Drying device and washing machine using hydrogen storage alloy as heat source

A drying device and hydrogen storage alloy technology, applied in the field of washing machines, can solve the problems that the technology has not been widely used, the product is large in size, and the cost is high, and achieve the effect of superior laundry drying performance and improved drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

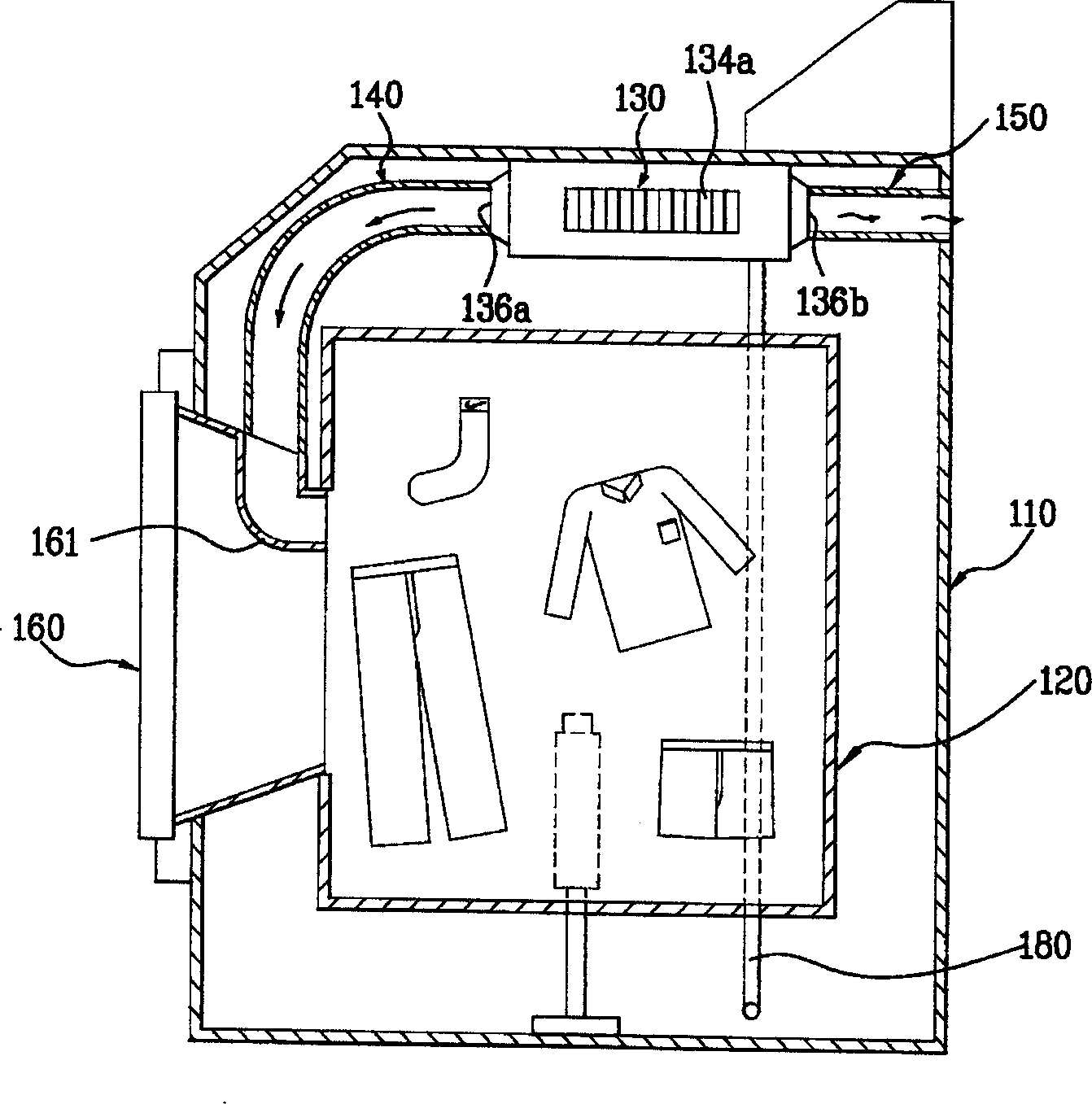

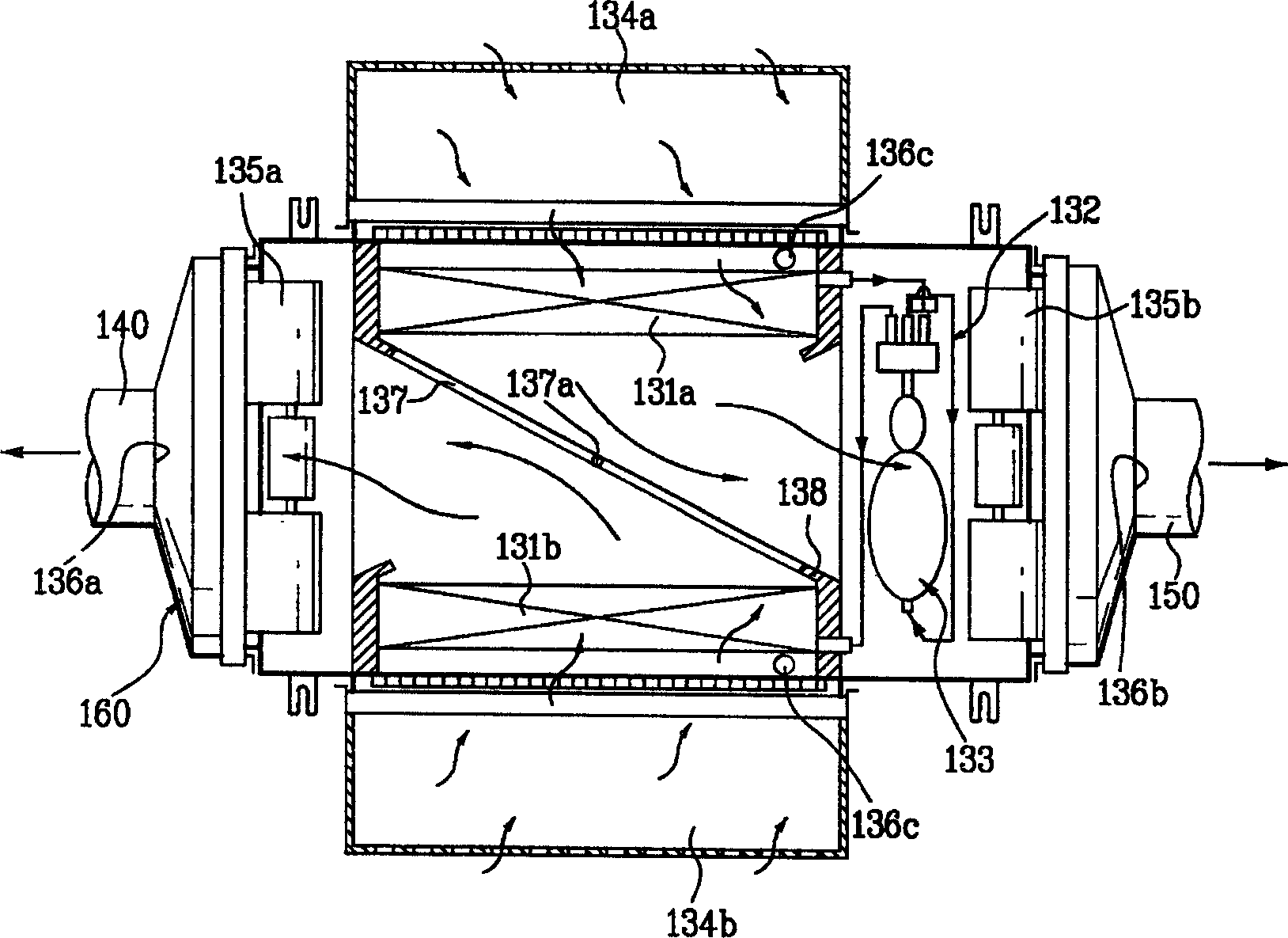

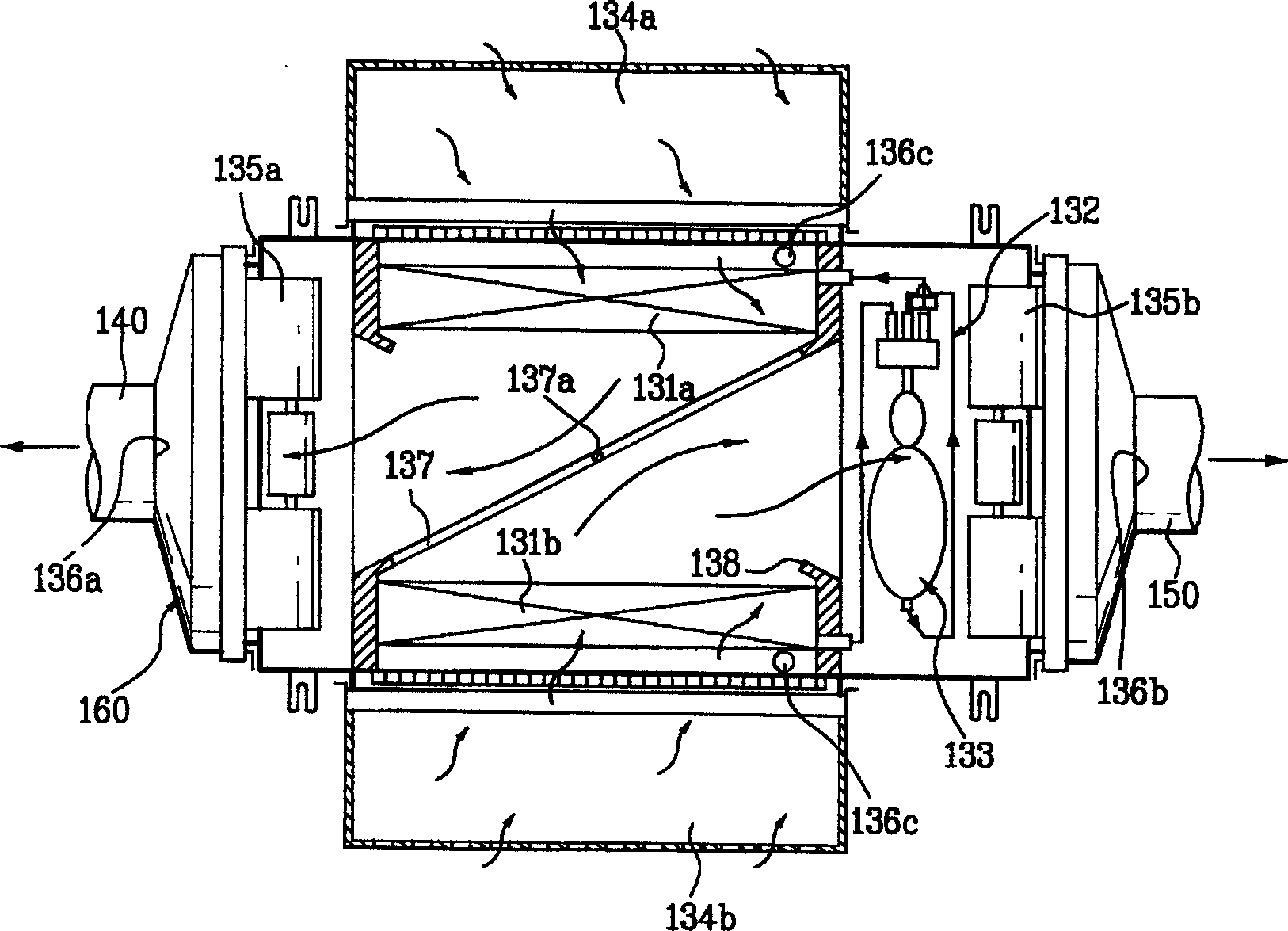

[0058] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be described in further detail: Figures 1 to 3 As shown, one form of the laundry drying device of the present invention is generally formed with a cover portion 160 that can be opened and closed for putting in laundry, and a body 110 that forms an outer shape; formed in the body, so that the laundry can be put in Drum-shaped drum 120 for clothes; heat source generator 130 for generating heated air for drying laundry; heated air discharge pipe 140; and cooling air discharge pipe 150.

[0059] The drum-shaped drum 120 is horizontally arranged in the main body 110, and its opening, that is, the opening for putting in laundry, is located in front of the main body.

[0060] An opening is formed for putting in and taking out laundry, and on the main body 110, a lid part 160 having an opening and closing opening which can be rotated is provided. The cover part 160 is disposed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com