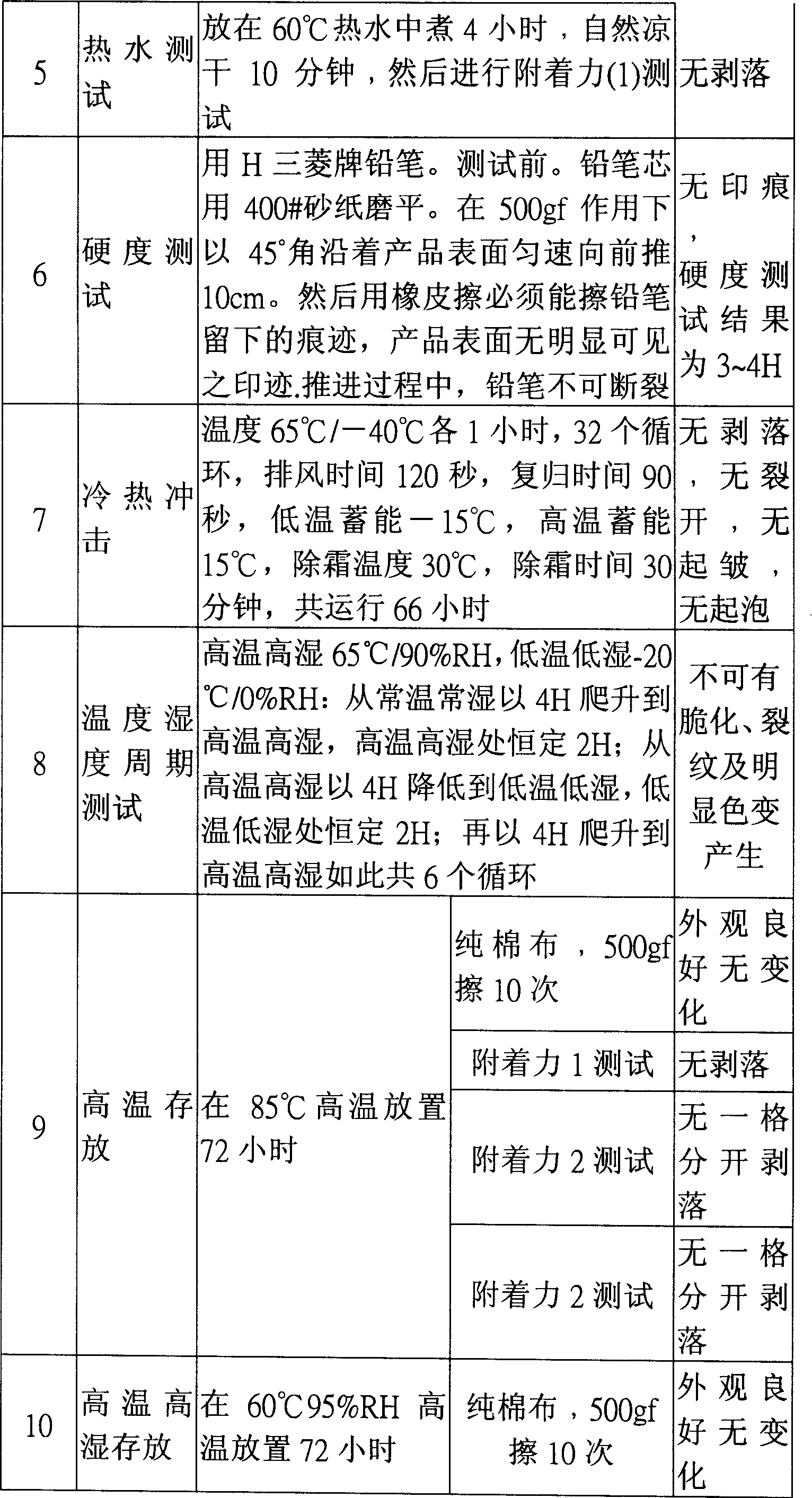

Examples

Embodiment Construction

[0017] Mix and dissolve its raw materials according to the following component formula:

[0018] Tripropylene glycol diacrylate 25;

[0019] Dipentaerythritol hexaacrylate 15;

[0020] Trifunctional aliphatic polyurethane acrylic resin 25;

[0021] Hexafunctional aliphatic urethane acrylic resin 35;

[0022] Acylphosphine oxide photoinitiator 4;

[0023] α-hydroxyketone photoinitiator 4;

[0024] Reactive organosiloxane leveling agent 0.5;

[0025] Non-reactive organosiloxane leveling agent 0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com