Protective casting method for feeding steel strips into crystallizer

A technology for protecting pouring and crystallizer, which is applied in the field of continuous casting, and can solve problems such as easy solidification of mold slag, low sleeve temperature, unfavorable protection pouring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

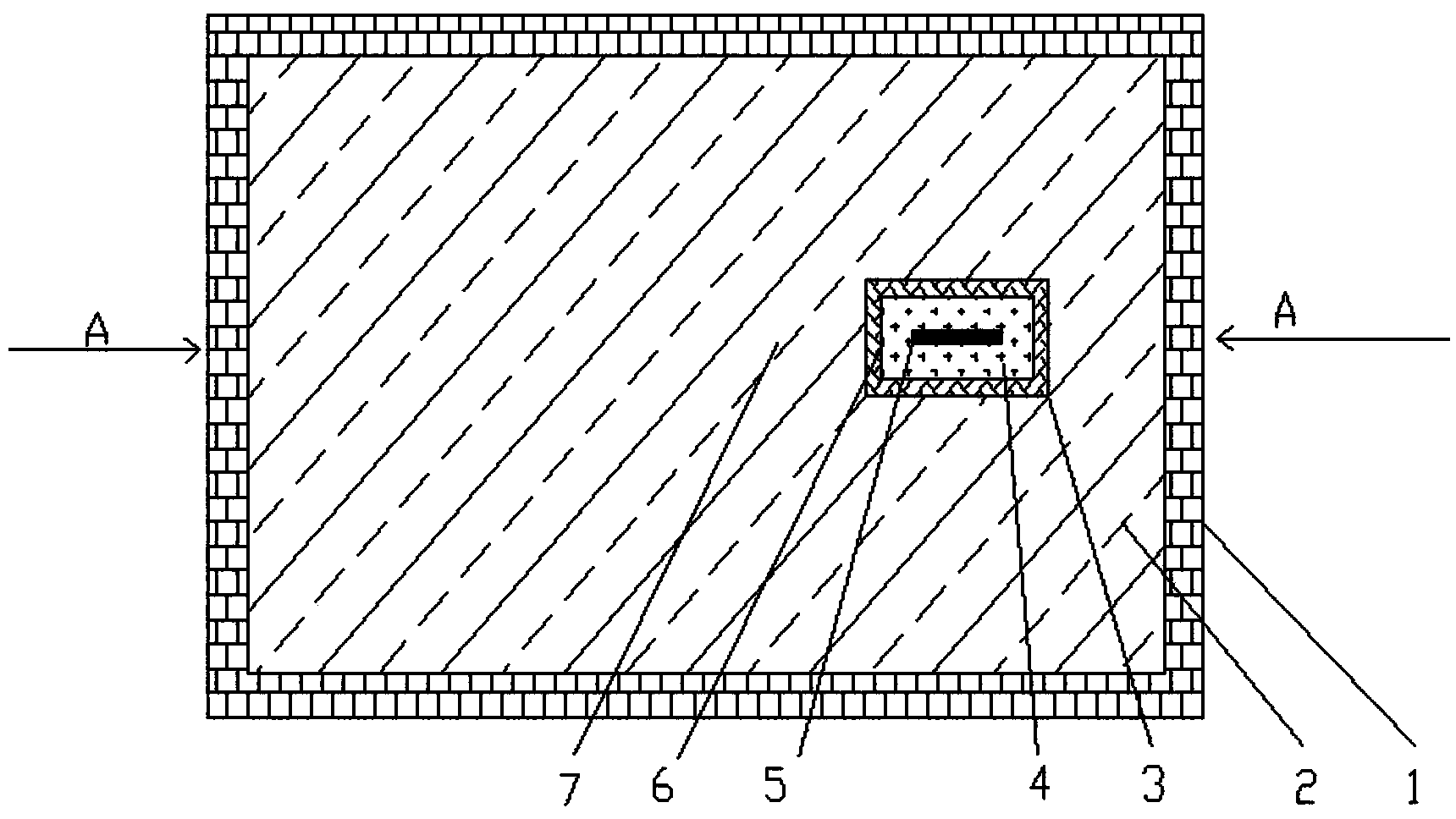

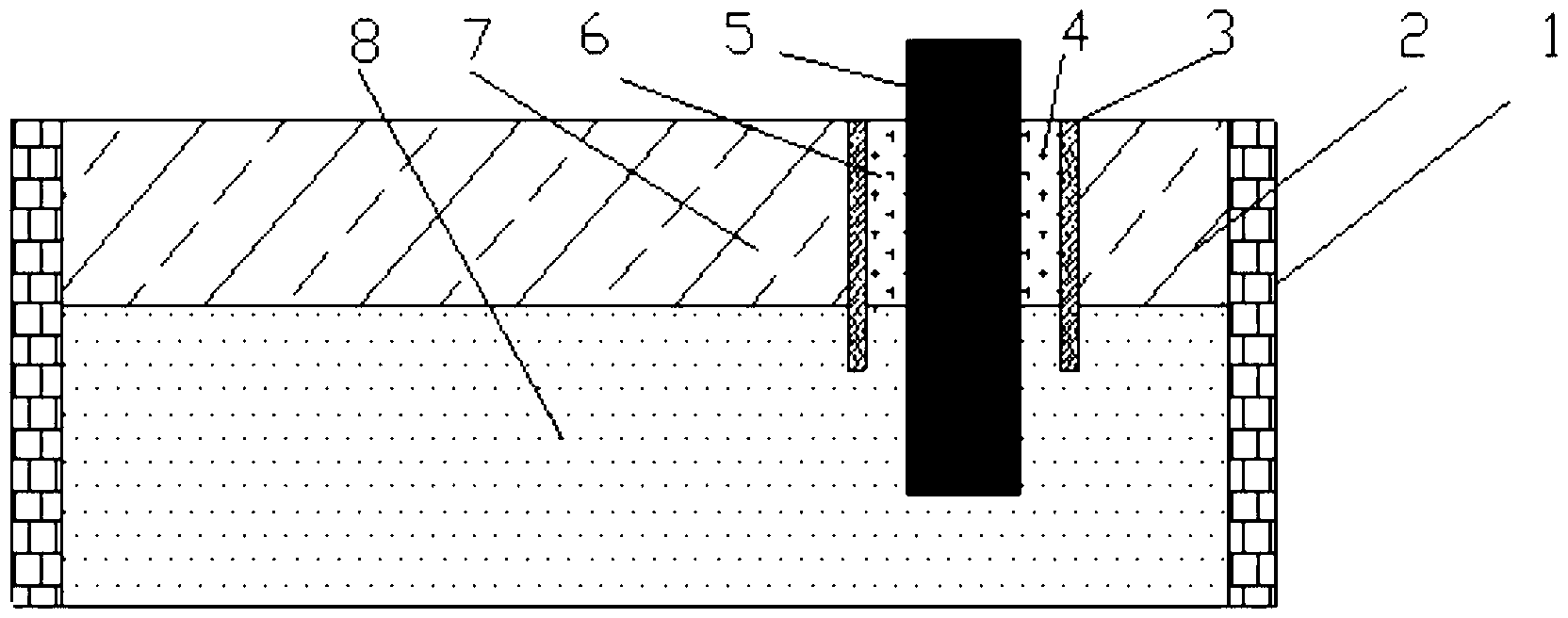

[0028] Such as figure 1 with figure 2 As shown, molten steel 8 is housed in the crystallizer 1, and the baffle plate 3 divides the crystallizer 1 into a rectangular feeding area 6 and an ordinary area 7. Feeding zone 6 uses low melting point slag 4 , and common zone 7 uses common mold slag 2 . Since the low-melting point slag 4 in the feeding area 6 has a low melting point, is easy to melt, and has a low viscosity, when the feeding steel strip 5 is added to the molten steel 8, defects of slag inclusion can be reduced.

[0029] When the steel strip is fed to the mold, ordinary mold slag is added to the common area, and casting slag with a melting point lower than the ordinary mold slag is added to the feeding area. The cast steel type is Q345B, the width of the mold feeding steel strip is 10-20% of the mold width, the thickness is 0.1-1% of the mold length, and the feeding speed is 0.3-0.6m / s. The material of the baffle used is the same as that of the submerged nozzle, both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com