Steel (iron) water slag-removing method

A technology of molten iron and molten steel, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing production costs, reducing production efficiency, time-consuming and labor-intensive, etc., and achieves the effects of saving paint, easy cleaning, and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

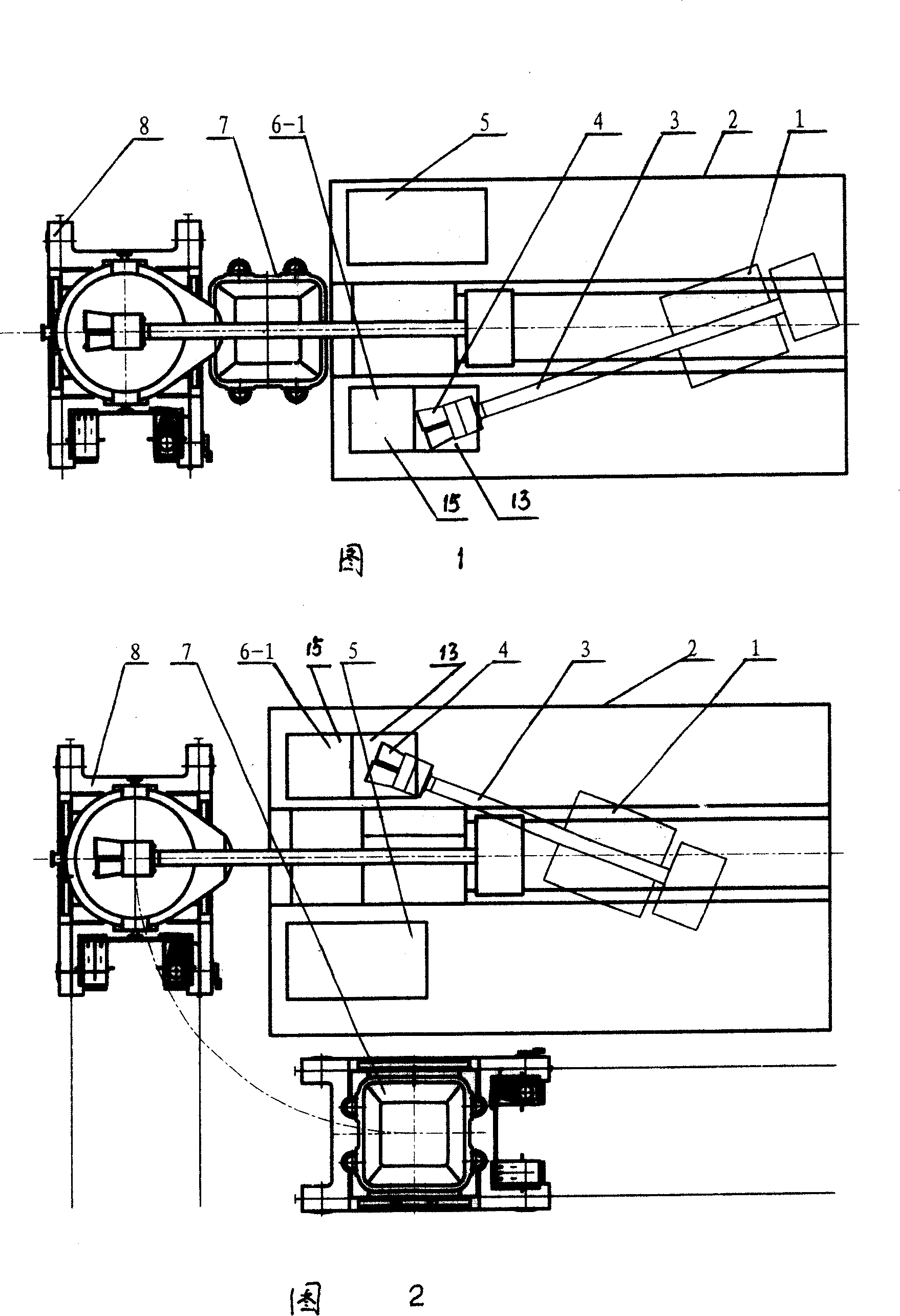

[0018] As shown in Figure 1, firstly, make the slag removing machine 1 be at the slag removing position, that is, the slag rake 4 is located at the molten steel or molten iron bag position 8, and implement the slag rake rotation to remove slag; Back to the slag unloading station, that is, the slag rake 4 is located at the slag hopper position 7, and the slag is unloaded; the above two steps are carried out alternately.

[0019] After a ladle of molten steel or molten iron is slag removed, the slag rake 4 is rotated with the cantilever 3 to the water-cooling dip-coating station 6-1, and the water-cooling or dip-coating or water-cooling+dip-coating operation of the slag rake 4 is implemented. Wherein, the water cooling is carried out in the cooling pool 15, and the dip coating is carried out in the coating pool 13.

Embodiment 2

[0021] As shown in Figure 2, firstly, make the slag removing machine 1 be at the slag removing position, that is, the slag rake 4 is located at the molten steel or molten iron bag position 8, and implement the slag rake rotation to remove slag; Rotate to the slag unloading station, that is, the slag rake 4 is located at the slag hopper position 7, and the slag is unloaded; the above two steps are carried out alternately.

[0022] After a ladle of molten steel or molten iron is slag removed, the slag rake 4 is rotated with the cantilever 3 to the water-cooling dip-coating station 6-1, and the water-cooling or dip-coating or water-cooling+dip-coating operation of the slag rake 4 is implemented. Wherein, the water cooling is carried out in the cooling pool 15, and the dip coating is carried out in the coating pool 13.

Embodiment 3

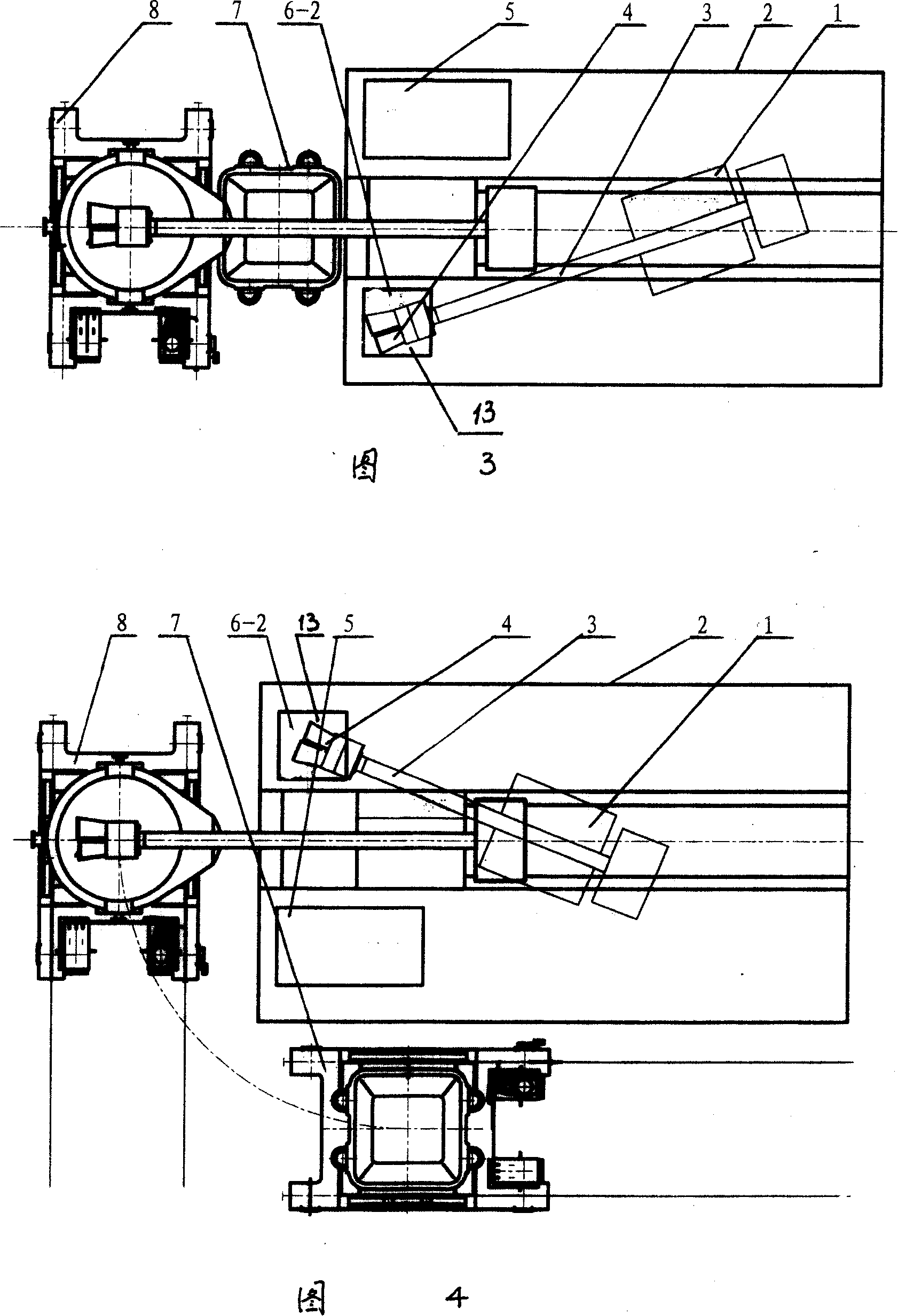

[0024] As shown in Figure 3, firstly, make the slag removing machine 1 in the slag removing position, that is, the slag rake 4 is located at the molten steel or molten iron ladle position 8, and implement the slag rake rotation to remove slag; Back to the slag unloading station, that is, the slag rake 4 is located at the slag hopper position 7, and the slag is unloaded; the above two steps are carried out alternately.

[0025] After a ladle of molten steel or molten iron is slag removed, the slag rake 4 is rotated with the cantilever 3 to the dip coating station 6-2, and the slag rake 4 is dip-coated in the coating pool 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com