Patents

Literature

44results about How to "Reduce sticky residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Side sealing plate for thin-belt continuous casting and manufacturing method

The invention relates to a side sealing plate for a thin-belt continuous casting system. The side sealing plate is characterized by comprising the components in percentage by weight: 10-50% of boron nitride, 5-35% of zirconium boride, 5-25% of zirconium oxide, 1-15% of boron powder, 1-10% of graphite and 0.1-5% of carbon fiber. As the fabricate particles are firstly adopted in the side sealing plate, then the techniques such as high-temperature sintering and oil immersion and the like are adopted in the common sizing flame-resistant material technique, the porosity and the density of a product are obviously improved, and boron carbide (extremely hard substance) is formed in high-temperature sintering, so that the strength is further improved.

Owner:上海柯瑞冶金炉料有限公司

Rare earth alloy, preparation technique and application thereof

The invention relates to a light rare earth base heavy rare earth alloy, a preparation technology and application thereof. The alloy contains 1-40wt% heavy rare earth, and is prepared by oxide fused salt electrolysis process in fluoride molten salt. The electrolyte is composed of rare earth fluoride, lithium fluoride and magnesium fluoride, the compositions are: 65 to 87wt% of base fluoride in rare earth fluoride, 5 to 25wt% of heavy rear earth fluoride, 5-12wt% of lithium fluoride and 0.5 to 3wt% of magnesium fluoride. Since the electric efficiency is larger than 75%, the metal recovery rate is large than 90%, the preparation technology is especially suitable for industrialized mass production.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Ladle castable

The invention relates to ladle castable. The use of the castable can reduce the slag adhesion of ladles, improve the yield of hot metal and operation efficiency, and can reduce the maintenance cost for the ladles. The ladle castable comprises the chemical components in percentage by weight: 45 to 60 percent of Al2O3, 30 to 40 percent of SiO2, 5 to 15 percent of ZrO2, less than 1 percent of CaO, and 2 to 5 percent of SiC. The ladle castable is used for integral casting of the ladles.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

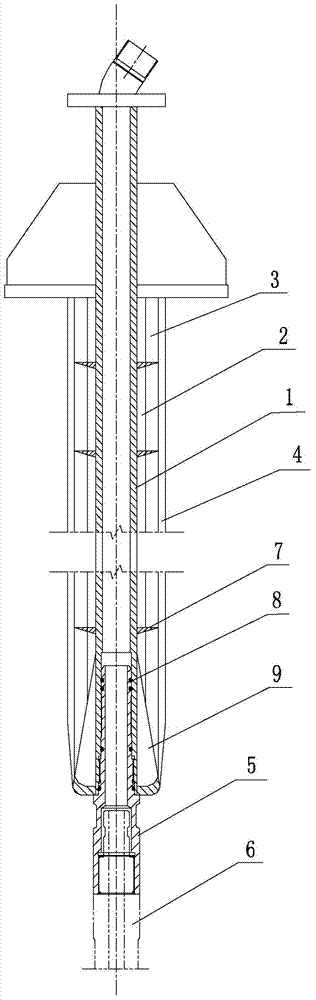

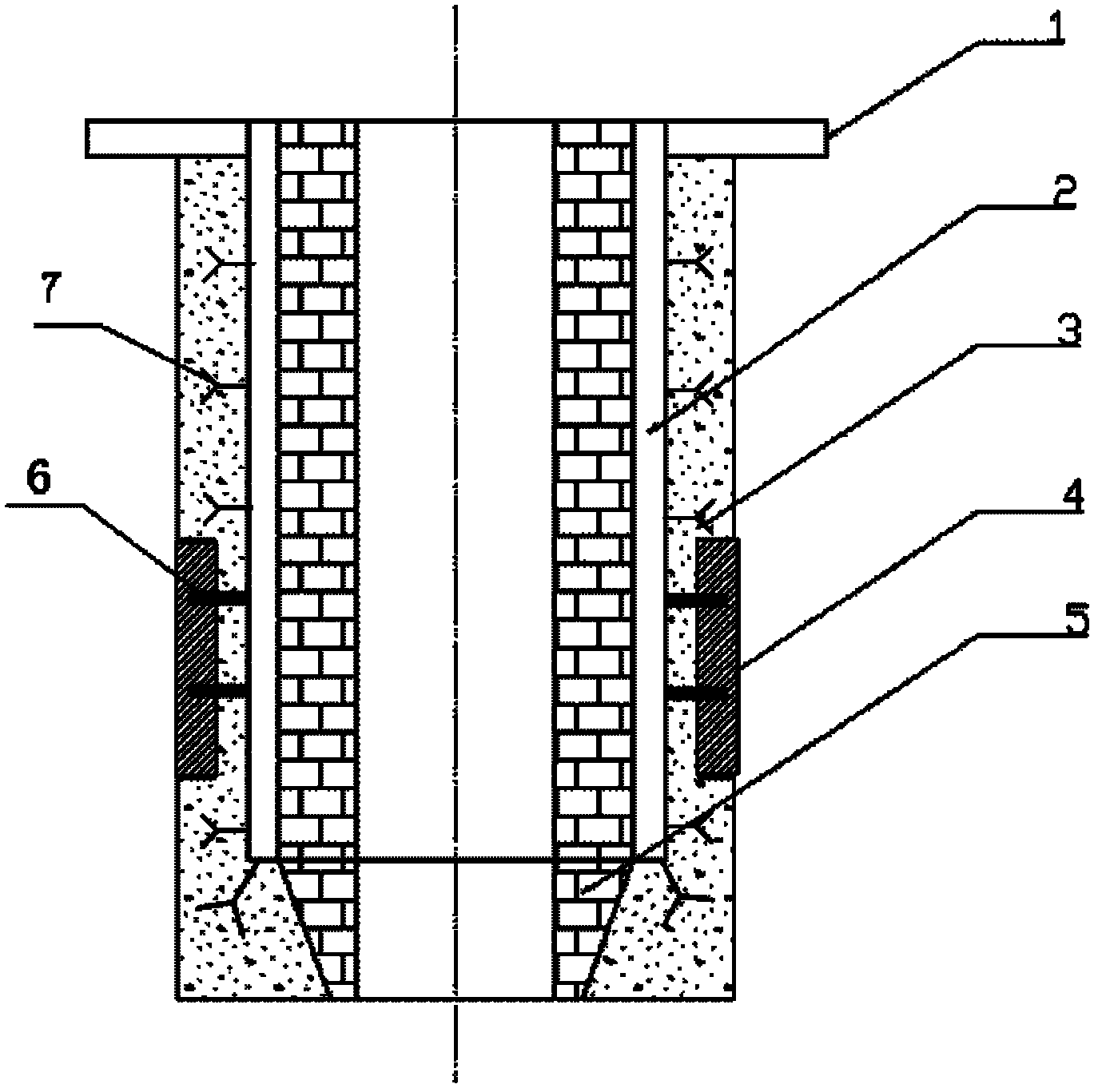

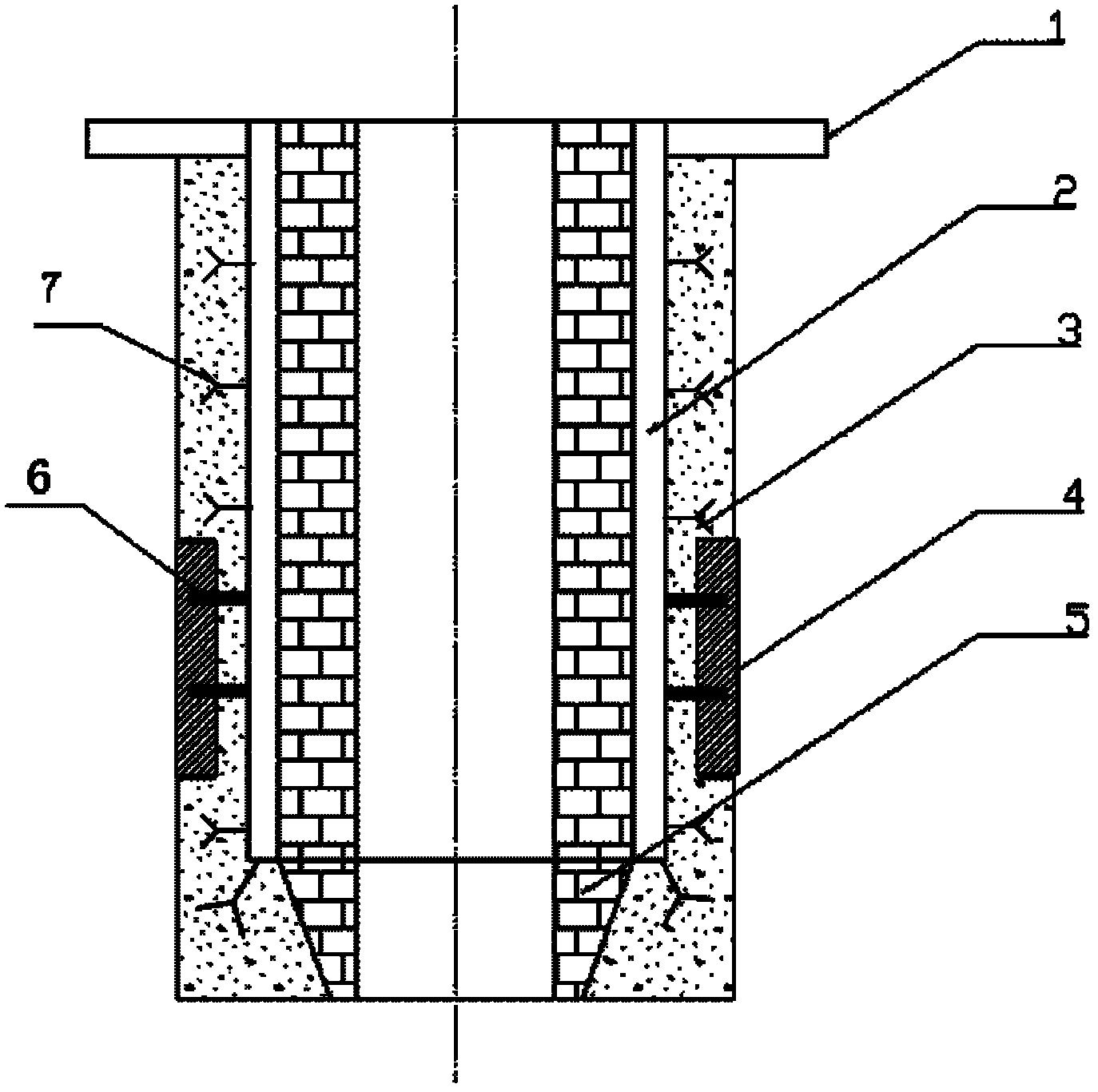

Insertion tube of vacuum cycle degassing refining furnace and preparation method thereof

The invention provides an insertion tube of a vacuum cycle degassing refining furnace and a preparation method thereof. The insertion tube comprises a tubular steel structure, refractory bricks built on the inner wall of the steel structure and a pouring layer formed on the outer wall of the steel structure, wherein the pouring layer includes first and second pouring layers distributed up and down; the first pouring layer is contacted with molten steel when undergoing vacuum cycle degassing refining and contains 1-3% of nano zirconia powder and 2-4% of alumina hollow balls by weight; and the second pouring layer is not contacted with the molten steel when undergoing vacuum cycle degassing refining. The insertion tube is provided with the pouring layer with components and high temperature performance changing in a gradient manner, thus the insertion tube has good thermal shock resistance and longer service life.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Refractory castable for molten iron tank

The invention provides a refractory castable for a molten iron tank. The refractory castable comprises the following components in percentage by weight: 50-65 percent of high-alumina particles, 10-30 parts of high-alumina powder, 1-10 percent of quartz sand, 1-20 percent of diaspore clay fine powder, 3-7 percent of calcium aluminate cement, 1-7 percent of silicon fine powder, 0-4 percent of alumina fine powder, 1-3 percent of zirconium silicate powder, 0.2-2 percent of heat-resistant steel fiber, 0.05-0.3 percent of metal aluminum powder and 0-0.3 percent of sodium tripolyphosphate. The refractory castable for a molten iron tank has the advantages of long service life, high slag resistance and low production cost, is suitable for a molten iron tank for receiving acid slag with high viscosity, is prevented from being eroded, and contributes to reducing adhesive slag.

Owner:山国强

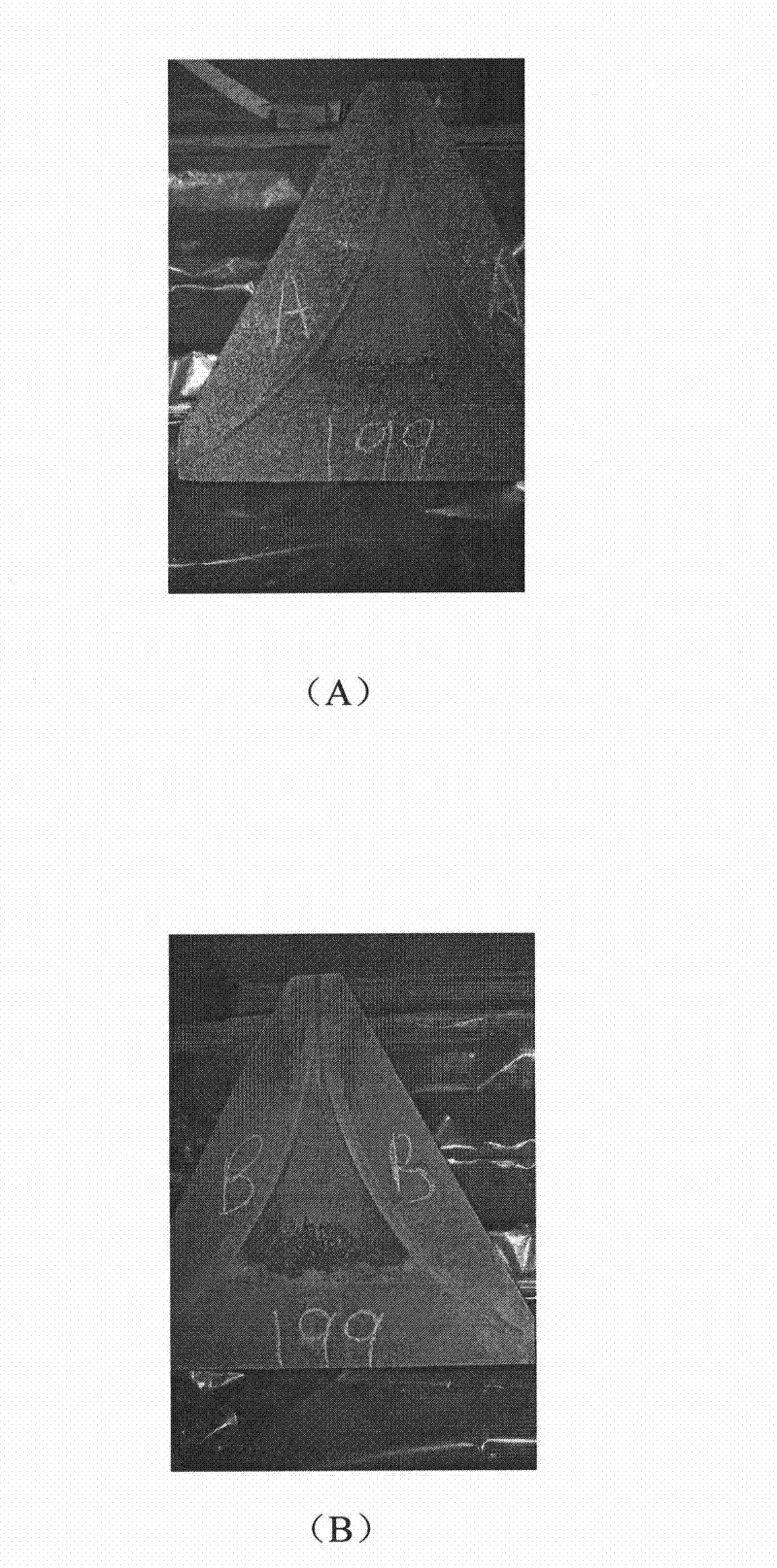

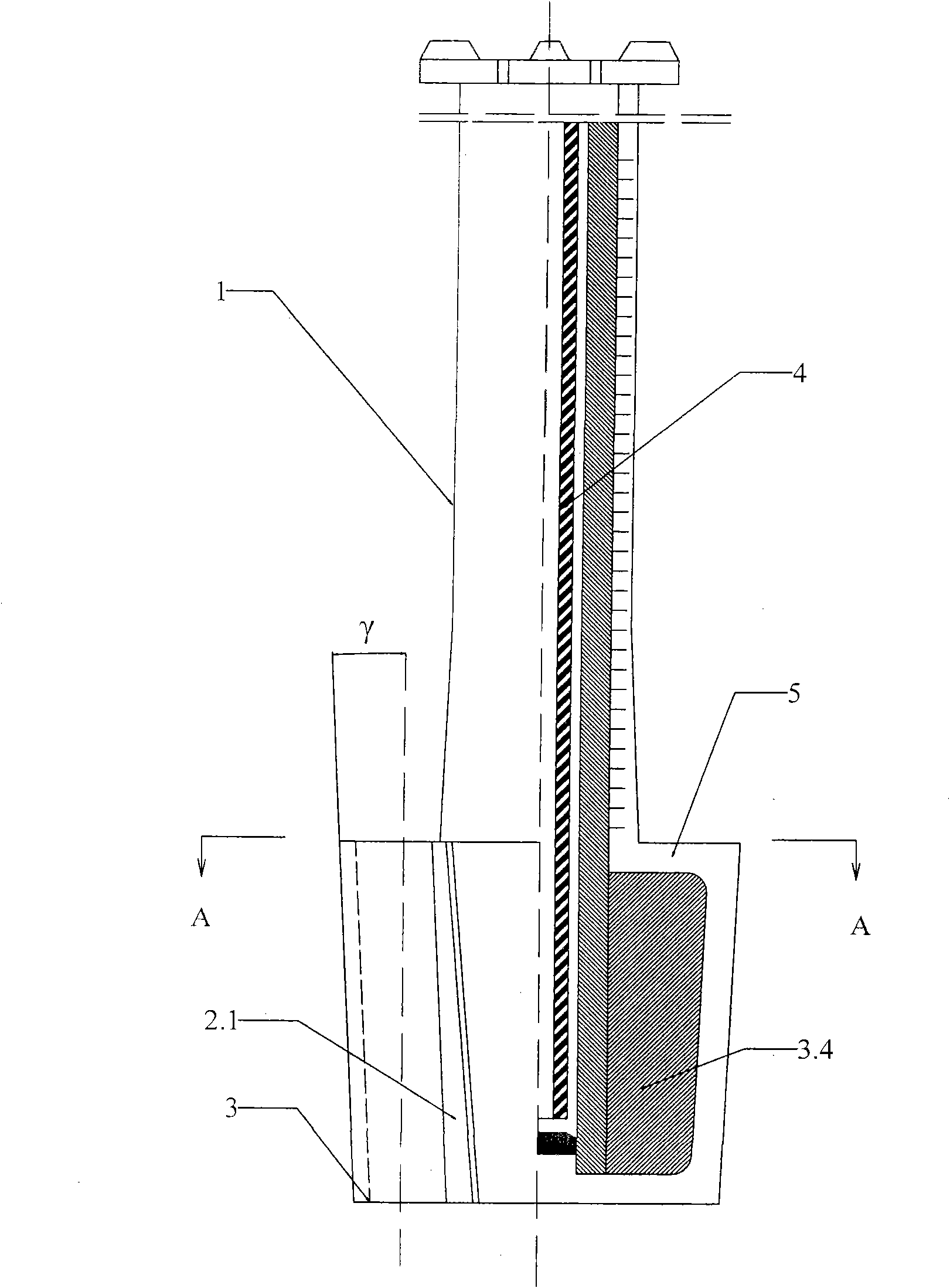

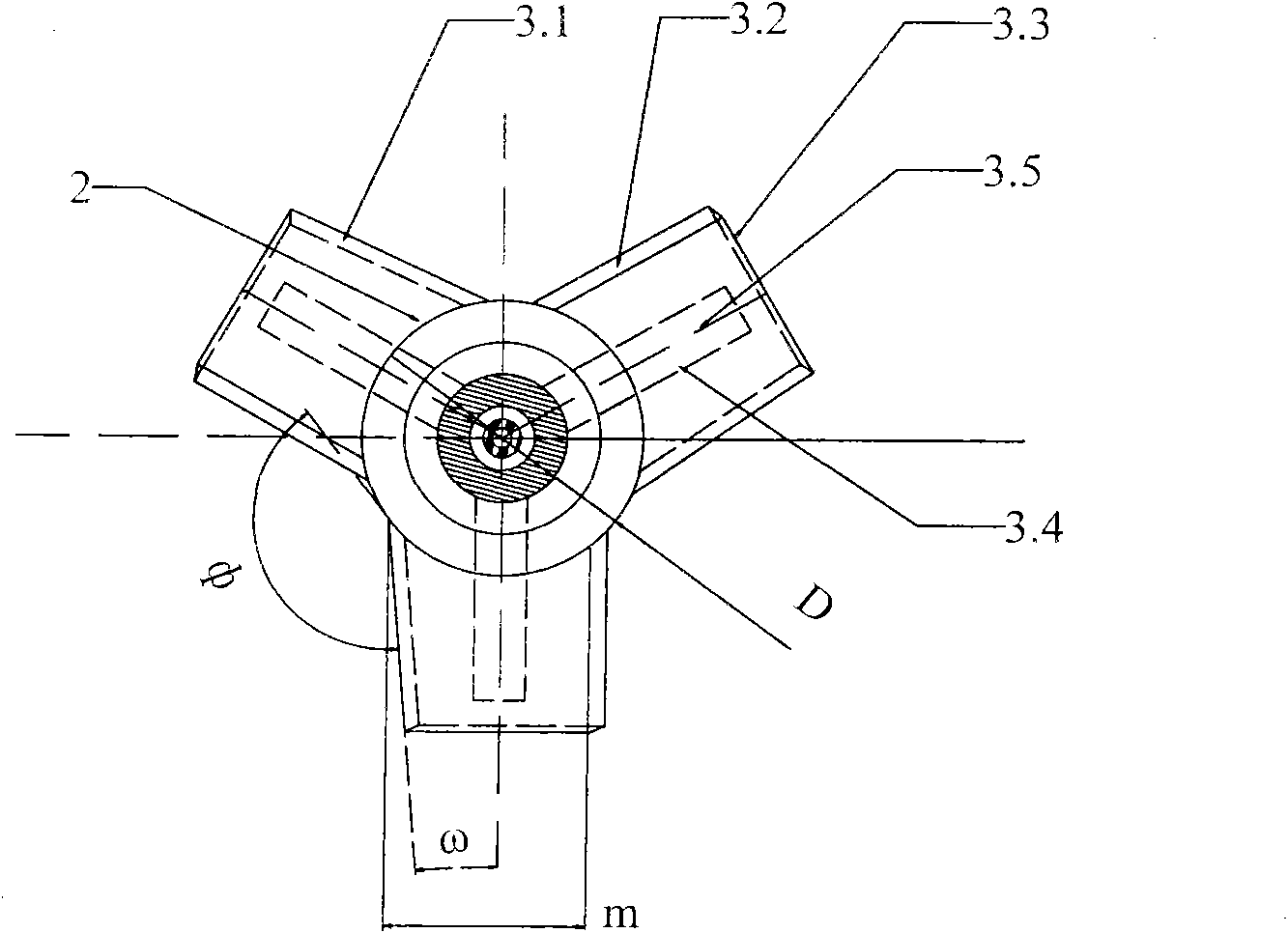

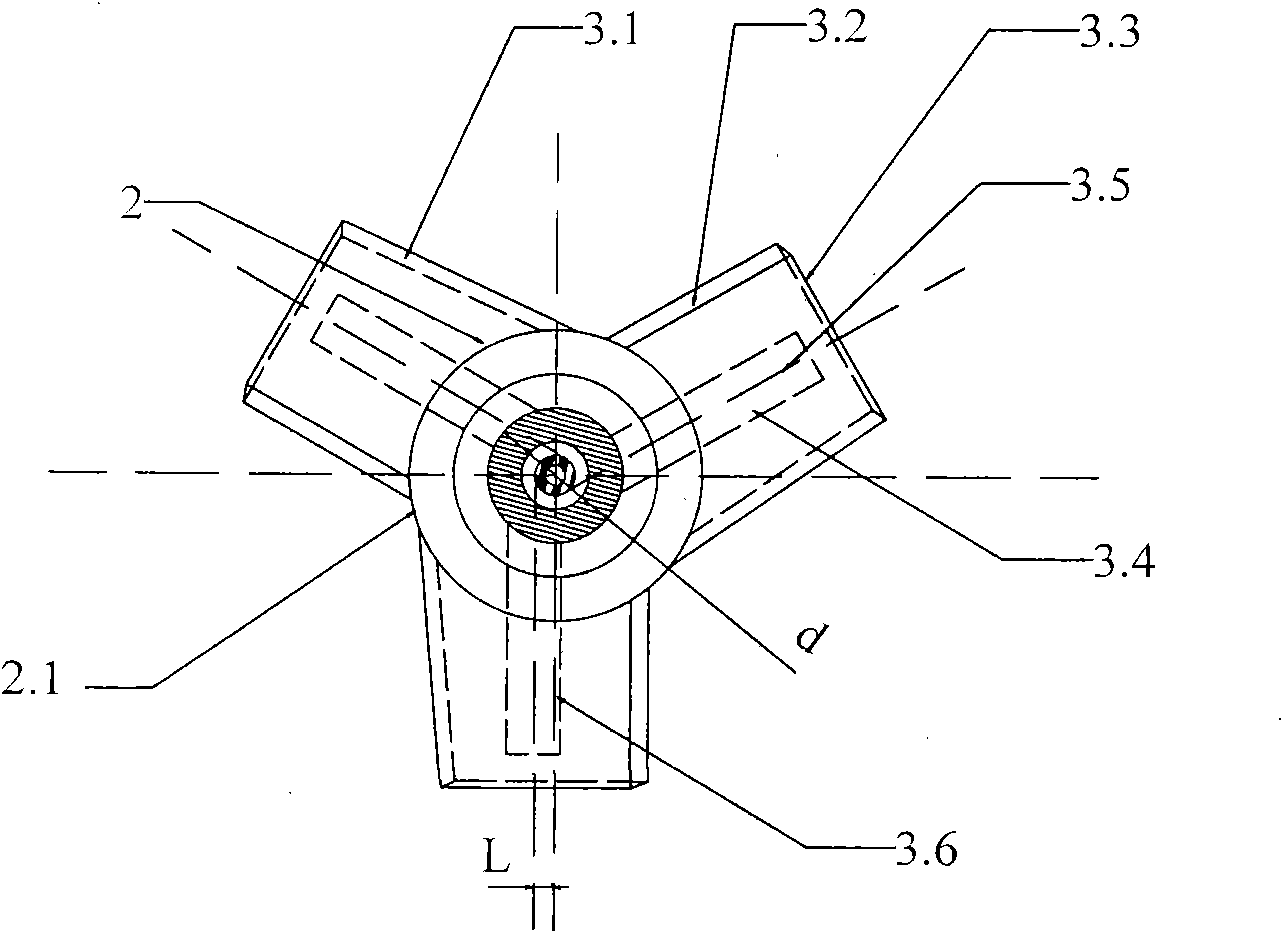

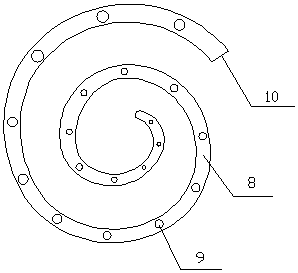

Turbine type stirrer used for molten iron mechanical stirring desulfuration

The invention discloses a turbine type stirrer used for molten iron mechanical stirring desulfuration, comprising a rotating shaft, a wheel hub and three stirring vanes, wherein, each stirring vane comprises a stirring vane metal core and is evenly distributed at the periphery of the wheel hub; the surface facing melt iron, the surface deviating melt iron and the side face of the stirring vane are all inclined planes inclining forwards from bottom to top, and the angles of inclination alpha, beta and gamma respectively satisfy the following conditions: alpha is more than or equal to 1 degree and less than or equal to 10 degrees, beta is more than or equal to alpha and less than or equal to 15 degrees, and gamma is more than or equal to 0 degree and less than or equal to 3 degrees; the stirring vane metal core is in eccentric arrangement; the flat surface on which the thickness symmetry plane of the stirring vane metal core is located is a first vertical plane; the flat surface parallel to the first vertical plane and passing the centre line of the rotating shaft is a second vertical plane; the first vertical plane is overlapped with the second vertical plane horizontally moving a distance of L towards the direction of the surface facing melt iron, wherein, L satisfies the condition that L is more than 0 and less than or equal to (d-a) / 2; d is the diameter of the metal core of the rotating shaft; and a is the thickness of the stirring vane metal core; by applying the invention, the stirring power consumption of the invention is low, the sticky dregs between the stirring vanes are less; and the dynamical condition of stirring desulfuration is good.

Owner:武钢集团有限公司

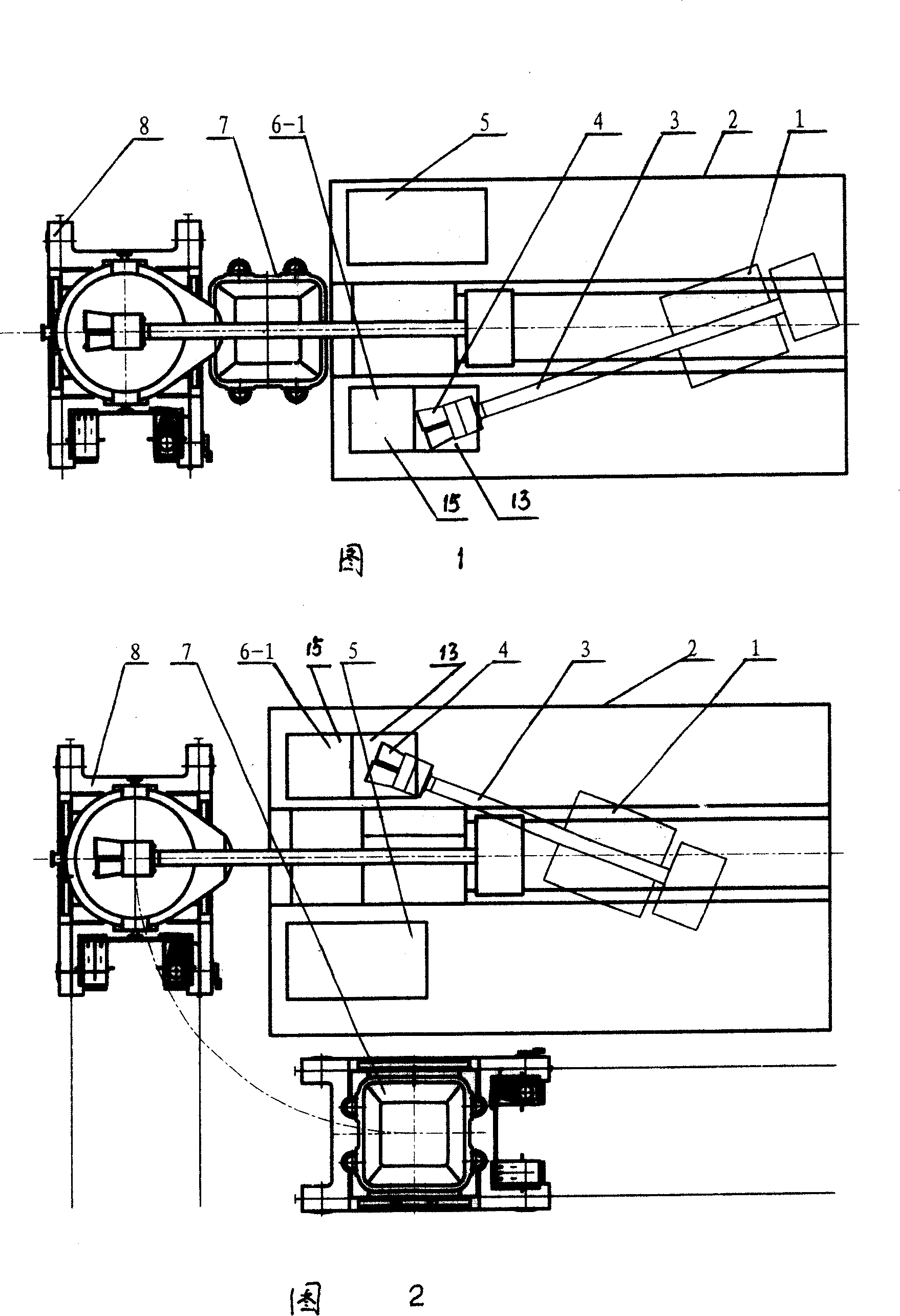

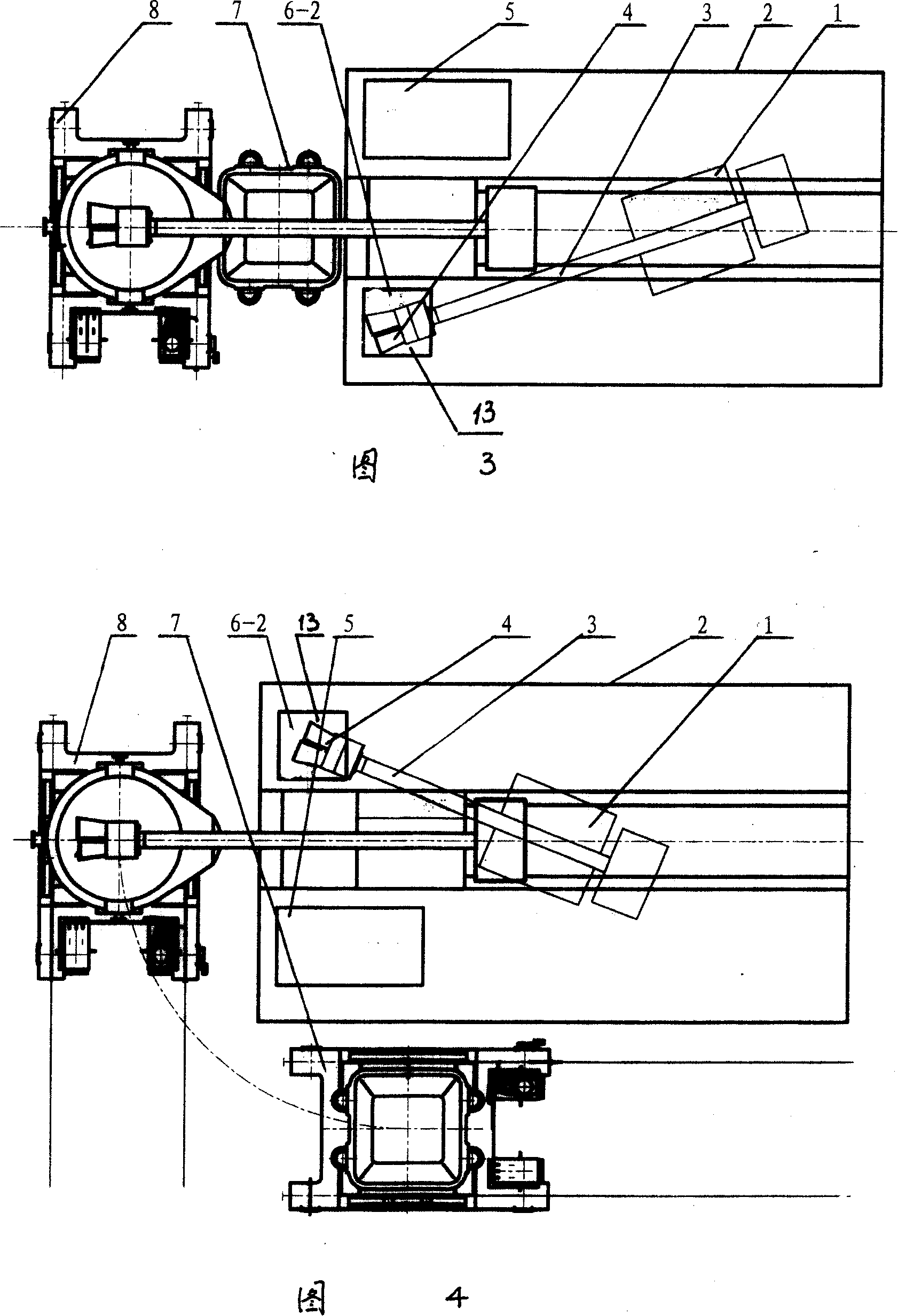

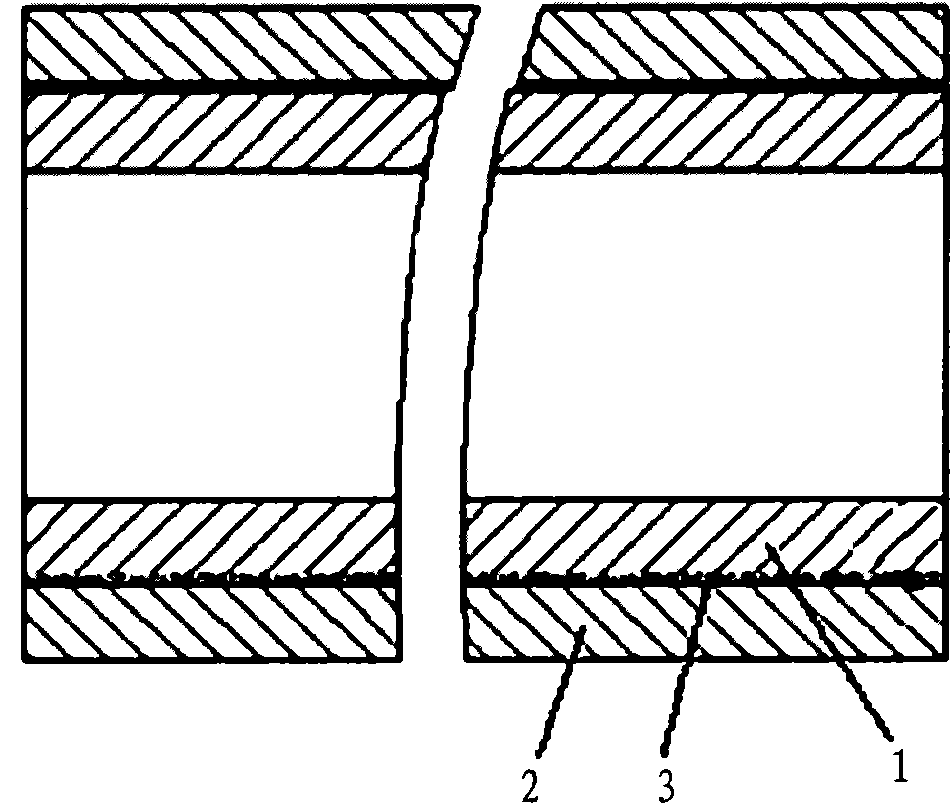

Converter sublance body

ActiveCN104513880AGuaranteed cooling effectGuaranteed StrengthManufacturing convertersFlexural strengthUltimate tensile strength

The invention provides a converter sublance body, which includes a center steel pipe. A thermal insulating layer and an asbestos thermal insulating layer are fixedly sleeved on the outer circumferential wall of the center steel pipe from the inside out in order. A composite spray layer is coated outside the asbestos thermal insulating layer, a connecting pipe is inserted into the front end of the center steel pipe, and one connecting pipe end extending out of the center steel pipe is connected to a probe holder for mounting a probe. The converter sublance body provided by the invention can be applied into various types of converter sublance systems to adapt sublance probes with different functions. The multilayer structure of the sublance body ensures the flexural strength of the sublance body and also satisfies the heatproof function, realizes weight reduction of the sublance body under the premise of effective protection of a sensing cable in the sublance body, and reduces cooling water consumption of the converter system, thereby being conducive to optimizing the structure of the sublance system, and reducing energy medium consumption of the sublance system and the production cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Refractory castable for ladle

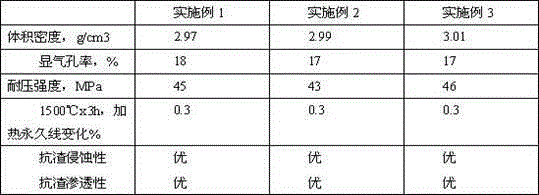

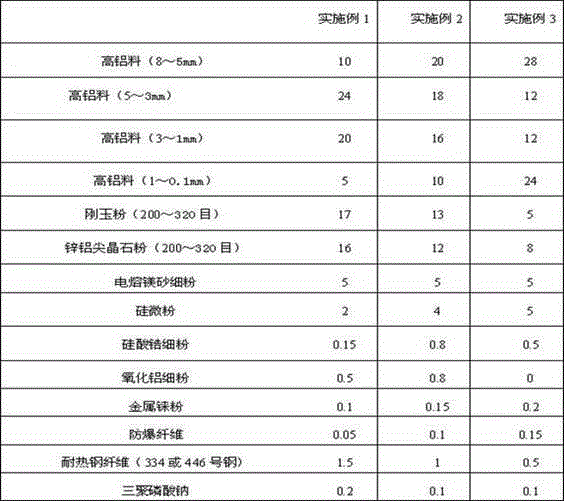

The invention provides a refractory castable for a ladle. The refractory castable is prepared by mixing a castable matrix and a proper amount of additive, wherein the castable matrix is composed of the following components in percentage by weight: 50-75% of high-aluminum particles, 10-20% of corundum powder, 1-10% of zinc-aluminum spinel powder, 1-20% of fine fused magnesia powder and 1-7% of silicon micropowder; the additive is composed of the following components in percentage by weight: 0-1% of fine aluminum oxide powder, 0.1-0.5% of fine zirconium silicate powder, 0.1-0.2% of metal rhenium powder, 0.2-3% of refractory steel fiber, 0.03-0.3% of anti-explosion fiber and 0-0.3% of sodium tripolyphosphate. The refractory castable for the ladle is long in service life, strong in slag resistance, certain in desulfuration effect, low in production cost, suitable for a ladle with meta-alkaline slag and a ladle with relatively-high-viscosity acidic slag, and capable of eroding the ladle to reduce bonded slag.

Owner:张婷

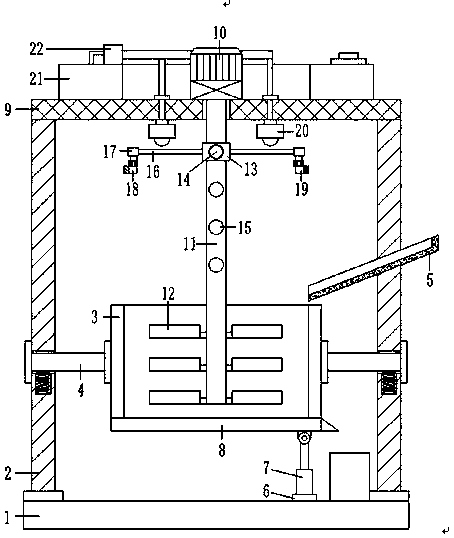

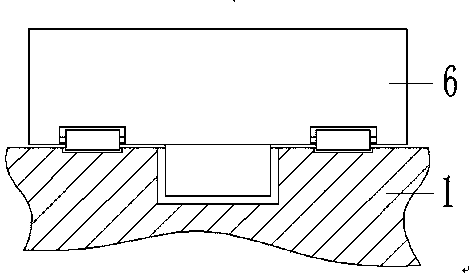

Device and method for reducing slag amount in tapping process of steelmaking converter

PendingCN112593043AReduce back phosphorusReduce sticky residueManufacturing convertersSteelmakingBrick

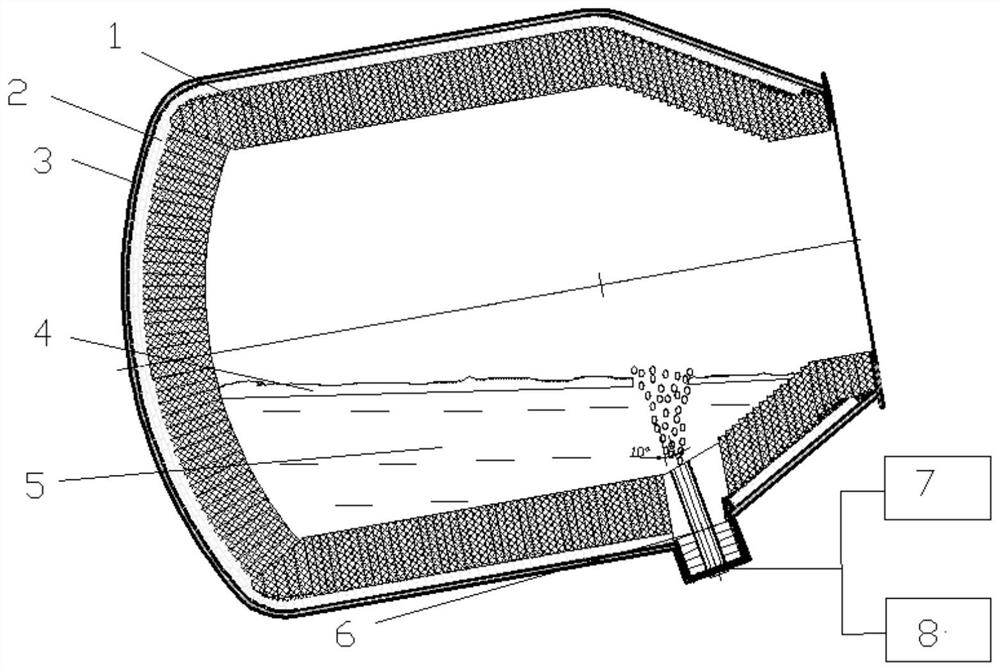

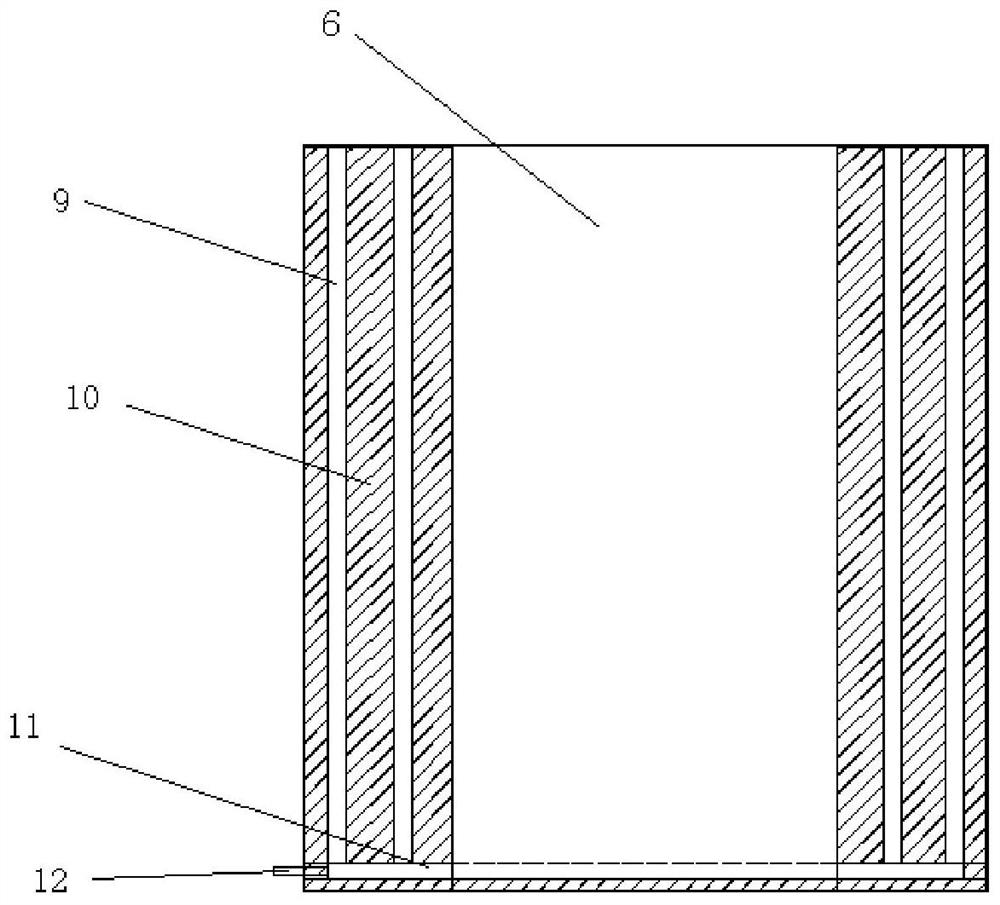

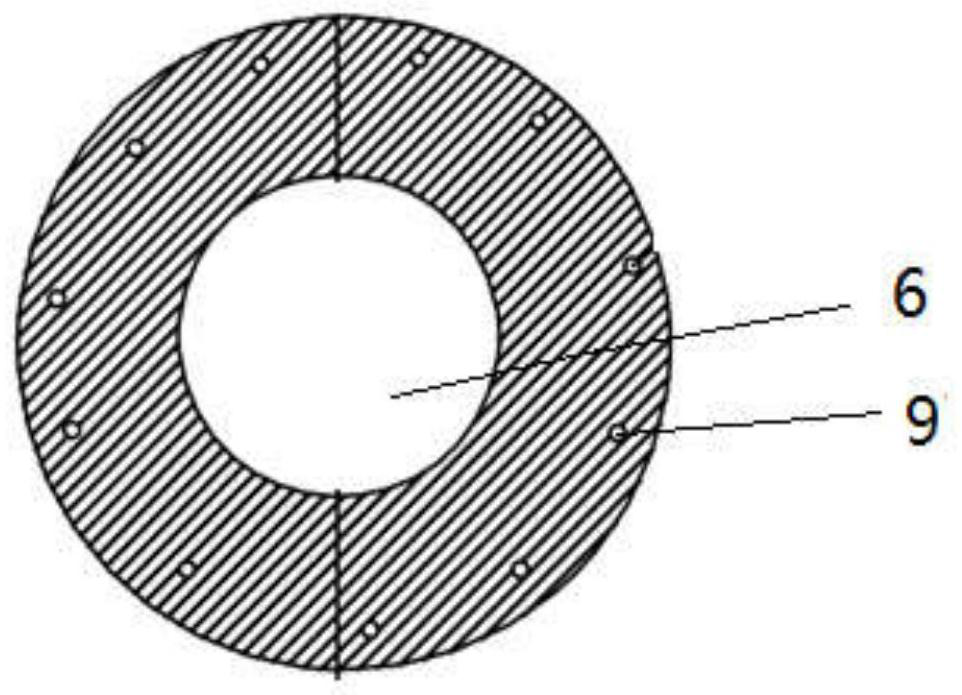

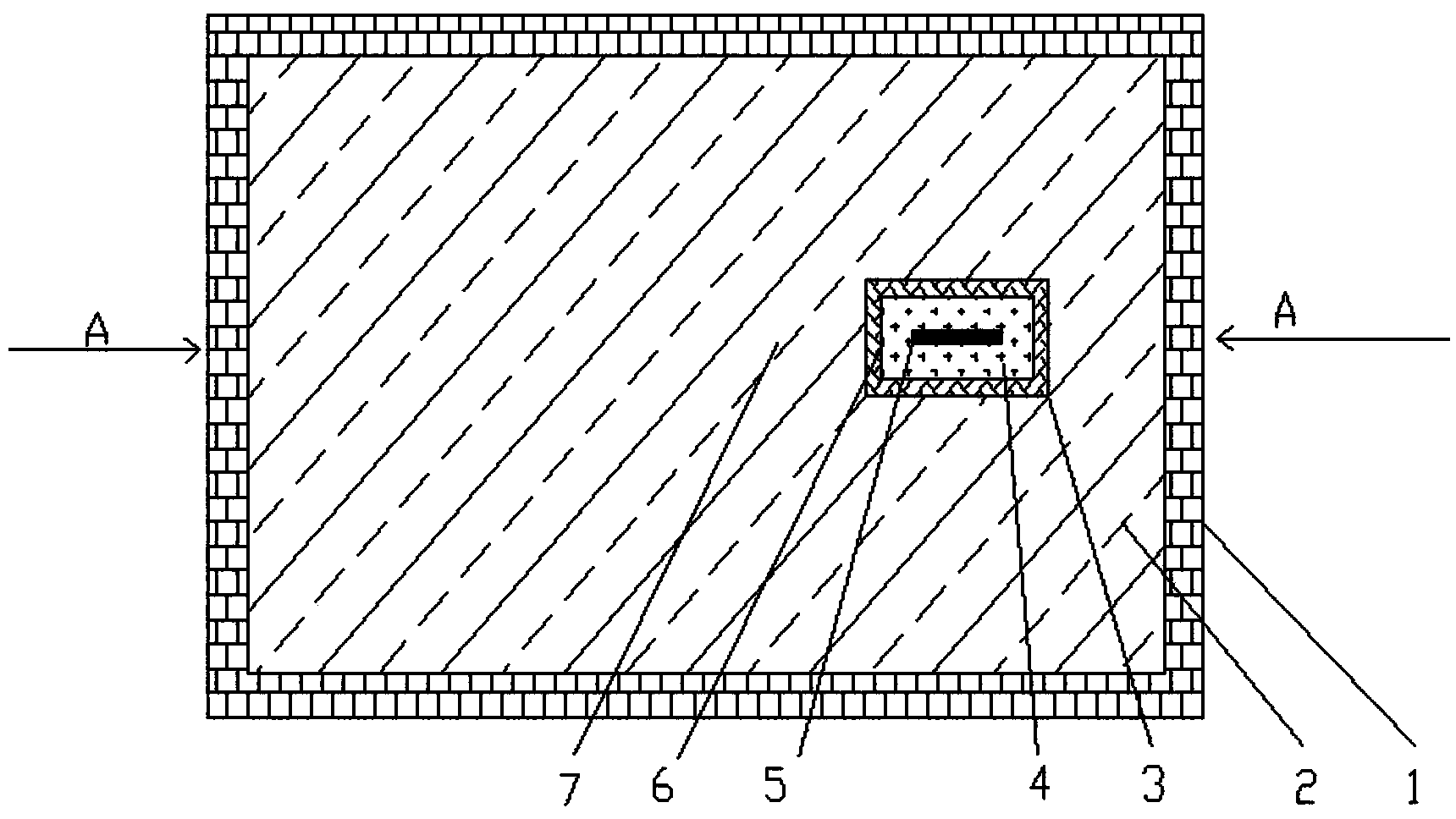

The invention belongs to the technical field of converter smelting, and particularly provides a device for reducing the slag amount in the tapping process of a steelmaking converter. The device comprises a converter, a converter tapping hole and a gas source structure, wherein a converter lining is arranged on the inner wall of the converter, a magnesite brick permanent layer is adopted as the converter lining, and working layer bricks are built on the converter lining; and a refractory material pipe with thickness is arranged at the tapping hole, a plurality of uniformly distributed air inletslots are formed in the wall of the refractory material pipe, an annular air chamber is arranged at the bottom of the refractory material pipe, and the bottom ends of the plurality of air inlet slotsrespectively communicate with the annular air chamber. The device is simple in structure, convenient to operate and low in investment, vortex slag entrapment in the tapping process can be effectivelyinhibited, the slag amount in the tapping process of the steelmaking converter is reduced, molten steel rephosphorization can be reduced, the alloy yield is increased, inclusions in steel can be reduced, the molten steel cleanliness is improved, steel ladle slag adhesion can be reduced, the service life of a steel ladle is prolonged, and good conditions can be provided for molten steel refining,so that the quality of molten steel is improved.

Owner:BENGANG STEEL PLATES

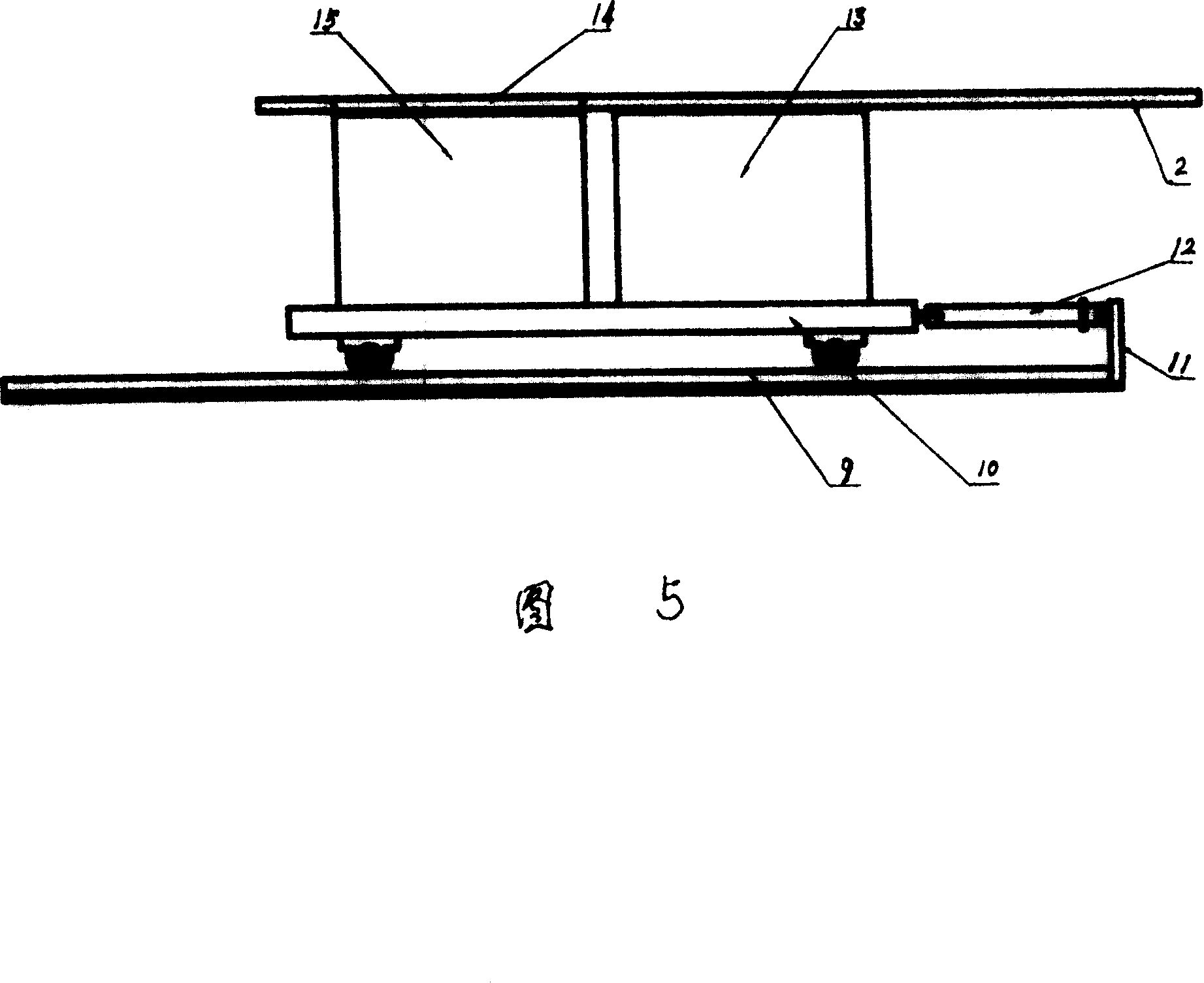

Protective casting method for feeding steel strips into crystallizer

The invention discloses a protective casting method for feeding steel strips into a crystallizer. The method comprises the following steps: (1) dividing the liquid surface of the crystallizer into a feeding area and a common area by a baffle; and (2) adding common protective slag into the common area and adding low-melting-point slag with a melting point being lower than that of the common protective slag into the feeding area when the steel strips are fed into the crystallizer. The widths of the steel strips fed into the crystallizer are 10-20% of the width of the crystallizer; the thicknesses of the steel strips fed into the crystallizer are 0.1-1% of the length of the crystallizer; the feeding rate is 0.3-0.6 meter per second. The method is low in cost and is simple and effective.

Owner:SHANDONG IRON & STEEL CO LTD

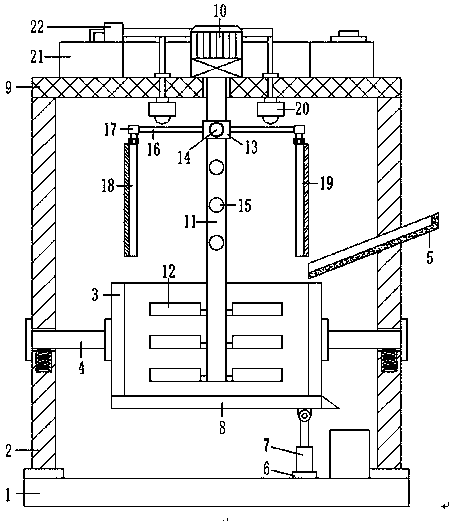

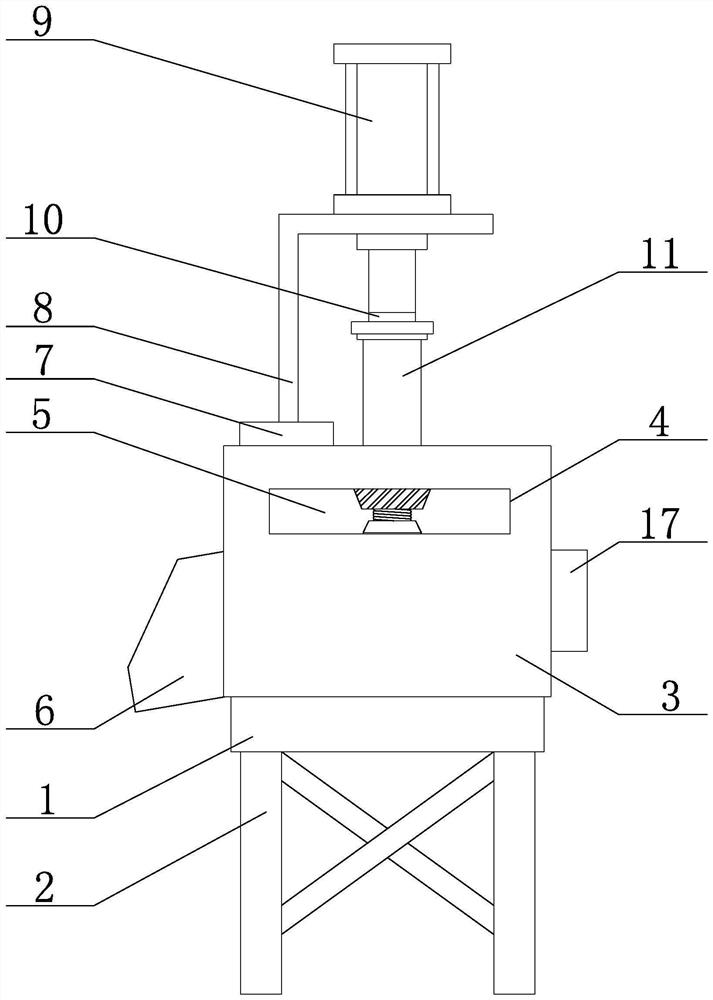

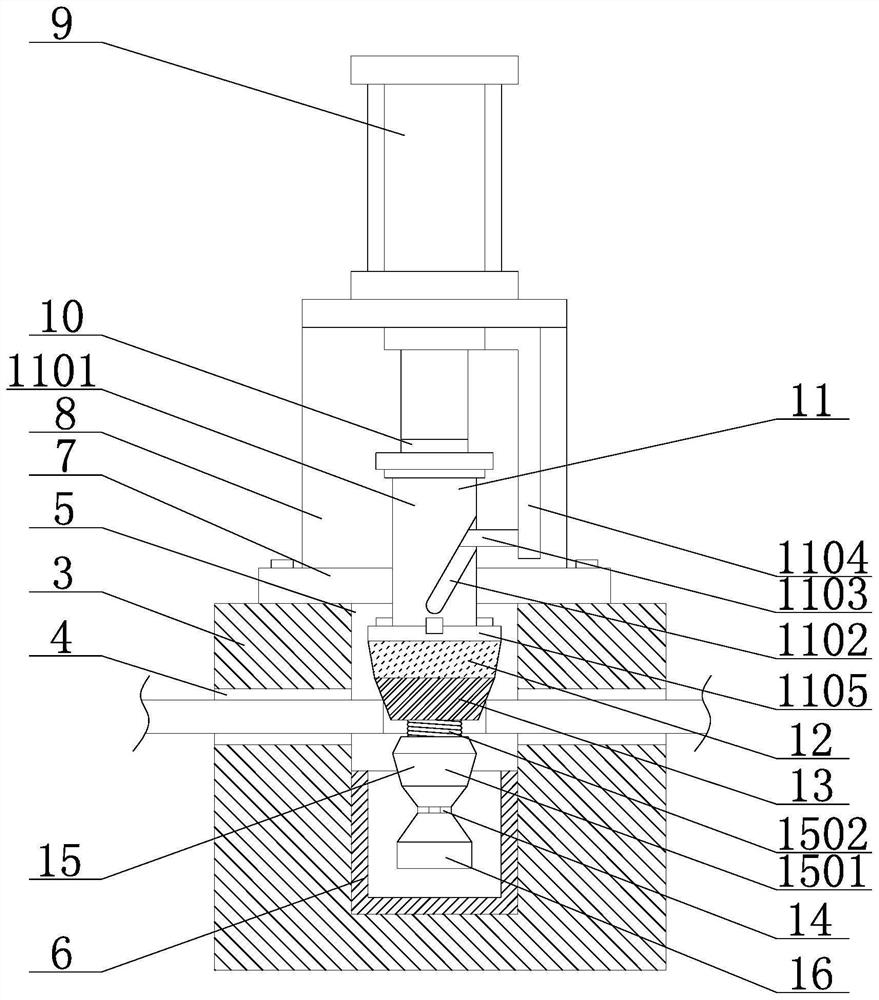

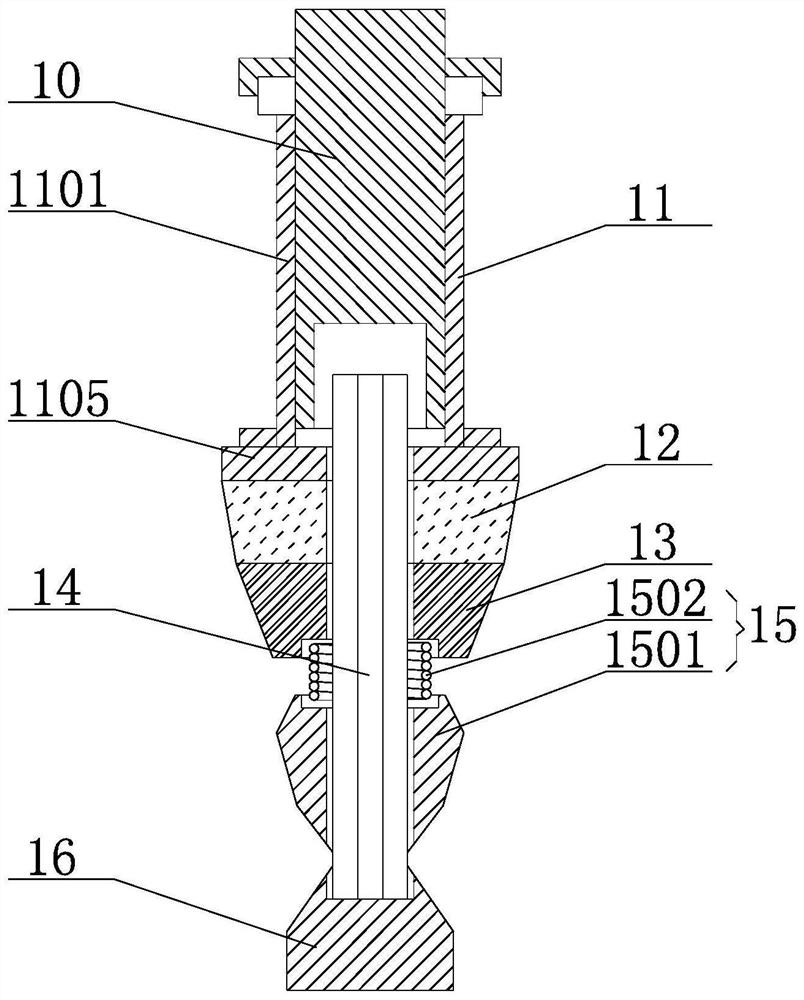

Multifunctional material stirring device

PendingCN109261005AEasy to adjust reachEasy to eradicateTransportation and packagingRotary stirring mixersEngineering

The invention discloses a multifunctional material stirring device which comprises a base. The top of the base is fixedly connected with supporting plates, a stirring barrel is disposed between the supporting plates, the left side and the right side of the stirring barrel are fixedly connected with supporting rods, the top of the base is connected with a supporting seat, the top of the supportingseat is fixedly connected with a hydraulic push rod, a sealing plate is hinged to the top of the hydraulic push rod, the top of the supporting plate is provided with a bearing plate, the top of the bearing plate is provided with a stirring motor, the upper end of a stirring shaft is sleeved with a sliding sleeve, the left side and the right side of the sliding sleeve are symmetrically fixedly connected with cross rods, the two groups of cross rods are provided with hinged seats, a cleaning hairbrush is hinged to the bottom of the hinged seat on the left side, a shoveling blade is hinged to thebottom of the hinged seat on the right side, and water sprayers are symmetrically disposed on the left side and the right side of the bottom of the bearing plate. The multifunctional material stirring device is reasonable in structural design, the cleaning of the stirring device is facilitated, the cleanliness in the stirring device is improved, materials adhering into the stirring device are also removed, and adhering residue of the materials in the stirring device is reduced.

Owner:NANJING GAOZHENG AGROCHEM

Molten steel cleaning agent

PendingCN111876557AImprove qualityReduce energy consumptionProcess efficiency improvementSlagNon-metallic inclusions

The invention discloses a molten steel cleaning agent which is used for removing suspended non-metallic inclusions in molten steel in a molten state and gas dissolved in a metal solution, improving the quality of the molten steel and reducing the slag hole and pore rate of a casting product. The molten steel cleaning agent comprises 70%-80% of cement and 30%-20% of fluorite powder. By adding the molten steel cleaning agent into a furnace, the quality of molten steel can be improved, the slag hole and pore rate of casting products is reduced, and the percent of pass of the casting finished products is greatly increased. Different from the situation that similar products are limited to slagging in a ladle outside a furnace, extra temperature drop is caused by standing of molten steel, and heat is lost, the in-furnace slagging characteristic of the molten steel cleaning agent can reduce furnace wall slag adhesion, lower the furnace wall thickness, improve the induction heating efficiencyand reduce the energy consumption, the use amount of the molten steel cleaning agent is smaller than that of similar products on the market, the capacity of removing gas and inclusions in molten steelis better, the economic benefit is higher, and the molten steel cleaning agent is suitable for wide application and popularization.

Owner:姚玉美

Working lining castable

The invention relates to a working lining castable, in particular to a castable for a ladle lining or a working lining. The technical problem to be solved by the invention is to provide a castable used on a direct lining, in contact with molten iron, of a ladle, wherein the castable comprises the following components in percentage by weight: 8-20 percent of homogenized alumina with size of 12-18mm, 11-15 percent of sintered microporous alumina spinel with size of 8-5mm, 12-15 percent of sintered microporous alumina spinel with size of 5-3mm, 10-15 percent of sintered microporous alumina spinel with size of 3-1mm, 30-35 percent of sintered microporous alumina spinel with size smaller than or equal to 1mm, 0-5 percent of modified magnesia-calcium clinker with size smaller than or equal to 1mm, 1 percent of trichromium dicarbide powder, 3-5 percent of composite gel powder, 1 percent of hydrated alumina micro-powder, 1 percent of pearl-clay powder, 0.5 percent of bismuth germinate powder, 3-5 percent of modified pure calcium aluminate cement, additionally 0.1 percent of C7H10N2O2S, 0.1 percent of C21H14Na2O6S2 and 0.05 percent of 2-morpholineethanesulfonic acid. The working lining castable has the advantages that the high temperature performance and corrosion resisting performance of ladle products can be improved, the thermal shock resistance of the ladle is improved, the service life of the integrally casted ladle working lining is effectively improved, and the service life is improved by more than 30 percent relative to the conventional ladle working lining of the same type.

Owner:江苏泽嘉流体控制有限公司

Alloy material resistant to corrosion of molten aluminum and casting process for alloy material

The invention discloses an alloy material resistant to corrosion of molten aluminum. The alloy material comprises the following components in percentage by weight: 0.40%-0.60% of C, 9%-11% of Cr, 2%-2.5% of Si, 0.7%-1.0% of Mo, 0.7%-3% of W, 0.05%-0.2% of Ti, 0.05%-0.2% of rare earth and the balance of iron and inevitable impurities. According to the alloy material, a novel alloy design thought is adopted, a Ni-free alloy design is adopted, a proper amount of Si, Mo, W and trace Ti and rare earth are added on the basis of medium carbon (0.40%-0.60%) and medium chromium (9%-11%), and smelting, casting and thermal treatment are carried out, so that the alloy material has very high tempering stability and high-temperature hardness, can be used for a long time in the molten aluminum at 620-650 DEG C; and the alloy material has tensile strength greater than or equal to 820MPa, surface hardness greater than or equal to 280HB, and ductility greater than or equal to 18%, and especially has tensile strength greater than or equal to 620MPa and ductility greater than or equal to 21% at a high temperature of 620 DEG C, so that the service life of the alloy material is prolonged by more than once on the basis of a conventional material and the production efficiency is improved.

Owner:JIANGSU HUAYE TECH

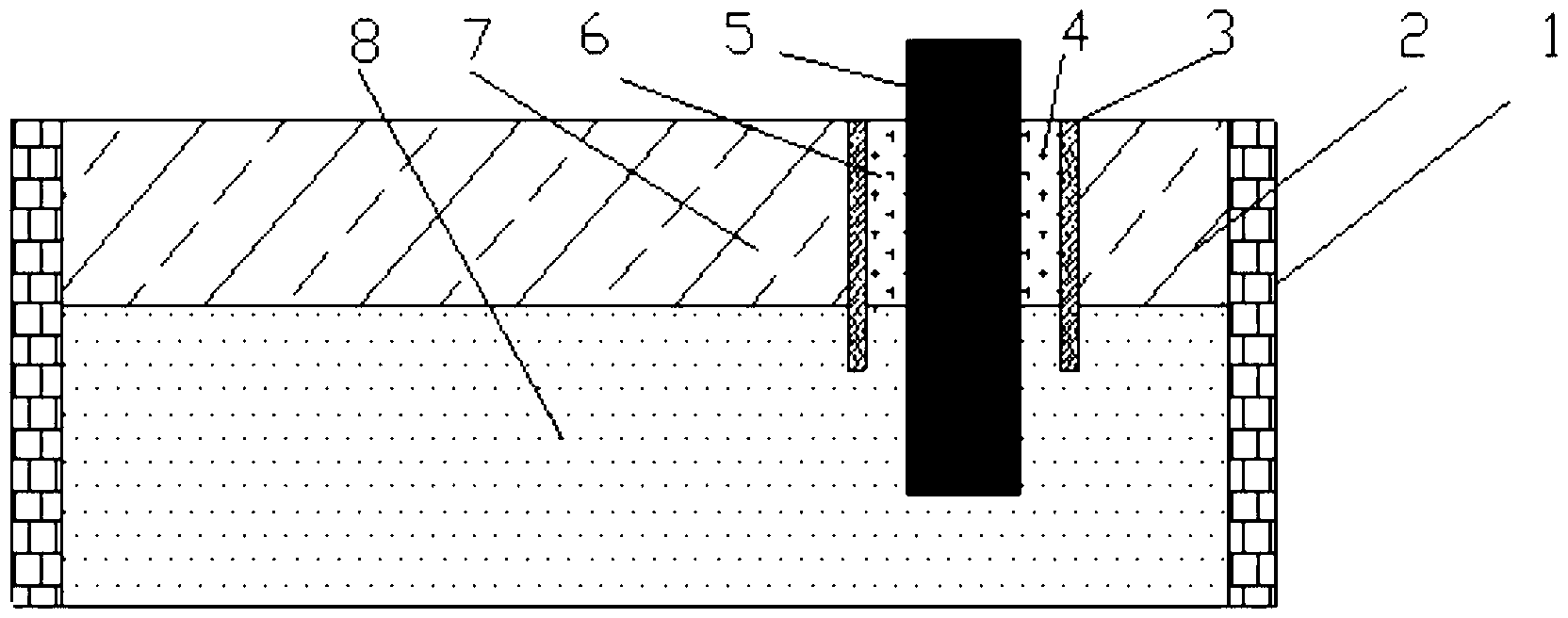

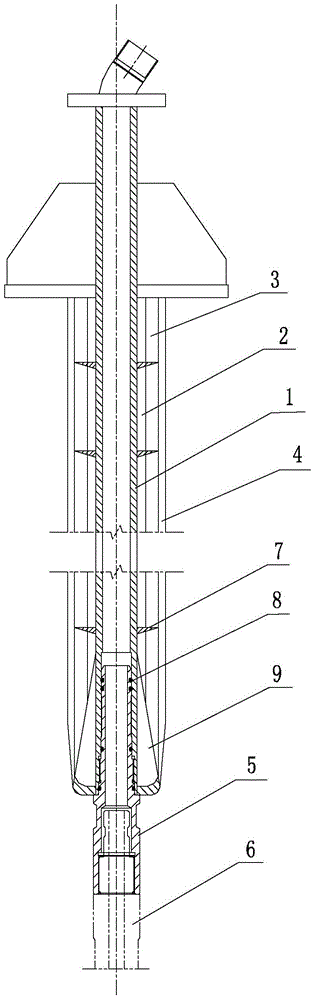

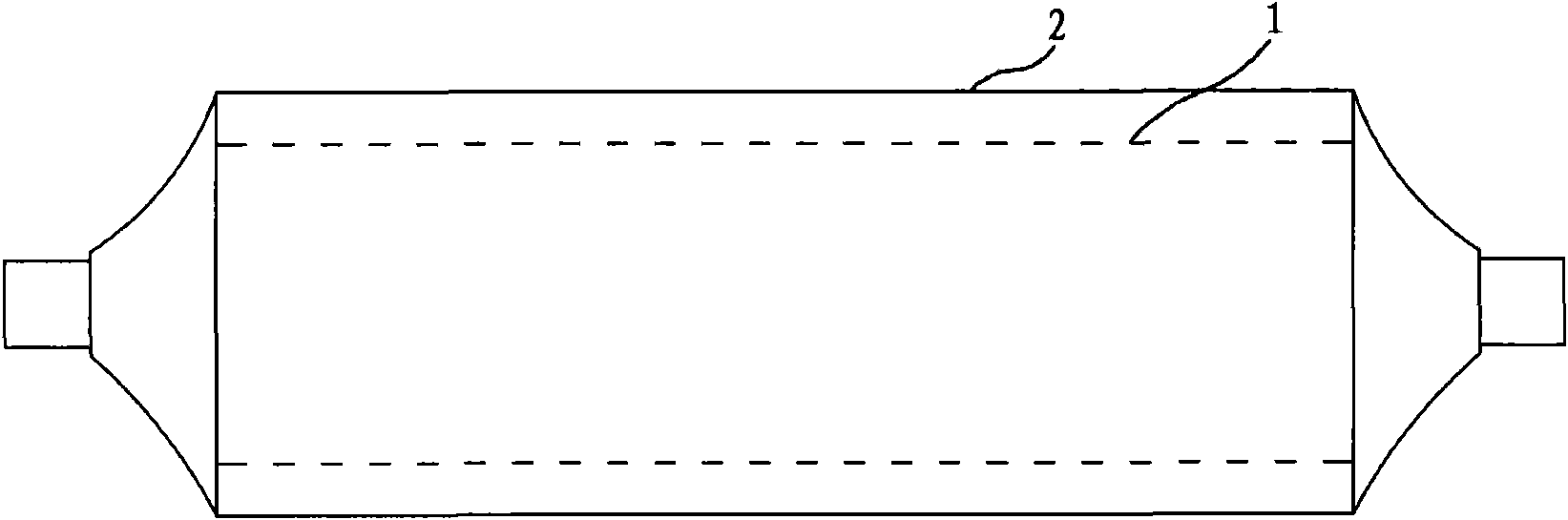

Vacuum circulation degassing insert tube

The invention discloses a vacuum circulation degassing insert tube used for external refining RH devices; an annular groove is disposed on the outer wall of the insert tube; Al2O3-C bricks (4) are disposed in the annular groove. With the characteristic that the Al2O3-C refractory material is not easy to be moisturized by slag, the erosion of the vacuum circulation degassing insert tube caused by slag is reduced, and the purpose of bonded slag reduction is realized; therefore, the service life of the vacuum circulation degassing insert tube is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

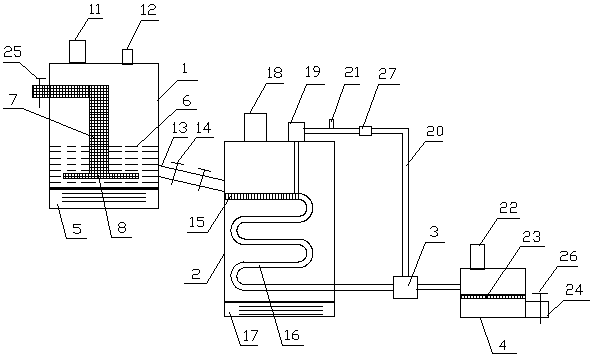

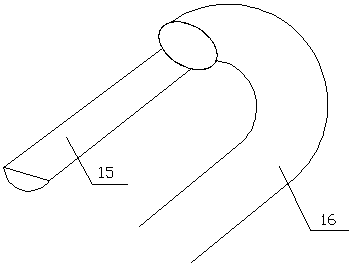

3-chloropropyltrichlorosilane synthesis tail gas treatment mechanism and treatment method thereof

PendingCN108525487AReduce sticky residueAvoid equipment jamsSequential/parallel process reactionsGas treatmentEthanol absorptionDistillation

The invention discloses a harmless treatment mechanism of 3-chloropropyltrichlorosilane synthesis tail gas. The harmless treatment mechanism comprises a reaction chamber, a synthesis chamber, a distillation machine and a neutralization chamber. A treatment method of the 3-chloropropyltrichlorosilane synthesis tail gas comprises the following steps: dissolving and reacting non-condensable gases including trichlorosilane, silicon tetrachloride and propyltrichlorosilane in the 3-chloropropyltrichlorosilane synthesis tail gas by using excess absolute ethyl alcohol absorption liquid under a freezing condition with micro-positive pressure, wherein the non-condensable gases in the 3-chloropropyltrichlorosilane synthesis tail gas after being treated by the process only include hydrogen chloride and purified propylene; adding the non-condensable gases only including hydrogen chloride and purified propylene into the synthesis chamber and carrying out chloride-free treatment; carrying out alcoholysis and hydrolysis of an incompletely-esterified crude product which is the ethyl alcohol absorption liquid after absorbing the non-condensable gases including trichlorosilane, silicon tetrachlorideand propyltrichlorosilane to prepare a polysiloxane product with an additional value. The harmless treatment mechanism is novel in structure; the treatment method is environmentally friendly; the waste can be used and changed into wealth; the economic benefit is improved.

Owner:南京曙光精细化工有限公司

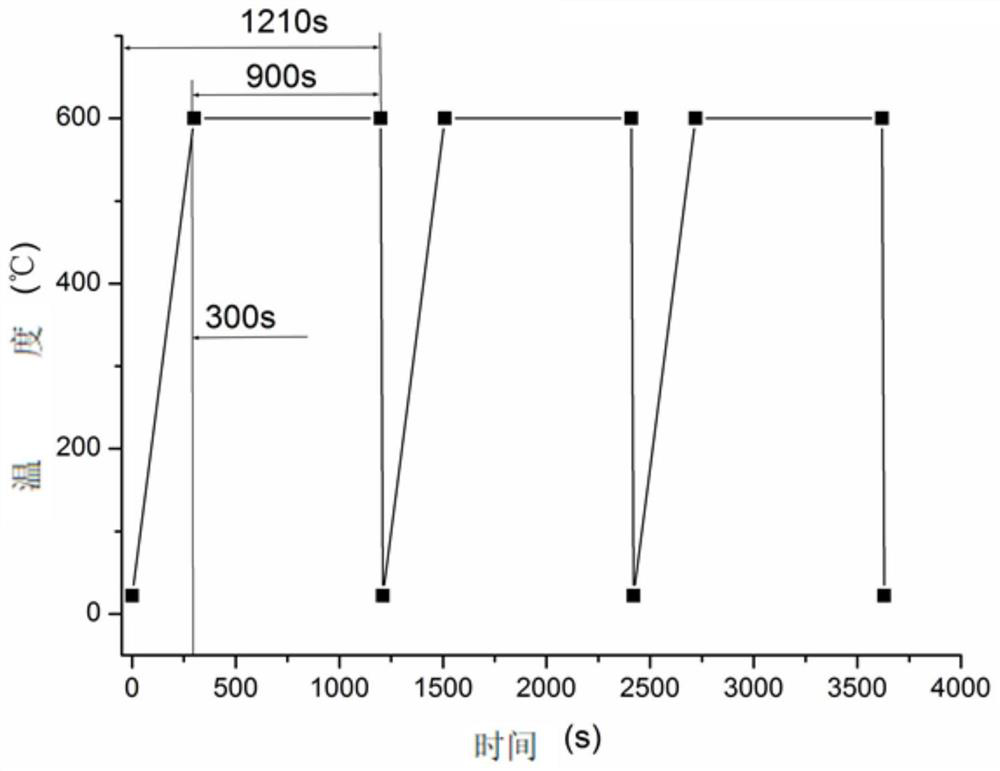

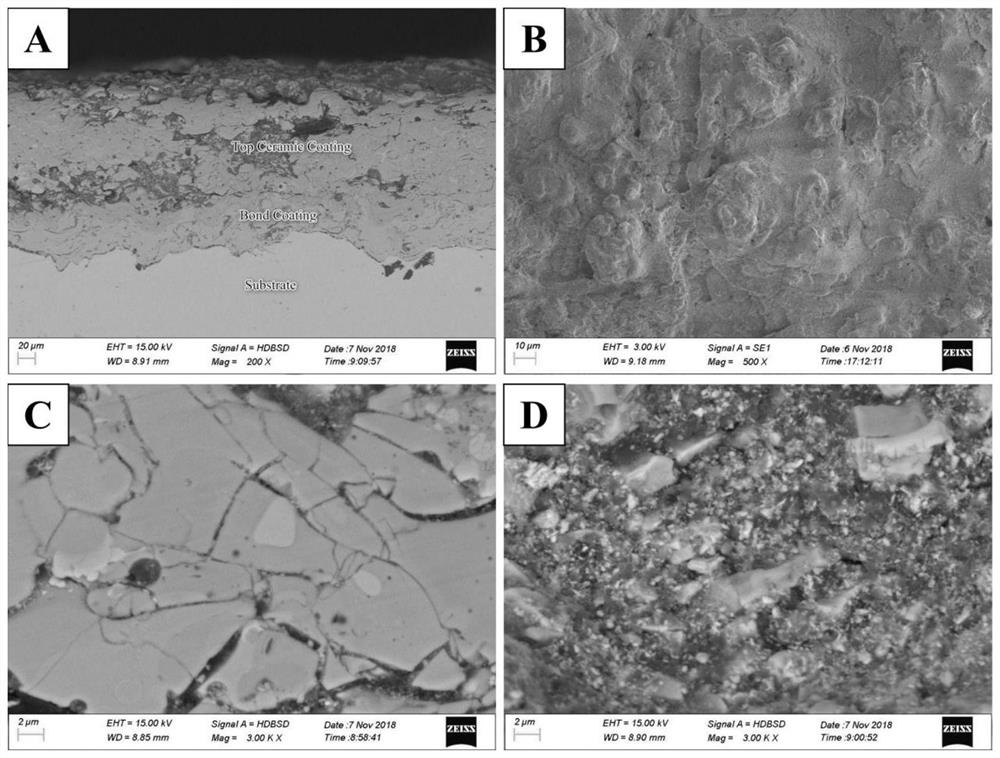

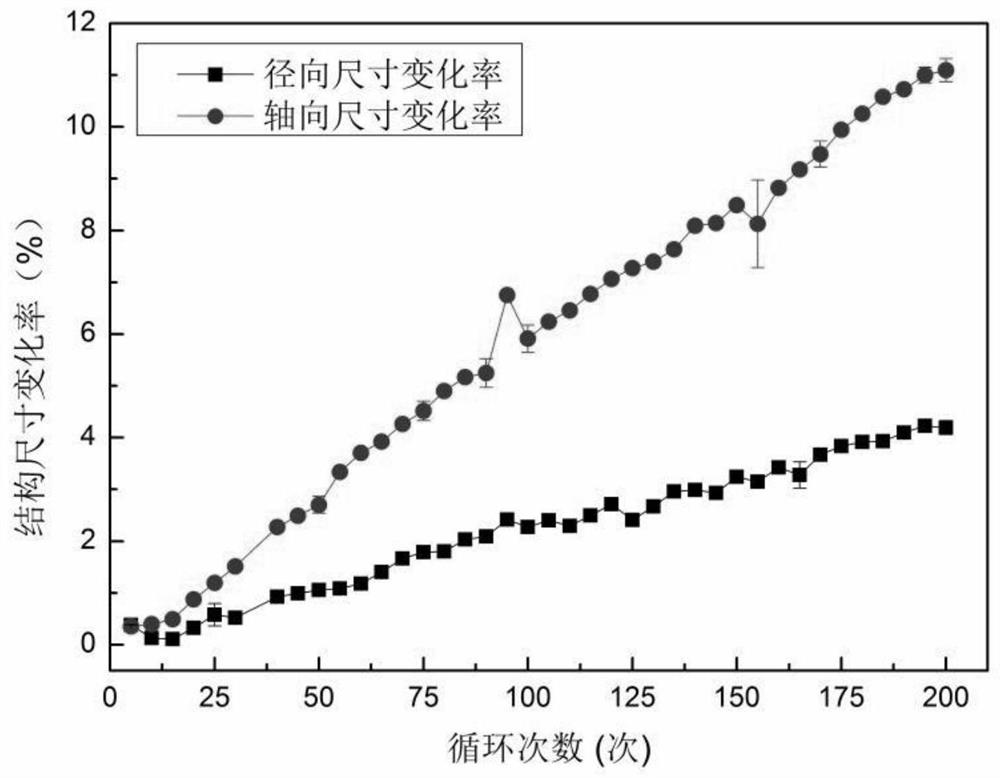

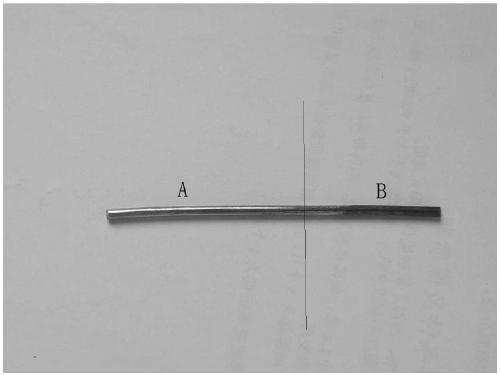

Oxygen lance nozzle end face high-temperature protection coating and preparation method thereof

InactiveCN112593042AReduce sticky residueExtend your lifeMolten spray coatingManufacturing convertersCoated surfaceThermal spraying

The invention discloses an oxygen lance nozzle end face high-temperature protection composite coating and a preparation method thereof. The coating is composed of a bonding layer and a ceramic anti-sticking layer, the bonding layer is a NiCoCrAlY layer sprayed on an oxygen lance nozzle end face base body, and the ceramic anti-sticking layer is a ZrO2-24MgO layer sprayed on the surface of the bonding layer. The preparation method comprises the following steps of grinding and polishing the end surface of an oxygen lance nozzle, conducting ultrasonic cleaning, and conducting drying for later use;conducting sand blasting on the end face of the oxygen lance nozzle, wherein the sand blasting granularity is not larger than 30 meshes; and spraying the NiCoCrAlY layer and the ZrO2-24MgO layer on the end surface of the oxygen lance nozzle by adopting an atmospheric plasma thermal spraying process. According to the preparation method, the oxygen lance nozzle end face high-temperature protection(composite) coating can be successfully constructed through the atmospheric plasma thermal spraying technology, the obtained coating is smooth and flat in surface, high in density and high in bondingstrength with a base body, the service life of the oxygen lance nozzle is remarkably prolonged, and environmental pollution is avoided; and the preparation method of the oxygen lance nozzle end face high-temperature protection (composite) coating is simple, economical and practical, and can be used for industrial production.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND +1

Control method for reducing bonded slag of thermal top cover of vacuum chamber

ActiveCN105063281AReduce slaggingReduce sticky residueProcess efficiency improvementSlagVacuum chamber

The invention discloses a control method for reducing bonded slag of a thermal top cover of a vacuum chamber and belongs to the technical field of metallurgical production equipment control. The control method can effectively reduce the bonded slag of the thermal top cover of the vacuum chamber in the work process of the thermal top cover of the vacuum chamber and includes the following steps that when the vacuum chamber starts to be vacuumized, a relief valve on the thermal top cover of the vacuum chamber is opened and delayed for 400 ms to 600 ms; then, a vacuum valve on the thermal top cover of the vacuum chamber is opened according to a set curve and meanwhile vacuumization is counted and the stop of the relief valve is counted down; and finally, the vacuum valve is closed when the period of vacuumization is ended and the relief valve is opened again to finish the vacuumizing process of the vacuum chamber.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Ladle castable

The invention relates to ladle castable. The use of the castable can reduce the slag adhesion of ladles, improve the yield of hot metal and operation efficiency, and can reduce the maintenance cost for the ladles. The ladle castable comprises the chemical components in percentage by weight: 45 to 60 percent of Al2O3, 30 to 40 percent of SiO2, 5 to 15 percent of ZrO2, less than 1 percent of CaO, and 2 to 5 percent of SiC. The ladle castable is used for integral casting of the ladles.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

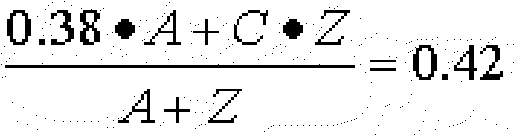

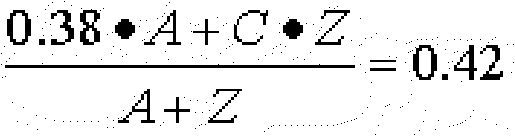

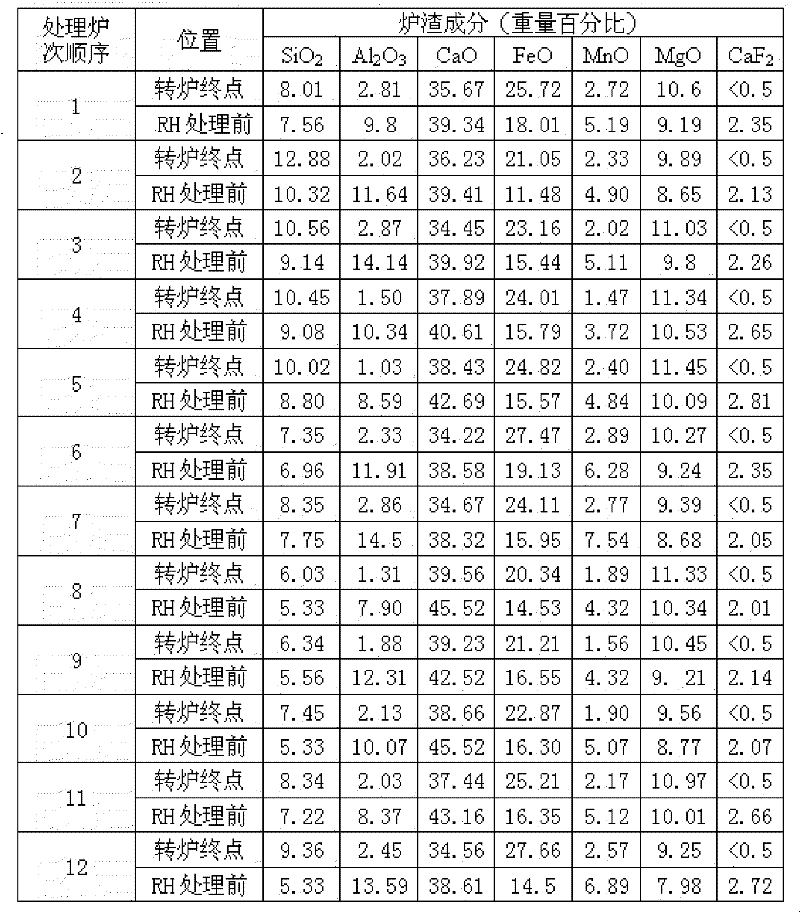

RH decarburization method during ultra-low-carbon steel production process by revolving furnace

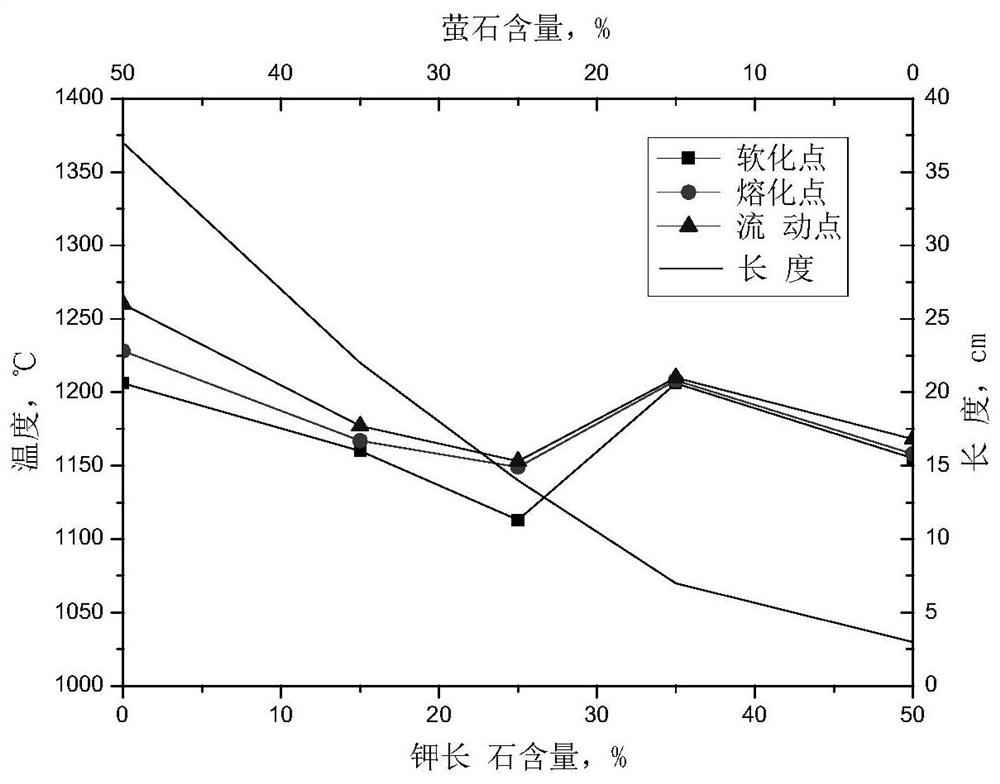

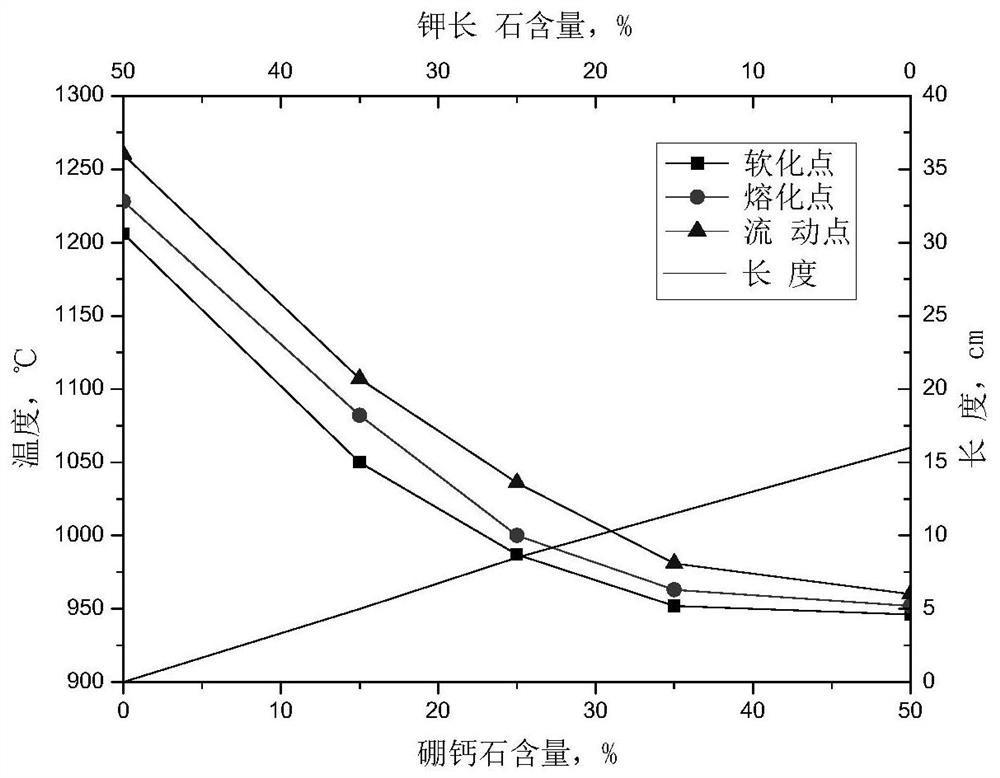

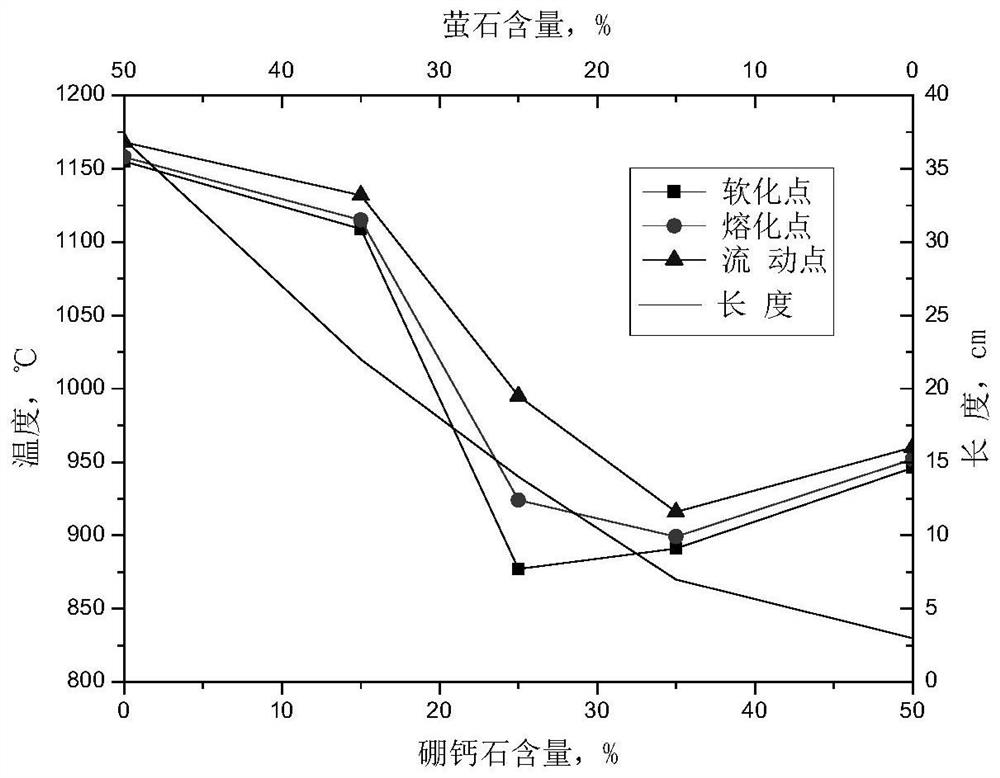

InactiveCN101457281BLow melting pointLow viscosityProcess efficiency improvementChemical compositionSlag

The invention relates to an RH decarburization treatment method in the process of producing ultra low carbon steel by a converter, and belongs to the technical field of ferrous metallurgy. The technical problem to be solved by the invention is that an RH insert tube is prevented from sticking slag in the process of producing the ultra low carbon steel by the converter process. The technical proposal is as follows: chemical compositions of ladle slag in the process of the RH decarburization treatment of the ultra low carbon steel are controlled as follows based on the weight percentages: 5.0-11.0% of SiO2, 40.0-48.0% of CaO, 7.5-15.0% of Al2O3, 7.5-12.0% of MgO, 20.0% of FeO, 7.0% of MnO, Fe2O3, CaF2 and micro constituents such as S, P, TiO2 and the like, thus improving the CaO / Al2O3 ratio and the (CaO / SiO2) / Al2O3 ratio, effectively inhibiting the separation of high-melting point phase of the ladle slag, reducing the melting point and the viscosity of the ladle slag, enhancing the flowability of the ladle slag, lightening the slag sticking of the RH insert tube and increasing the number of furnaces to be continuously treated without slag removal.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

A converter sub-gun body

ActiveCN104513880BGuaranteed cooling effectGuaranteed StrengthManufacturing convertersFlexural strengthUltimate tensile strength

The invention provides a converter sublance body, which includes a center steel pipe. A thermal insulating layer and an asbestos thermal insulating layer are fixedly sleeved on the outer circumferential wall of the center steel pipe from the inside out in order. A composite spray layer is coated outside the asbestos thermal insulating layer, a connecting pipe is inserted into the front end of the center steel pipe, and one connecting pipe end extending out of the center steel pipe is connected to a probe holder for mounting a probe. The converter sublance body provided by the invention can be applied into various types of converter sublance systems to adapt sublance probes with different functions. The multilayer structure of the sublance body ensures the flexural strength of the sublance body and also satisfies the heatproof function, realizes weight reduction of the sublance body under the premise of effective protection of a sensing cable in the sublance body, and reduces cooling water consumption of the converter system, thereby being conducive to optimizing the structure of the sublance system, and reducing energy medium consumption of the sublance system and the production cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Steel (iron) water slag-removing method

ActiveCN100364698CReduce the amount of ironMeet production rhythm requirementsCasting cleaning apparatusSlagLiquid steel

The invention relates to a method for gaining slag in liquid steel (iron), which comprises: first arranging slag catcher at the working position, rotating slag harrow to catch slag; then folding the slag harrow and moving it back with suspending arm or rotating it to discharging position; when completing catching slag, moving slag harrow back with suspending arm or rotating it to the water-cool dipping position, to cool it with water or / and plating. With said invention, the slag harrow has long service life, lower adhered slag on it, short operation time and high efficiency.

Owner:YANTAI SHENGLIDA ENG TECH

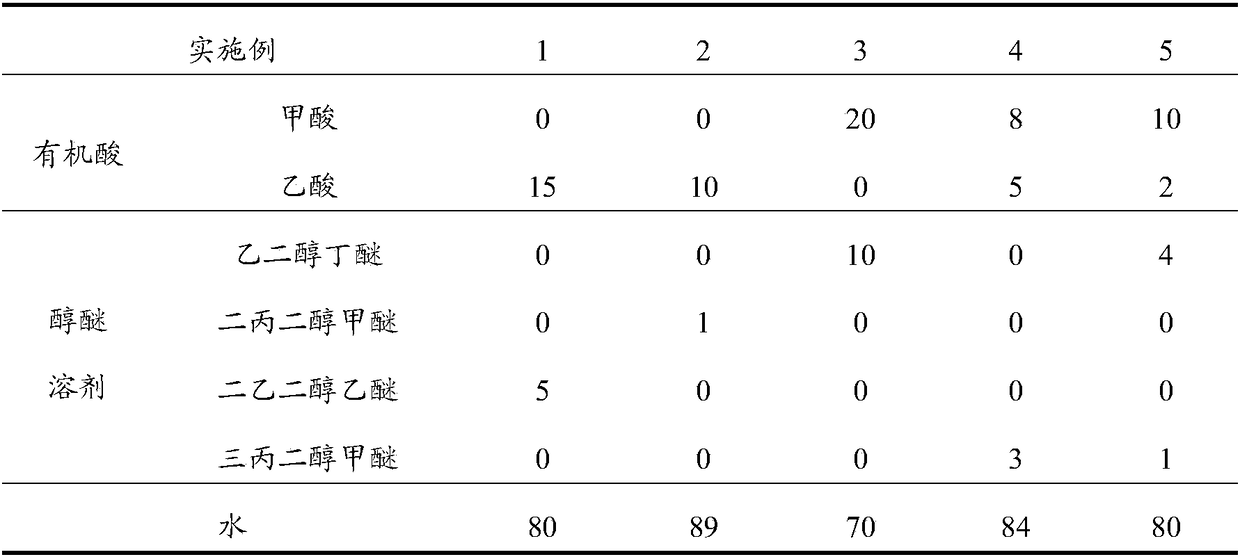

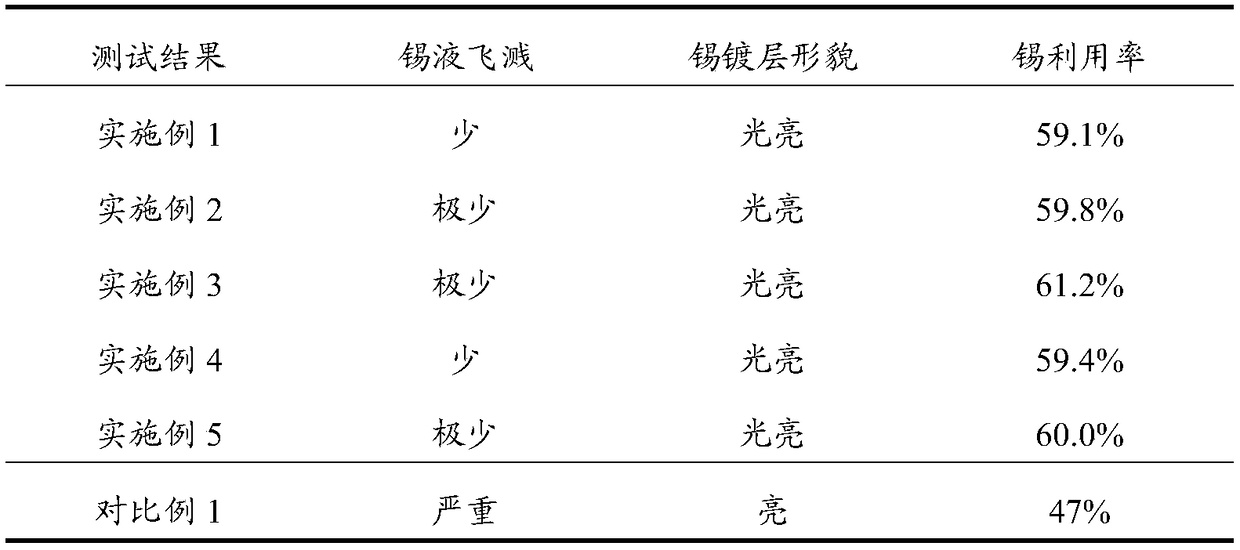

Water-soluble soldering flux and acid washing method of copper product

InactiveCN109267072AFully removedReduce sticky residueHot-dipping/immersion processesSurface treatment compositionsOrganic acidWater soluble

The invention belongs to the technical field of welding auxiliary agents and in particular relates to a water-soluble soldering flux and an acid washing method of a copper product. The water-soluble soldering flux provided by the invention comprises organic acid, an alcohol-ether solvent and de-ionized water. The water-soluble soldering flux takes the organic acid as an active component and oxideand impurities on the surface of a part to the welded can be sufficiently removed under the action of the alcohol-ether solvent; adhesion residues of acidic substances on the surface of the part to the welded can be reduced. In a tin-plating process of the part to the welded, which is treated by the water-soluble soldering flux provided by the invention, splashing of tin liquid can be effectivelyinhibited and the utilization rate of tin is improved.

Owner:WUYI UNIV

A film punching device for pharmaceutical production packaging bags

ActiveCN112025825BNeat and tidy shapeImprove punch qualityEdge grinding machinesGrinding drivesRotation - actionThin membrane

The invention discloses a film punching device for producing packaging bags for medicines, which comprises a punching table, and the bottom of the punching table is fixedly connected with a foot. The invention relates to the field of product packaging production equipment. The film punching device used in the production of pharmaceutical packaging bags produces a rotating action through the downward movement of the rotating tube, and drives the cutting head and the grinding head to deflect, which can cut, clean and polish the burrs on the punching hole wall, and the inner wall of the hole after punching The shape is more standardized and tidy. The wall of the hole pierced by the punch is pre-expanded through the pressure relief device, which delays and reduces the impact wear of the cutting head, reduces the deformation of the punching hole, and enables the cutting head to better meet the tangential direction of rotation. Cutting towards the punching burr, while passivating the top and bottom edges of the punching hole, to avoid scratching the operator in subsequent operations. This solves the problems that burr edges are easily produced on the inner wall of the punched hole of the existing film, the punched hole is easily deformed, and the sharp inner wall of the hole affects assembly.

Owner:ZIBO HUA ZHI LIN PACKING PROD CO LTD

A kind of alloy material and its casting process resistant to molten aluminum zinc liquid corrosion

ActiveCN105506491BHigh temperature strength and hardnessMeet wear resistance requirementsRare earthAlloy

The invention discloses an alloy material resistant to corrosion of molten aluminum. The alloy material comprises the following components in percentage by weight: 0.40%-0.60% of C, 9%-11% of Cr, 2%-2.5% of Si, 0.7%-1.0% of Mo, 0.7%-3% of W, 0.05%-0.2% of Ti, 0.05%-0.2% of rare earth and the balance of iron and inevitable impurities. According to the alloy material, a novel alloy design thought is adopted, a Ni-free alloy design is adopted, a proper amount of Si, Mo, W and trace Ti and rare earth are added on the basis of medium carbon (0.40%-0.60%) and medium chromium (9%-11%), and smelting, casting and thermal treatment are carried out, so that the alloy material has very high tempering stability and high-temperature hardness, can be used for a long time in the molten aluminum at 620-650 DEG C; and the alloy material has tensile strength greater than or equal to 820MPa, surface hardness greater than or equal to 280HB, and ductility greater than or equal to 18%, and especially has tensile strength greater than or equal to 620MPa and ductility greater than or equal to 21% at a high temperature of 620 DEG C, so that the service life of the alloy material is prolonged by more than once on the basis of a conventional material and the production efficiency is improved.

Owner:JIANGSU HUAYE TECH

Vacuum circulation degassing insert tube

The invention discloses a vacuum circulation degassing insert tube used for external refining RH devices; an annular groove is disposed on the outer wall of the insert tube; Al2O3-C bricks (4) are disposed in the annular groove. With the characteristic that the Al2O3-C refractory material is not easy to be moisturized by slag, the erosion of the vacuum circulation degassing insert tube caused by slag is reduced, and the purpose of bonded slag reduction is realized; therefore, the service life of the vacuum circulation degassing insert tube is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Sink roller and stabilizing roller

InactiveCN101597730BImprove corrosion resistanceImprove wear resistanceHot-dipping/immersion processesSlagWaste product

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

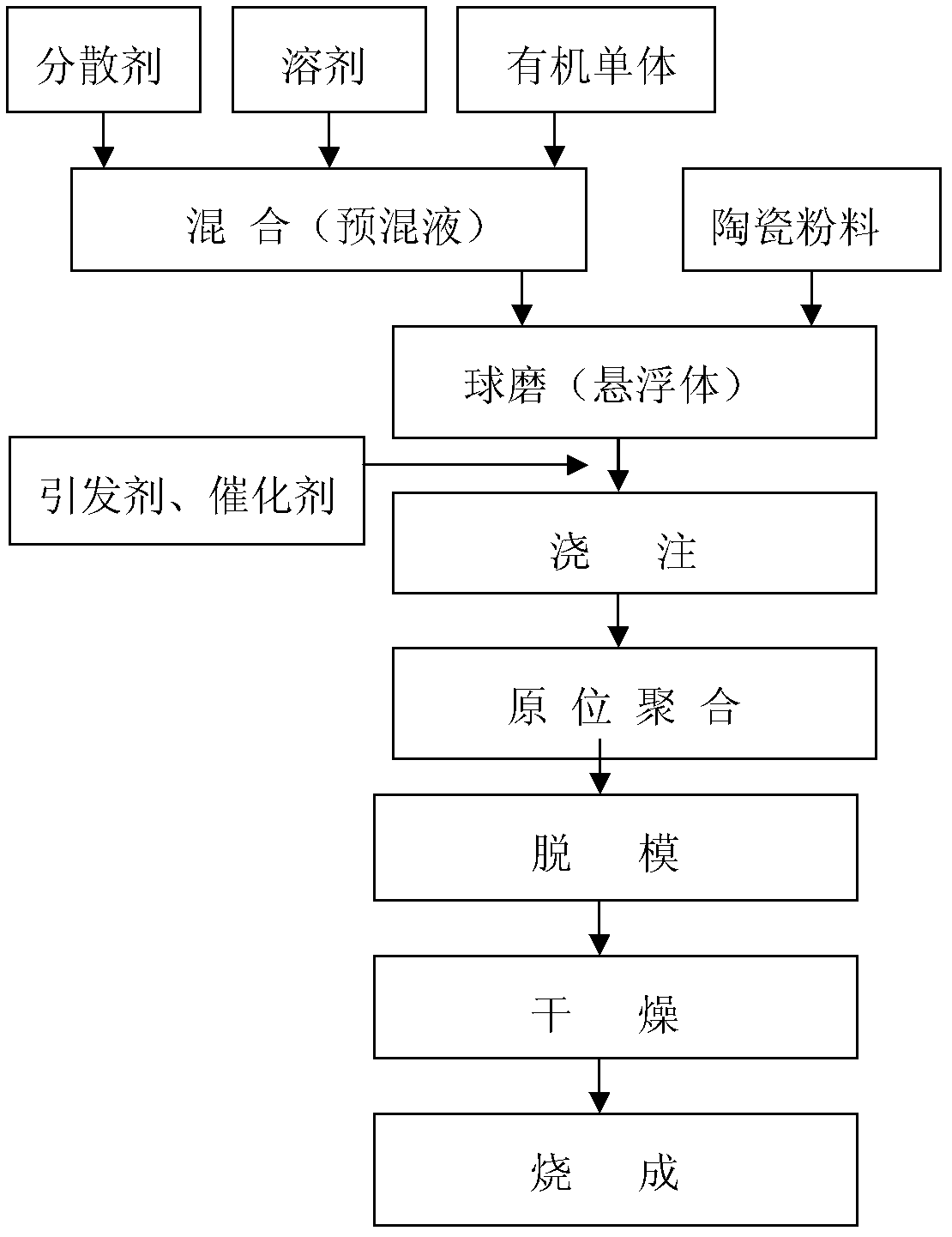

Method for manufacturing specially-shaped sprue cup by colloidal forming

The invention discloses a method for manufacturing a specially-shaped sprue cup by colloidal forming, which is designed for solving the technical problems that the quality and the like of the product are severely affected for the reason that the conventional sprue cup pressed and formed by a press is very high in cost, low in strength, severely worn due to being pressed by a steel mould for a long time and capable of introducing a plurality of impurities on the mould. The method adopting a gel-casting process comprises the following steps of: preparing a gel-casting monomer solution; adding a hard clay refractory material to the monomer solution for uniformly mixing to obtain a stable sizing agent; adding a catalyst and an initiator to the stable sizing agent; degassing under vacuum; pouring ceramic slurry to a mould; enabling the monomer and the cross-linking agent to completely react under the set temperature to obtain a ceramic biscuit; and drying and sintering the ceramic biscuit to obtain a precision-casting sprue cup product. The sprue cup manufactured by the method disclosed by the invention is high in strength, scouring resistant, good in thermo-plasticity under high temperature, less in bonded slag, and higher in quality than the sprue cup manufactured by the conventional method, and has the fire-resistant degree of 1670 DEG C to 1770 DEG C.

Owner:LIAONING SILICATE RES INST

Molten iron slag modifier

The invention relates to a molten iron slag modifier which comprises the following chemical components in percentage by weight: 10.0 to 20.0% of CaO; 0 < = SiO2 < = 8.0%; 25.0 to 35.0% of B2O3; 25.0 to 35.0 % of CaF2; S< = 0.05%; LOI < = 15.0%; wherein the particle size of the molten iron slag modifier is smaller than or equal to 3.0 mm, and the part of the molten iron slag modifier with the particle size being smaller than 0.1 mm does not exceed 10% by weight. The molten iron slag modifier disclosed by the invention is used for modifying the slag adhesion of the blast furnace 'glass slag ', eliminating or reducing the adverse effects of the blast furnace 'glass slag' on the desulfurization efficiency and stability of molten iron and the removal property of desulfurization slag, and reducing nodulation and slagging of a ladle, a slagging-off plate, a KR stirring paddle and the like; the problem of molten steel resulfurization caused by bringing desulfurized slag into the converter along with desulfurized molten iron is reduced; and the service lives of the ladle, the slagging-off plate, the KR stirring paddle and the like are prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

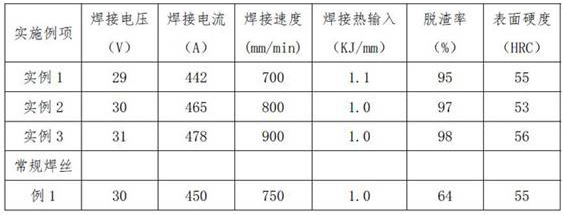

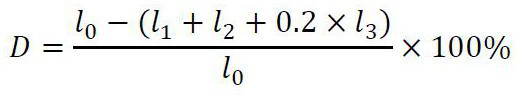

A kind of high-niobium flux-cored welding wire used for hard surface repair of roller press and preparation method thereof

ActiveCN114289926BEasy to peelReduce generationWelding/cutting media/materialsProcess efficiency improvementNiobiumMolten slag

The invention relates to a high-niobium flux-cored welding wire used for repairing the hard surface of a roller press and a preparation method thereof, and relates to the field of welding technology, including a flux core and a steel strip, and the steel strip covers the flux core; wherein the flux core contains a weight ratio 20% to 35% oxide, 10% to 30% fluoride by weight, 2% to 5% kyanite powder by weight, and 10% to 15% carbonate by weight , Calcium sulfide with a weight ratio of 1% to 4% and a metal alloy including ferroniobium with a weight ratio of 30% to 45%; the steel strip adopts a cold-rolled SPCC low-carbon steel strip, and the present invention has the advantages of adjusting the flux core of the welding wire The advantages of improving the slag detachability of the flux-cored wire are to improve the physical and chemical properties of the slag, the coefficient of linear expansion, and the microscopic appearance of the slag.

Owner:北京奥邦新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com