Environmentally-friendly acrylate structural adhesive and preparation method thereof

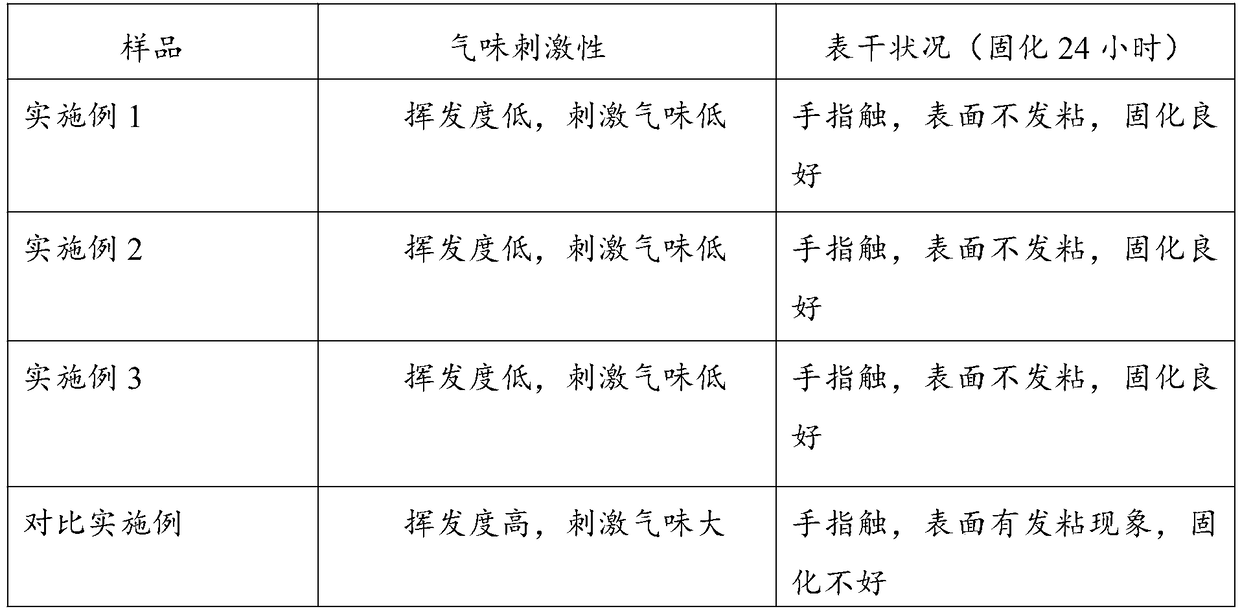

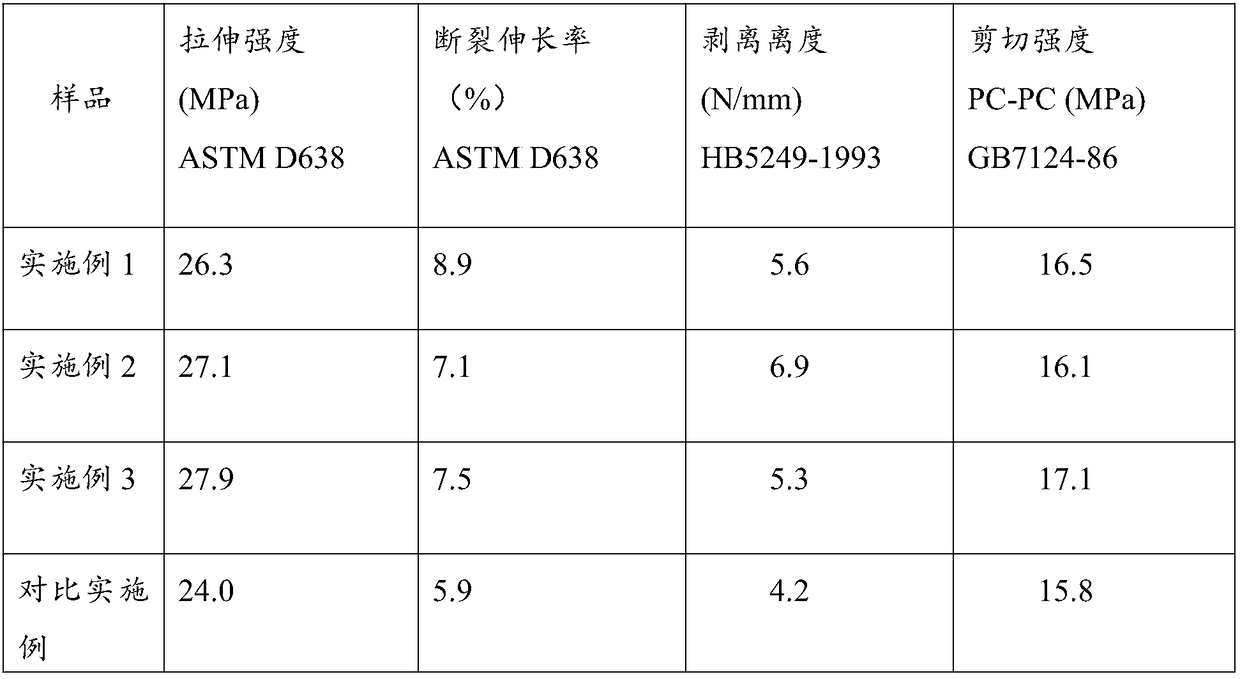

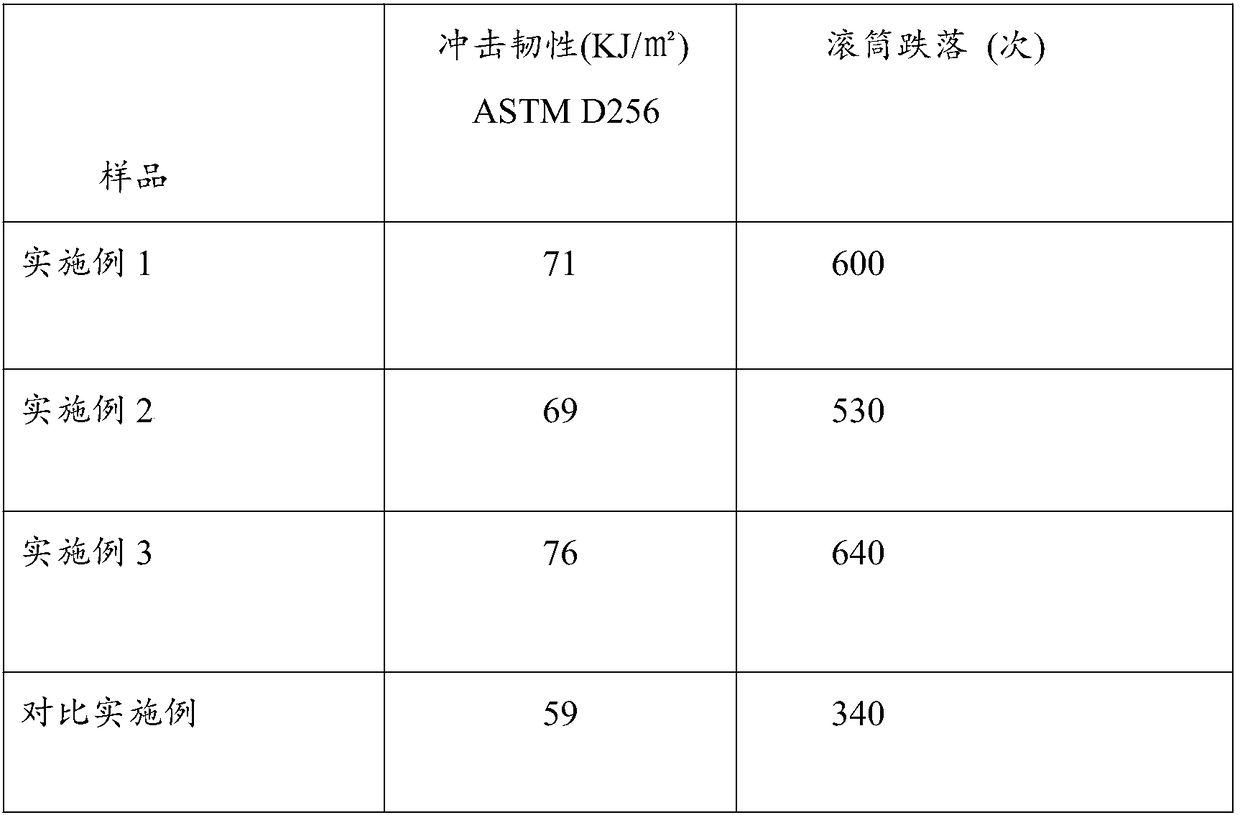

A technology of acrylate and methacrylate, which is applied in the field of acrylate structural adhesives and its preparation, can solve problems such as failure to meet adhesive performance and application process requirements, sticky surface of the adhesive layer, poor impact resistance, etc., and achieve the elimination of surface adhesives. Effects of stickiness, low product odor, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An environment-friendly acrylic structural adhesive, comprising component A and component B mixed at a volume ratio of 10:1, component A includes 10 parts of hydroxypropyl methacrylate, 45 parts of tetrahydrofuryl methacrylate, methacrylic acid 25 parts, 16 parts of prepolymer, 22 parts of nitrile rubber N41, 5.0 parts of tetramethylthiourea, 0.6 parts of 2,5-di-tert-butyl hydroquinone, 2.0 parts of liquid paraffin; B component includes 28 parts of benzoyl oxide, 30 parts of environmentally friendly plasticizer Benzoflex 2088, 35 parts of polyethylene powder, 17 parts of thixotropic agent fumed silica;

[0042] The preparation method of the prepolymer is as follows: 30 parts of polyether polyol PPG-2000, 10 parts of polyester polyol PS-70L, 9 parts of hydrogenated bisphenol A, 28 parts of isobornyl methacrylate, xylene 16 parts of formaldehyde resin, heat up and stir until all components are dissolved, dehydrate at 110°C, -0.095MPa for 2 hours, cool down to 70°C, add 0....

Embodiment 2

[0044] An environment-friendly acrylic structural adhesive, comprising A component and B component mixed at a volume ratio of 10:1, A component includes 25 parts of hydroxyethyl methacrylate, 28 parts of ethylene glycol dimethacrylate, 16 parts of methacrylic acid, 50 parts of prepolymer, 35 parts of SBS resin D1155, 2.7 parts of triethylamine, 0.01 part of 2-tert-butyl hydroquinone, 1.0 part of polyethylene wax; component B includes tert-butyl 10 parts of hydrogen peroxide, 45 parts of bisphenol F type epoxy resin NPEL-170, 22 parts of polytetrafluoroethylene powder, 5 parts of thixotropic agent fumed silica;

[0045] The preparation method of the prepolymer is as follows: 35 parts of polyolefin polyol R-45HT, 20 parts of polycarbonate diol PCDL-2000, 5 parts of hydrogenated bisphenol A, 19 parts of isobornyl methacrylate, two 11 parts of toluene formaldehyde resin, heated up and stirred until each component was dissolved, dehydrated at 110°C, -0.095MPa for 2 hours, cooled to...

Embodiment 3

[0047] An environment-friendly acrylic structural adhesive, comprising A component and B component mixed at a volume ratio of 10:1, A component includes 17 parts of hydroxypropyl methacrylate, 10 parts of indenyl methacrylate, methacrylic acid 5 parts, 32 parts of prepolymer, 8 parts of ABS resin Blendex 338, 0.5 parts of N,N-diethyl-o-toluidine, 0.3 parts of phenothiazine, 0.1 parts of methyl silicone oil; component B includes benzoic acid peroxide 45 parts of tert-butyl ester, 15 parts of bisphenol A epoxy resin E-51, 8 parts of MBS resin, 25 parts of thixotropic agent fumed silica;

[0048] The preparation method of the prepolymer is as follows: 50 parts of polytetrahydrofuran glycol PTMEG-3000, 20 parts of polyolefin polyol HTBS-II, 2 parts of hydrogenated bisphenol A, 10 parts of isobornyl methacrylate, xylene 6 parts of formaldehyde resin, heat up and stir until all components are dissolved, dehydrate at 100°C and -0.095MPa for 2 hours, cool down to 70°C, add 0.01 part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com