Optimization method for drying oven body structure of suspension drying device

A box structure and optimization method technology, applied in the direction of multi-objective optimization, design optimization/simulation, special data processing applications, etc., can solve problems such as huge energy consumption, environmental pollution, etc., and achieve improved drying performance, velocity field and pressure field Smooth, improved coating quality and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in combination with specific embodiments.

[0045] The invention provides a method for optimizing the structure of the oven body of a suspension drying device, comprising the following steps:

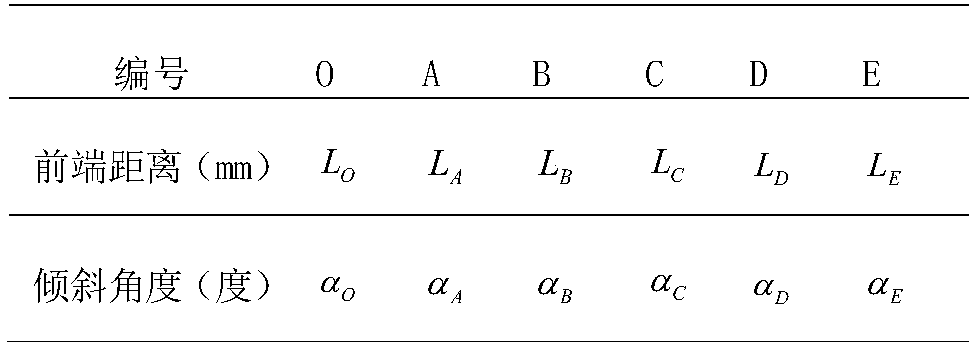

[0046] Step 1: Carry out simulation analysis on all the air nozzles of the suspension oven, and simulate the hot air flow field of all the air nozzles of the suspension oven and the surrounding fluid domain;

[0047] Step 1 specifically includes the following steps:

[0048] Step 1.1: Establish a three-dimensional model of the overall tuyere of the suspended oven based on the actual structure of the tuyere, and perform Boolean operations on the tuyere and its surrounding area to obtain the physical model of the fluid domain of the tuyere; network the physical model of the fluid domain of the tuyere grid division, using mixed grids and performing grid checks on the grid division results of the nozzle fluid domain;

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com