High-temperature-resistant dual-curing three-proof glue composition and application thereof

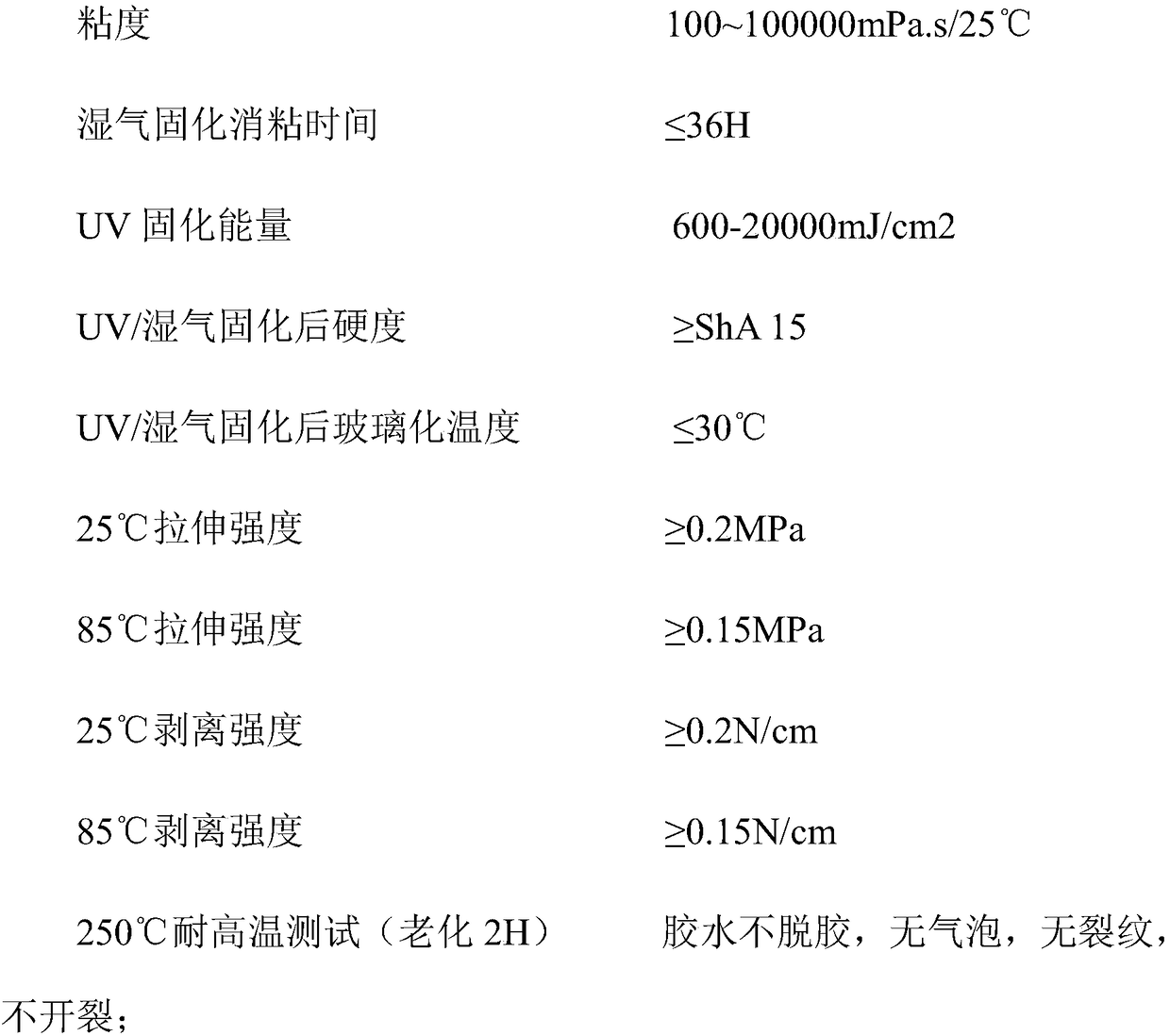

A dual-curing, three-proof glue technology, applied in the direction of adhesives, etc., can solve the problems that the glue cannot be cured in the shadow area, cannot provide effective protection, and the adhesive is prone to cracks, etc., to overcome the problem of oxygen inhibition, excellent high temperature resistance, glass effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation process of component A:

[0041] Match as follows:

[0042] 95.5 parts by weight of Wacker's OH Polymer 2000;

[0043] 4.4 parts by weight of KBM-503 of Japan Shin-Etsu Corporation;

[0044] 0.1 parts by weight of zinc acetylacetonate.

[0045] Put the above materials into a glass three-necked flask, turn on the vacuum device to below 10KPa, slowly raise the temperature to 60°C, and stir for 1 hour; stop vacuuming and cool down, and feed N2; continue to stir and keep the constant temperature at 50°C, and stir for 12 hours Overnight; raise the reaction temperature to 80°C and turn on the vacuum device to below 10KPa, vacuum remove the by-product methanol generated by the reaction for 1 hour, and obtain a UV / moisture cured polymer.

Embodiment 1

[0047] Prepare adhesive composition according to following formula:

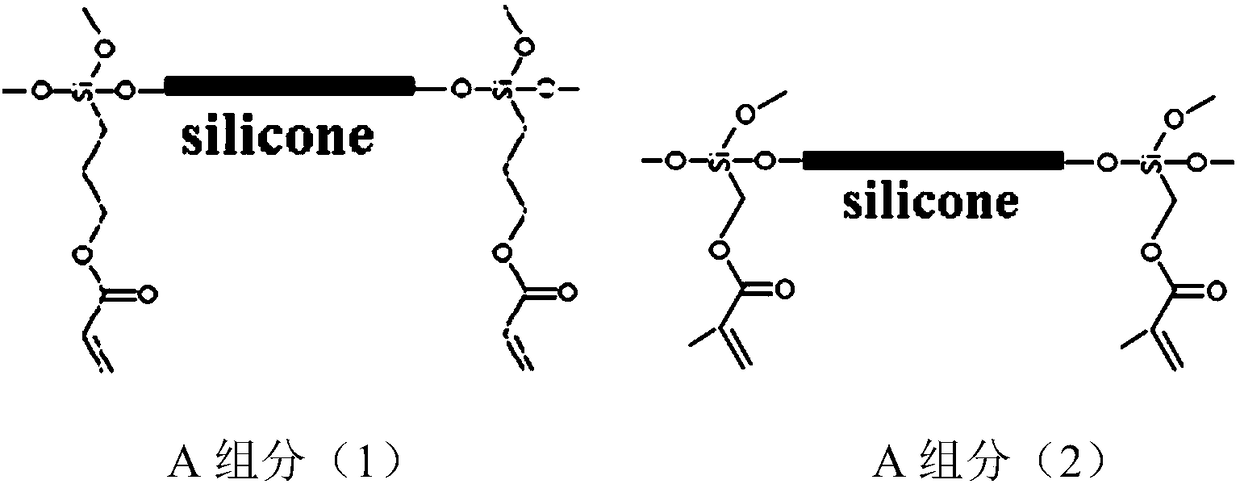

[0048] 6.0 parts of 3-acryloyloxypropyltrimethoxysilane (Shin-Etsu KBM-5103) capped the 500mPa.s OH silicone oil (F-0.5) of Jiangsu Kexing Coisl Company;

[0049] 5.0 parts of 3-acryloyloxypropyl trimethoxysilane (Japan Shin-Etsu KBM-5103) end-capped 100mPa.s OH silicone oil (DMS-S21) of Gelest Company

[0050] 85.0 parts of γ-methacryloxypropyltrimethoxysilane (Japan Shin-Etsu KBM-503) end-capped 100mPa.s OH silicone oil (DMS-S21) of Gelest Company

[0051] 2.5 parts of Rahn AG's photoinitiator Genocure DEAP, α, α'-ethoxyacetophenone

[0052] 1.0 parts of Wuhan University's methyl trimethoxy silicon (WD921)

[0053] 0.5 parts of tetraisopropyl titanate produced by Nanjing Pinning Coupling Agent Co., Ltd. as a catalyst

[0054] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0055] Specific preparation method:

[0056] The above-mentioned components (total 100g...

Embodiment 2

[0058] Prepare adhesive composition according to following formula:

[0059] 70.0 parts of 3-acryloyloxypropyltrimethoxysilane (Shin-Etsu KBM-5103) end-capped the 500mPa.s OH silicone oil (F-0.5) of Jiangsu Kexing Coisl Company;

[0060] 28.0 parts of 3-acryloyloxypropyltrimethoxysilane (Shin-Etsu KBM-5103) blocked Wacker Chemical OH Polymer 2000;

[0061] 1.5 parts of 3-acryloxypropyltrimethoxysilane (Shin-Etsu KBM-5103);

[0062] 0.15 parts of Omnirad TPO from IGM: 2,4,6-trimethylbenzoyl-diphenylphosphine oxide;

[0063] The photoinitiator Genocure DEAP of the Rahn AG company of 0.15 parts, α, α '-ethoxy acetophenone;

[0064] 0.20 parts of Fomrez UL 28, dimethyltin dilaurate, from the company Momentive.

[0065] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0066] Specific preparation method:

[0067] The above-mentioned components (total 100g) are successively added into a plastic bucket with a capacity of 150g, and put int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com