Device for automatically controlling curing degree of optical fiber coating, and optical fiber production equipment

An automatic control device and optical fiber coating technology, which is applied to cladding optical fiber, glass optical fiber, optical waveguide and light guide, etc., can solve the problems of different curing degree of optical fiber outer coating, easy fluctuation of oxygen content, and inability to guarantee the adjustment range, etc. Achieve the effect of solving the curing of optical fiber coating, facilitating popularization and application, and ingenious overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

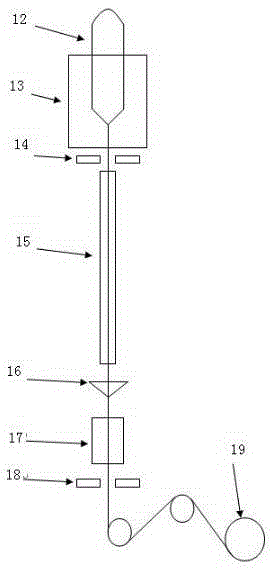

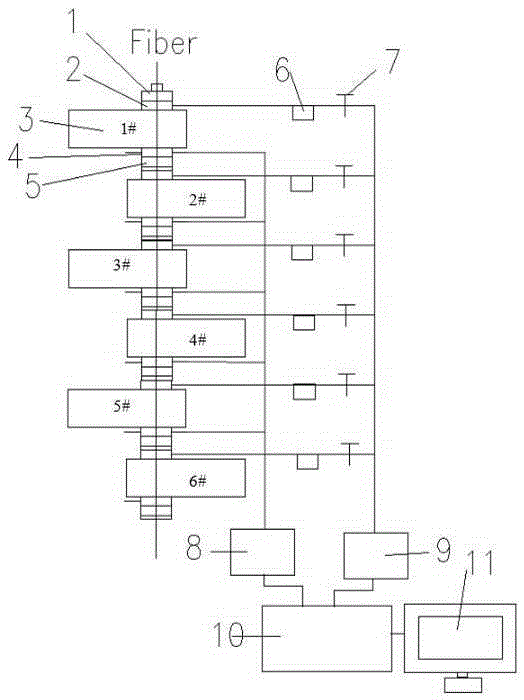

[0020] Example 1: See figure 1 , The optical fiber coating curing degree automatic control device, the automatic control device includes an ultraviolet curing oven 3, a connector, a gas flow sensor 6, an oxygen concentration measuring instrument 8, a controller 10, and a host computer 11, an ultraviolet curing oven 3 Connectors are provided on the upper and lower sides. The oxygen concentration measuring instrument 8 is connected to the controller 10 through a signal line, and the upper computer 11 is connected to the controller 10 through a control line; the connectors include a curing furnace upper connector 2 The lower port connector 4 of the curing furnace and the connector 5 with elastic sealing ring, wherein the upper port connector 2 of the curing furnace is arranged above the ultraviolet curing furnace 3 and connected to the nitrogen pipeline, and the nitrogen pipeline is equipped with a gas flow sensor 6. The gas flow sensor 6 is connected to the controller 10 through ...

Embodiment 2

[0021] Example 2: See figure 1 As an improvement of the present invention, the number of the ultraviolet curing oven is at least two, generally set to 6-10, according to the actual situation, use belt elasticity between two adjacent ultraviolet curing ovens The connector 5 of the sealing ring is connected to play a role of sealing, and a shutter 1 with adjustable inner diameter is connected to the upper mouth of the uppermost ultraviolet curing furnace 3 to prevent air from entering. The rest of the structure and advantages are exactly the same as the first embodiment.

Embodiment 3

[0022] Example 3: See figure 1 As an improvement of the present invention, the automatic control device further includes a gas flow adjustment device 9, which is arranged on the nitrogen pipeline and connected to the controller 10 through a signal line, wherein the nitrogen pipeline is arranged There is a regulating valve 7 to facilitate timely adjustment and control of the nitrogen content. The control method is as follows. After the bare fiber is coated, it enters the UV curing furnace for curing, and multiple oxygen concentration measuring instruments measure the oxygen concentration in the UV curing furnace connected in series to obtain the measured oxygen concentration. The signal is transmitted to the controller, and the controller compares and analyzes the collected oxygen concentration with the standard oxygen concentration set by the host computer. Through calculation, the nitrogen flow rate is automatically adjusted within a certain range. When the flow rate is adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com