Resin composition and prepreg, laminated board and interlayer insulating film manufactured thereby

A resin composition and prepreg technology, applied in the directions of lamination, lamination equipment, chemical instruments and methods, etc., can solve the problem of decreased rigidity and cohesiveness, affecting the board's cohesiveness, drilling processability, and excellent polybutadiene. Dielectric properties can not be fully reflected and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with embodiment:

[0069] A kind of resin composition, adopts the component and the proportioning of following table 1 and table 2 to make: (table 1 is actual

[0070] Embodiment 1 to 8, table 2 is comparative example 1 to 6)

[0071] Table 1

[0072]

[0073] Table 2

[0074]

[0075] Note: The specific structure and physical property parameters of each component in Tables 1 and 2 are as follows:

[0076] Maleimide 1: The structural formula is as follows:

[0077]

[0078] where R 1 is methylene, R 2 and R 3 Both are methyl.

[0079] Maleimide 2: The structural formula is as follows:

[0080] where R 1 for -O-, R 2 and R 3 Both are methyl.

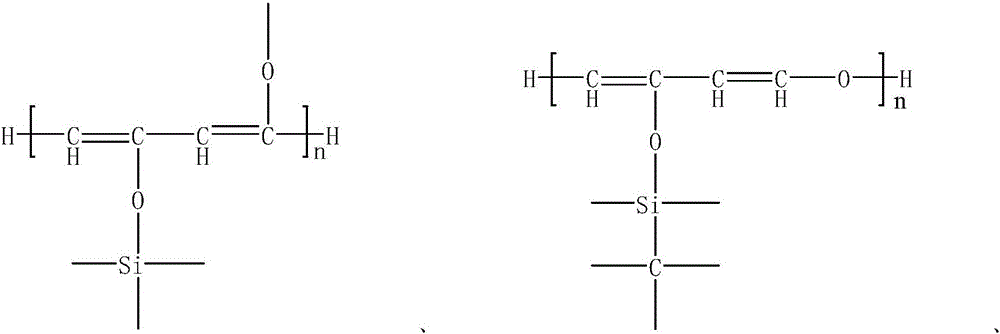

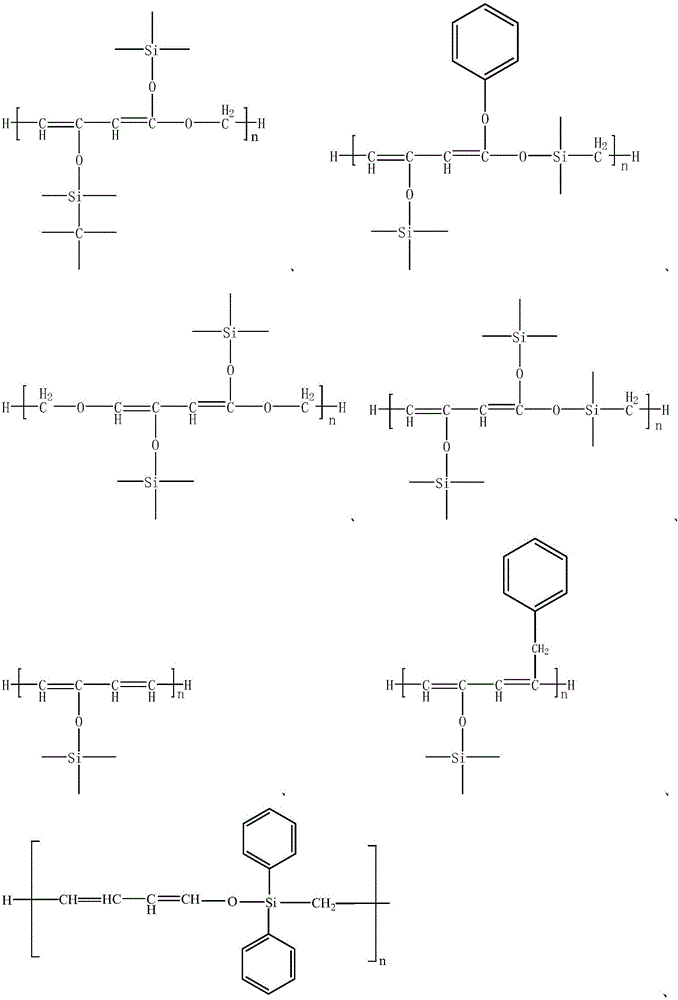

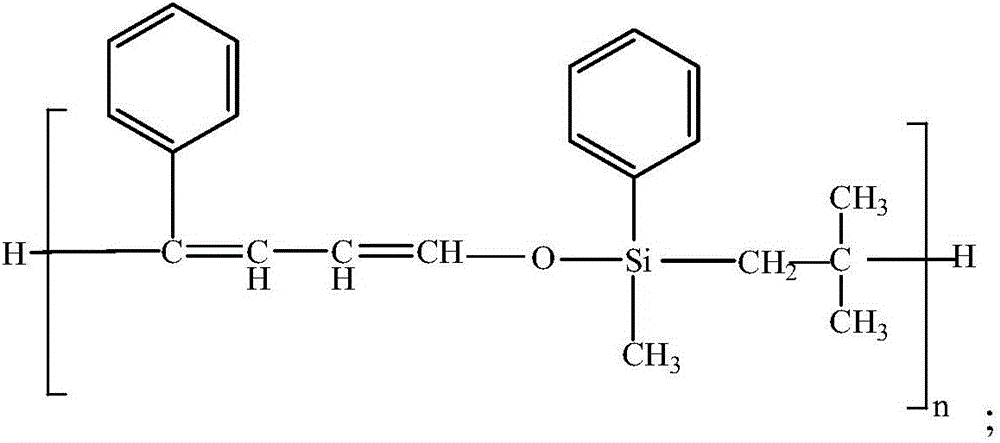

[0081] Silicone crosslinking agent 1: SiO-1, imported, the structural formula is

[0082] Silicone crosslinking agent 2: SiO-2, imported, the structural formula is

[0083] Silicone crosslinking agent 3: SiO-3, imported, the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com