Molten iron slag modifier

A modifier and hot metal slag technology, applied in the field of hot metal slag modifier, to achieve the effects of easy removal, improved desulfurization efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

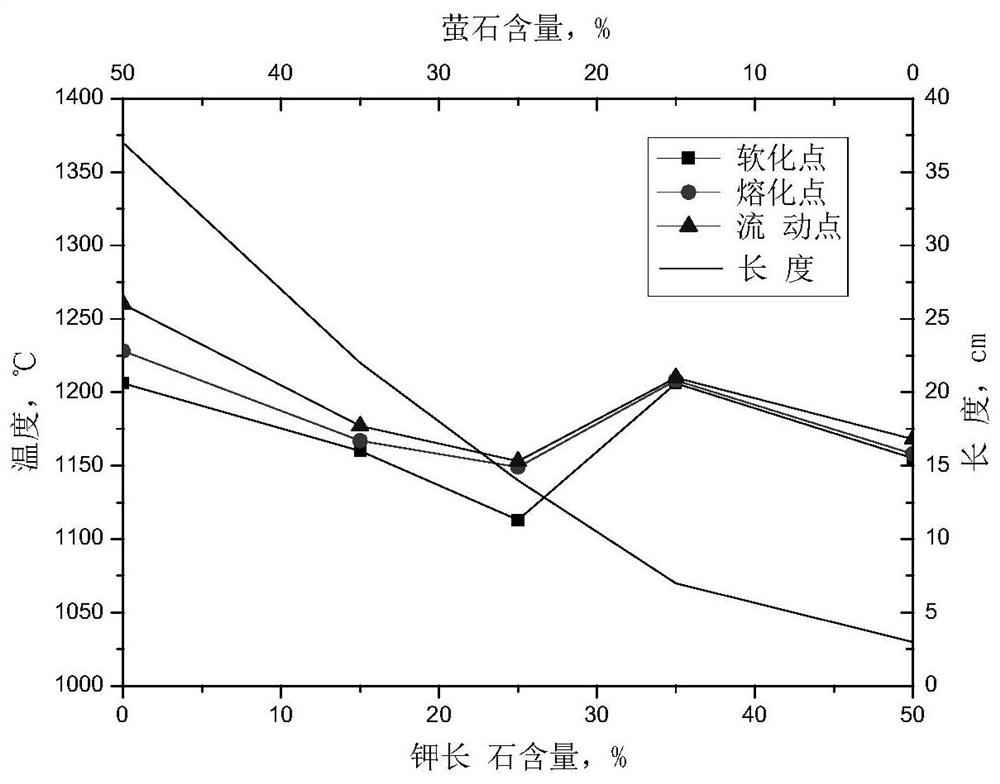

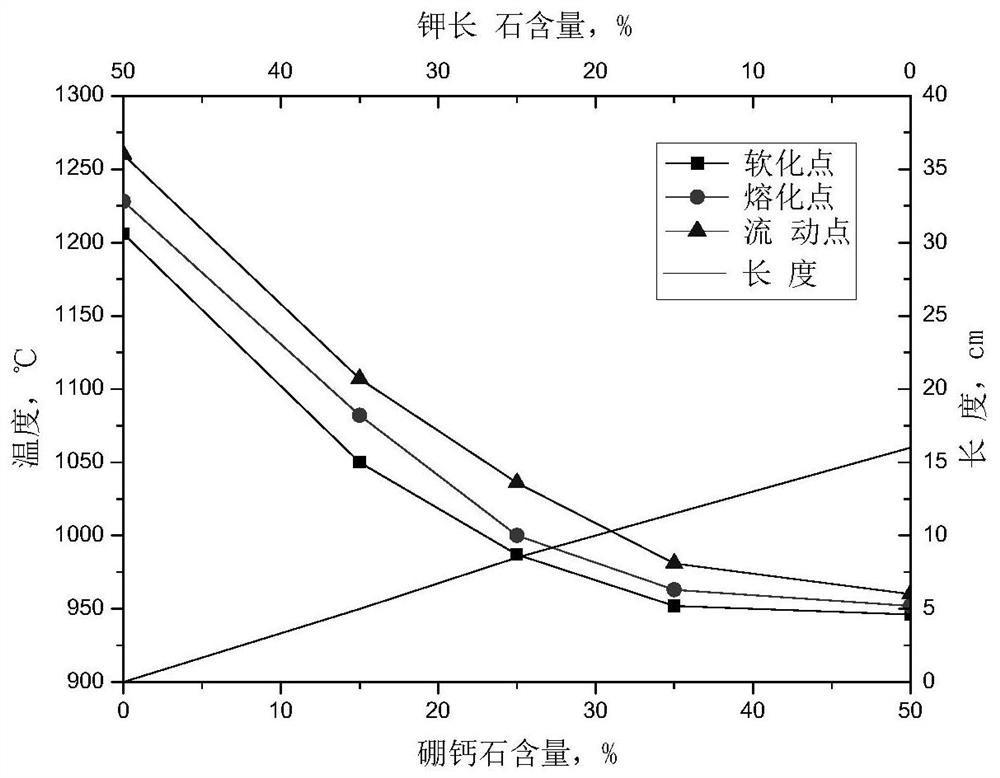

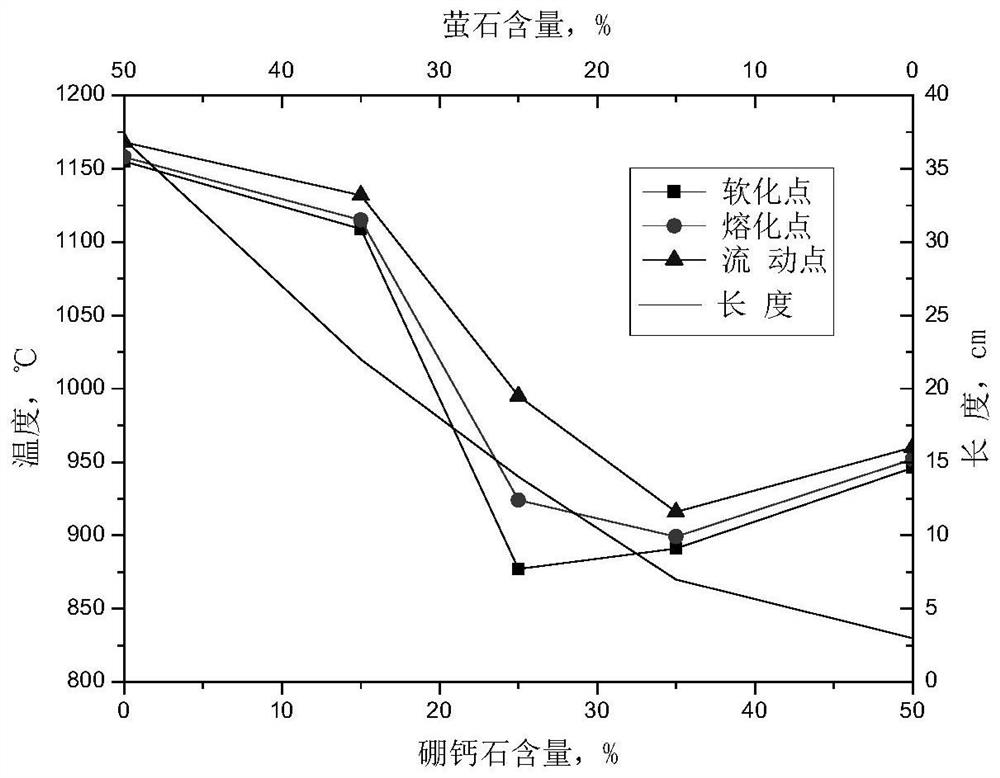

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with embodiment.

[0053] Refer to Table 6 for the composition of the embodiment of the molten iron slag modifier of the present invention.

[0054] Table 6 Unit wt%

[0055] Example CaO SiO 2

[0056] Pretreatment and desulfurization of KR hot metal in a steelmaking plant. Steel numbers 558815, 658819, 658822, and 659396A were found to be sticky slag. The operator added 100kg / package of these treatments at the end of the front pickling. The iron slag modifier of the invention. The sulfur analysis results after treatment are all 5ppm, and there is no sticky slag in the slag after desulfurization, and there is no sticky slag on the ladle and stirring paddle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com