Polymer waterborne polyester and preparation method thereof

A water-based polyester and polymer technology, which is applied in the field of polyester, can solve the problems of unstable quality of stiffening agent, unenvironmental protection of the production process, and excellent stiffening effect, and achieve the effects of flexible variety changes, moderate surface tension, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

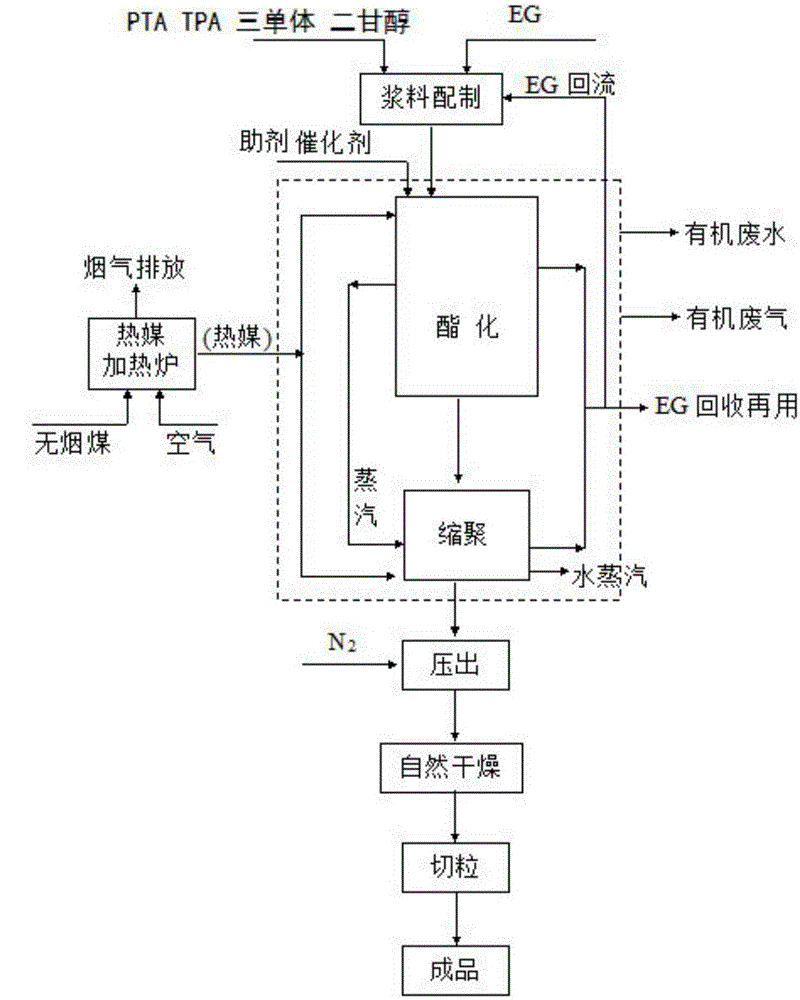

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

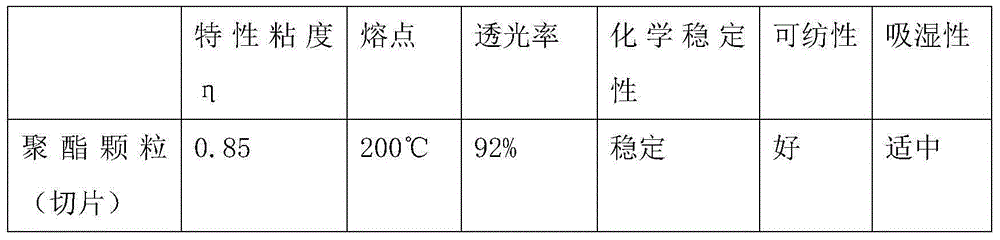

[0028] A kind of polymer water-based polyester, it is made of 50% purified terephthalic acid (PTA), 1.8% isophthalic acid (IPA), 24% ethylene glycol (EG), 12.5% diethylene glycol, 10% three simple Body, 0.3% catalyst and 1.4% other additives are used as raw materials by weight percentage and synthesized with mother liquor through esterification and polycondensation. The additives are commonly used stabilizers, defoamers, dehydrating agents, etc.

[0029] like figure 1 Shown, its specific preparation method is as follows:

[0030] Step S1: Beating

[0031] Pump the EG with a weight ratio of 24% to the EG high-level metering tank, and then enter the beating kettle. Under the stirring state, put PTA, IPA, three monomers, and diethylene glycol into the beating kettle evenly through the metering pump Stir for 1 to 2 hours to make a slurry, and then use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com