Ultraviolet curing itaconic acid-based polyester resin and preparation method thereof

An itaconic acid-based, polyester resin technology, applied in polyester coatings, coatings, etc., can solve the problems of low production efficiency, high cost and complexity of itaconic acid-based resin, and achieve the effect of easy polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The UV-curable itaconic acid-based resin of the present invention is synthesized in one step by melt polymerization;

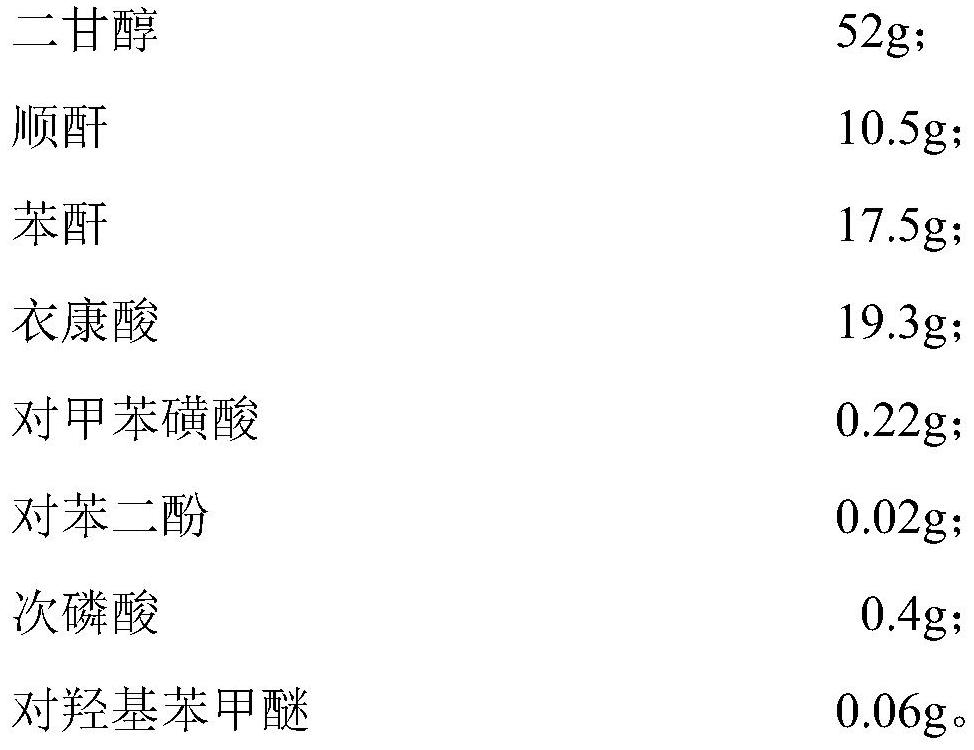

[0024] 1. First, synthesize UV-curable itaconic acid-based resin, which is made of the following raw materials in weight ratio:

[0025]

[0026] 2. Preparation method:

[0027] Drop into 52g diethylene glycol, 10.5g maleic anhydride, 17.5g phthalic anhydride, 19.3g itaconic acid and 0.22g p-toluenesulfonic acid, 0.02g hydroquinone, 0.4g hypophosphorous acid in the four-necked flask according to the formula design amount, Install a four-necked flask, a mechanical stirrer and a reflux condenser on the heating mantle, and feed it into a 10-20m 3 / h flow rate of nitrogen protection, heating to 145°C and keeping it warm for 0.5 hours, then raising the temperature to about 160°C for 2 hours, and finally raising the temperature to 168-170°C to react until the acid value Av<25mgKOH / g is detected, that is At the end of the reaction, after cooling down to b...

Embodiment 2

[0030] The UV-curable itaconic acid-based resin of the present invention has the same formula as in Example 1, and is synthesized in two steps by melt polymerization;

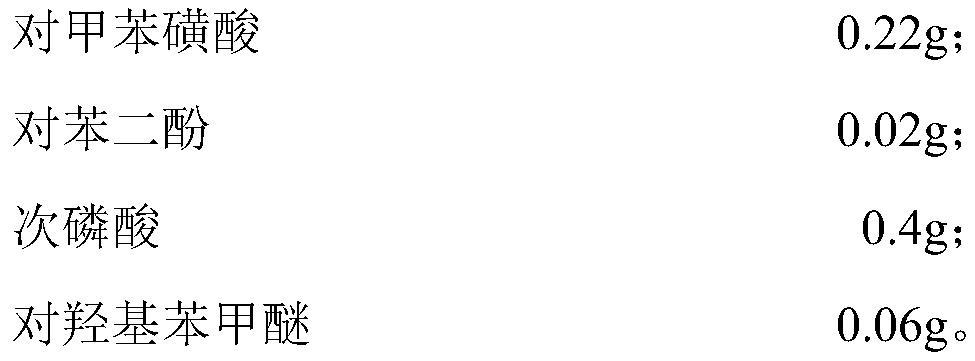

[0031] 1. First, synthesize UV-curable itaconic acid-based resin, which is made of the following raw materials in weight ratio:

[0032]

[0033]

[0034] 2. Preparation method:

[0035]Step 1: Put 52g of diethylene glycol, 10.5g of maleic anhydride, 17.5g of phthalic anhydride and 0.02g of hydroquinone into a four-necked flask according to the amount designed in the formula, and install a four-necked flask, a mechanical stirrer and reflux condensation on the heating mantle The tube is fed with nitrogen protection at a flow rate of 10-20m3 / h, heated to 150°C and then raised to 200-210°C at a rate of 20°C / h and kept for 1h.

[0036] Step 2: Cool down to 120°C, add 19.3g of itaconic acid, 0.22g of p-toluenesulfonic acid, and 0.4g of hypophosphorous acid under the protection of nitrogen gas, quickly raise t...

Embodiment 3

[0039] The UV-curable itaconic acid-based resin of the present invention is synthesized in one step by melt polymerization;

[0040] 1. First, synthesize UV-curable itaconic acid-based resin, which is made of the following raw materials in weight ratio:

[0041]

[0042] 2. Preparation method:

[0043] Put 37.5g of diethylene glycol, 11.36g of ethylene glycol, 11.36g of maleic anhydride, 16.8g of phthalic anhydride, 22.16g of itaconic acid, 0.4g of p-toluenesulfonic acid, and 0.02g of hydroquinone in a four-necked flask according to the formula design , 0.34g hypophosphorous acid, install a four-necked flask, a mechanical stirrer and a reflux condenser on the heating mantle, feed nitrogen protection with a flow rate of 10-20m3 / h, heat up to about 145°C and keep it warm for 0.5 hours, then heat up to React at 160°C for 2 hours, and finally raise the temperature to 168-170°C to react until the acid value Av<25mgKOH / g is detected, which is the end of the reaction. After cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com