Patents

Literature

62results about How to "Improve drying performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for manufacturing semiconductor device with pump unit and method for cleaning the pump unit

InactiveUS20070095282A1Improve drying performanceKeep dryElectrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringInternal pressure

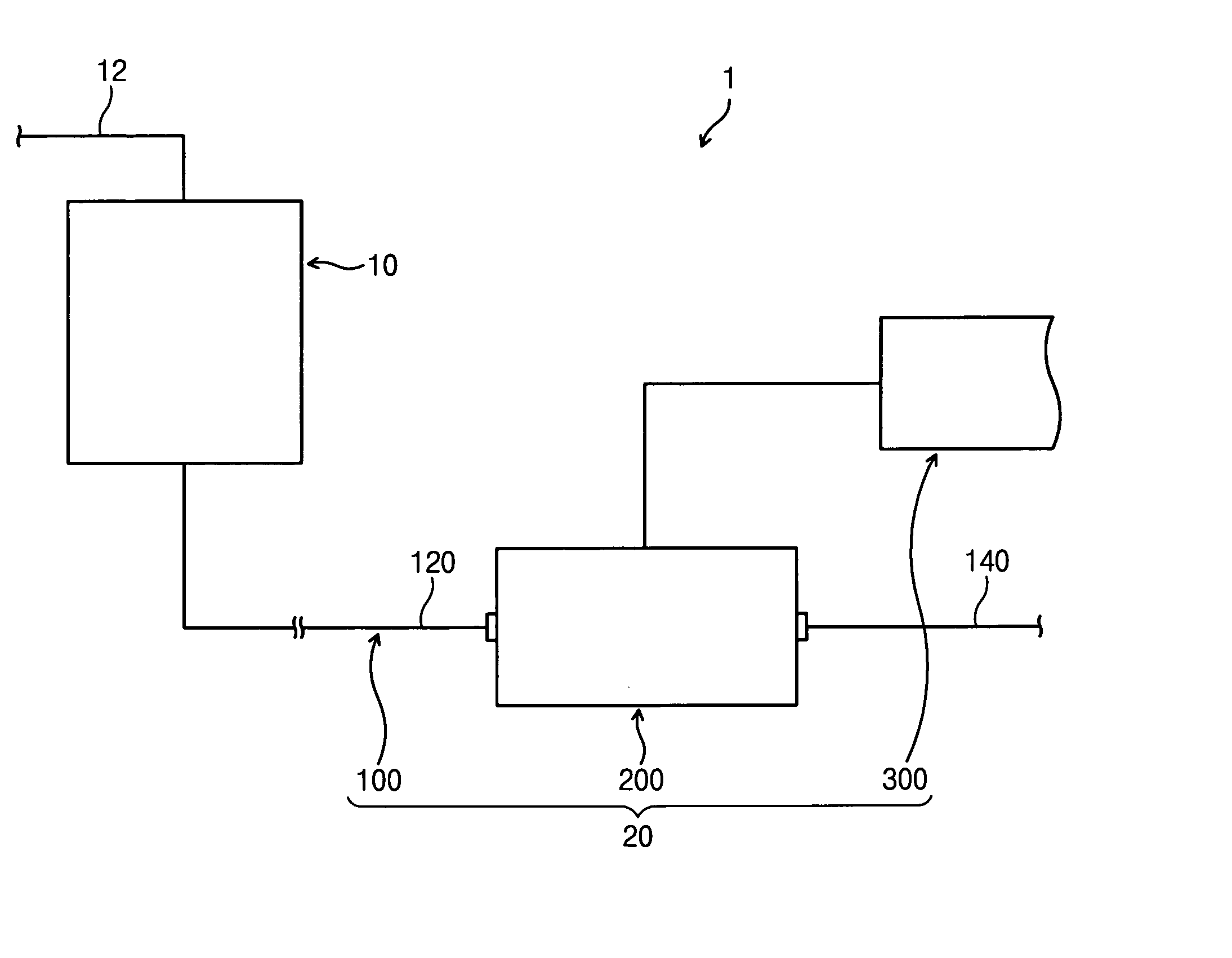

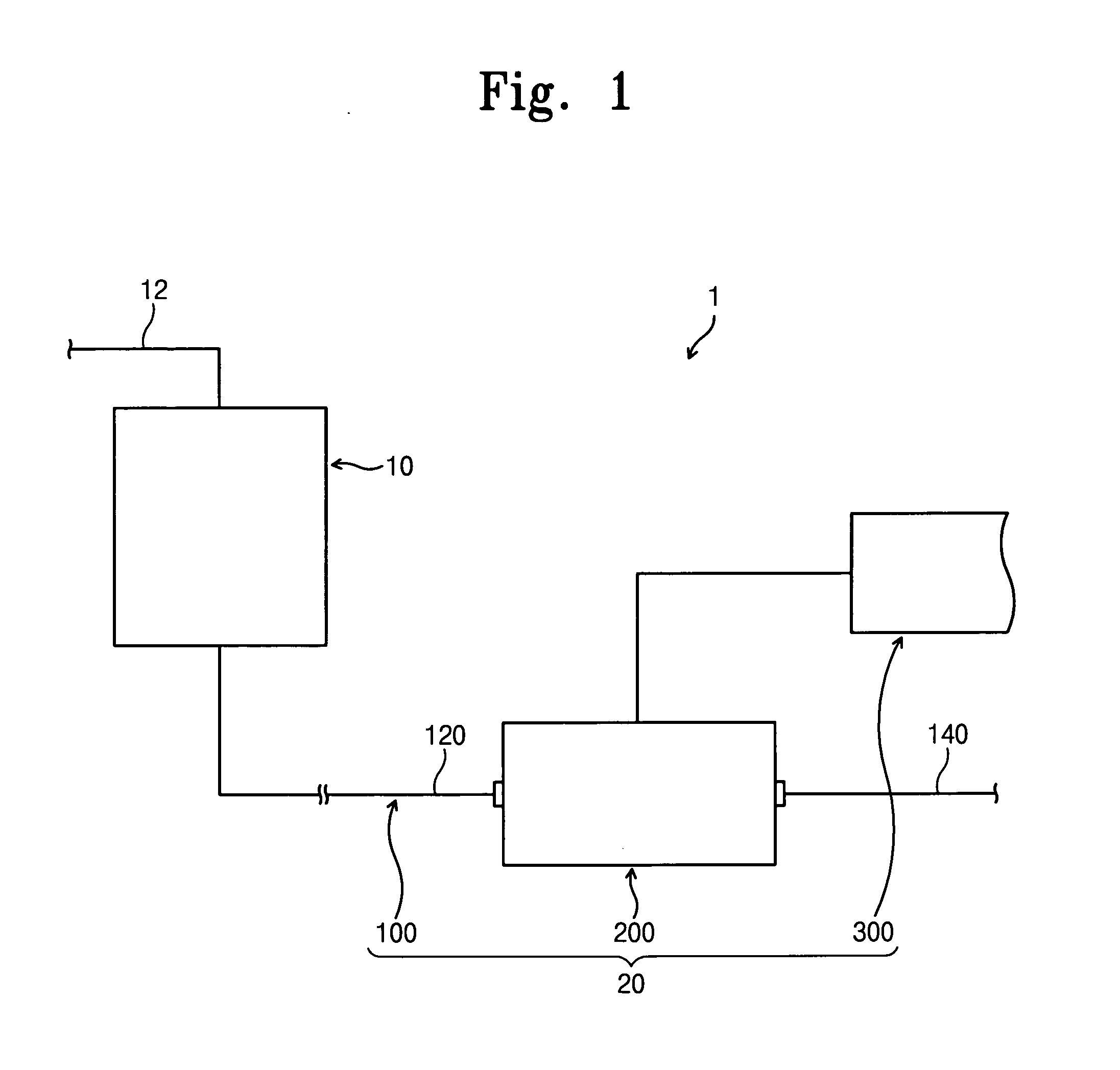

An apparatus for manufacturing a semiconductor device includes a chamber and an exhaust system for exhausting byproducts from the chamber and adjusting an internal pressure of the chamber. The exhaust system includes an exhaust pipe connected to the chamber, a pump unit coupled with the exhaust pipe, and a cleaning unit connected to a portion of the exhaust pipe or directly connected to the pump unit to supply a cleaning gas to the pump unit.

Owner:SAMSUNG ELECTRONICS CO LTD

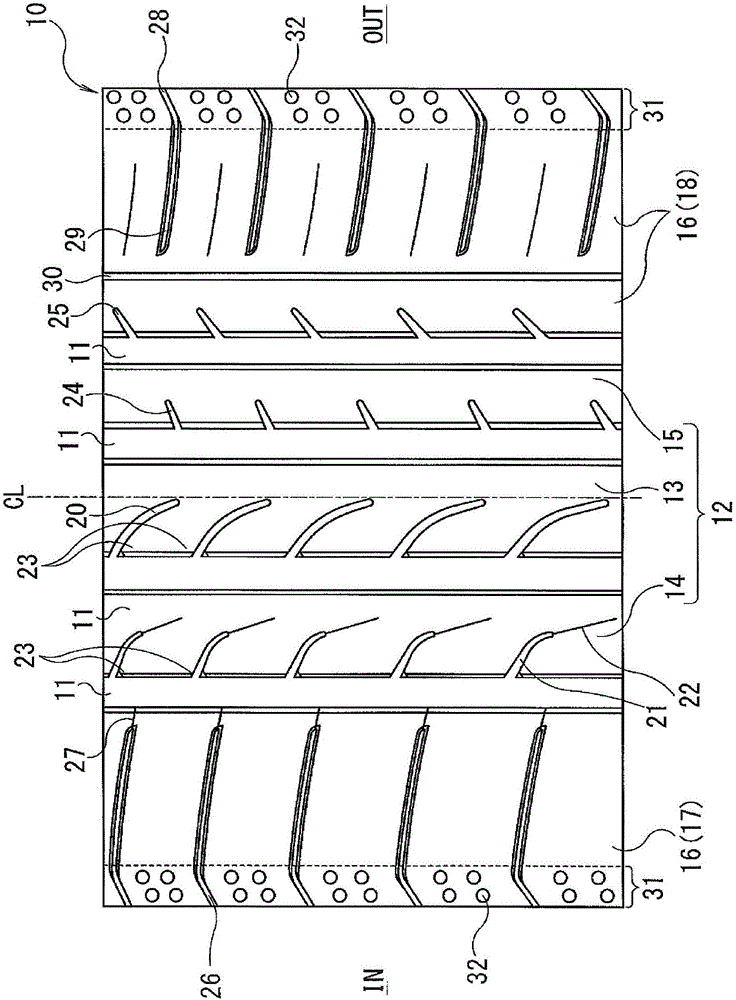

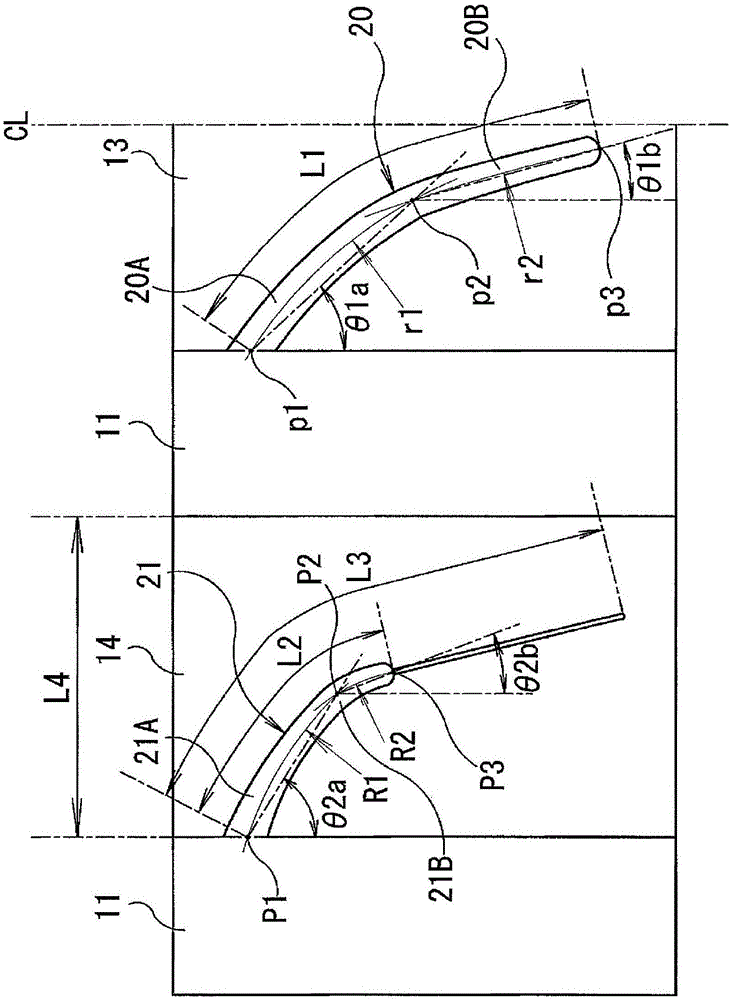

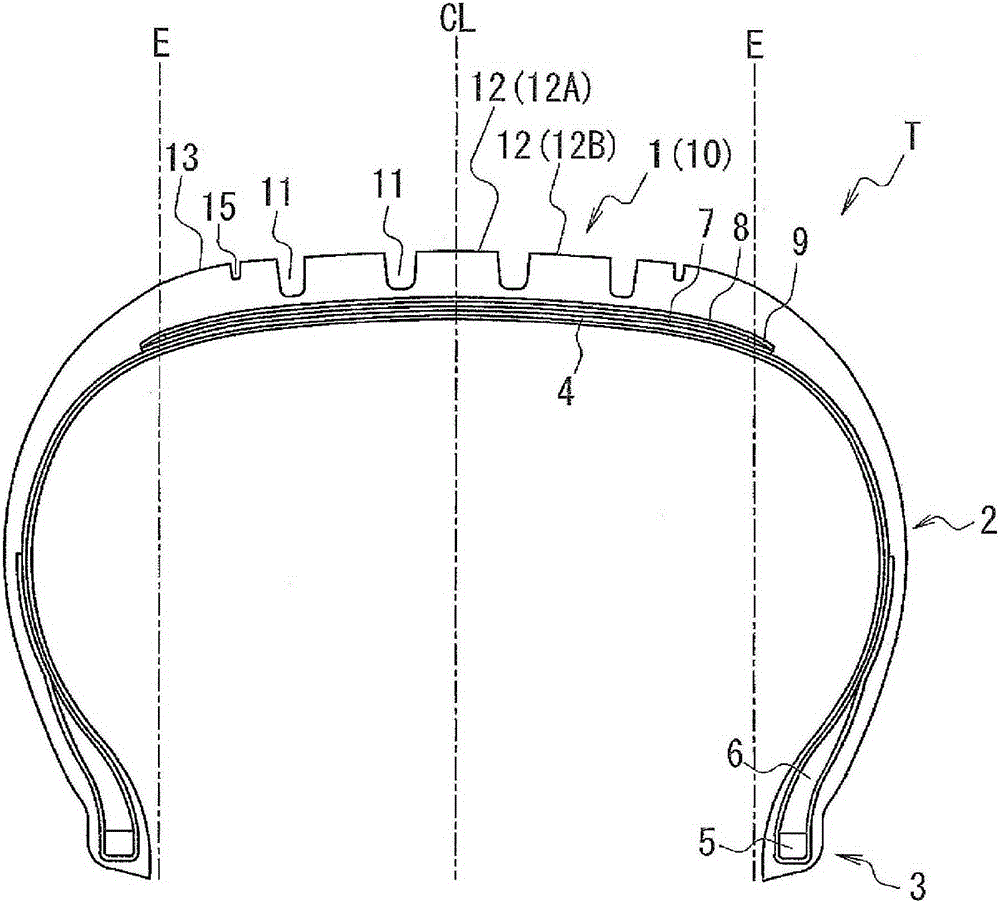

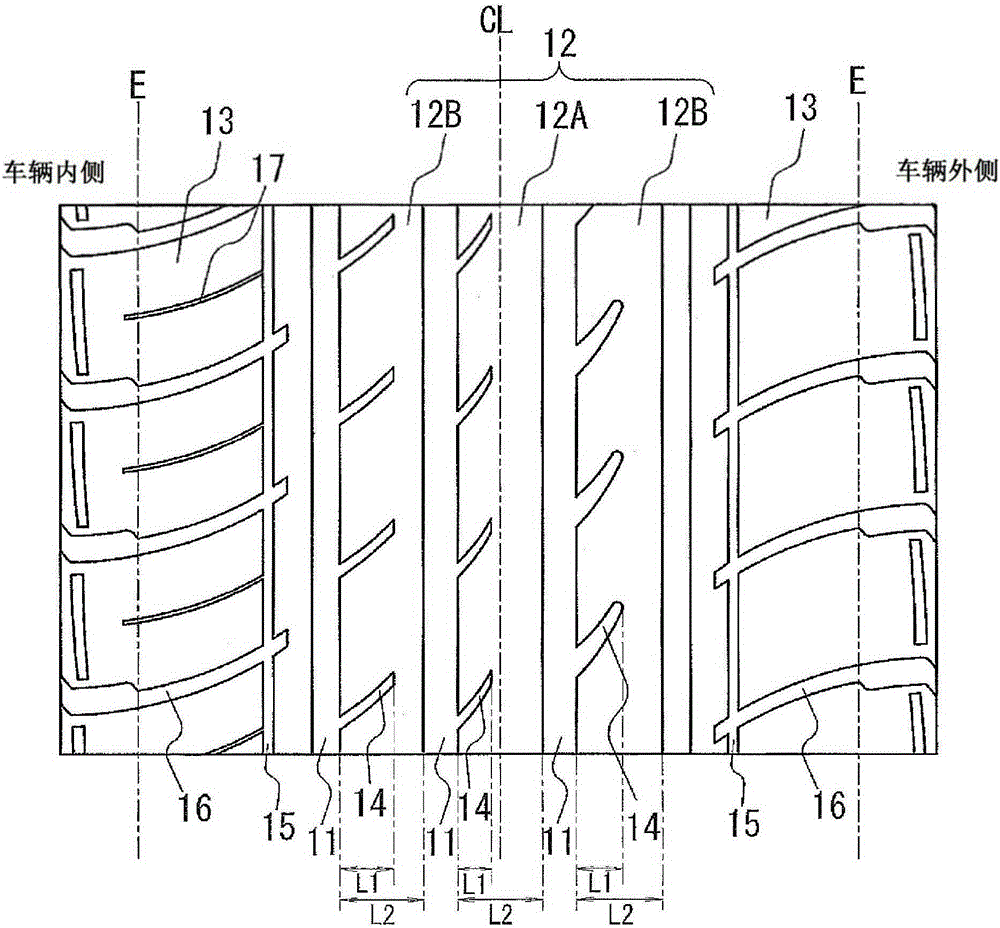

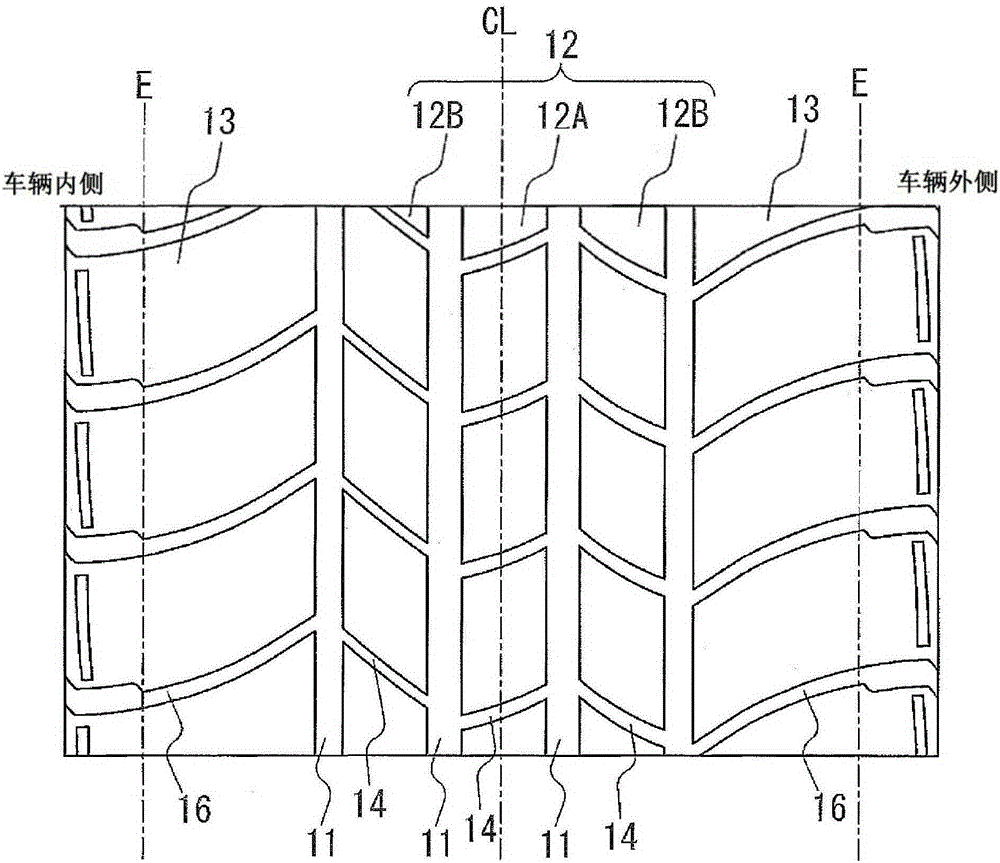

Pneumatic tire

ActiveCN106132729AReduce outside noiseGood drainageInflatable tyresTyre tread bands/patternsRoad surfaceAerospace engineering

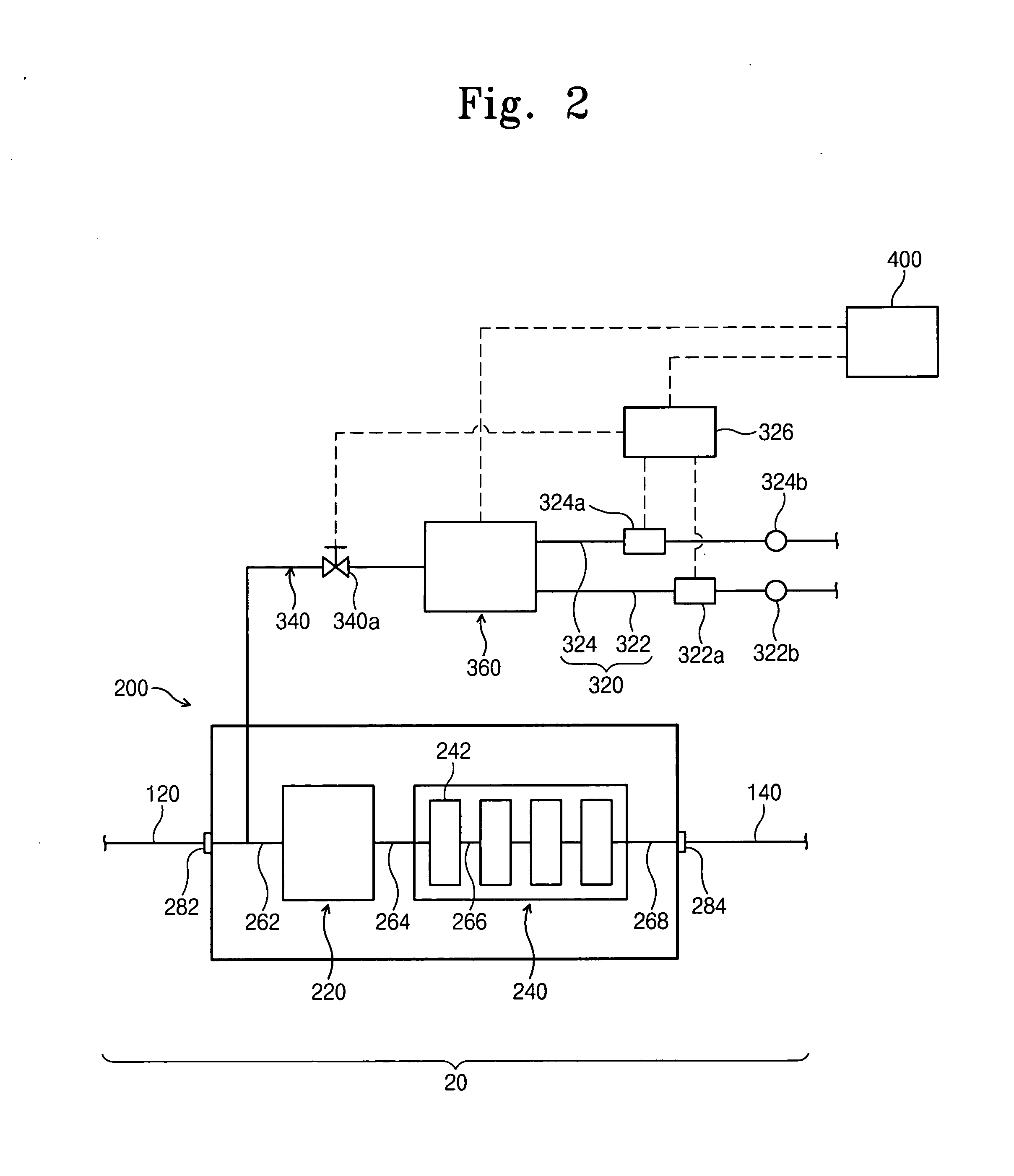

Provided is a pneumatic tire enabling an increase in noise performance while achieving both steering stability on dry road surface and driving performance on wet road surface. In a pneumatic tire (T) including a center land portion (13), an inner central land portion (14), an outer central land portion (15), an inner shoulder land portion (17), and an outer central land portion (18) which are separately formed by at least four main grooves (11), the pneumatic tire having a designated vehicle mount direction, the center land portion (13) is formed with center lug grooves (20) that open only to one of the main grooves (11) on the vehicle inner side, the inner central land portion (14) is formed with inner central lug grooves (21) that open only to another of the main grooves on the vehicle inner side, each of the lug grooves (20, 21) comprising a first inclination portion (20A, 21A) positioned on an opening end side and having a relatively large inclination angle and a second inclination portion (20B, 21B) positioned on a terminal side and having a relatively small inclination angle, and an inner central sipe (22) is formed at the terminal portion of each of the inner central lug grooves (21) terminating within the inner central land portion (14), wherein the relationships L1 ;gt; L2 and L3 ;gt; L4 are satisfied, where L1 is the length of the center lug groove (20), L2 is the length of the inner central lug groove (21), L3 is the sum of the length L2 and the length of the inner central sipe (22), and L4 is the width of the inner central land portion (14).

Owner:YOKOHAMA RUBBER CO LTD

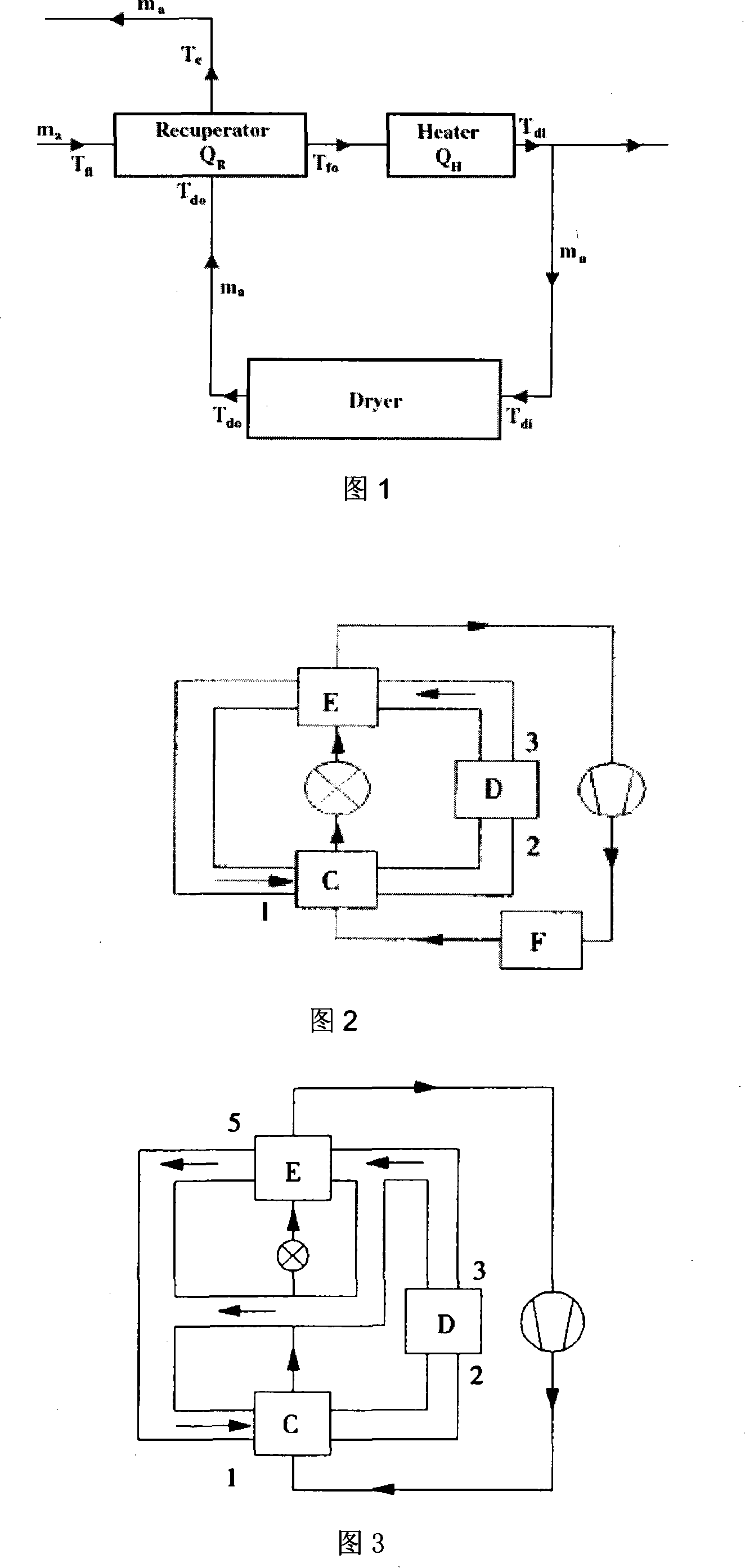

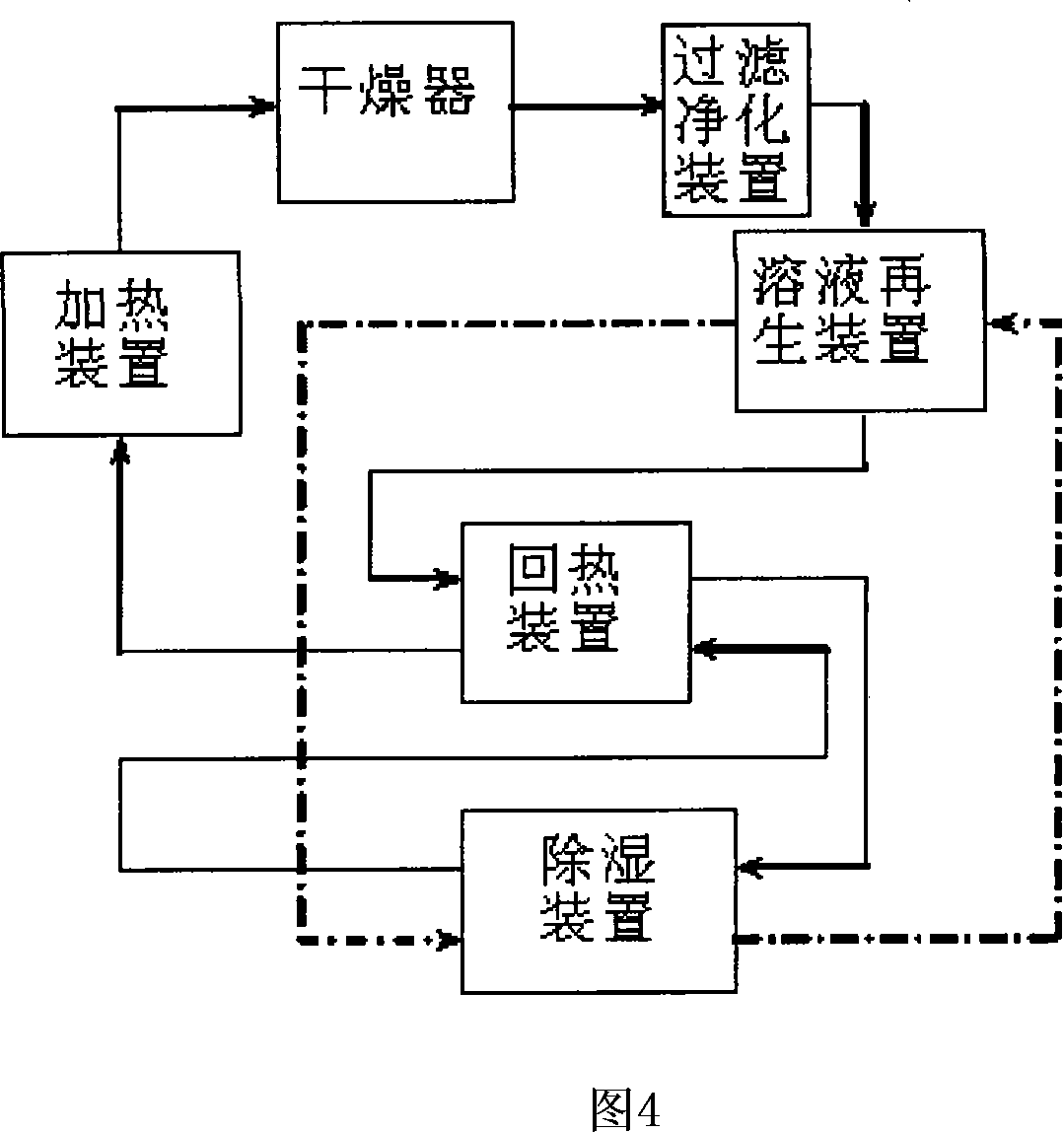

Exhaust-free highly-effective drying system and method

InactiveCN101149213AMeet the requirements for reuseNo lossDrying gas arrangementsWater vaporProcess engineering

This invention relates to a non gas discharging high efficient drying system and its method. The discharged gas from dryer is firstly filtered and purified by filtering purification device. The generated heat energy is used to heating the dilute solution after dehumidifying in solution regenerating device. It fulfills the regeneration of concentrated solution. At the same time, part of the water vapor in the discharged gas separates out and becomes condensing water. It reduces the moisture content of discharged gas. Then, in heat regenerating device, the heat energy of the discharged gas from solution regenerator is used to heating the dry air after dehumidifying. It reduces the temperature, humidify and enthalpy of the wet air entering into dehumidifying device. In the dehumidifying device, the wet air undertakes solution dehumidifying processing. The dry air after dehumidifying enters into the heat regenerating device for initial heating. Then, the air passes through heating device in order to reach the parameter request of drying technique. At last, the dry air enters into the dryer to dry the materials. This invention saves energy and protects environment.

Owner:DONGHUA UNIV

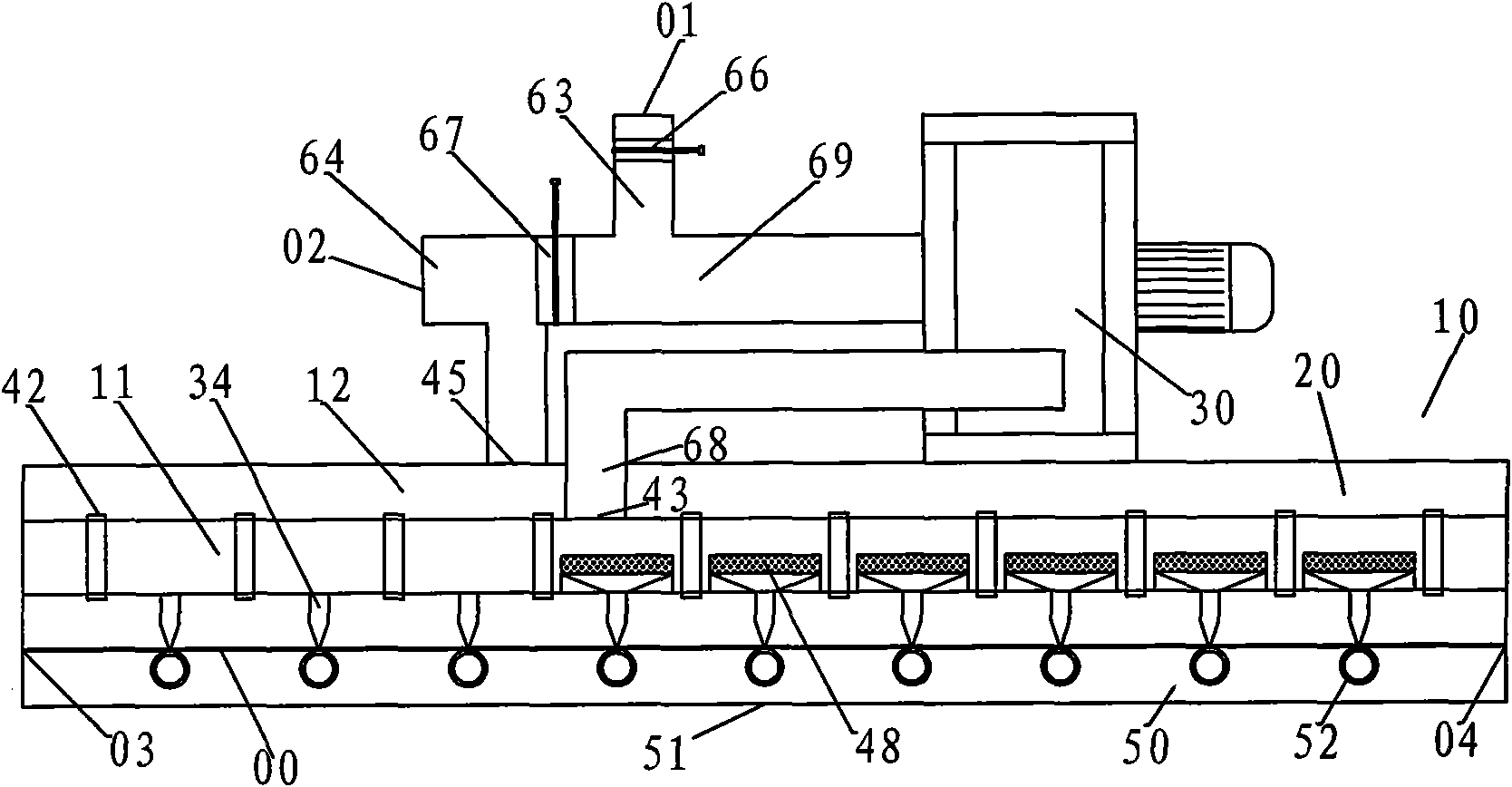

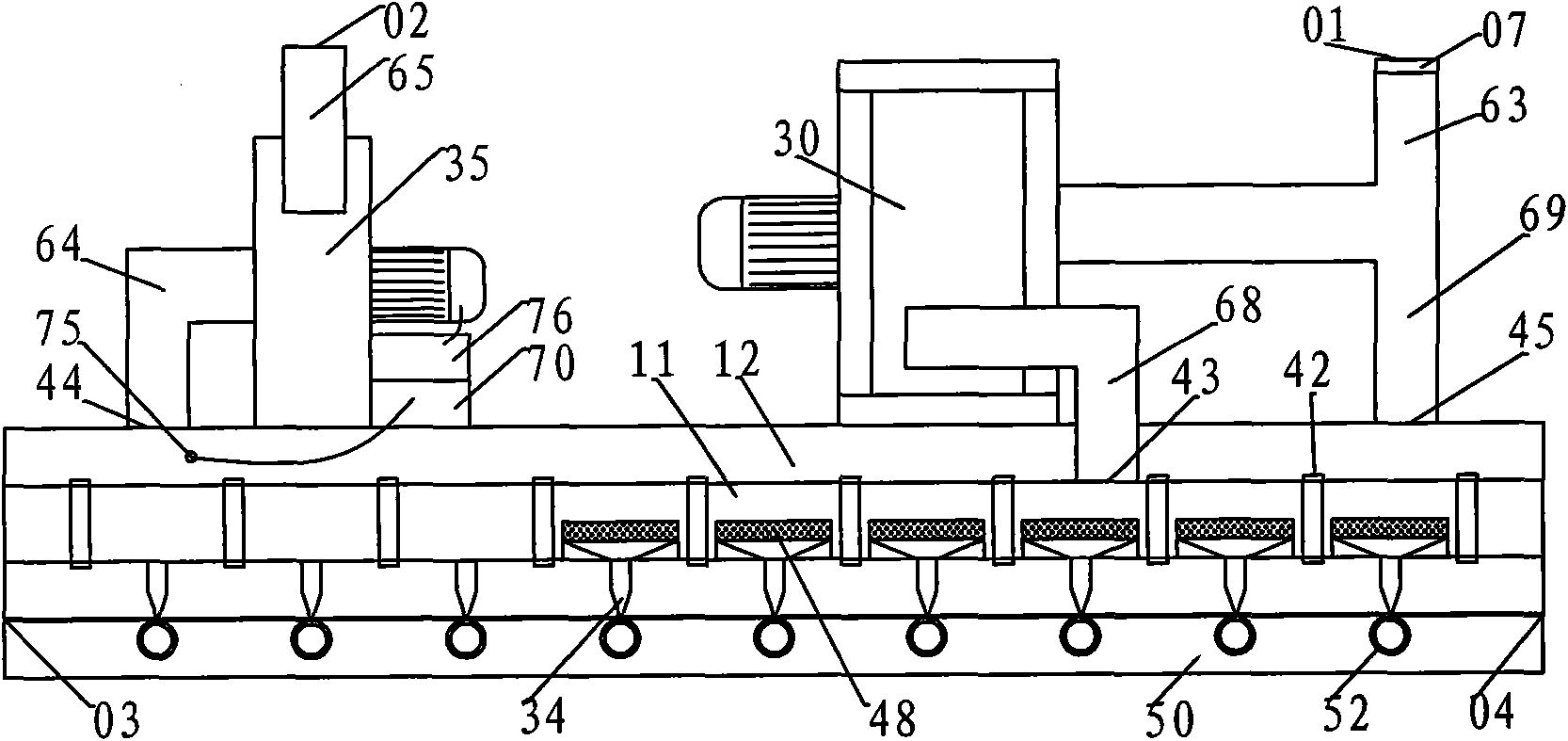

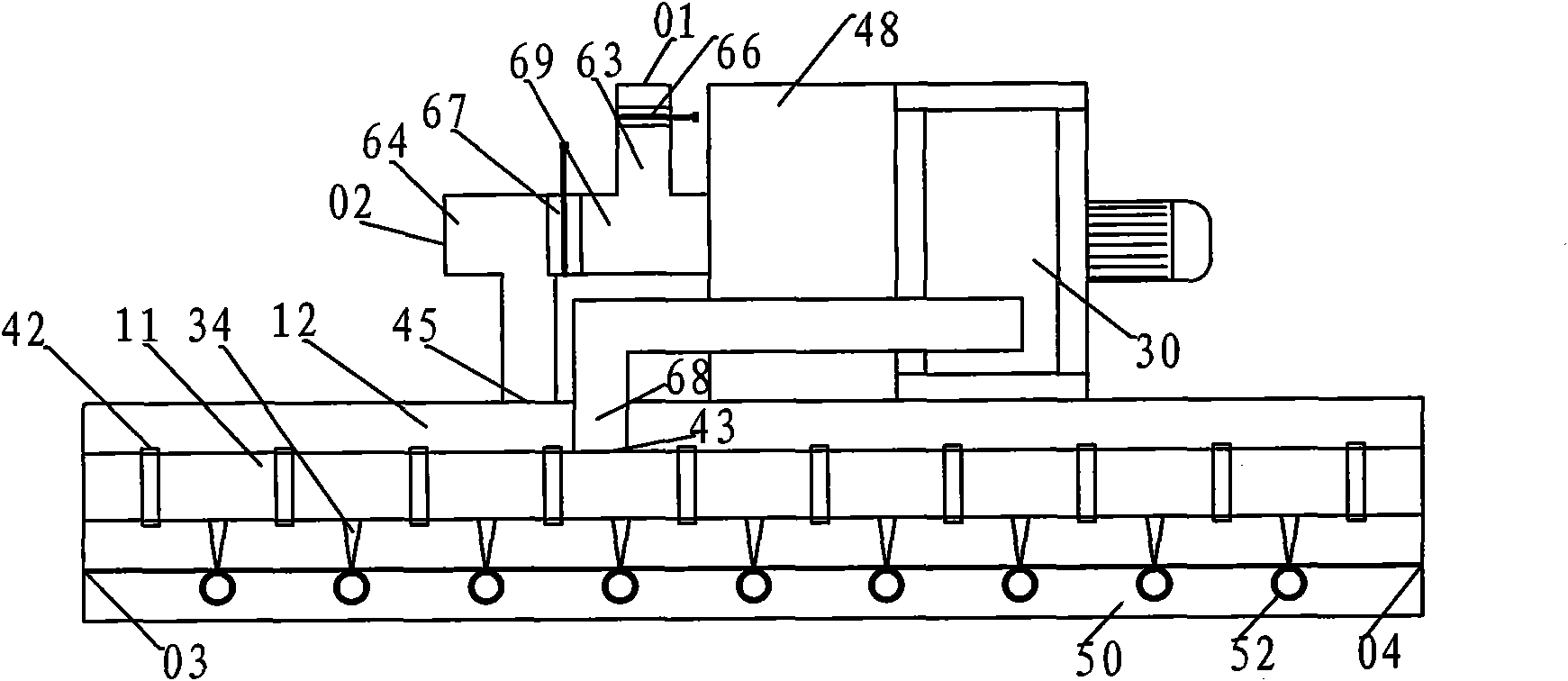

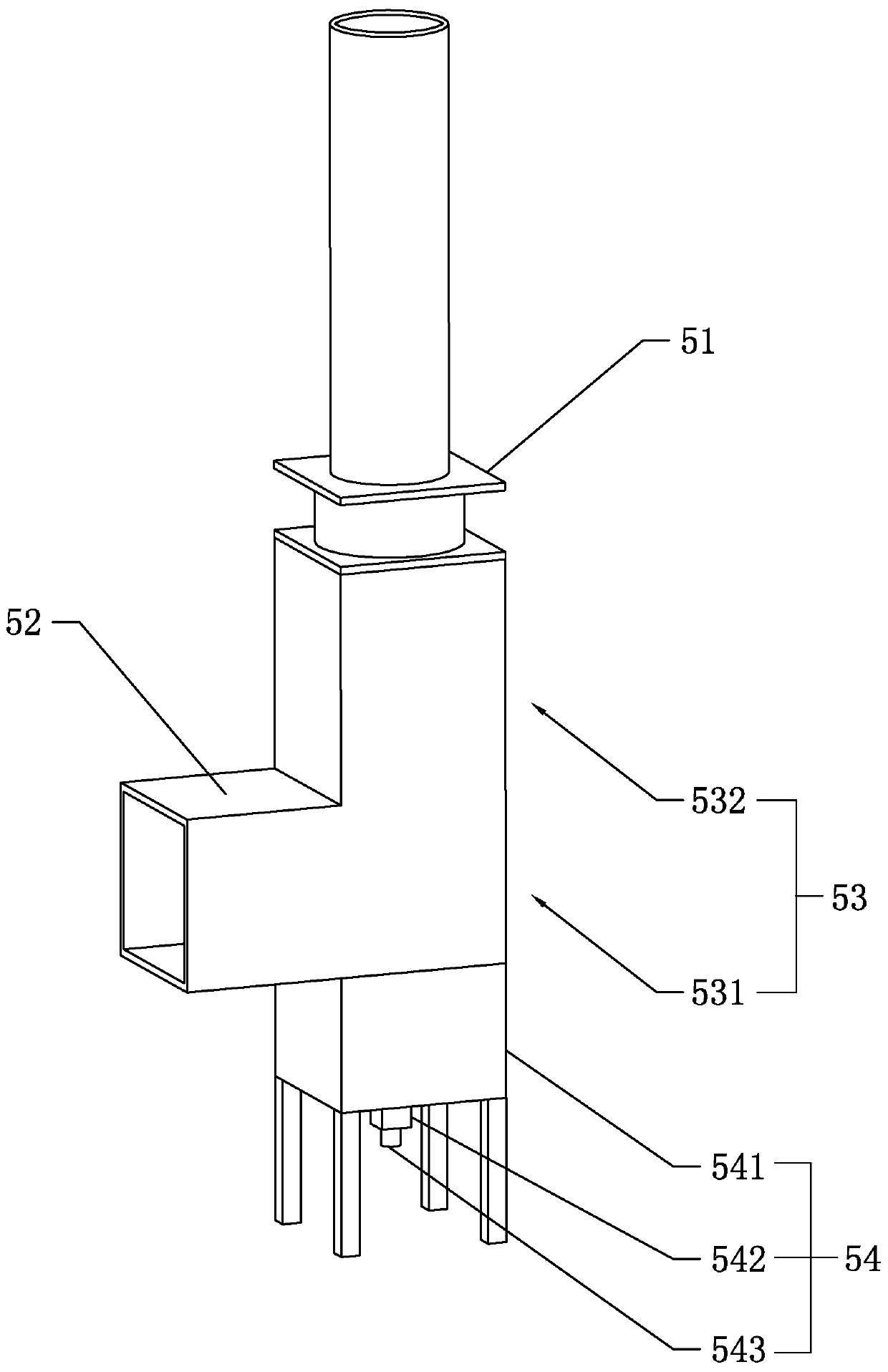

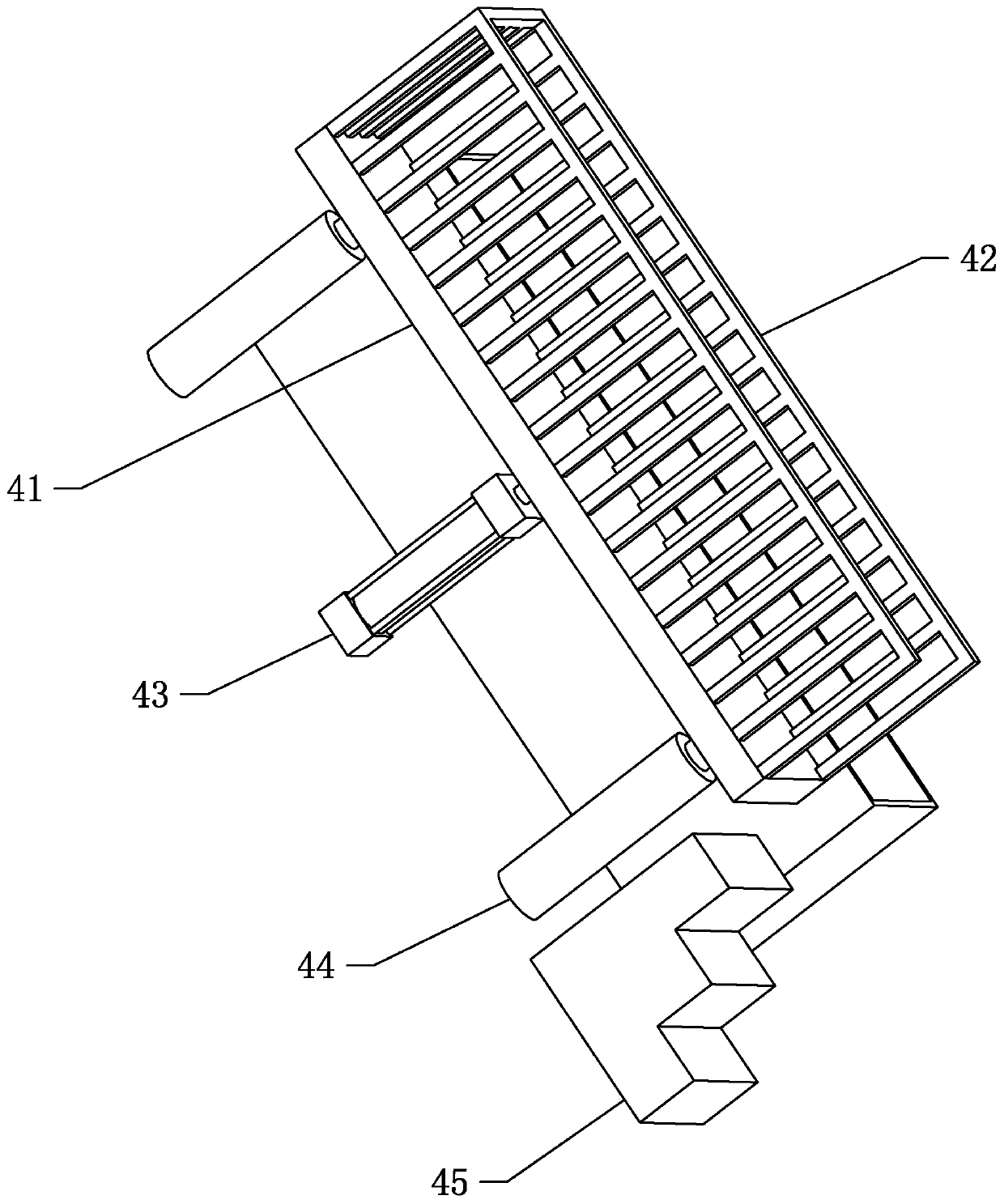

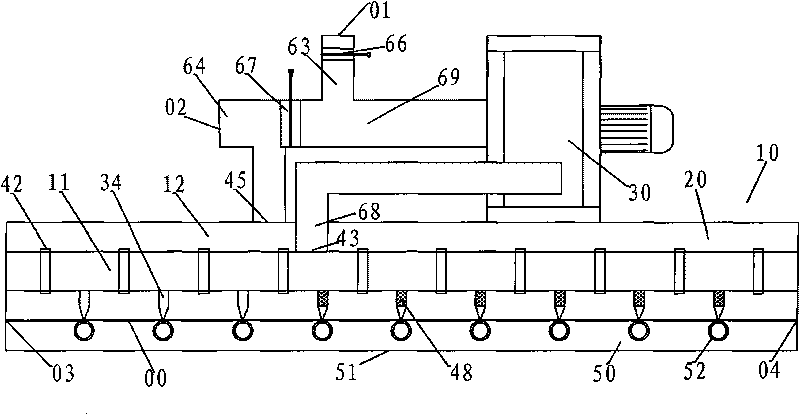

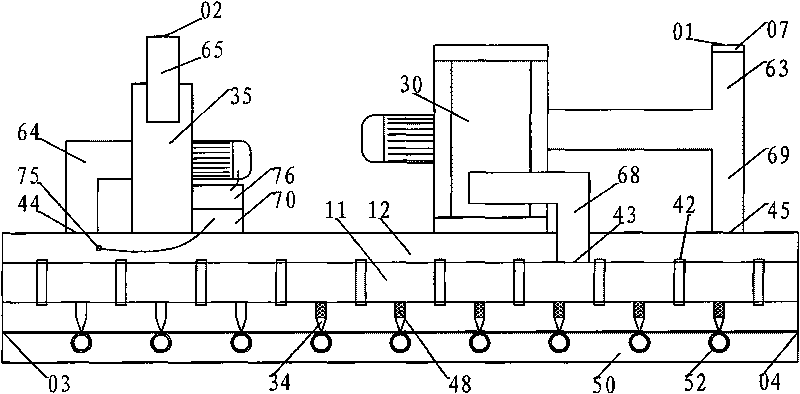

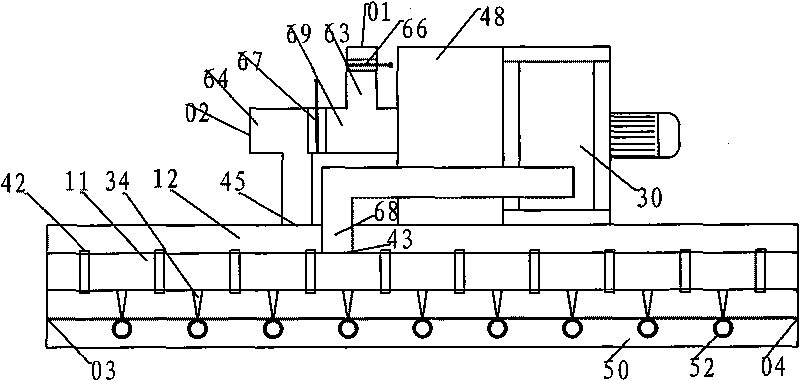

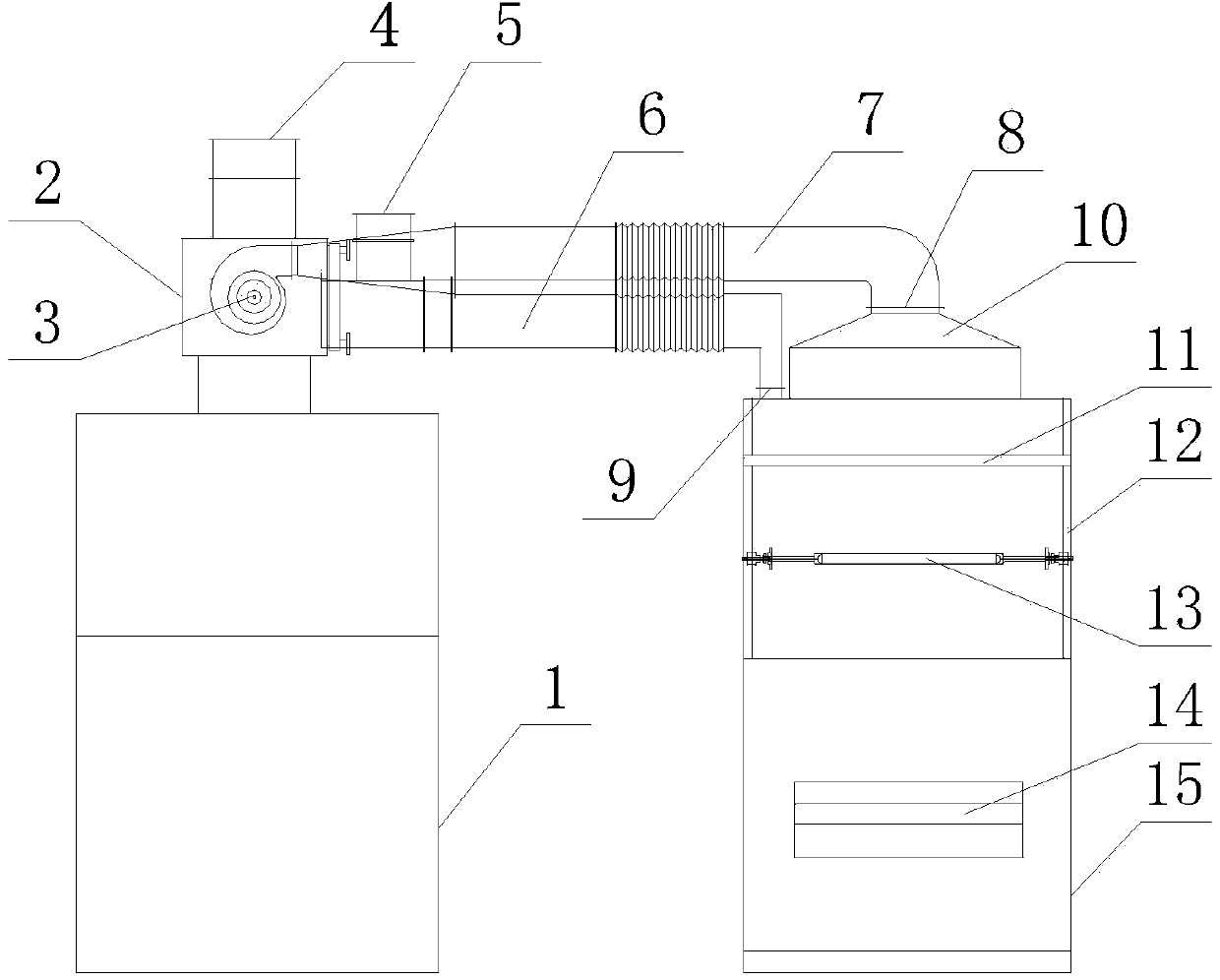

Nozzle heating type drying equipment

InactiveCN101850327AIncrease the exposed areaSpeed up evaporationLamination ancillary operationsLaminationInlet channelEngineering

The invention relates to a piece of nozzle heating type drying equipment, which comprises a drying oven (10), a fan (30), and heaters (48). An air outlet of the fan is communicated with an inner cavity of the drying oven; and the drying oven (10) comprises a drying oven cover (20) and a base (50), and a delivery channel for delivering prints is arranged between the drying oven cover (20) and the base (50). The nozzle heating type drying equipment is characterized in that: 1) an air inlet cavity (11) is formed inside the drying oven cover, a plurality of nozzles (34) are arranged inside the drying oven cover (20) and on the upper part of the delivery channel; the nozzles (34) are communicated with the air inlet cavity (11) or arranged inside the air inlet cavity (11); the heaters (48) are arranged inside the nozzles (34); and the air outlet of the fan (30) is communicated with an air inlet (43) of the air inlet cavity (11) through an air inlet channel (68). The nozzle heating type drying equipment is widely applied to coating machines, compound machines, printing machines, roller coating lines, gluing machines, and similar processing equipment, and also can be used for drying continuously delivered objects.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

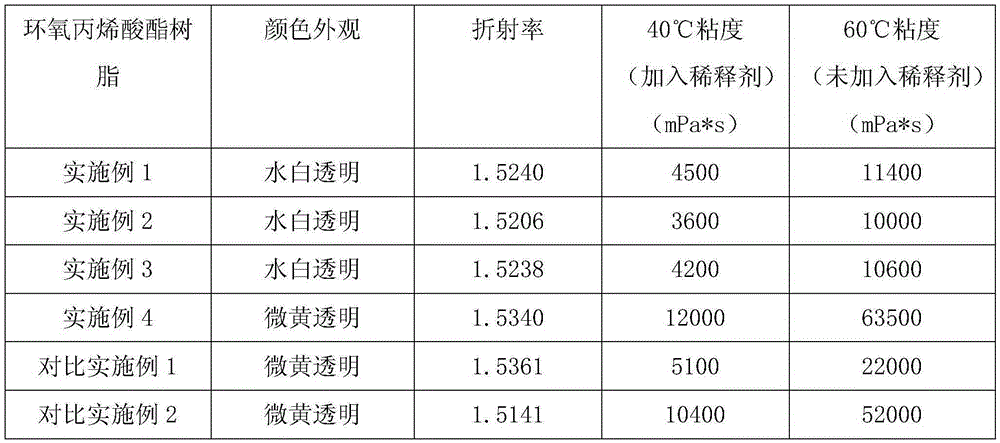

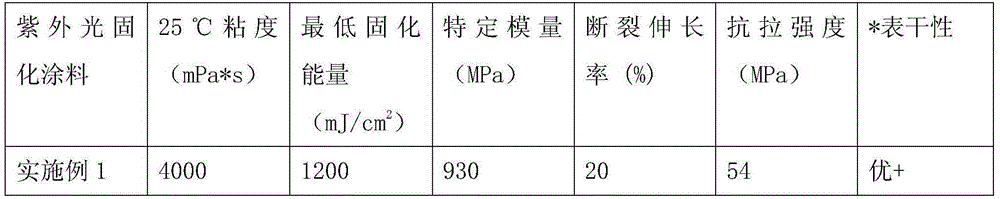

Asymmetric-structure modified epoxy acrylic resin and continuous method synthetic method

The invention relates to asymmetric-structure modified epoxy acrylic resin and a continuous method synthetic method. The continuous method synthetic method comprises the following steps: causing an acrylic acid monomer and epoxy resin to react to prepare epoxy acrylic resin; adding a modified monomer and anhydride into a reaction system at one time, controlling temperature and reaction time, and preparing the asymmetric-structure modified epoxy acrylic resin; adding active diluting monomer to regulate viscosity, and discharging. The epoxy acrylic resin module prepared with the continuous method synthetic method has an asymmetric structure, can be applied to various photocuring coatings and ink products, especially photocuring optical fiber coatings and has the advantages of low finished product viscosity, high curing speed and good surface drying performance. A solidification membrane simultaneously has high modulus and toughness. The preparation method is simple in technology and can be used for continuous production, production efficiency is improved, and production cost is saved.

Owner:瑞通高分子科技(浙江)有限公司

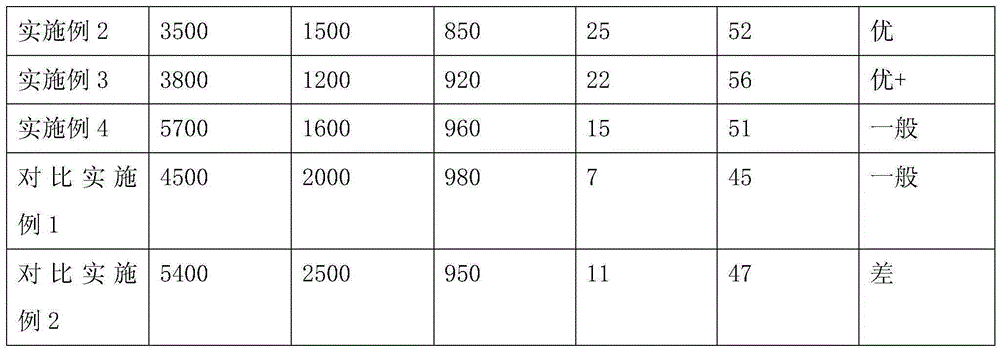

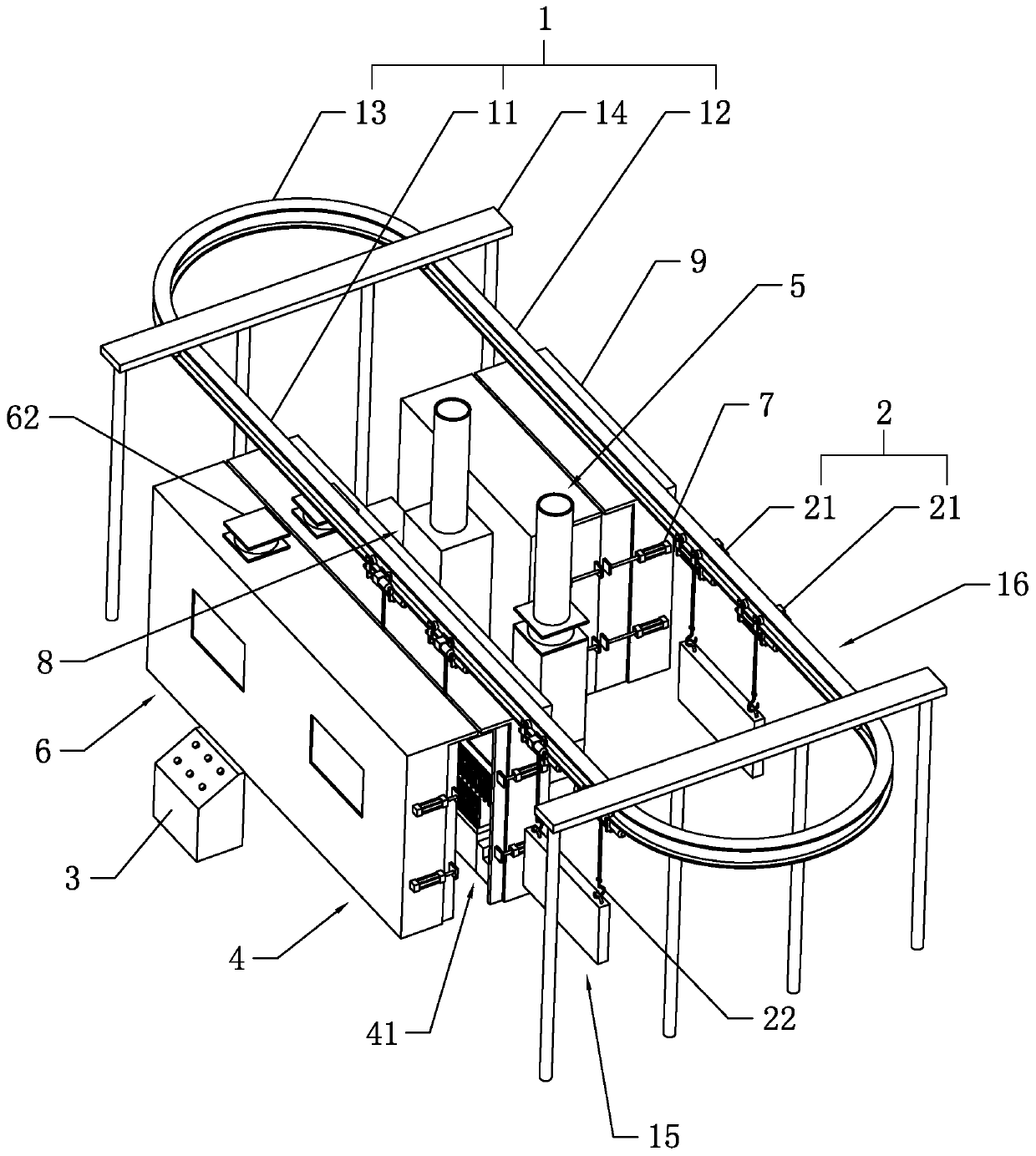

Paint spraying circulation line

PendingCN111036473AReduce area occupancyImprove the efficiency of paint drying operationsSpray boothsEngineeringTransfer line

The invention discloses a paint spraying circulation line and relates to the technical field of decorative building material paint spraying. The paint spraying circulation line comprises a paint spraying chamber, a drying chamber and a conveying line body used for conveying workpieces, wherein the conveying line body is arranged to be a circulating line body, the conveying line body conveys workpieces to sequentially pass through the paint spraying chamber and the drying chamber, the circulating line body comprises a feeding line body and a returning line body which are continuous and oppositein conveying direction, and the feeding line body and the returning line body convey the workpieces to pass through the paint spraying chamber and the drying chamber respectively, and a feeding and discharging station is arranged at the position, located between the feeding line body and the returning line body, of the circulation line body. The paint spraying circulation line is advantaged in that the conveying line body, the paint spraying chamber and the drying chamber are matched to achieve circulation type paint spraying and drying operation, and then a purpose of reducing the area occupancy rate of a production workshop on the premise that productivity is kept unchanged is achieved.

Owner:上海惠元机械制造有限公司

Environment-friendly fireproof coating and preparation method thereof

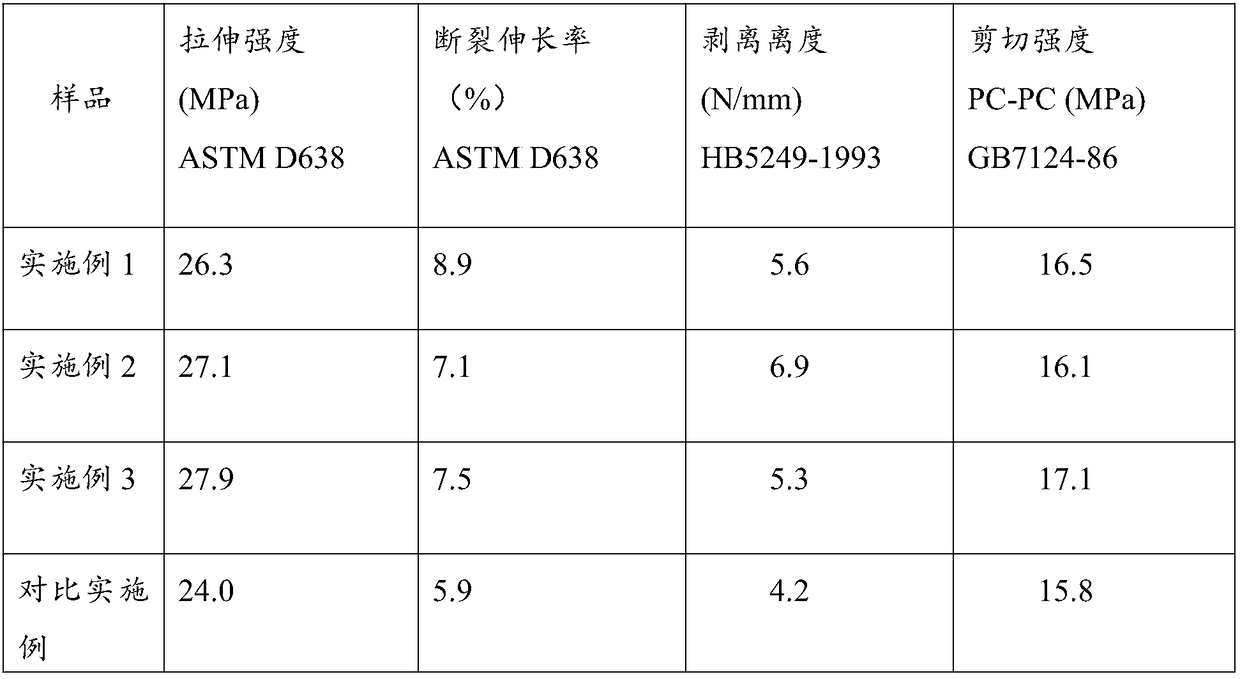

InactiveCN111718631AGood film-forming performanceGood insulationFireproof paintsAnti-corrosive paintsFlame resistancePlasticizer

The environment-friendly fireproof coating is prepared from the following raw materials: intercalated phase-change energy storage material modified core-shell emulsion, low-molecular-weight epoxy resin, phenolic fibers, a flame retardant, pigments and fillers, a plasticizer, a thickener, a flexibilizer, an emulsifier and a dispersing agent; the intercalated phase change energy storage material modified core-shell emulsion is a bentonite-urea intercalation compound modified acrylate core-shell emulsion; the low-molecular-weight epoxy resin is low-molecular-weight bisphenol F epoxy resin, and the average molecular weight of the low-molecular-weight epoxy resin is less than 700. According to the invention, the components are adjusted to the most scientific and most reasonable state; related properties and part of technical indexes such as flame retardance, rust resistance, waterproofness, leveling property and strength of the fireproof coating are improved, the cost is low, the coating isuniform, continuous, compact and wear-resistant; the toughness, coloring property, adhesiveness, dryness, certain gloss and other properties of the coating are improved, and the product quality is improved.

Owner:广州珈鹏科技有限公司

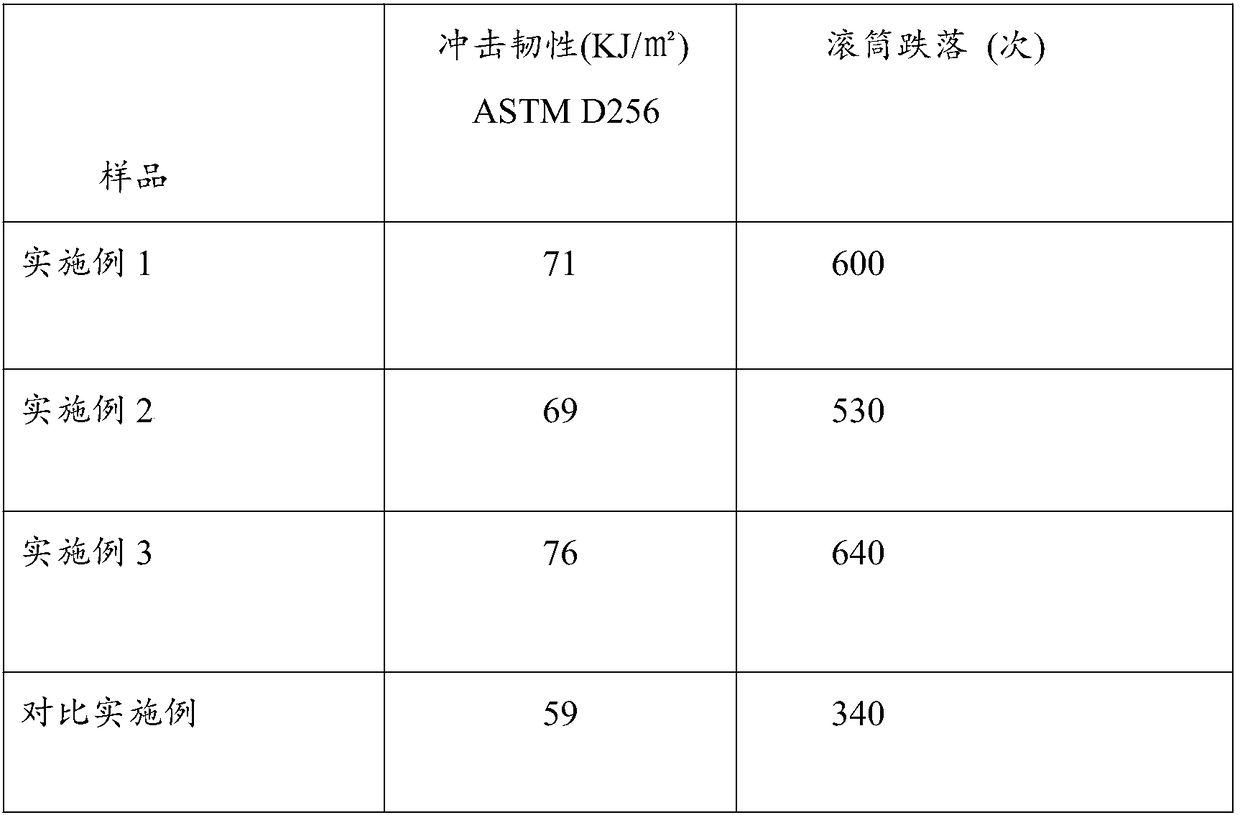

Environmentally-friendly acrylate structural adhesive and preparation method thereof

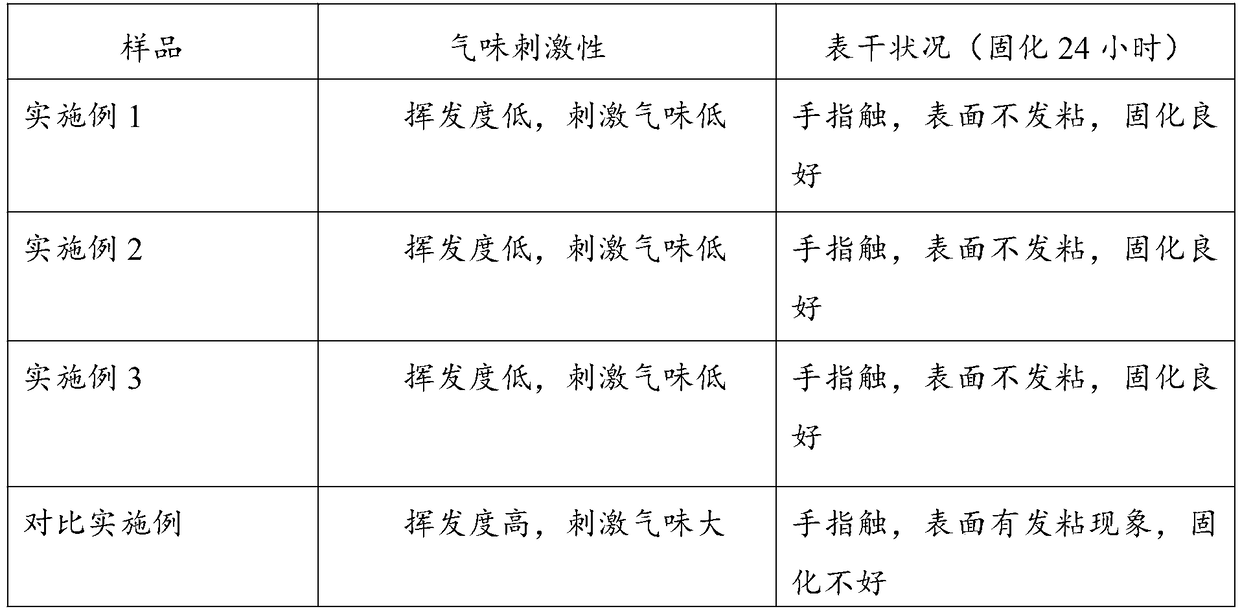

ActiveCN109439233ASmall smellNo stickinessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention relates to an environmentally-friendly acrylate structural adhesive and a preparation method thereof. The prepared acrylate adhesive overcomes the defects of severe irritating odor of atraditional acrylate structural adhesive, sticky surface of an adhesive layer after the structural adhesive is cured and low anti-impact performance, is used in the fields of consumer electronics assembly industries and general industries, not only has relatively low odor and high surface dry performance, but also has high bonding mechanical property and impact resistance, can greatly improve theon-site use environment of an assembly line and improve the production efficiency, and has important pushing significance for increasing the technical level of the acrylate structural adhesive.

Owner:YANTAI DARBOND TECH

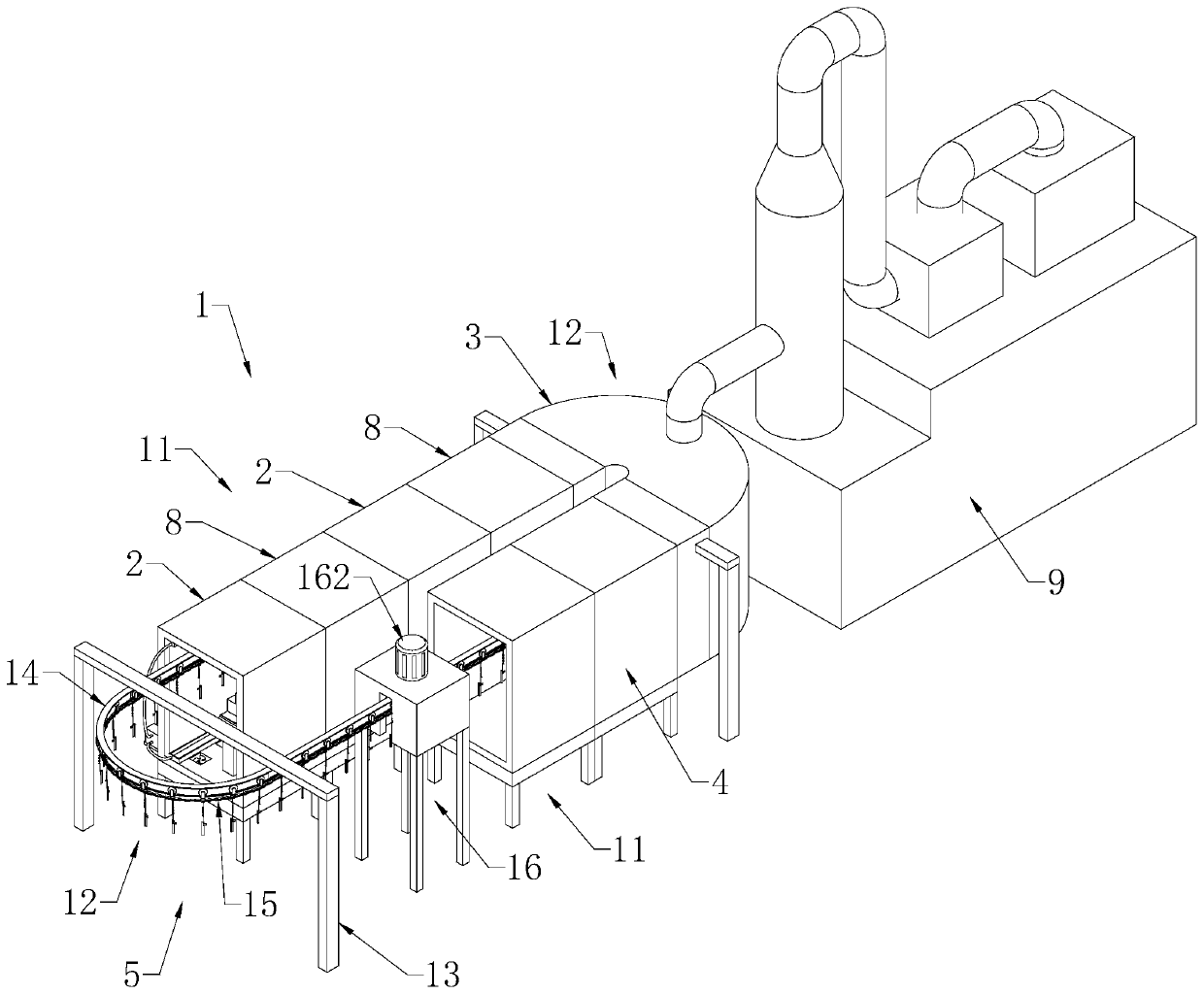

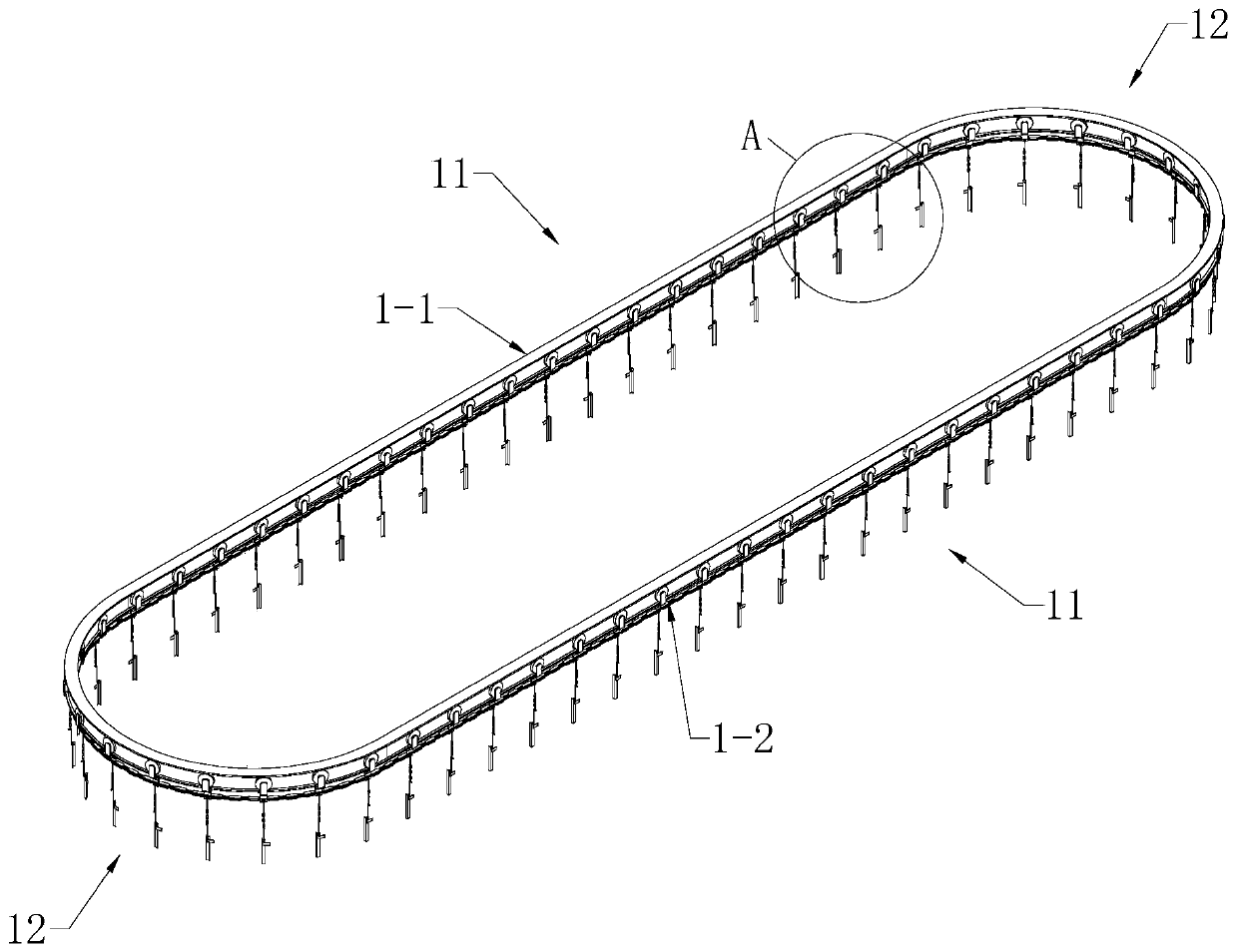

Painting circulating line used for civil air defense door

InactiveCN111330793AIncrease productivityReduce wasteSpray boothsConstruction engineeringStructural engineering

The invention discloses a painting circulating line used for a civil air defense door, and relates to the technical field of civil air defense engineering. The painting circulating line comprises a painting chamber, a drying chamber and a conveying annular line for conveying the civil air defense door; the conveying annular line is used for conveying the civil air defense door to pass through thepainting chamber and the drying chamber in sequence; the conveying annular line comprises a continuous material feeding line body, material return line body and annular line body; the conveying directions of the material feeding line body and the material return line body are opposite; the annular line body is used for connecting the material feeding line body and the material return line body; the material feeding line body and the material return line body are used for conveying the civil air defense door to pass through the painting chamber and the drying chamber in sequence; and a feedingstation and a discharging station are arranged on the material feeding line body and the material return line body respectively. The painting circulating line has the advantages of improving the production efficiency of the civil air defense door.

Owner:上海徽锋人防工程设备有限公司

Environment-friendly nano fire-retardant coating

ActiveCN101747693AImprove flame retardant performanceImprove rust resistanceFireproof paintsPentaerythritolNano sio2

The invention relates to an environment-friendly nano fire-retardant coating which can be used on the surface of flammable base material, and can reduce the surface flammability of the material to be coated and retard the rapid spread of the fire so as to improve the fire endurance of the material to be coated. The fire-retardant coating is prepared by acrylic resin, polyphosphoric acid amine, nano SiO2, pentaerythritol, butanol and titanium dioxide according to ratio of parts by weight. The components are adjusted to the most scientific and reasonable state, a little nano-material is added, therefore the related properties and partial technical indexes of the fire-retardant coating such as fire retardance, antirust property, waterproofness, levelling property and strength are improved, the cost is low, the coating is uniform and continuous, compact and wear-resisting, the tenacity, dyeing property, adhesiveness, fast-drying nature and certain gloss of the coating are improved; and the nanotechnology is effectively combined with the formula and process of the coating, therefore the product quality is improved.

Owner:张静 +1

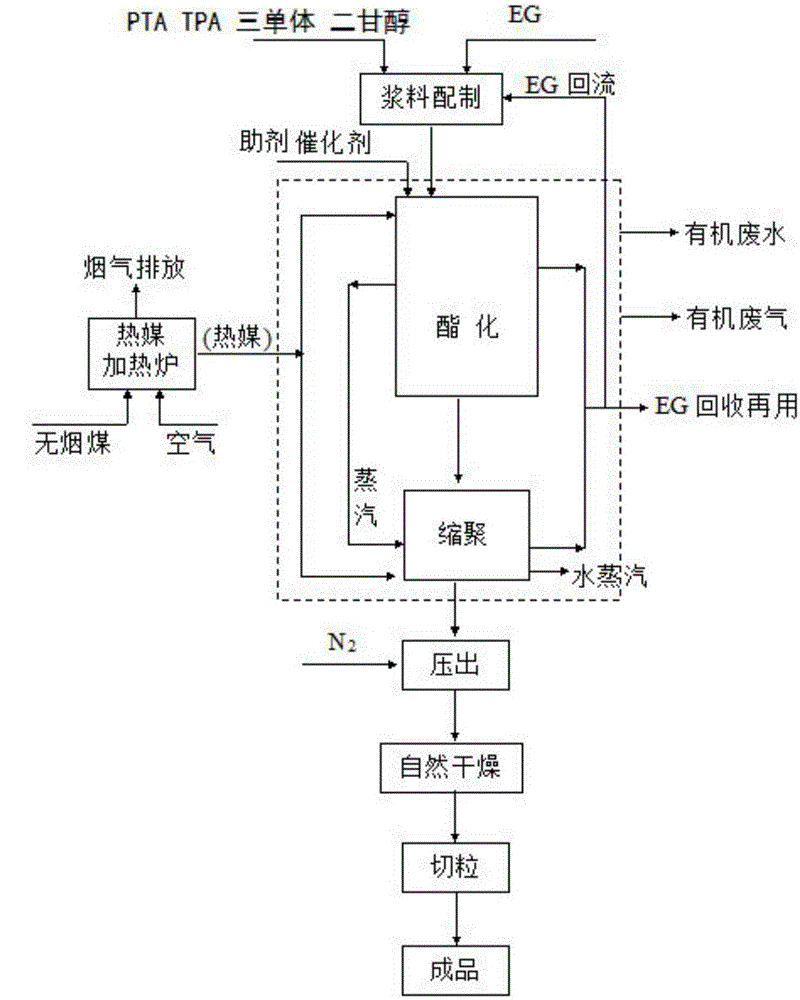

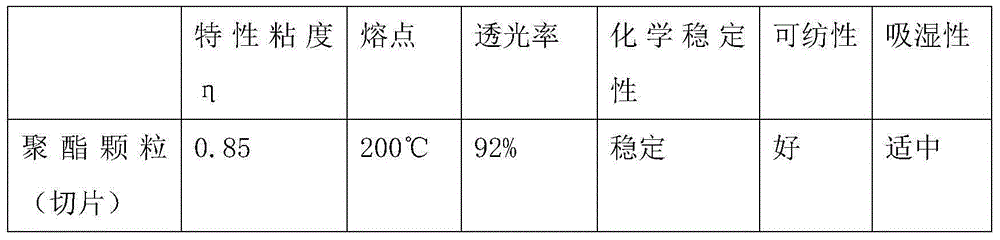

Polymer waterborne polyester and preparation method thereof

ActiveCN105111423AHigh molecular weightExcellent adhesionFibre treatmentPolymer scienceCarvacryl acetate

The invention discloses polymer waterborne polyester. The polymer waterborne polyester is prepared in the mode that terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol, ternary monomers, a catalyst and other auxiliaries serve as raw materials, and the raw materials and mother liquid are subjected to esterification and condensation polymerization for synthesis. A preparation method of the polymer waterborne polyester includes the steps that firstly, terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol and ternary monomers are made into paste and evenly fed into an esterification kettle through a metering pump, the catalyst is added for an esterification reaction, the auxiliaries are added to monomers generated by the esterification reaction, the mixture is filtered and guided into a condensation polymerization kettle for a condensation polymerization reaction, when a certain process value is reached, the mixture is extruded out through nitrogen, and the transparent polyester product is prepared after cooling, grain-sized dicing, drying and screening. The polymer waterborne polyester replaces traditional acrylic and vinyl acetate products, and urea resin and cyanamide resin which are not environmentally friendly, has a series of advantages of being excellent in adhesive force, high in molecular weight, good in environment friendliness and the like, and can serve as a textile hardening agent to be widely used.

Owner:广州市弘浩纺织助剂有限公司

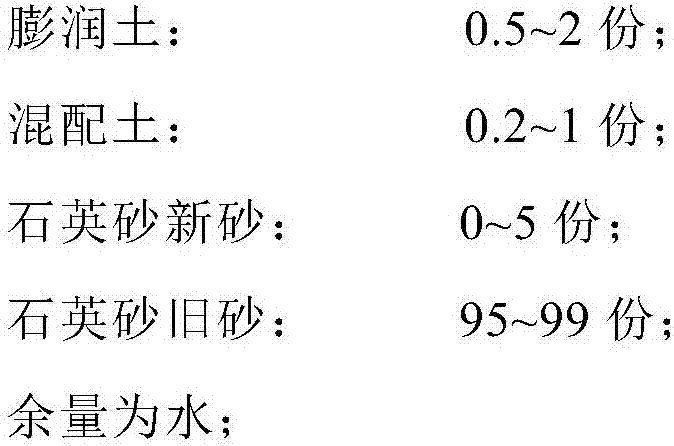

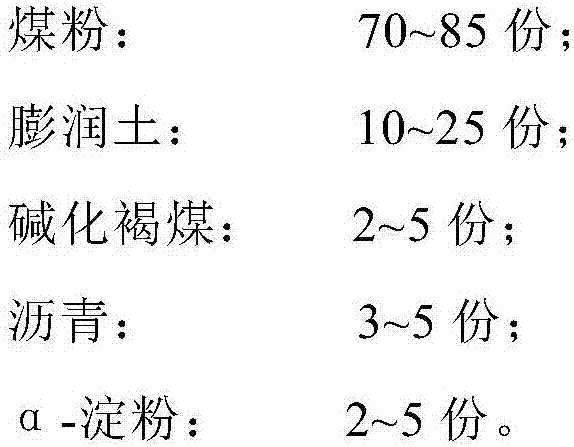

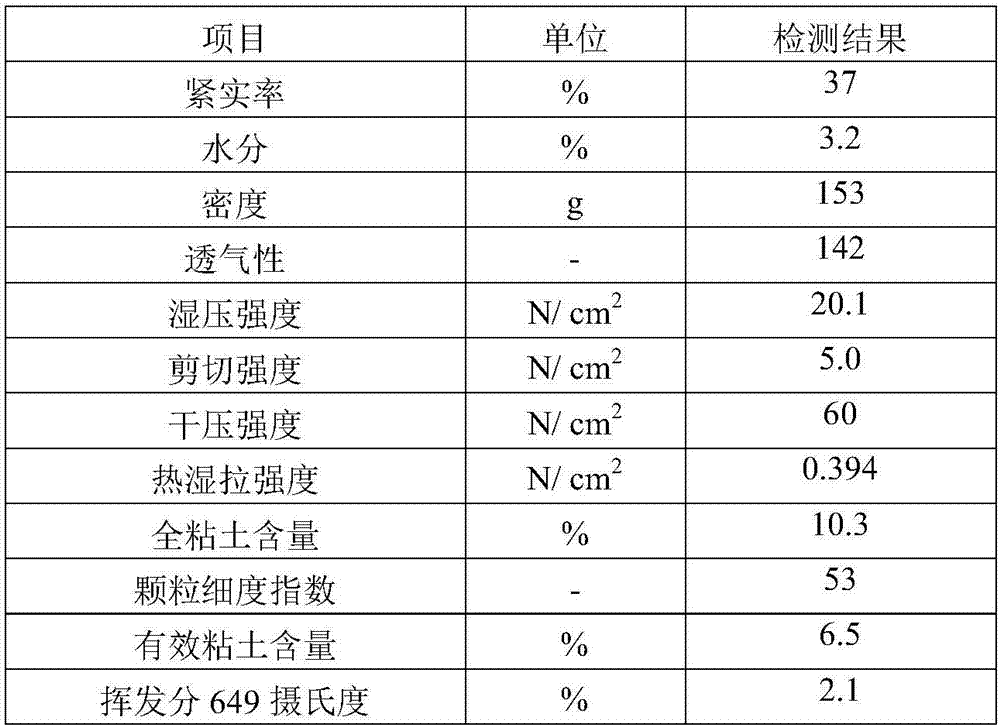

Wet moulding sand used for iron casting high density molding and preparation method of wet moulding sand

ActiveCN107971452AImprove mobilityGuaranteed comprehensive performance and quality stabilityFoundry mouldsFoundry coresCoalBalance water

The invention discloses wet moulding sand used for iron casting high density molding and a preparation method of the wet moulding sand. The wet moulding sand is made of the following raw materials of,by weight, 0.5-2 parts of bentonite, 0.2-1 parts of mixture soil (the mixture soil is composed of 70-85 parts of efficient pulverized coal, 10-25 parts of bentonite, 2-5 parts of alkaline lignite, 3-5 parts of asphalt, and 2-5 parts of alpha-starch), 0-5 parts of quartz sand new sand, 95-99 parts of quartz sand old sand, and the balance water. The wet moulding sand used for iron casting high density molding not only has high compression strength and wet-heat tensile strength, and further has excellent breathability, liquidity and surface drying; the moulding sand preparation technology is simple, the construction cost is low, and the wet moulding sand used for iron casting high density molding is suitable for large-scale popularization and application in high density molding.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

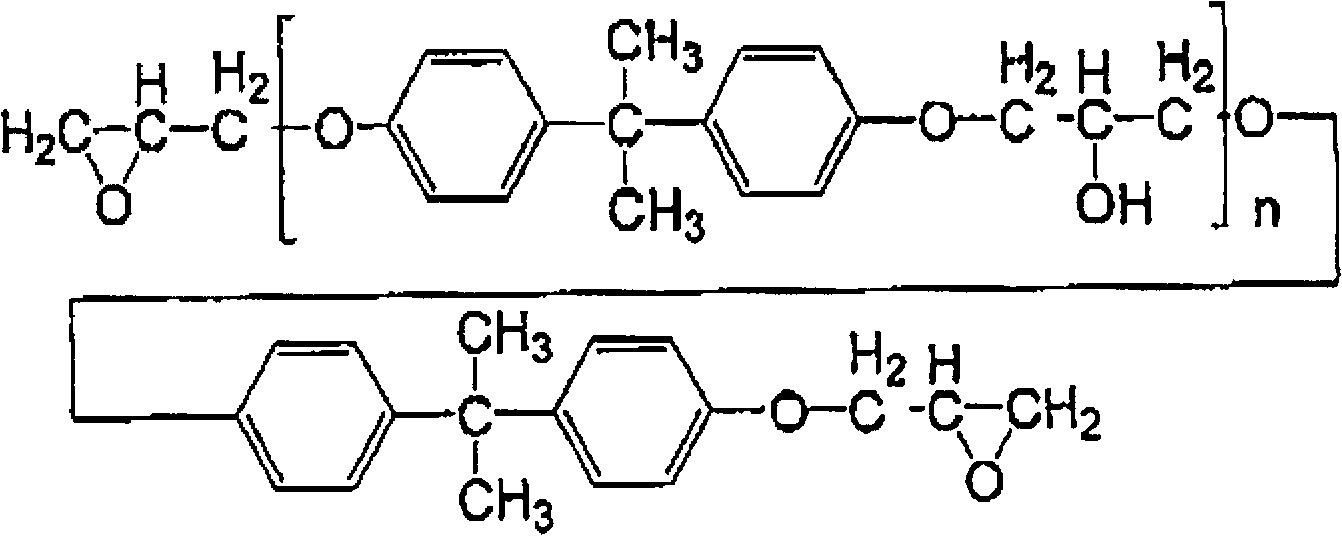

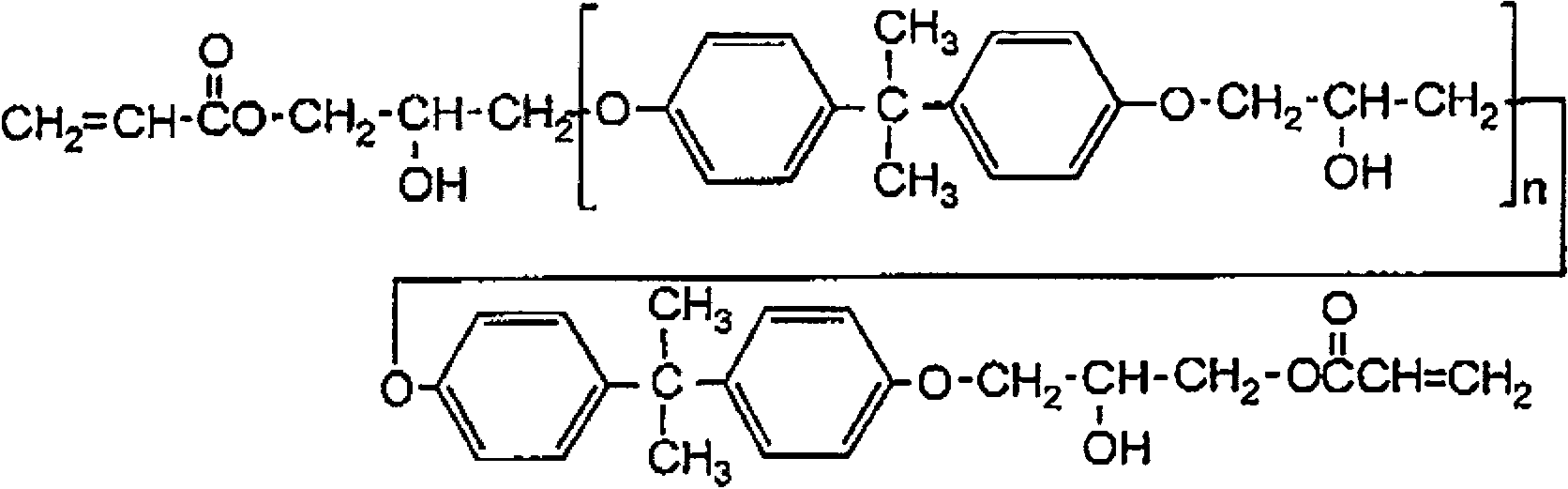

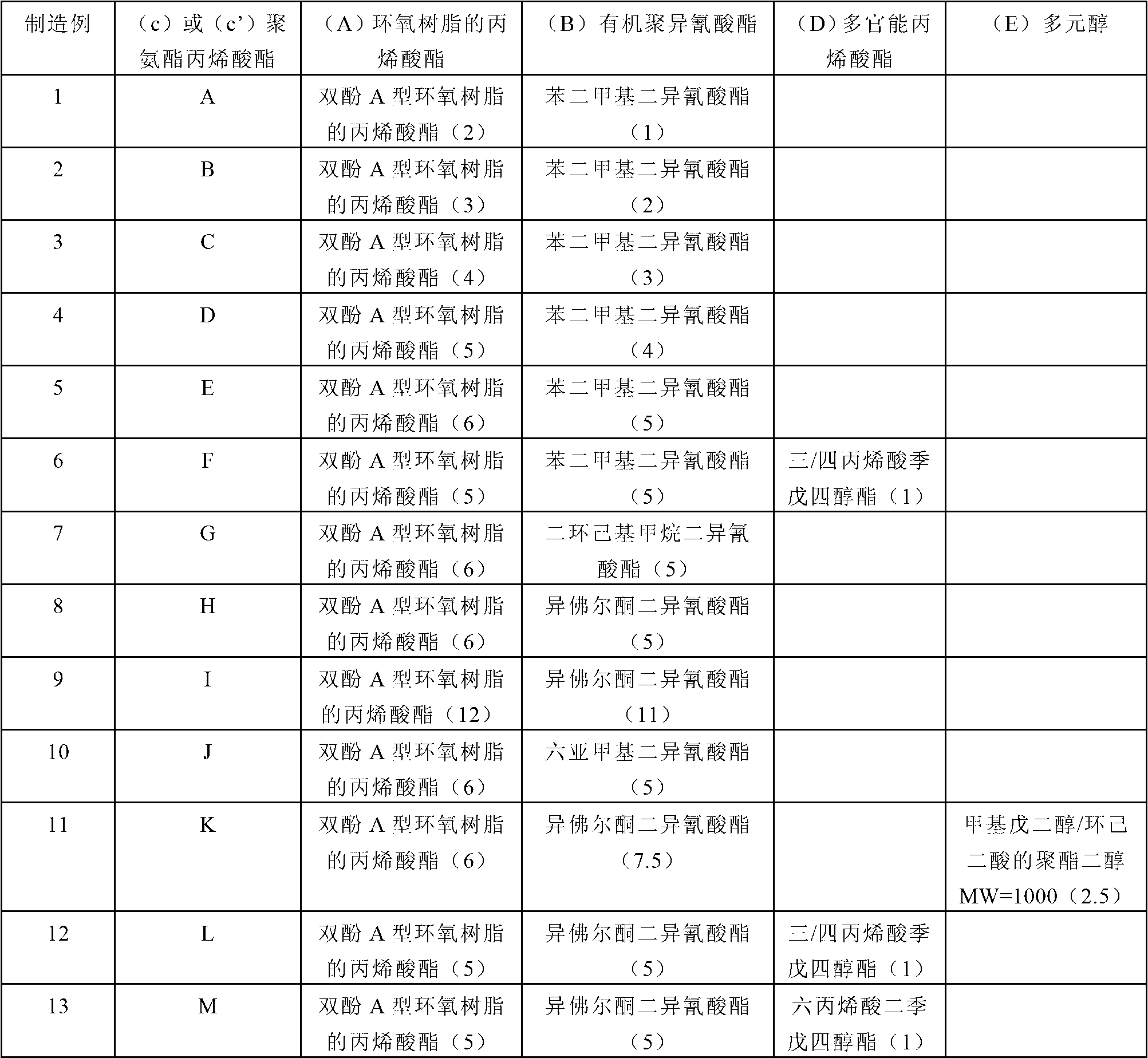

Plastics

InactiveCN102981361AImprove drying performancePhotosensitive materials for photomechanical apparatusEpoxyMethacrylate

The invention relates to a plastics, comprising polyurethane (methyl) acrylate compound (C) which is obtained by methacrylate compound (A) of epoxy resin which is a reactant of epoxy resin and (methyl) crylic acid reacting with at least organic polyisocyanate compound (B). A molar ratio NCO / OH of isocyanate groups of a component of (B) to hydroxyl of a component of (A) is lower than 1. A number-average molar mass of the polyurethane (methyl) acrylate compound (C) is 2000-20000. The plastics is coated on in-mold transfer printing films, and a coating is formed on a molded product after molding. Under a condition that only a solvent is volatilized, the plastics would not be tacky, and surface dry property is excellent.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Built-in dispersed heating type drying equipment

InactiveCN101703994AImprove the operating environmentReduce external heat dissipationLamination ancillary operationsLaminationPulp and paper industryCoating

The invention relates to built-in dispersed heating type drying equipment, which comprises an oven (10), a fan (30) and a heater (48). An air outlet of the fan is communicated with an inner cavity of the oven; the oven (10) comprises an oven cover (20) and a base (50); and a transfer passage used for transferring printed products is arranged between the oven cover (20) and the base (50). The drying equipment is characterized in that 1) an air inlet cavity (11) and a plurality of nozzles (34) are arranged in the oven cover (20); the nozzles (34) are communicated with the air inlet cavity (11) or arranged in the air inlet cavity (11), and air outlets of the nozzles (34) face the transfer passage used for transferring the printed products so as to form a built-in dispersed heating type mechanism; and 2) the air outlet of the fan (30) is communicated with an air inlet (43) of the air inlet cavity (11) through an air inlet passage (68). The built-in dispersed heating type drying equipment is widely applied to processing equipment such as coating machines, compound machines, printing machines, roller coating wires, size machines and the like, and can also be used for drying continuous transferred articles.

Owner:简苏 +1

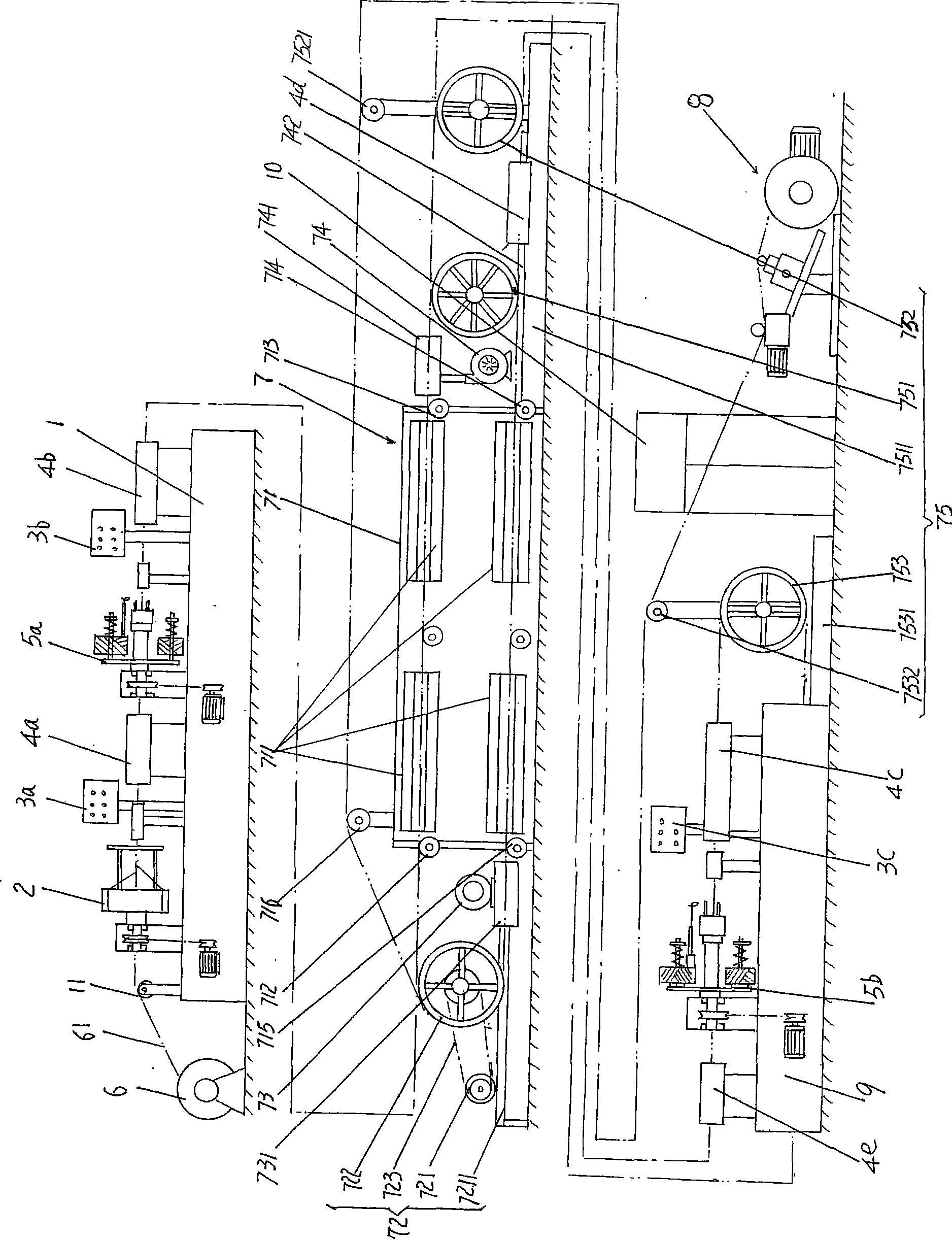

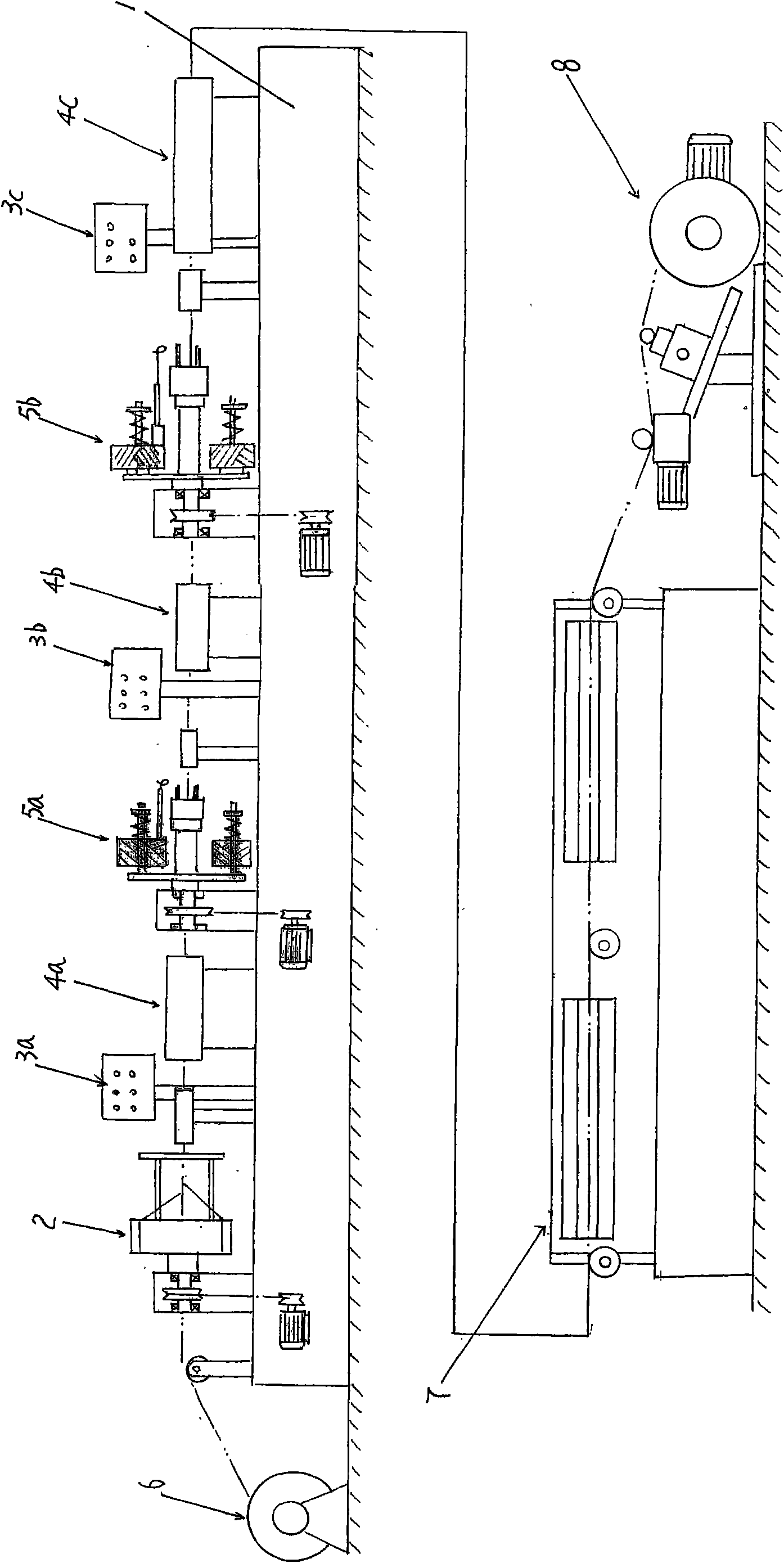

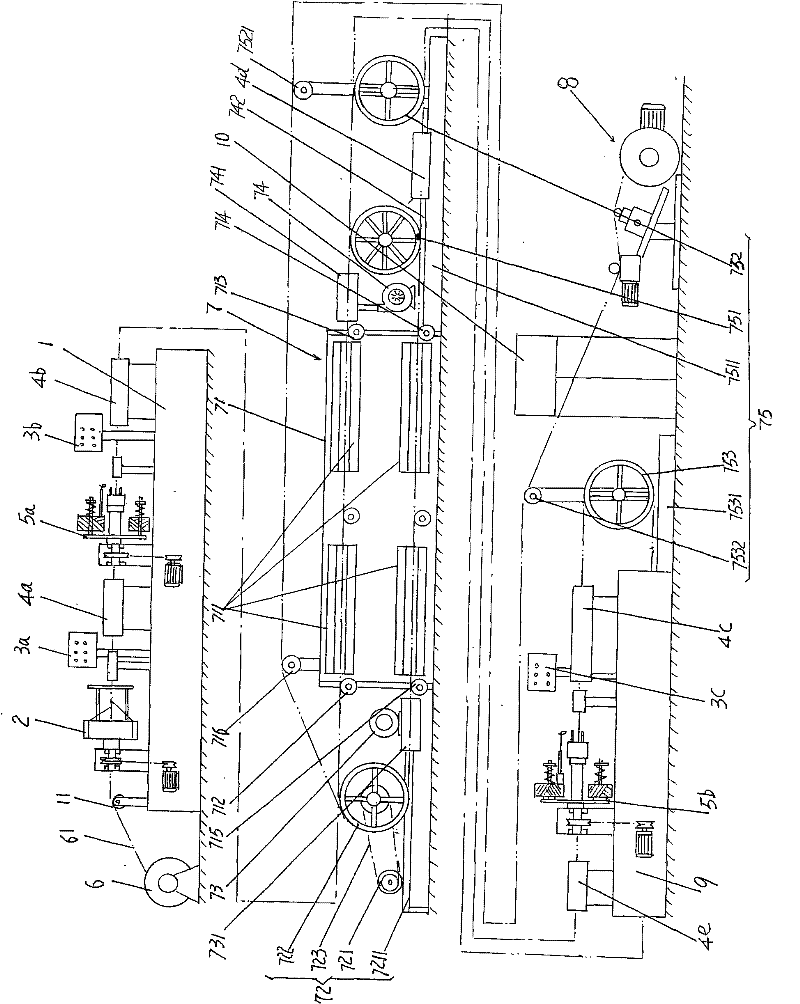

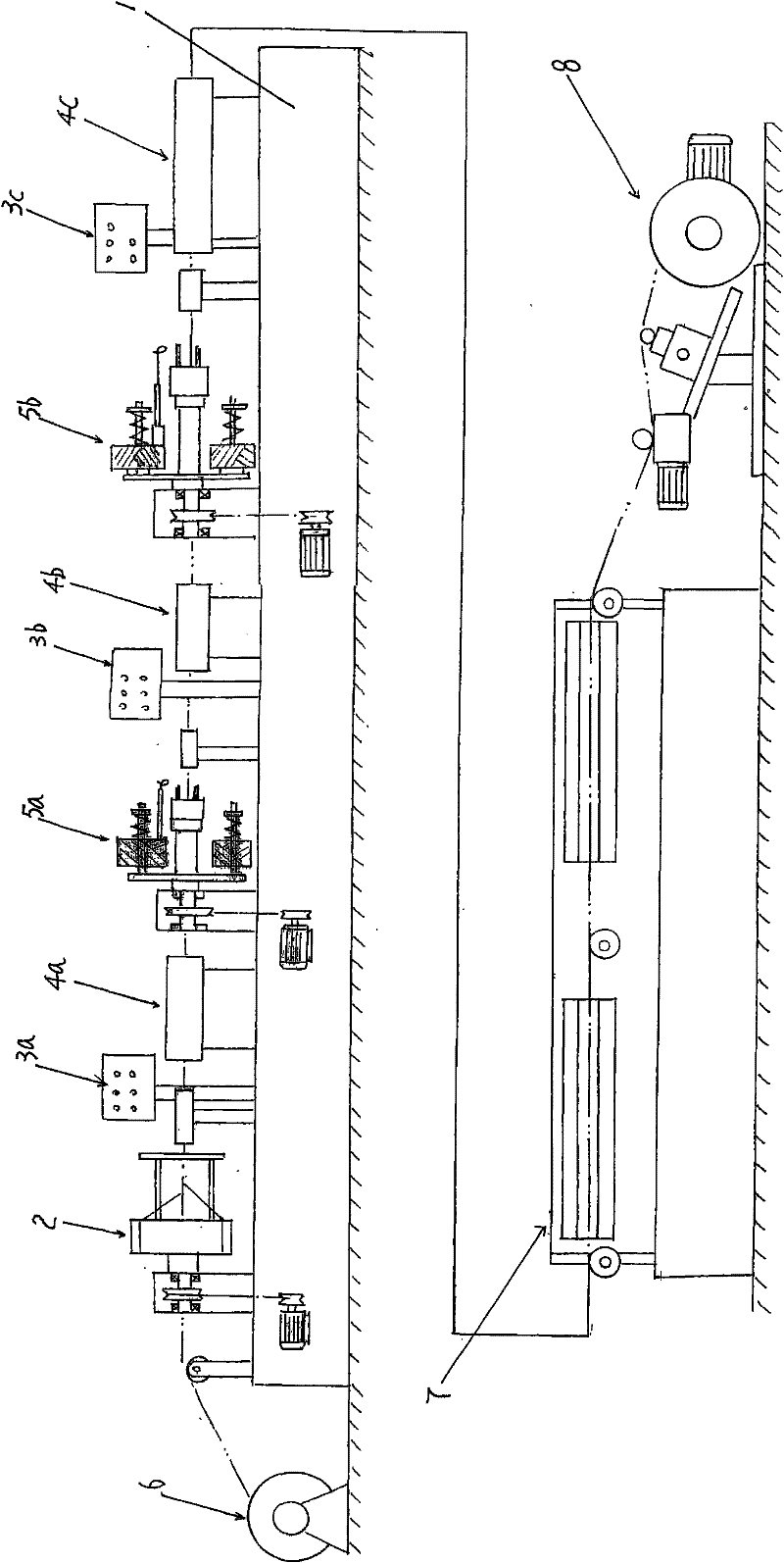

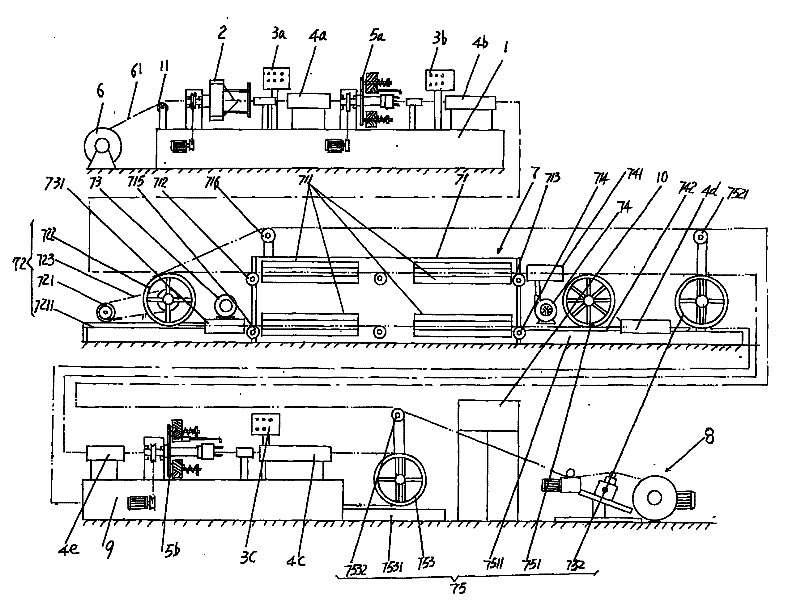

Film yarn covering and wrapping machine

InactiveCN101640084AImprove bindingImprove drying performanceInsulating conductors/cablesYarnElectrical conductor

The invention relates to a film yarn covering and wrapping machine belonging to the technical field of process equipment of electric wires and cables, which comprises a first machine table, a pay-offstand, a drier, a take-up stand, an insulating film wrapping machine, a first console, a second console, a third console, a first maceration tank, a second maceration tank, a third maceration tank, afirst insulating yarn-band wrapping machine, a second insulating yarn-band wrapping machine and a second machine table, wherein the drier is arranged between the first machine table and the second machine table, and the take-up stand corresponds to the tail end of the second machine table; the insulating film wrapping machine, the first console, the first maceration tank, the first insulating yarn-band wrapping machine, the second console and the second maceration tank are sequentially arranged in the length direction of the surface of the first machine table; and the second insulating yarn-band wrapping machine, the third console and the third maceration tank are sequentially arranged in the length direction of the surface of the second machine table. The film yarn covering and wrapping machine can increase the bonding effect between insulating film layer and the conductor, the bonding force between the insulating film layer and the insulating yarn-band layer and the bonding force between the insulating yarn-band layers, enhance the production efficiency and ensure the product quality.

Owner:CHANGSHU HAOWEIFU MACHINERY MFG

Pneumatic tire

Provided is a pneumatic tire (T) which makes it possible to improve noise performance while having both steering stability performance on dry road surfaces and driving performance on wet road surfaces. In this pneumatic tire (T), the tread surface (10) has at least four main grooves (11) extending in the tire circumferential direction; these main grooves (11) divide circumferential land portions (12) and shoulder land portions (13) and indicate the mounting direction relative to the vehicle. Multiple lug grooves (14) extending in the tire width direction are formed at intervals in the tire circumference direction on each of the multiple circumferential land portions (12). The lug grooves (14) communicate with the main grooves (11) on the inner side of the vehicle, but on the outer side of the vehicle, said lug grooves (14) terminate within the circumferential land portions (12) without communicating with the main groove (11).

Owner:THE YOKOHAMA RUBBER CO LTD

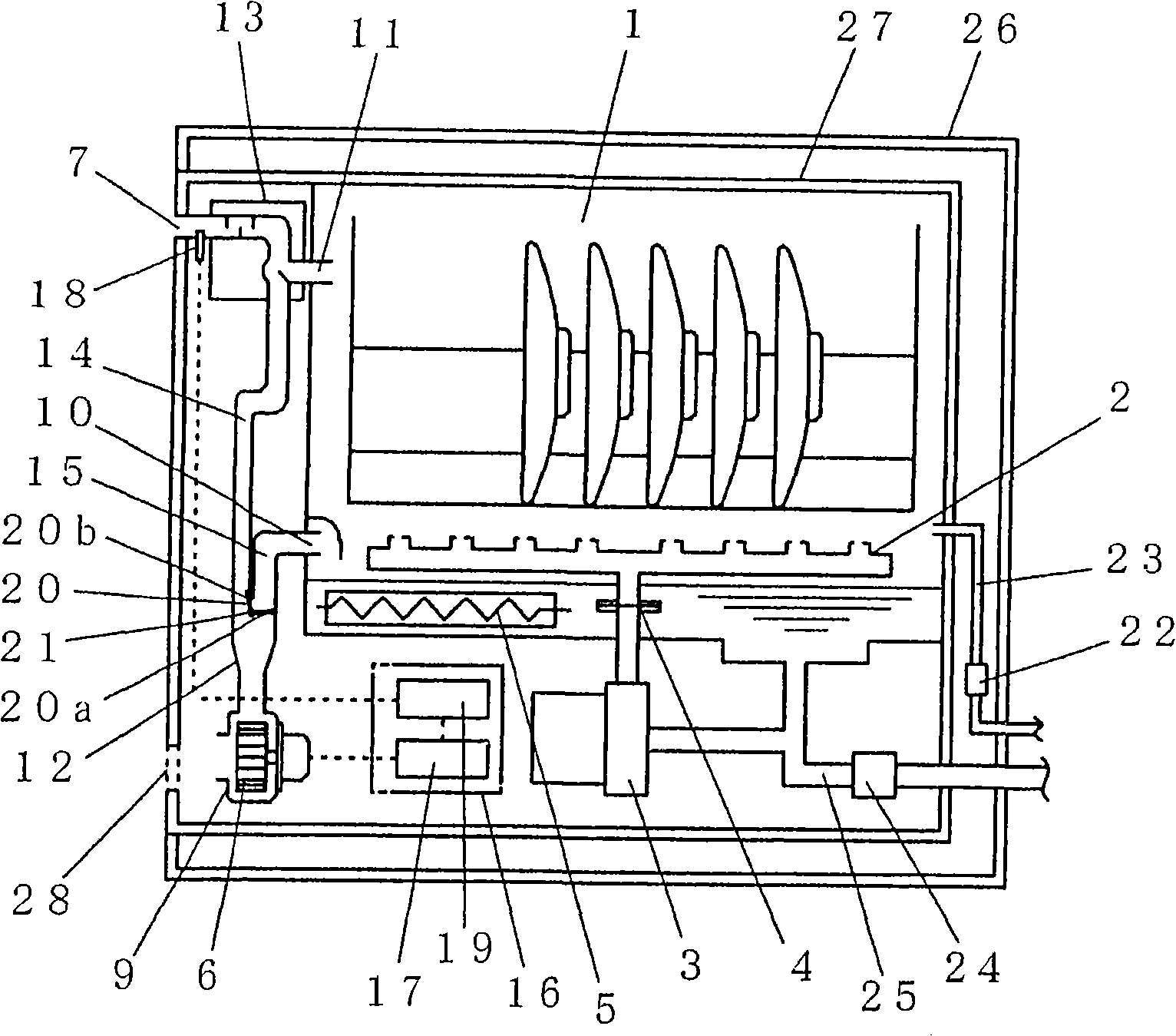

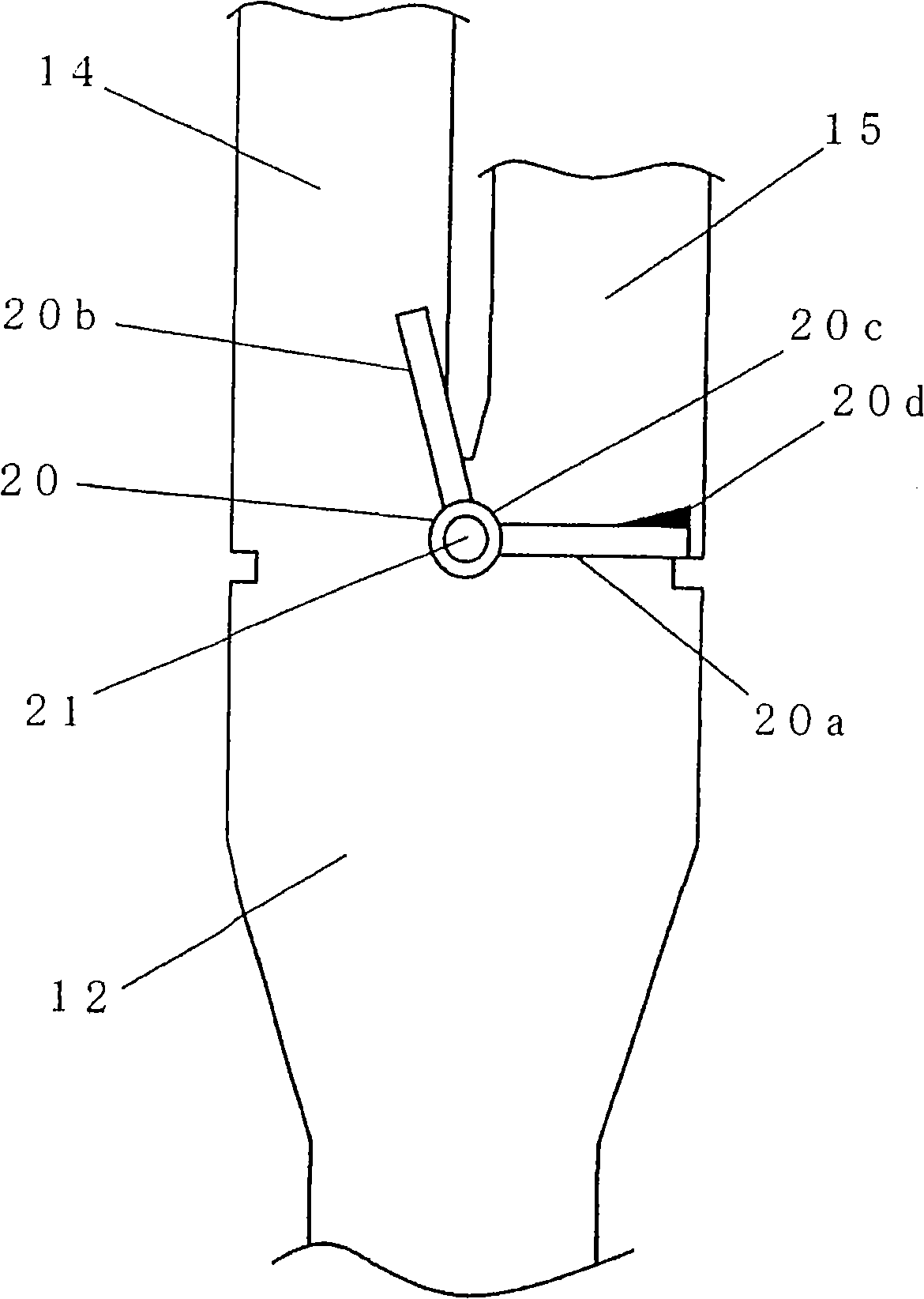

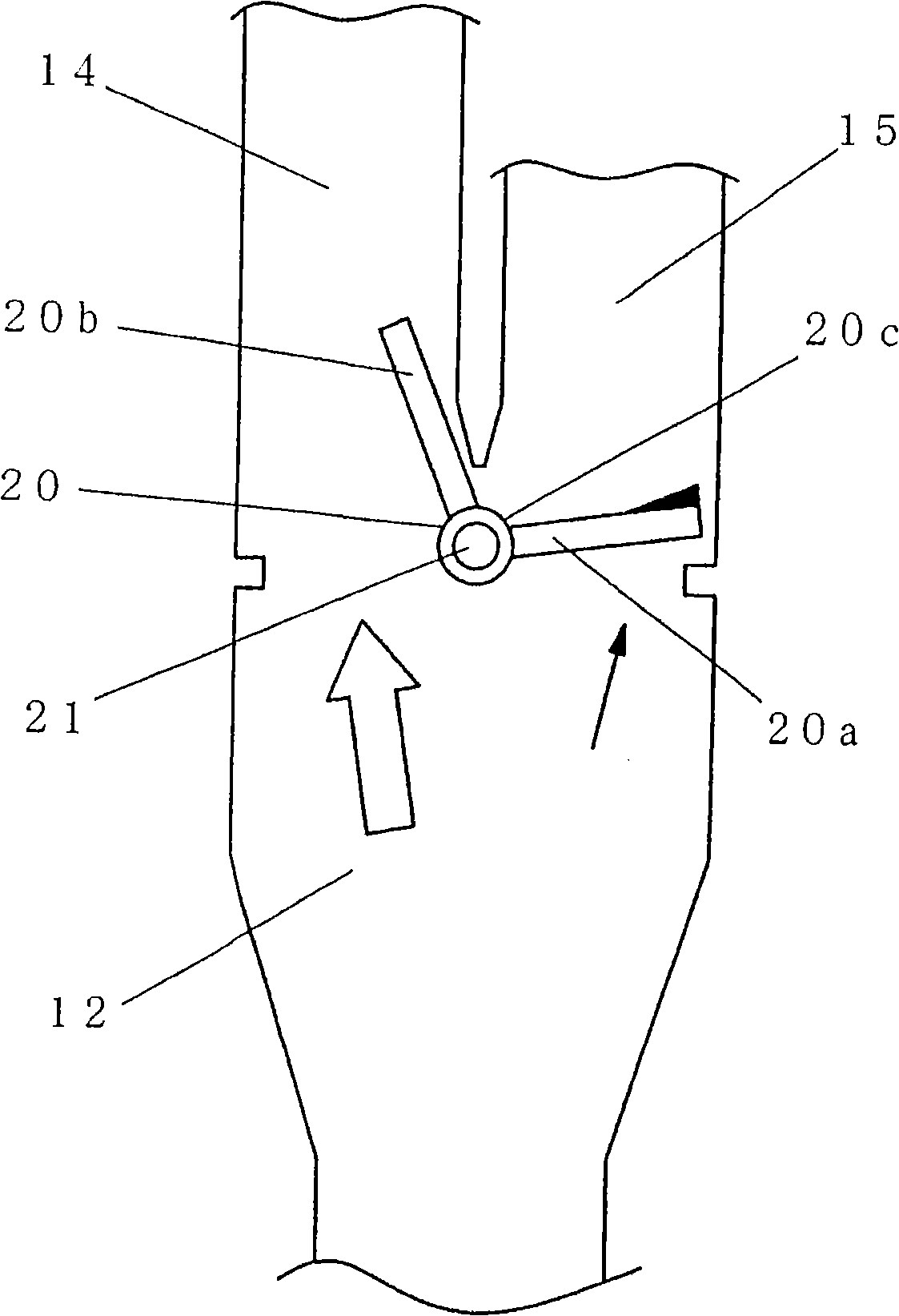

Dish washer/dryer

ActiveCN101406384AReduce temperature and humidityImprove drying performanceTableware washing/rinsing machine detailsAir volumeAir door

The invention provides a dish washer / dryer, which mixes enough outside-air in exhaust air of a rinse tank, reduces temperature and water of the exhaust air, increases comfort of the exhaust air when in drying operation. The dish washer / dryer comprises a mixing section (13) for mixing the outside-air with washing-tub-inside-air, and an air volume distribution section (12) for changing the feeding ratio of outside-air into the washing tub and the mixing section. The air volume distribution section is provided with an air door (20) causing opening to be changed through air pressure in an inside-air channel (15) of the rinse tank and an outside-air channel, a rinse tank air door (20a) arranged on the inside-air channel of the rinse tank and an outside-air door (20b) arranged on the outside-air channel are integrated. In the drying operation, the ratio of the outside-air flowing into the mixing section and the air in the rinse tank can be freely distributed / given, thereby reducing temperature and humidity of the exhaust air, reliably preventing hot air feel and increasing drying performance.

Owner:PANASONIC CORP

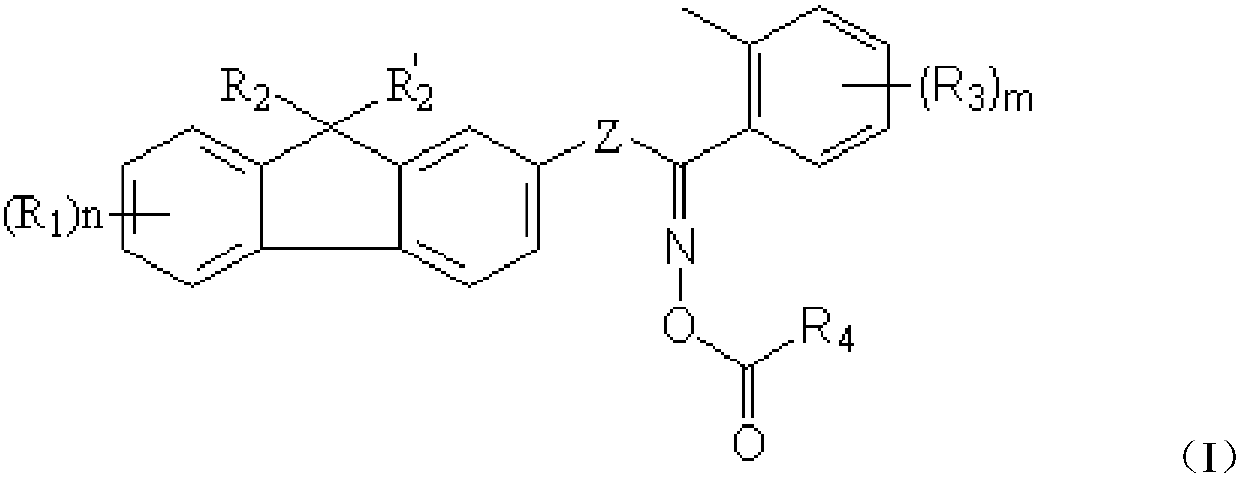

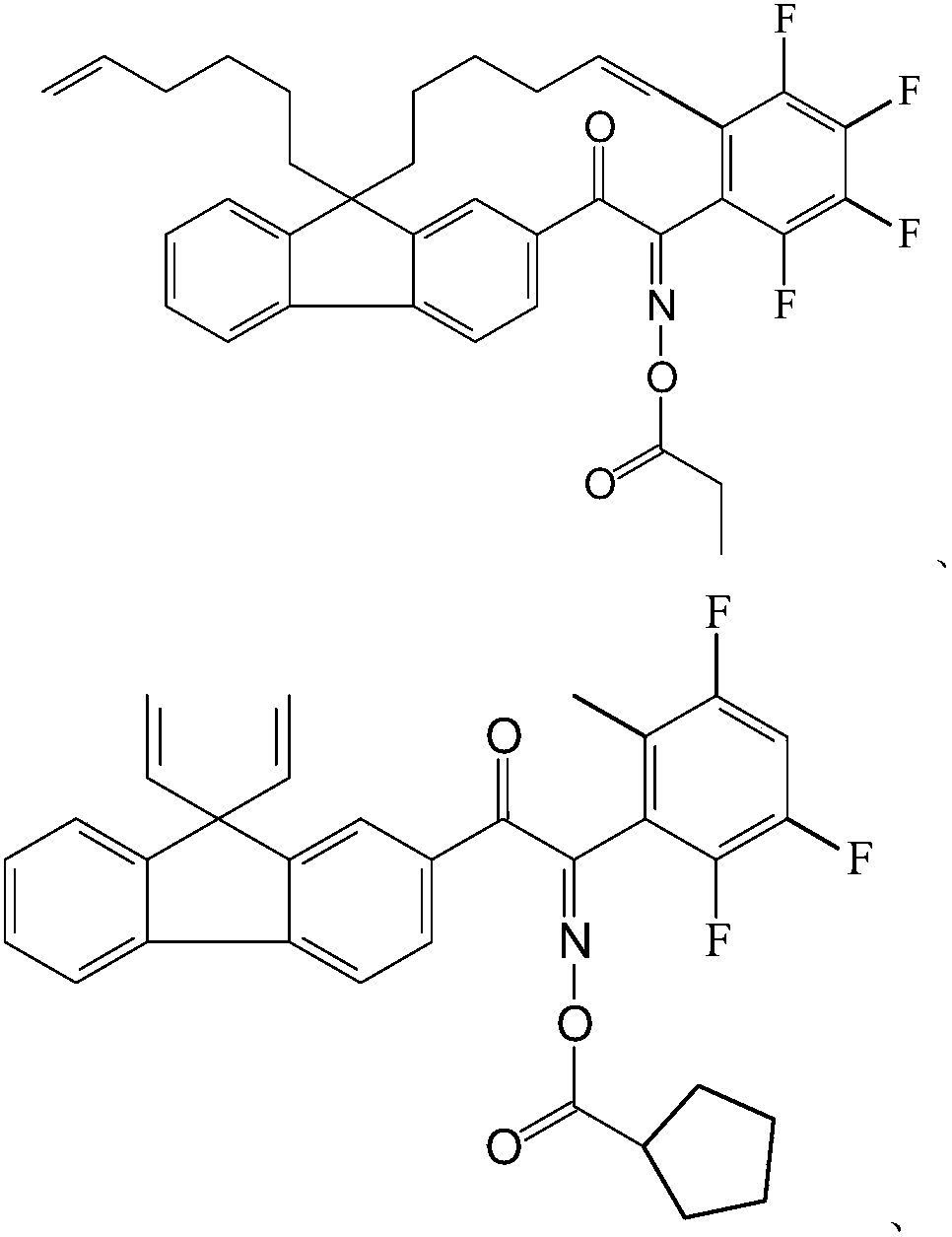

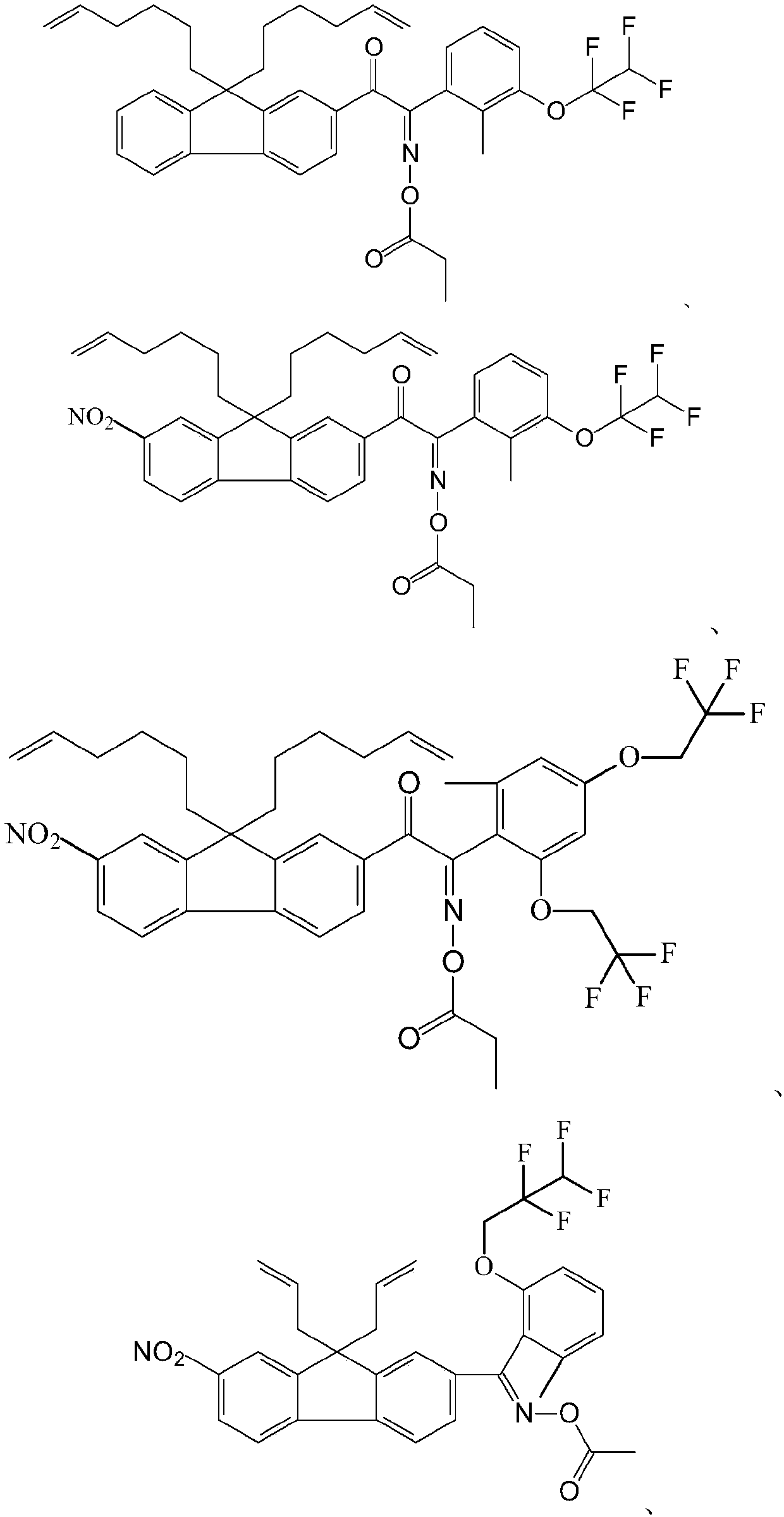

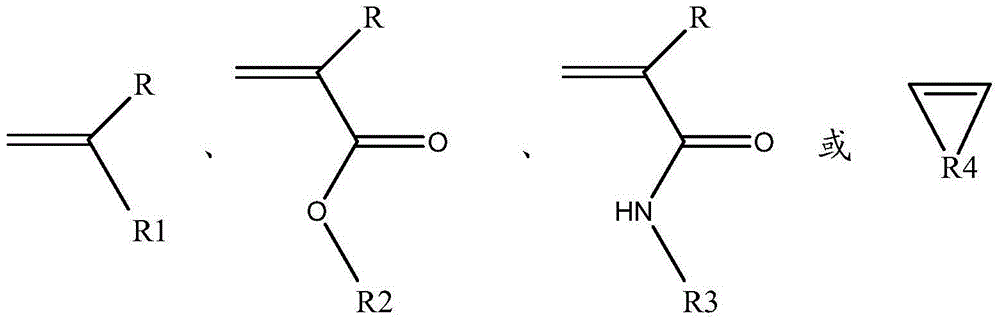

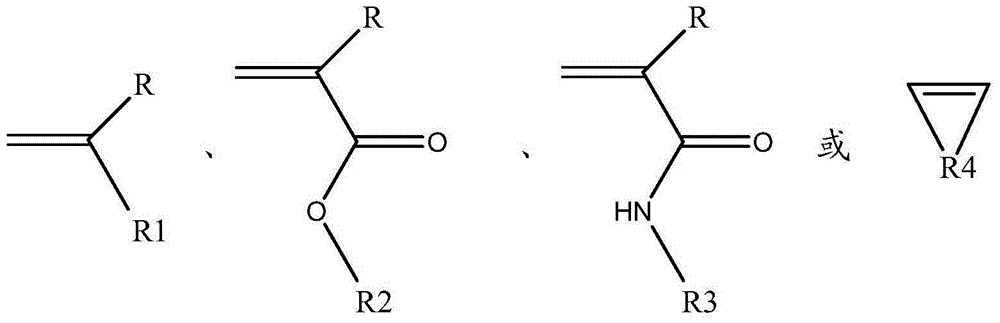

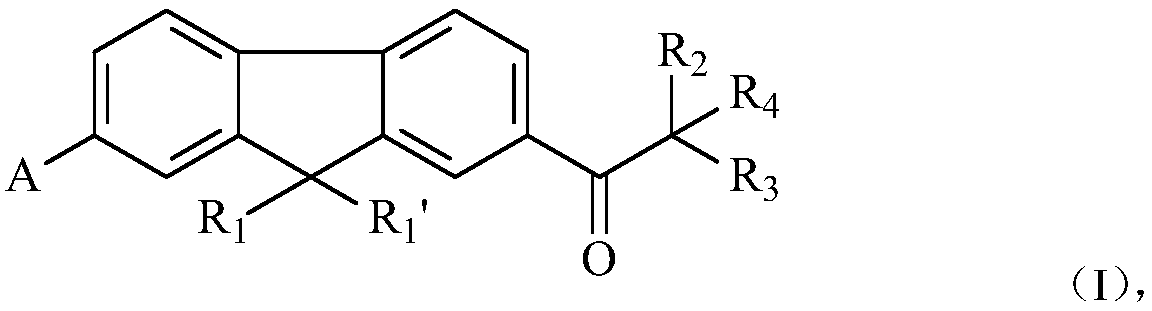

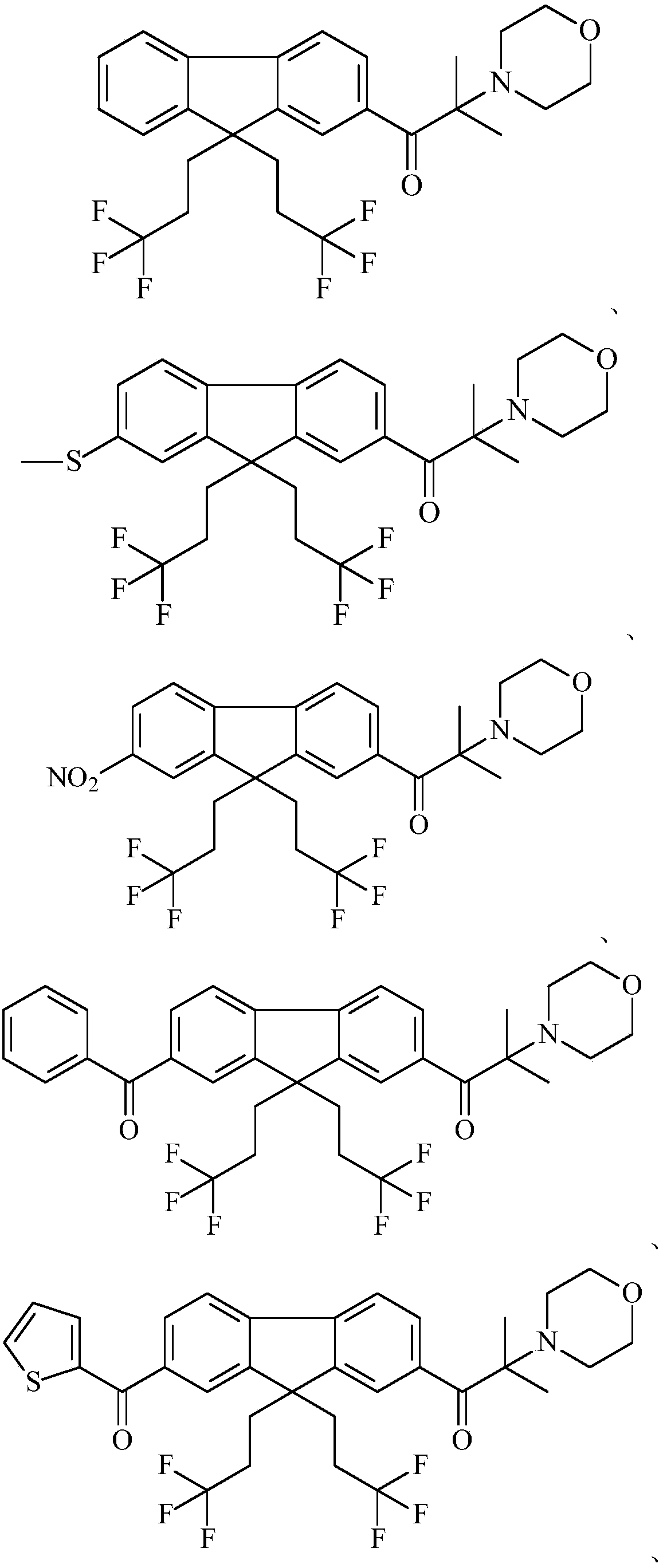

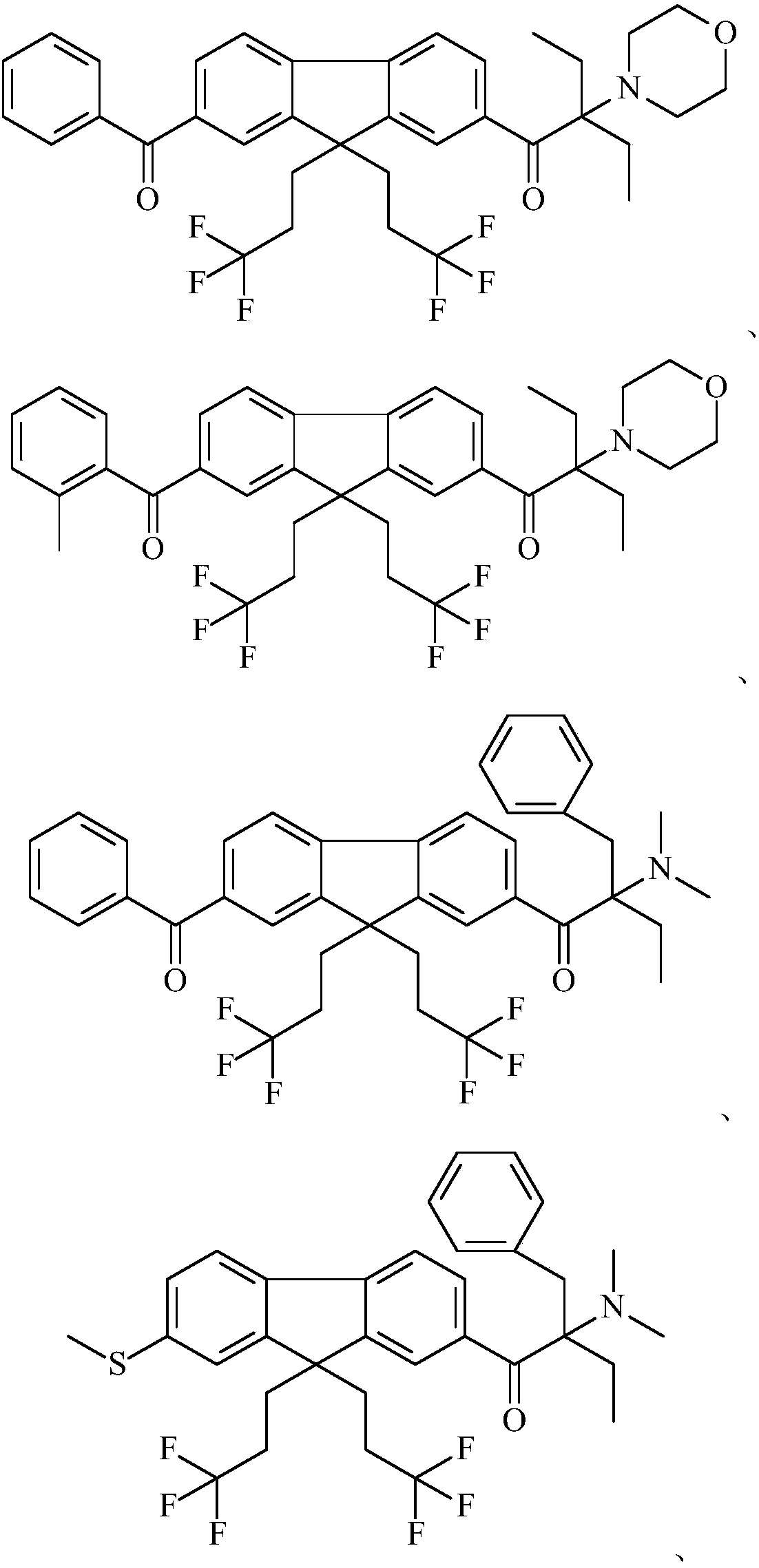

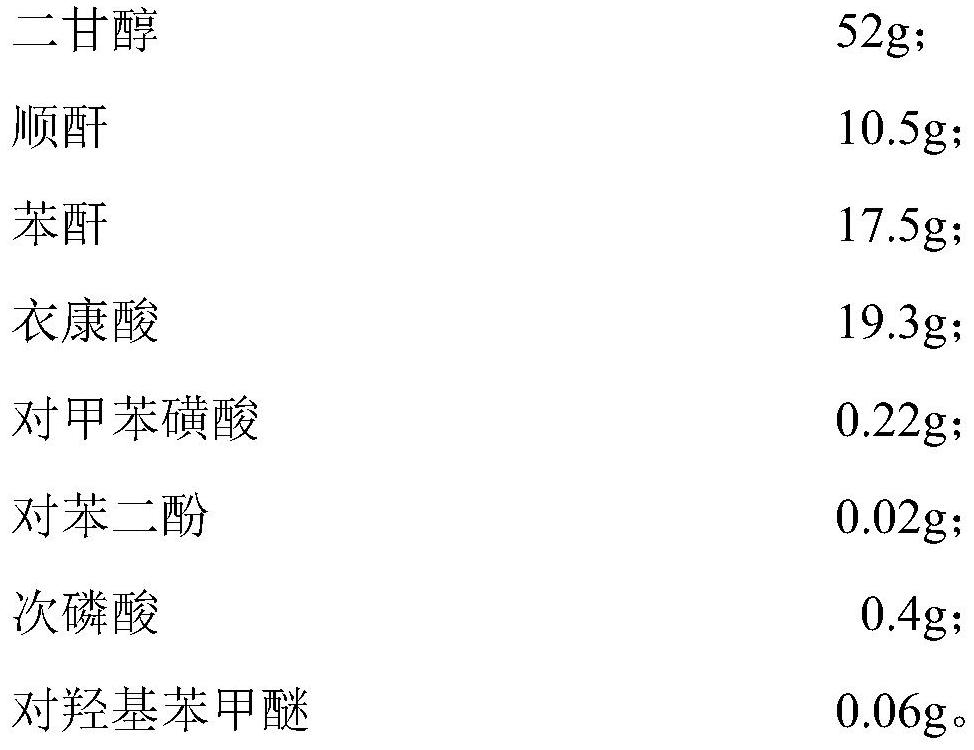

Fluoro-containing fluorene oxime ester photoinitiator, photocurable composition containing the same, and application thereof

ActiveCN109957046ANot easy to migrateInitiation efficiency is highOrganic chemistryPhotomechanical apparatusPhotoinitiatorFluorine containing

The invention provides a fluoro-containing fluorene oxime ester photoinitiator, a photocurable composition containing the same, and an application thereof. The photoinitiator has a structure representby that general formula (I). In the fluoro-containing fluorene oxime ester photoinitiator provided in the present application, by introducing a polymerizable group at the 9-position of the fluorene structure, the formed photoinitiator can be polymerized with a substrate, and thus the photoinitiator has the advantage of being difficult to migrate. At that same time, the photoinitiator provide in the present application also has the advantage of high initiation efficiency due to the introduction of fluorine-containing groups. In addition, the special structure of the photoinitiator also has theadvantages of good surface drying performance, good surface curing effect and so on. On this basis, the photoinitiator has the advantages of not easy migration, high initiation efficiency, good surface drying performance and good surface curing effect, and has a broad application prospect.

Owner:CHANGZHOU TRONLY ADVANCED ELECTRONICS MATERIALS CO LTD +1

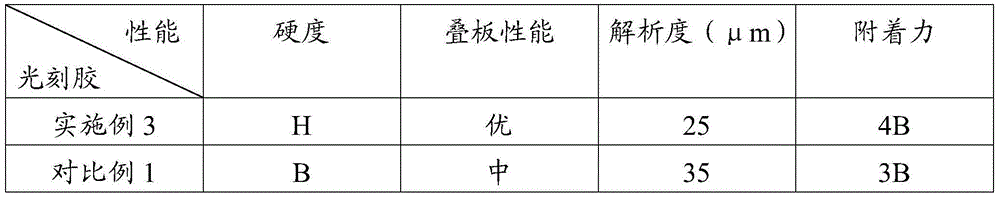

Photoresist

InactiveCN104865794AHigh hardnessImprove drying performancePhotomechanical apparatusPolymer scienceSolvent

The present invention discloses a photoresist, and belongs to the photoetching field. The photoresist comprises, by weight, 10-50 parts of an alkali-soluble resin, 5-25 parts of a photo polymerization monomer, 0.5-8 parts of a photoinitiator, 20-80 parts of a solvent, and 0.1-5 parts of a pigment, wherein at least one selected from an ethylene-based unsaturated monomer and a propylene-based unsaturated monomer, a (methyl) acrylic acid monomer, and a maleic anhydride monomer are subjected to a copolymerization reaction to obtain the alkali-soluble resin, and the glass transition temperature is more than or equal to 120 DEG C. According to the present invention, with the alkali-soluble resin having the glass transition temperature of more than or equal to 120 DEG C, the glass transition temperature of the photoresist can be significantly increased, and the conversion of the photoresist into the high elasticity state having a certain viscosity during the drying is avoided, such that the photoresist film coated on the PCB substrate and dried has characteristics of high hardness and good surface dry performance. The photoresist provided by the embodiments of the present invention has excellent scratch resistance and excellent plate stacking performance during the substrate stacking process.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Film yarn covering and wrapping machine

InactiveCN101640084BImprove bindingImprove drying performanceInsulating conductors/cablesYarnProcess equipment

The invention relates to a film yarn covering and wrapping machine belonging to the technical field of process equipment of electric wires and cables, which comprises a first machine table, a pay-off stand, a drier, a take-up stand, an insulating film wrapping machine, a first console, a second console, a third console, a first maceration tank, a second maceration tank, a third maceration tank, afirst insulating yarn-band wrapping machine, a second insulating yarn-band wrapping machine and a second machine table, wherein the drier is arranged between the first machine table and the second machine table, and the take-up stand corresponds to the tail end of the second machine table; the insulating film wrapping machine, the first console, the first maceration tank, the first insulating yarn-band wrapping machine, the second console and the second maceration tank are sequentially arranged in the length direction of the surface of the first machine table; and the second insulating yarn-band wrapping machine, the third console and the third maceration tank are sequentially arranged in the length direction of the surface of the second machine table. The film yarn covering and wrapping machine can increase the bonding effect between insulating film layer and the conductor, the bonding force between the insulating film layer and the insulating yarn-band layer and the bonding force between the insulating yarn-band layers, enhance the production efficiency and ensure the product quality.

Owner:CHANGSHU HAOWEIFU MACHINERY MFG

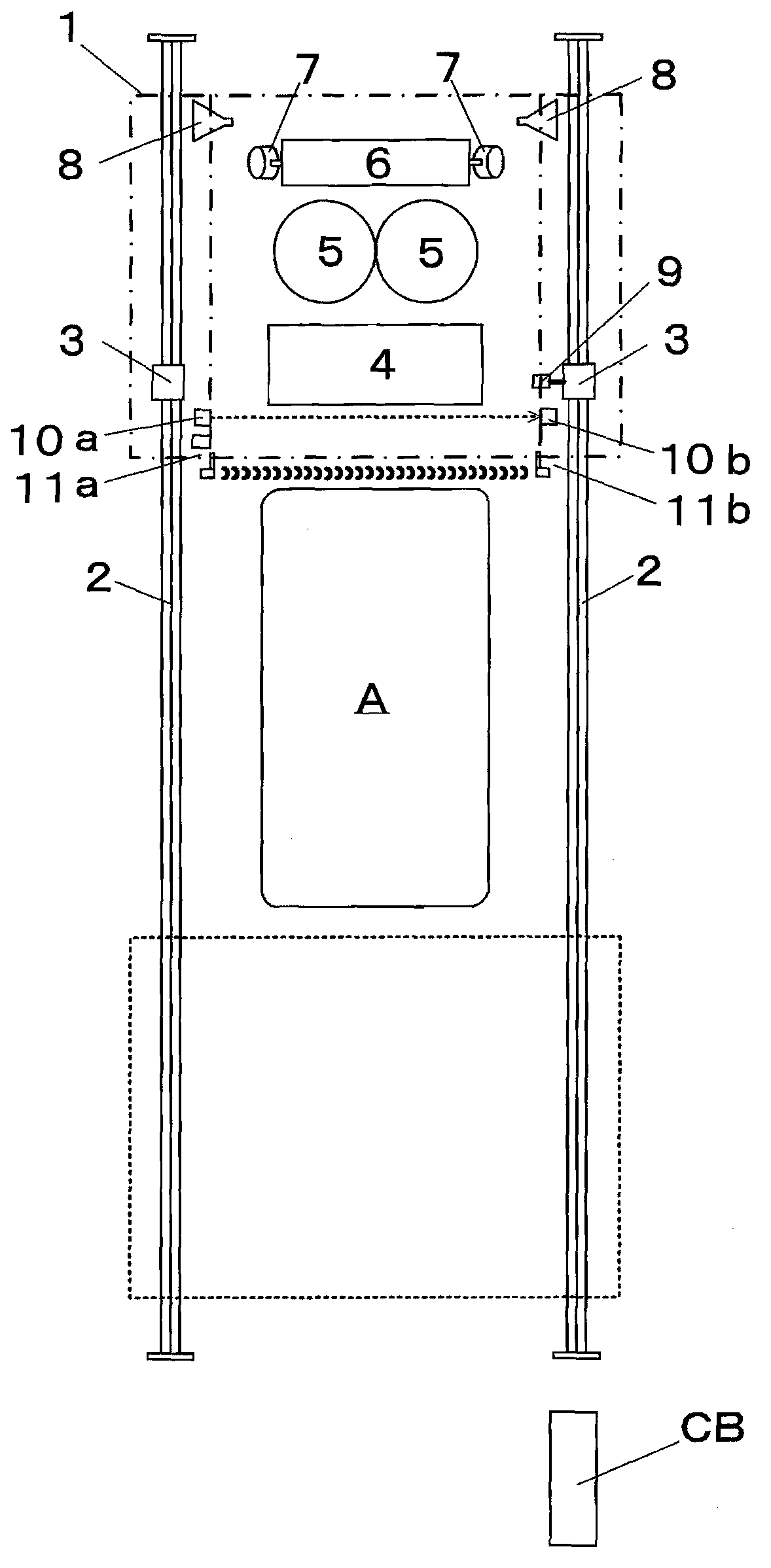

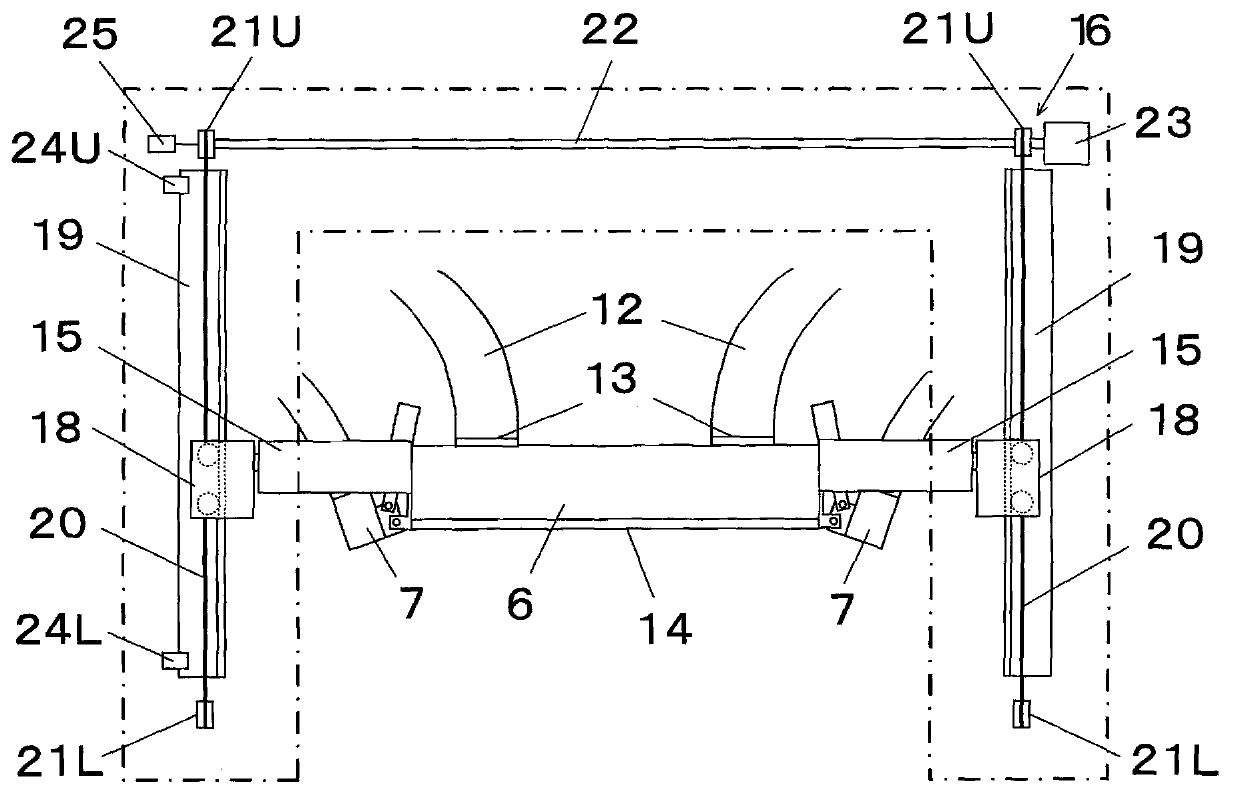

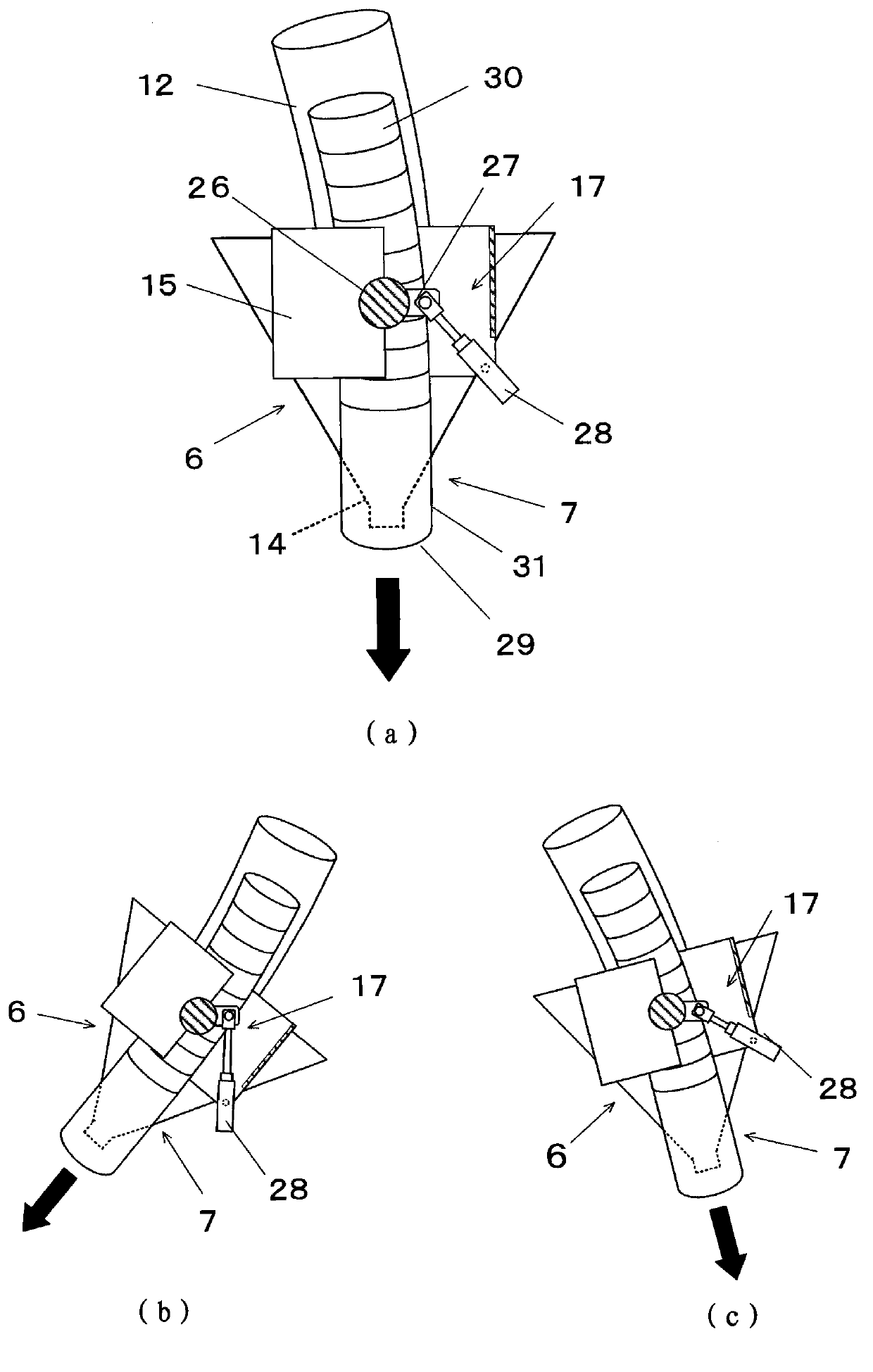

Vehicle washing machine

ActiveCN103101520AImprove drying performanceKeep dryCleaning apparatus for vehicle exteriorsMotor vehicle partEngineering

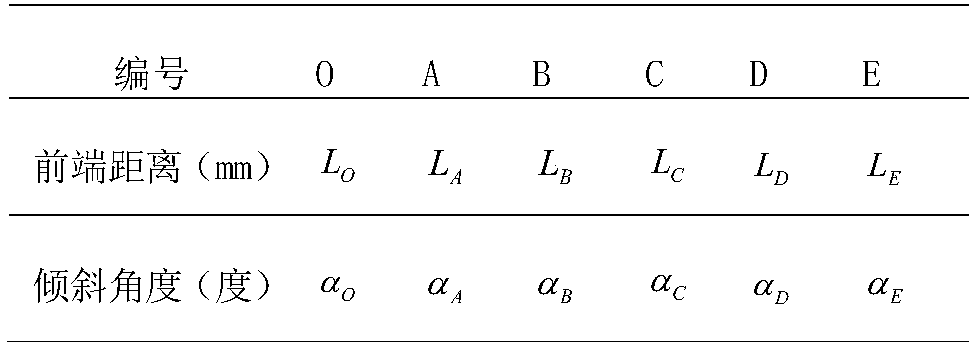

The invention is to provide a vehicle washing machine capable of improving the drying performances of the side surfaces of vehicles while independent of the types of the vehicles and the parts of the vehicles. The vehicle washing machine comprises a lifting unit (16) used for lifting an upper-surface drying nozzle (6) along the upper surface of a vehicle; a left-right swing unit (32) used for swing a lateral-surface upper drying nozzle (7) along the width direction of the lateral surface of the vehicle; and a vehicle washing control panel (35) used for controlling the lifting unit (16) and the left-right swing unit (32) according to the shapes of the upper surface and the lateral surface of the vehicle detected by an upper-surface shape detecting unit (10) and a lateral-surface shape detecting unit (11) respectively. A plurality of reference points for the shape of the vehicle are detected according to the shape of the upper surface of the vehicle, and then each of all the vehicle parts defined by the reference points are provided with a swing angle for the swing unit respectively according to the shapes of the upper surface and the lateral surface of the vehicle. Meanwhile, the swing unit (32) is controlled.

Owner:EMU KEE SEIKO

Drying oven for manufacturing solar backboard film

ActiveCN104197654ASimple structureReasonable designFinal product manufactureDrying gas arrangementsCold airAir blower

The invention discloses a drying oven for manufacturing solar backboard film. The drying oven for manufacturing the solar backboard film is provided with a base and a main case, an air blower case is installed on the surface of the base, an air blower is arranged in the air blower case, and a cold air inlet is formed in the air blower case. A main machine is arranged in the main case, a drying oven body is arranged above the main case, a heating pipe and a backboard film reeling shaft are arranged in the drying oven body, and the heating pipe is arranged above the backboard film reeling shaft. A cover hood is arranged in the center of the top end of the drying oven body, an air inlet is formed in the cover hood, and an air outlet is formed in the position, close to the cover hood, of the top end of the drying oven body. A cold air pipe is connected between the cold air inlet and the air inlet, the air outlet is connected with a hot air pipe, and a hot air outlet is formed in the top end of the hot air pipe. The drying oven is simple in structure, reasonable in design, rapid and convenient to operate, quite convenient to install and maintain, low in cost, good in drying performance and favorable for marketization competition, and production efficiency and product quality are improved.

Owner:江西泰明光伏有限公司 +1

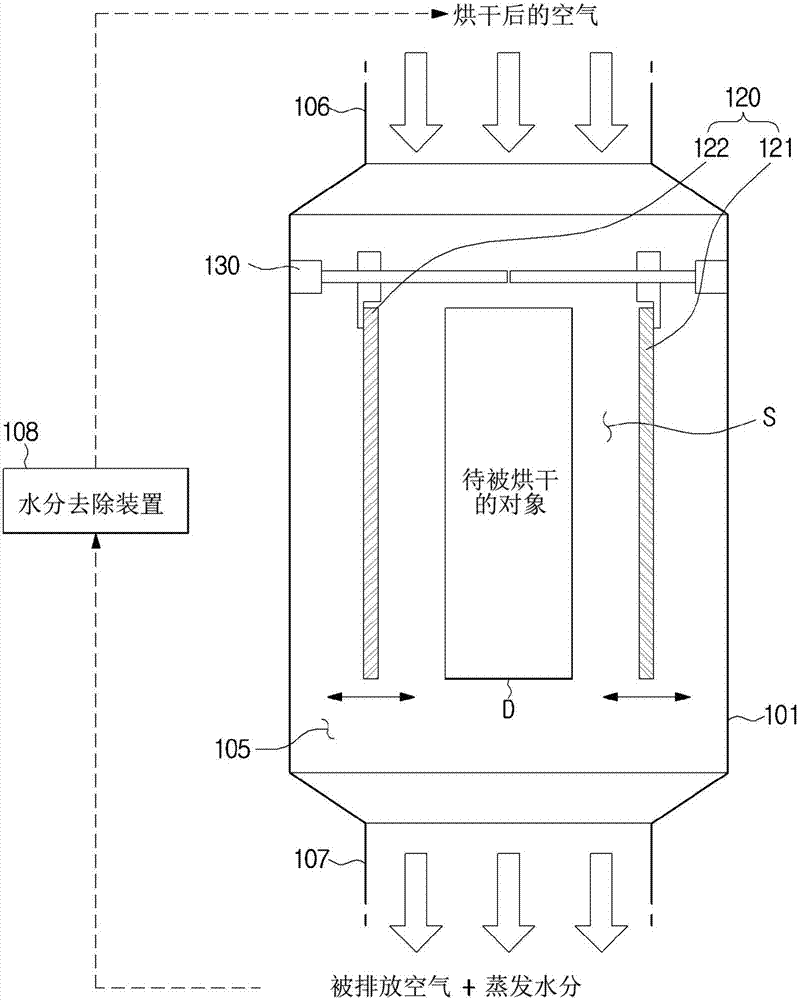

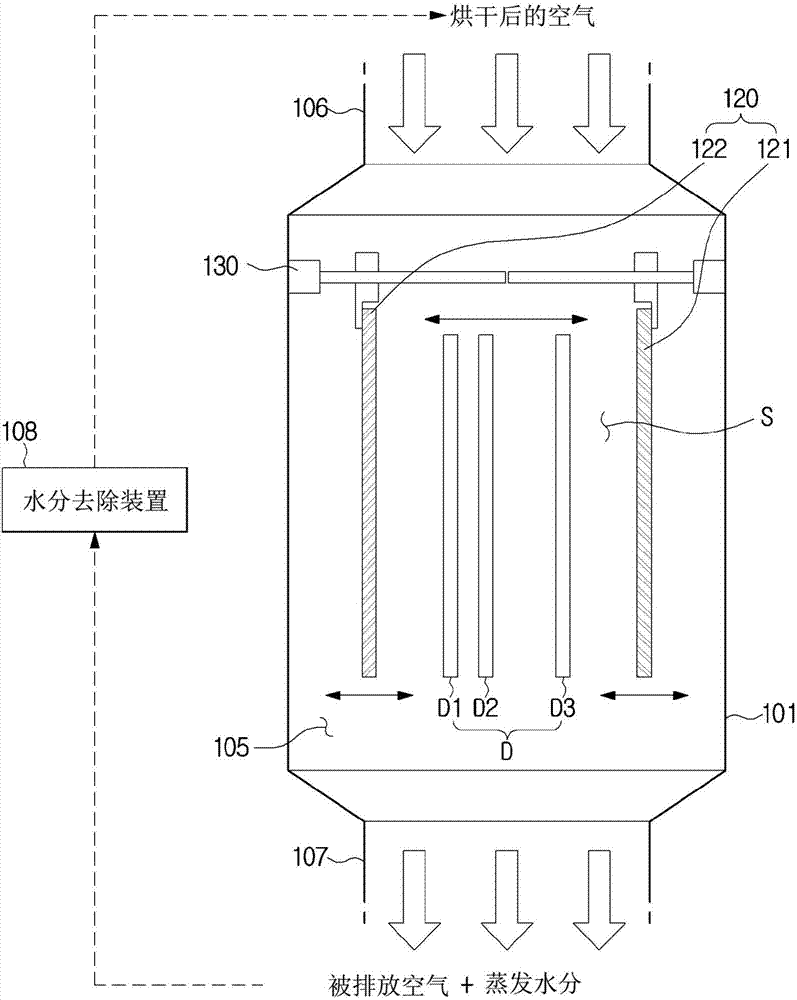

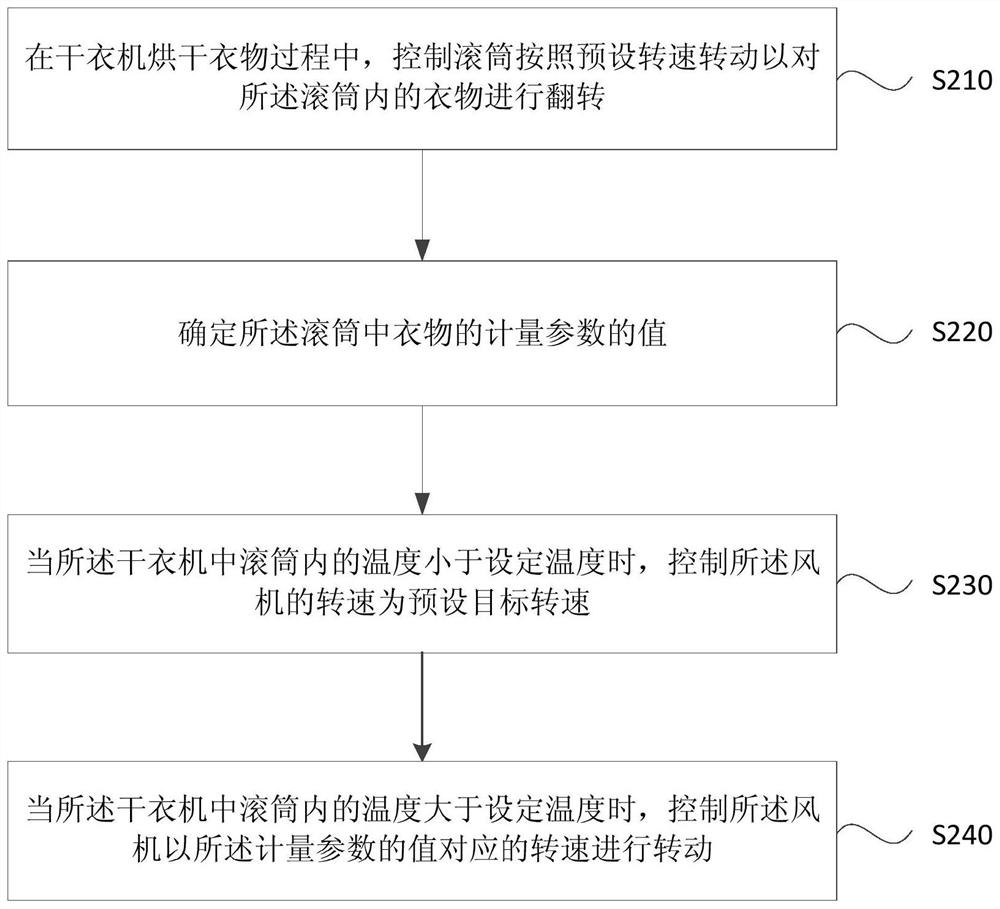

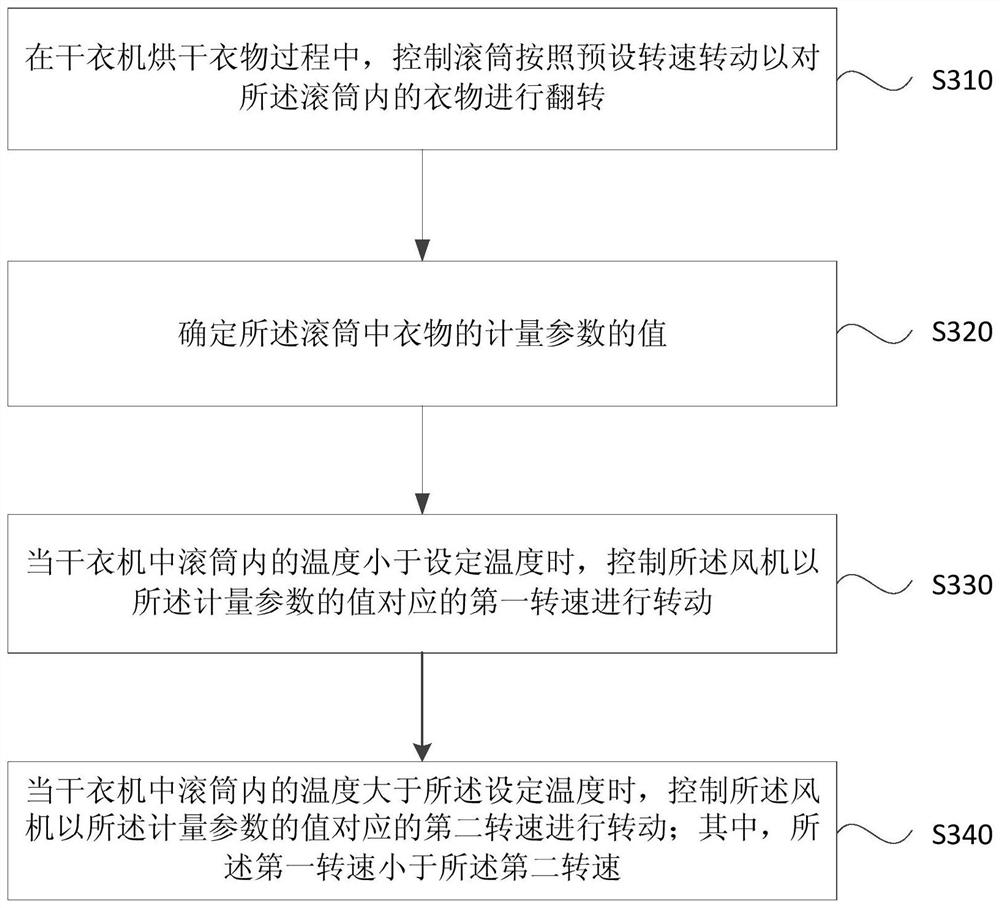

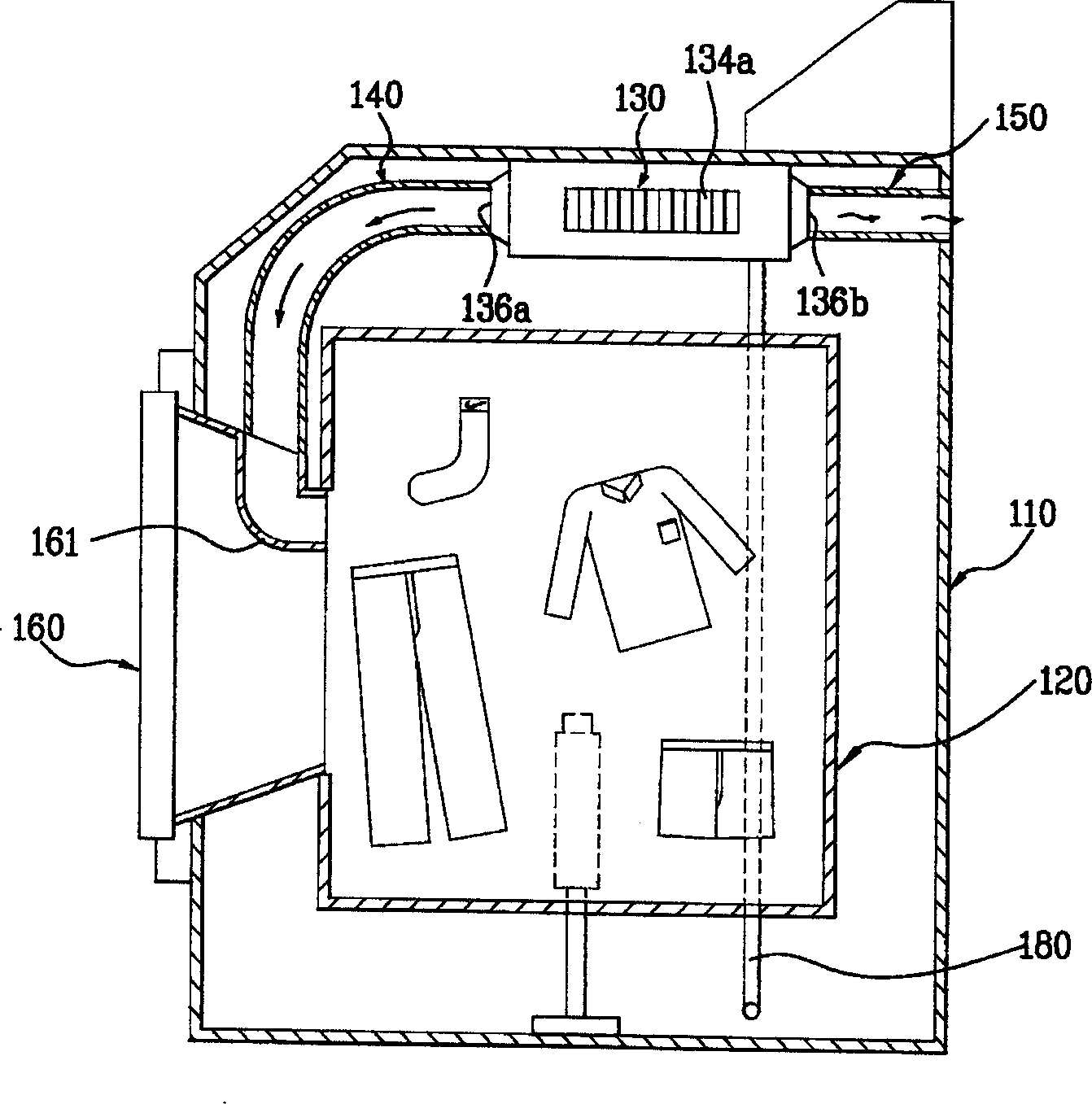

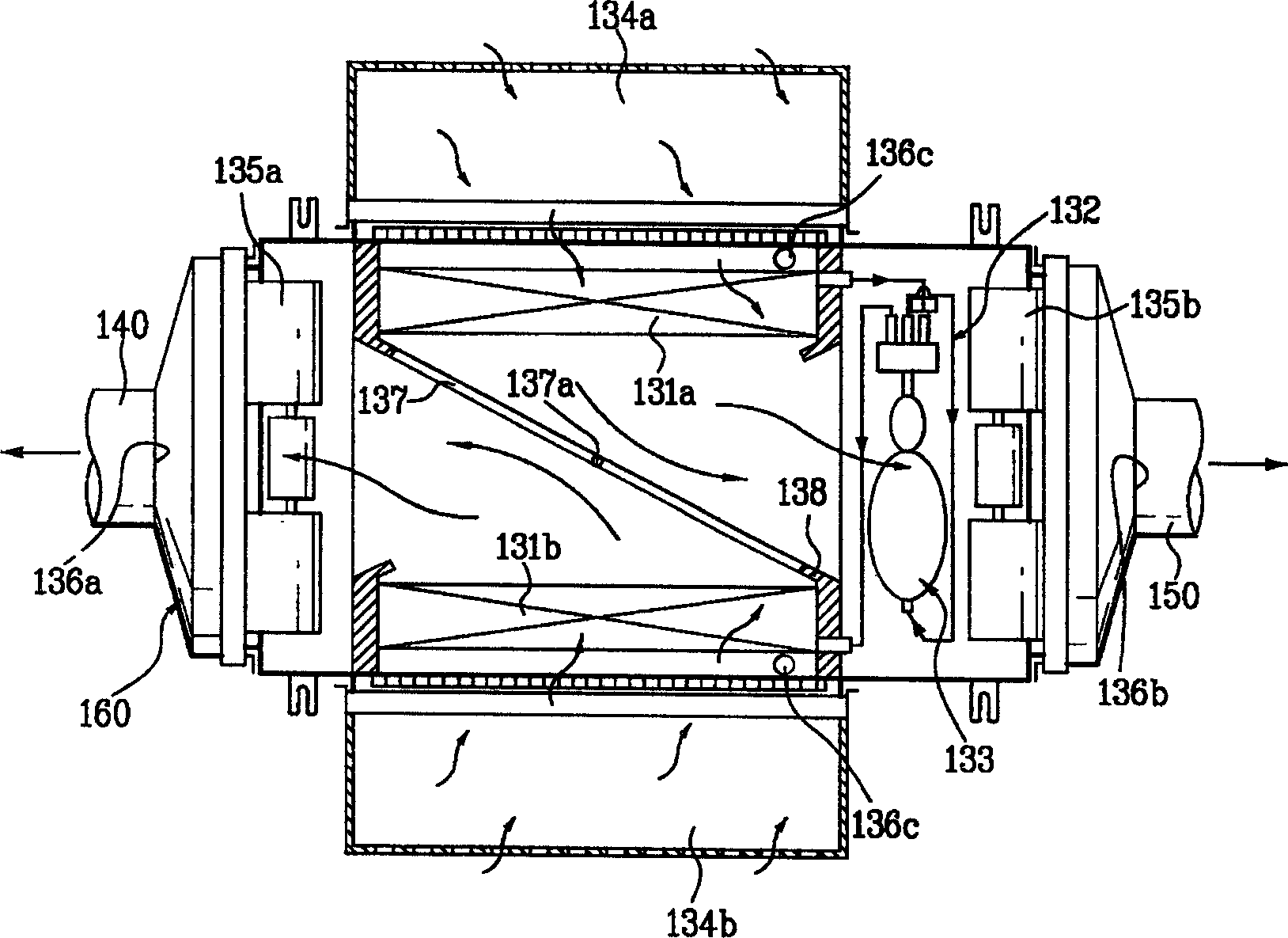

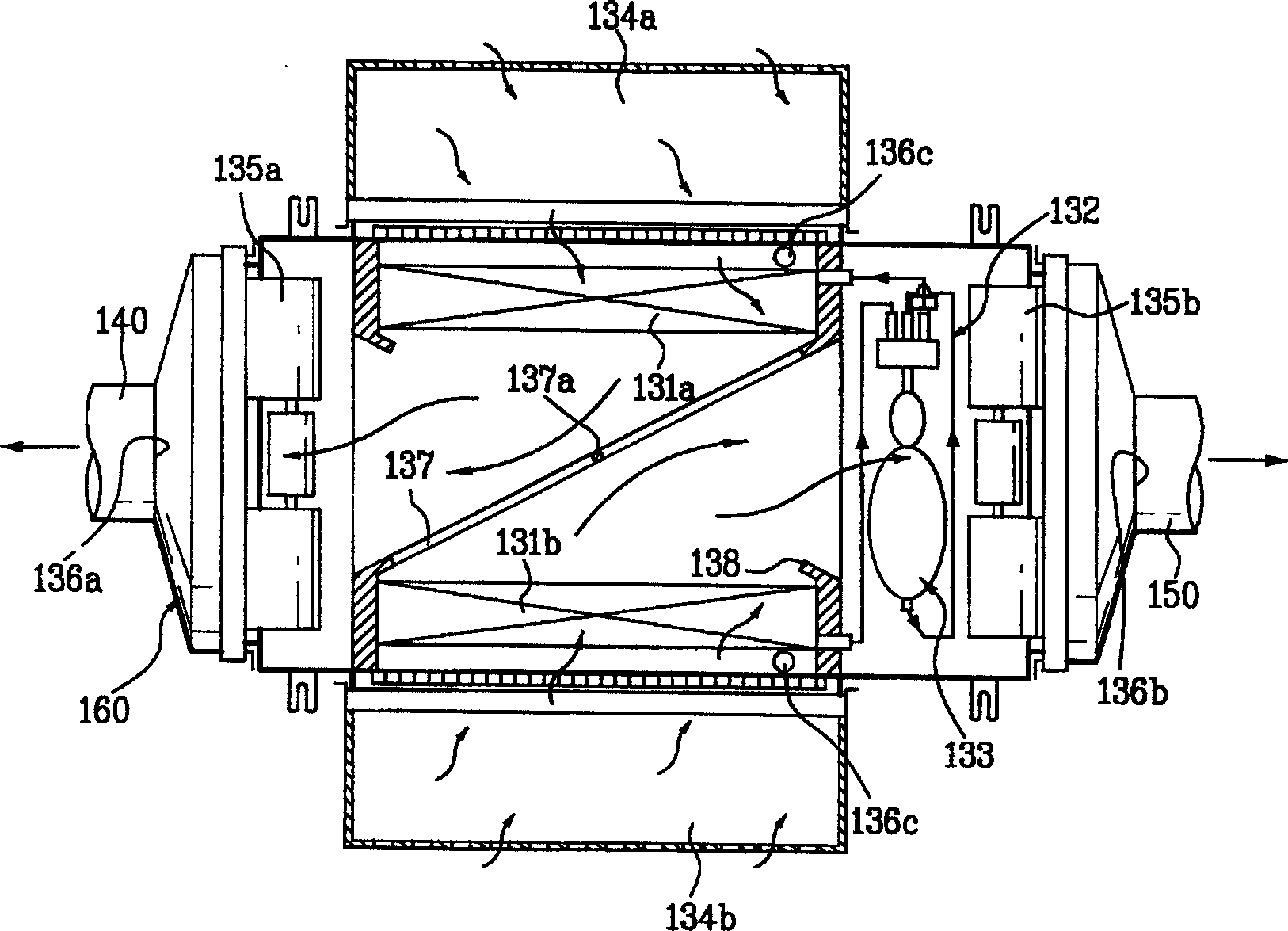

Dryer and control method thereof

InactiveCN107429472AImprove drying performanceDrying solid materials with heatResistance/reactance/impedenceControl engineeringControl cell

A dryer includes a main body, a drying chamber provided inside the main body and configured to accommodate objects to be dried, a conveying unit configured to convey the objects to be dried, a sensor unit configured to sense information on states of the objects to be dried, and a control unit configured to control the conveying unit to move the objects to be dried based on the information sensed by the sensor unit.

Owner:SAMSUNG ELECTRONICS CO LTD

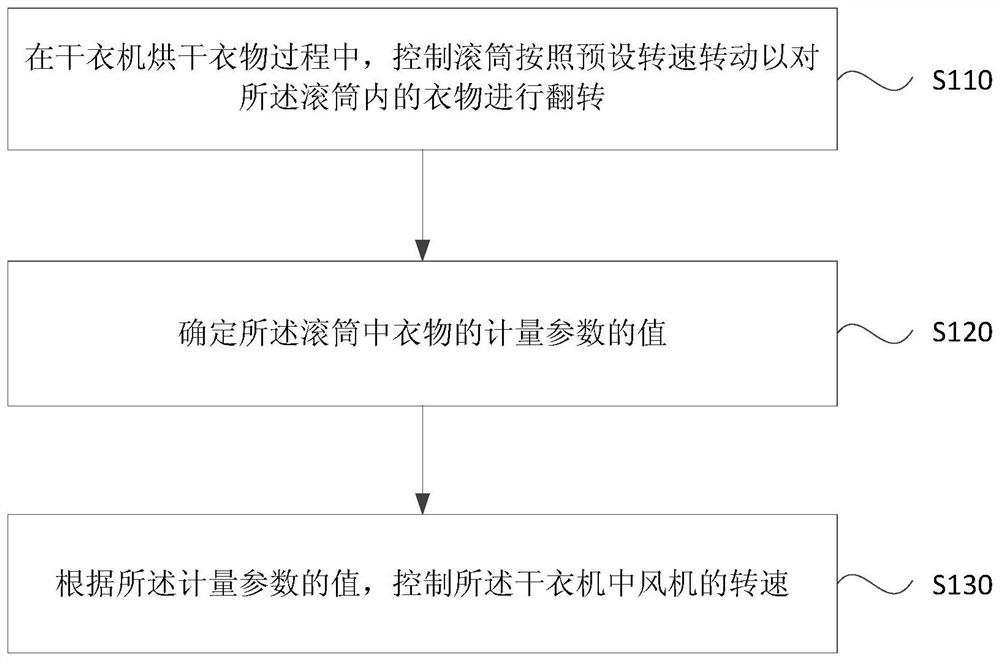

Clothes dryer drying method and device, clothes dryer and storage medium

PendingCN112095309AGood drying performanceStable air volume and pressureTextiles and paperLaundry driersAir volumeProcess engineering

The embodiment of the invention provides a clothes dryer drying method and device, a clothes dryer and a storage medium. The method comprises the steps that a drum is controlled to rotate according toa preset rotating speed in the clothes drying process of the clothes dryer, so that clothes in the drum are turned over; the value of a metering parameter of clothes in the drum is determined; and the rotating speed of a fan in the clothes dryer is controlled according to the value of the metering parameter. According to the technical scheme provided by the embodiment, the stability of air volumeand air pressure in the drum can be ensured, the influence of the clothes quantity on the air volume and air pressure is avoided, and good drying performance of the clothes dryer is ensured.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Preparation method of formaldehyde adsorption material

PendingCN113600144ALarge specific surface areaImprove adhesionGas treatmentOther chemical processesSodium carboxymethylcellulosePoly ethylene

The invention relates to a preparation method of a formaldehyde adsorption material. The preparation method is characterized by comprising the following steps of: (1) placing silica gel powder in a plasma reaction chamber so as to treat the silica gel powder, and taking out the treated silica gel powder; (2) dissolving polyethyleneimine in deionized water, performing uniform dispersing, adding an amine source, and performing uniform dispersing, forming a mixed solution; (3) adding plasma-treated silica gel powder into the mixed solution, performing dipping, dispersing and filtering, taking the effectively dipped silica gel powder, and drying the powder to obtain silica gel powder with the formaldehyde adsorption function; and (4) mixing the silica gel powder obtained in the step (3) with carboxymethyl cellulose and water, granulating and drying to obtain silica gel particles. The hydrophilic performance of the silica gel particles treated by the plasma is enhanced, and more ethylene urea can be loaded in the solution dipping process. Due to the existence of surface electrons, the amine source can be uniformly distributed inside and on the surface of silica gel channels during loading, and the formaldehyde adsorption performance of the material is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

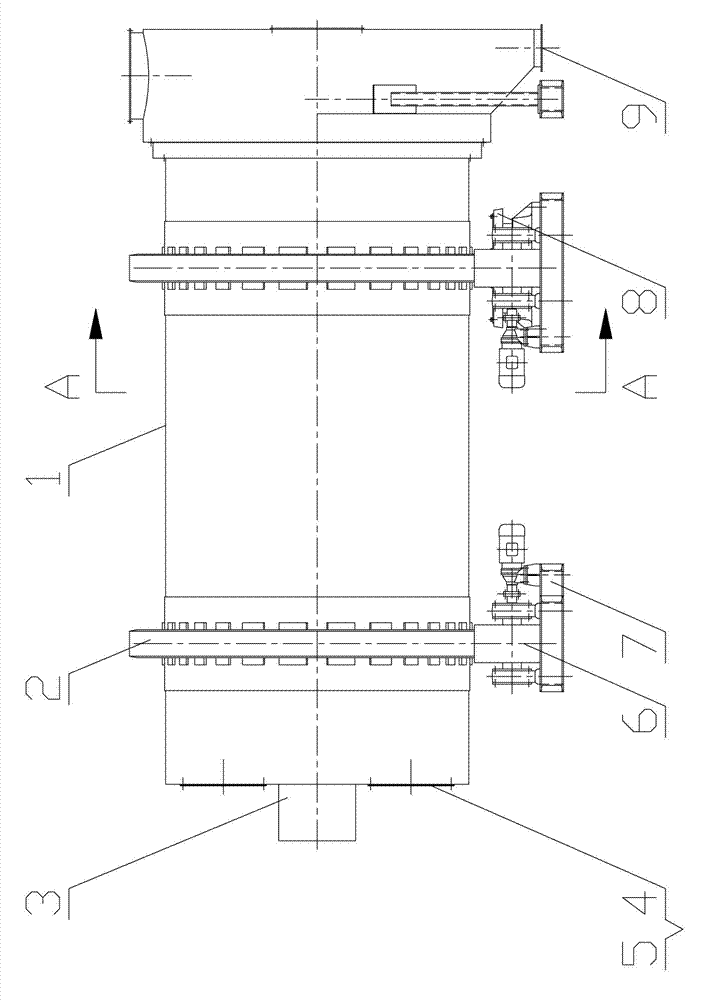

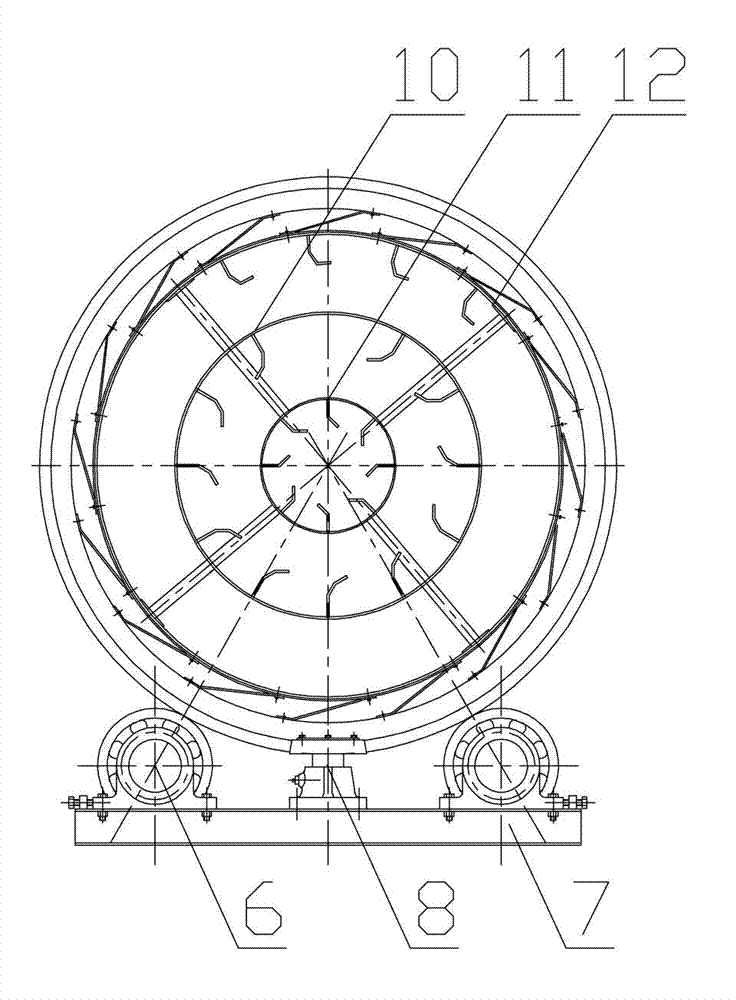

Three-layer type rotary drum dryer

InactiveCN104729248AImprove drying effectGood drying performanceDrying chambers/containersDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a three-layer type rotary drum dryer comprising a cylinder. The cylinder is provided with a plurality of large rolling rings, and the bottoms of the rolling rings are provided with supporting wheel assemblies fixed to a base; the cylinder is provided with a material inlet and a material outlet, and the material outlet is provided with a hole cover and a heat-resistant asbestos pad. The dryer is characterized by comprising an inner cylinder unit, a middle cylinder unit and an outer cylinder unit and is in a three-layer structure. The cylinder is in the three-layer structure, the drying performance is better, the processed material drying effect is ideal, and the dryer is mainly applied to industrial drying equipment.

Owner:邓海涛

Active energy photo-cured printing ink composition and application thereof

The invention provides an active energy photo-cured printing ink composition and an application thereof. The active energy photo-cured printing ink composition comprises a (methyl) acrylate polymer, aphotopolymerization initiator, an active diluent and a colorant, wherein the photopolymerization initiator includes an initiator with a structure as shown in a formula (I). According to the special structure of the photoinitiator, a photosensitive resin composition containing the photoinitiator has good weather resistance, chemical resistance and photoinitiation activity, so that the active energy photo-cured printing ink composition prepared from the photoinitiator can effectively inhibit the problem of excessively fast curing. Meanwhile, the reaction between the initiator and the componentssuch as the (methyl) acrylate polymer, the photopolymerization initiator, the active diluent and the colorant is relatively complete, and the molecular weight of a polymer formed after curing is relatively large, so that the active energy photo-cured printing ink composition also has the advantages of being difficult to migrate, free of odor and good in surface dry performance.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

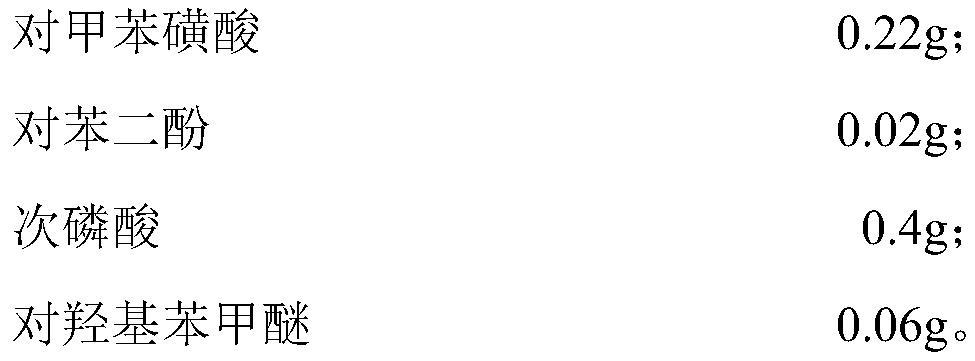

Ultraviolet curing itaconic acid-based polyester resin and preparation method thereof

ActiveCN113667106ASolve poor surface dryness in application performanceSolve defects such as not easy to polishPolyester coatingsPolymer sciencePolyol

The invention discloses an ultraviolet curing itaconic acid-based polyester resin. The resin comprises, by weight, 48.86-52% of micromolecular polyhydric alcohols; 19.3-22.16% of itaconic acid; 28%-28.16% of binary acid; 0.22-0.4% of a catalyst; 0.02% of a first polymerization inhibitor; and 0.06% of a second polymerization inhibitor and 0.34-0.4% of an antioxidant. The invention also discloses a preparation method of the ultraviolet curing itaconic acid-based polyester resin. The itaconic acid-based polyester resin is synthesized by adopting a melt polymerization method, which can be a one-step method or a two-step method. The ultraviolet curing itaconic acid-based polyester resin provided by the invention overcomes the defects of poor surface dryness, difficulty in polishing and the like of unsaturated polyester resin in photocuring application, especially in application of photocuring wood primer, can completely replace a part of common photocuring resin such as polyester acrylate to be applied to the photocuring wood primer, and can also be widely applied to the fields of stone coatings, wood primer finish, plastic paint, ink paper glazing and the like.

Owner:ZHAOQING FUTIAN CHEM IND

Drying device and washing machine using hydrogen storage alloy as heat source

InactiveCN1473985AImprove drying effectGood drying performanceExothermal chemical reaction heat productionExothermal chemical reactions for heatingProcess engineeringHydrogen storage

The drying device for washing machine utilizes hydrogen and hydrogen storage alloy to produce heating air for drying clothing. The washing machine with the drying device includes one washing machinebody with cover; drum shaped barrel inside the washing machine body for clothing to be set; heat source to utilize the heat absorption and heat release of hydrogen and hydrogen storage alloy to cool or heat surrounding air; and heating air conveying pipe connected between the heat source and the drum shaped barrel.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Optimization method for drying oven body structure of suspension drying device

InactiveCN108733945AStable pressure and velocity fieldsImprove drying performanceGeometric CADDesign optimisation/simulationProcess engineeringWind flow

The invention discloses an optimization method for the drying oven body structure of a suspension drying device. The optimization method specifically comprises the following steps that: S1: carrying out simulation analysis on all tuyeres of a suspension drying oven, and simulating the hot wind flow fields of all tuyeres of the suspension drying oven and the hot wind flow fields of the surroundingfluid domains of all tuyeres; S2: carrying out simulation analysis on the whole suspension drying oven, and simulating the hot wind flow field of the whole suspension drying oven; S3: carrying out thesimulation analysis on the key structure parameters of the suspension drying oven, selecting multiple groups of structure parameters to carry out comparison and analysis to obtain the optimal key structure parameter; S4: utilizing fives groups of key structure parameters obtained in S3 to carry out stricture optimization and simulation analysis on the whole suspension drying oven, and simulatingthe hot wind flow field of the whole suspension drying oven subjected to the structure optimization; and S5: comparing and analyzing six groups of hot wind flow field distribution situations of the suspension drying oven before and after the structure optimization is carried out, and determining the optimal model and the optimal structure parameter of the suspension drying oven. By use of the method, according to application requirements, the equipment structure parameter obtained when the drying efficiency of the drying oven is optimal can be conveniently optimized.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com