Melted iron desulfuration pretreatment furnace slag modifier and method for making same

A technology for desulfurization and modifier of molten iron, applied in the field of molten iron pretreatment, can solve problems such as limited modification ability and incompatibility, and achieve the effects of reducing iron content, iron loss, and viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The hot metal desulfurization pretreatment slag modifier is formulated and processed from glass powder, potassium feldspar, fluorite and soda; its chemical composition (weight%) satisfies: SiO 2 50%, CaF 2 19%, Al 2 o 3 3%, CaO 3% and K 2 O+Na 2 O 24%.

[0028]In order to realize that the modifier melts evenly on the molten iron desulfurization pretreatment slag, and give full play to the various functions of the desulfurization slag modifier, the modifier of the present invention is prepared by the following process: first, the raw materials glass powder, potassium feldspar, The chemical composition of fluorite and soda; secondly, according to the above chemical composition, calculate the weight of the required raw materials; then melt the above-mentioned proportionally weighed raw materials in the submerged arc furnace, and cool naturally after being released from the furnace; crushing and processing to 200 mesh; Add the crushed raw materials into the pan gran...

Embodiment 2

[0037] The chemical composition (weight %) of molten iron desulfurization pretreatment slag modifier is: SiO 2 52%, CaF 2 18%, Al 2 o 3 4%, CaO 4% and K 2 O+Na 2 O 21%. Its preparation method is with embodiment 1.

[0038] The composition and weight of the molten iron in the hot metal tank, the amount of slag in the hot metal tank before desulfurization, the adding method and the adding amount are all the same as in Example 1.

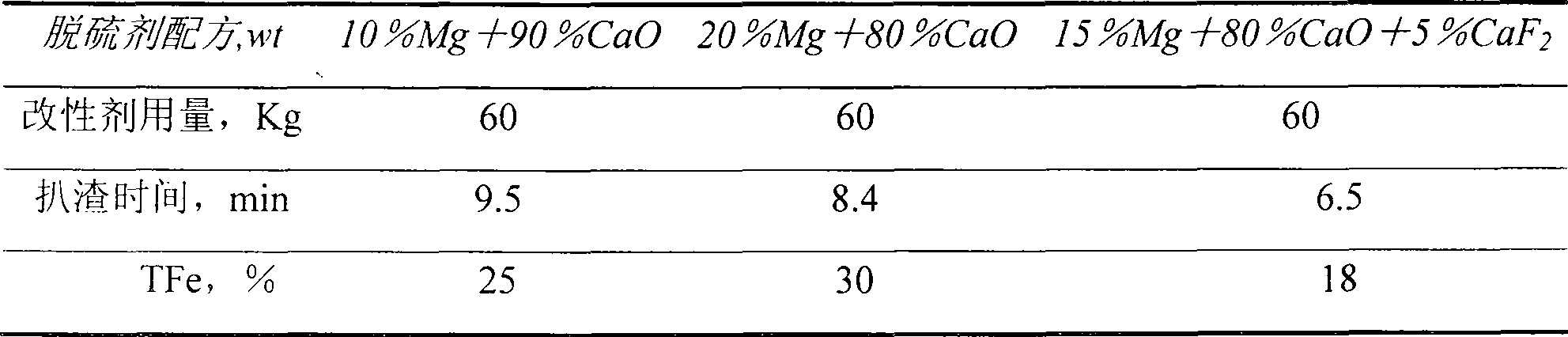

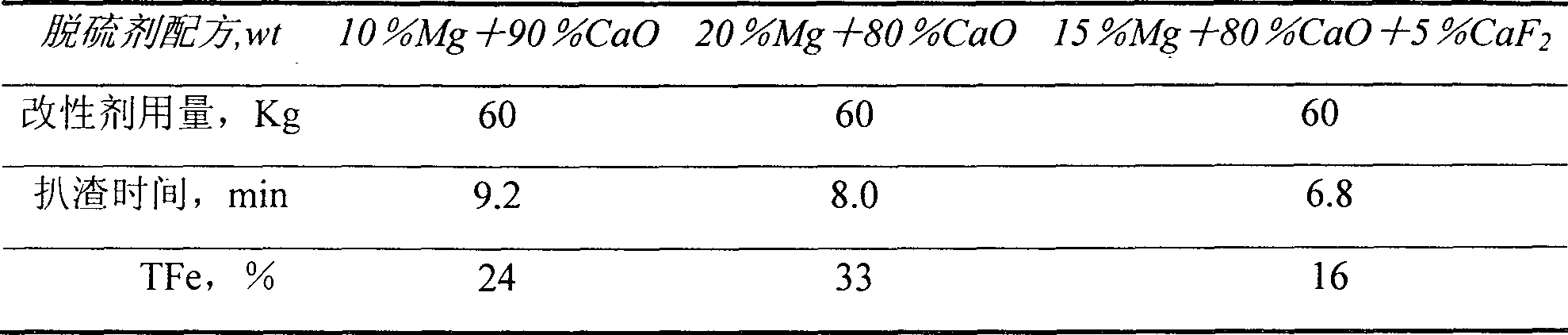

[0039] The modification effect of desulfurization slag after injection of different desulfurizers is shown in Table 3:

[0040] Table 3 Modification effects of modifiers on slag after desulfurization using different desulfurizers

[0041]

[0042] In Table 3, on the basis of Example 1, the formula of the modifier for hot metal desulfurization pretreatment slag is changed, and the modification effect of the modifier on the slag after desulfurization by different desulfurizers is the same as that in Table 2.

Embodiment 3

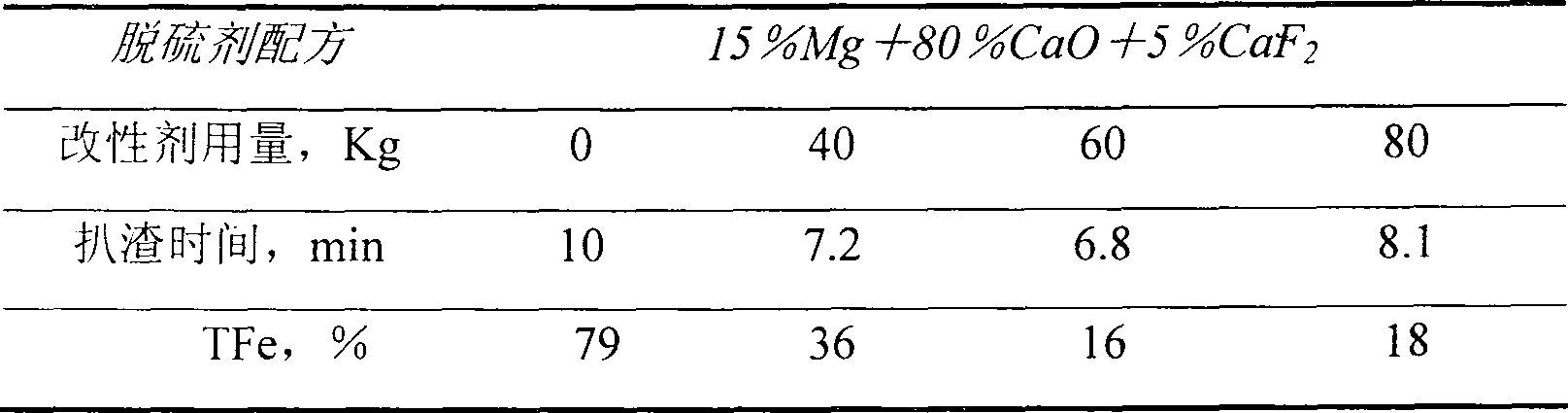

[0044] The chemical composition of the molten iron desulfurization pretreatment slag modifier is as in Example 1, and the desulfurizer in this example is the same, and its formula is 15%Mg+80%CaO+5%CaF 2 ; Except that the consumption of the molten iron desulfurization pretreatment slag modifier that adds in every heat ladle is different, other conditions are identical with embodiment 1.

[0045] See Table 4 and Table 5 for the modification effect of desulfurization slag when the amount of modifier is different:

[0046] Table 4 Modification effect of desulfurization slag with different modifier dosage

[0047]

[0048] According to the above examples, after adding the molten iron desulfurization pretreatment slag modifier, the separation of slag and iron is better, the slag and iron are easy to remove, and the slag removal time is reduced, which ultimately leads to a reduction in process time and process temperature drop. Therefore, after adding the hot metal desulfurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com