Patents

Literature

53results about How to "Moderate surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc oxide-based nanoparticle ink and electroluminescent device

InactiveCN107099190AVolatileEvenly dispersedMaterial nanotechnologySolid-state devicesAlcoholNanoparticle

The invention provides zinc oxide-based nanoparticle ink. The zinc oxide-based nanoparticle ink comprises a solvent and zinc oxide-based nanoparticles uniformly dispersed in the solvent. The zinc oxide-based nanoparticle ink comprises, by mass, 0.01 to 20.00% of the zinc oxide-based nanoparticles and 80.00 to 99.99% of the solvent. The zinc oxide-based nanoparticle ink is characterized in that the solvent comprises at least one alcohol ether ester compound. The zinc oxide-based nanoparticle ink can solve the problem that the existing zinc oxide-based nanoparticle ink is not suitable for ink-jet printing and has poor film-forming quality. The invention provides an electroluminescent device. An electron transport layer of the device is prepared from the zinc oxide-based nanoparticle ink through ink-jet printing.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Preparation method of porous metal film

InactiveCN109745870AStrengthen the bridging effectLess prone to defectsSemi-permeable membranesFoaming agentMass ratio

The invention relates to a preparation method of a porous metal film. The preparation method specifically comprises the following steps: respectively weighing 3-10 percent by weight of bonding agent,0.45-1 percent by weight of dispersing agent, 0.05-0.3 percent of a de-foaming agent and the balance of deionized water, wherein the sum of the mass percents of the components is 100 percent; mixing and dissolving the weighted bonding agent, dispersing agent, de-foaming agent and deionized water to prepare slurry; pouring metal powder and the prepared slurry into a stirring tank according to the mass ratio of 1:(0.8-1.5) and uniformly mixing to prepare mixed liquid; spraying the prepared mixed liquid onto the surface of a rotary tubular porous metal supporting body by adopting a spray gun, disassembling a metal film after the completion of absorption and successively performing drying, degreasing and sintering treatment on the metal film to prepare the porous metal film. The porous metal film prepared by the preparation method provided by the invention is high in permeability, good in film layer uniformity, high in filtering precision and high in finished product rate.

Owner:WESTERN BAODE TECH CO LTD

Powder 3D printing method based on instant inorganic binder

The invention discloses a powder 3D printing method based on instant inorganic binder. The powder 3D printing method comprises the following steps: firstly, using deionized water as a binder for a 3D printer, and adding a co-volatile agent, a coloring agent and a modifying agent to form a mixed solution as a binder for powder 3D printing; secondly, using instant sodium silicate as a solid binder, mixing the solid binder with 3D printer raw material powder, and then adding flux to form mixed powder as a material for the powder 3D printing; finally, performing the powder 3D printing by using the prepared binder and the mixed powder, wherein the binder prepared from water and the instant sodium silicate are used as the binder for a powder 3D printing process; as for a powder 3D printing nozzle, a solution with the viscosity close to water is only filled, and the solution is stable in performance, easier to store, unlikely to block the nozzle and free of corrosive effect on the nozzle. By the powder 3D printing method, rapid powder 3D printing of a product with complex structure is achieved, and the environment friendliness of the manufacturing process is ensured; by the powder 3D printing method, the production cost is reduced and the product quality is improved.

Owner:XI AN JIAOTONG UNIV

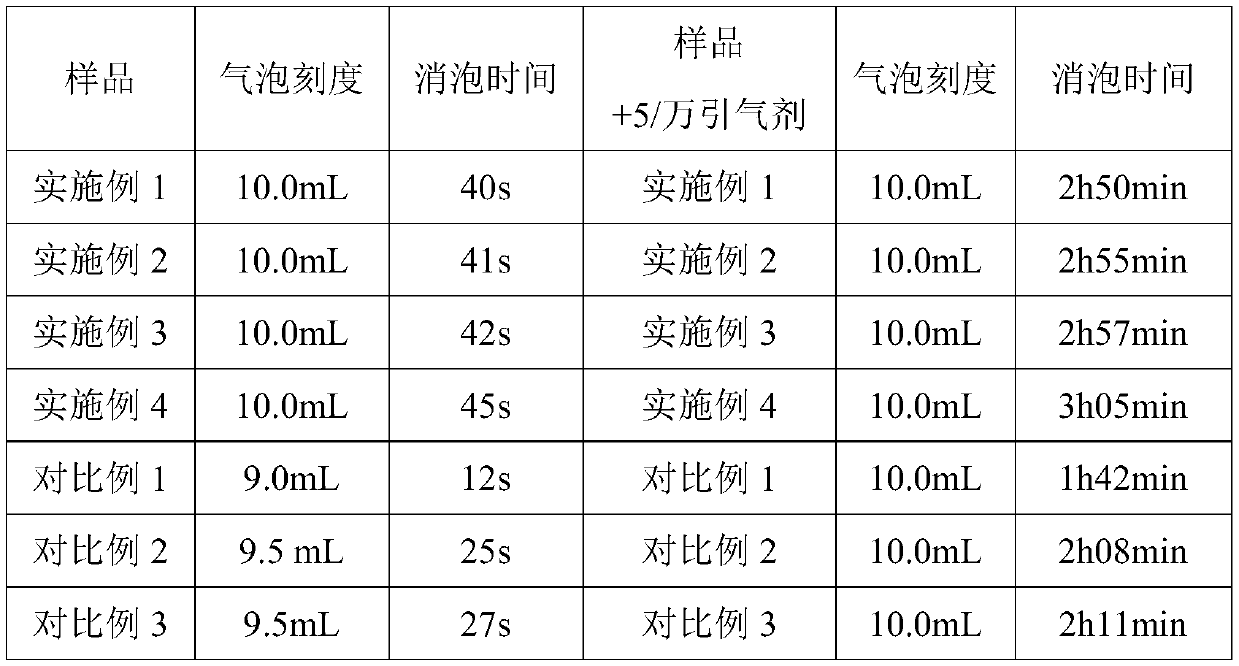

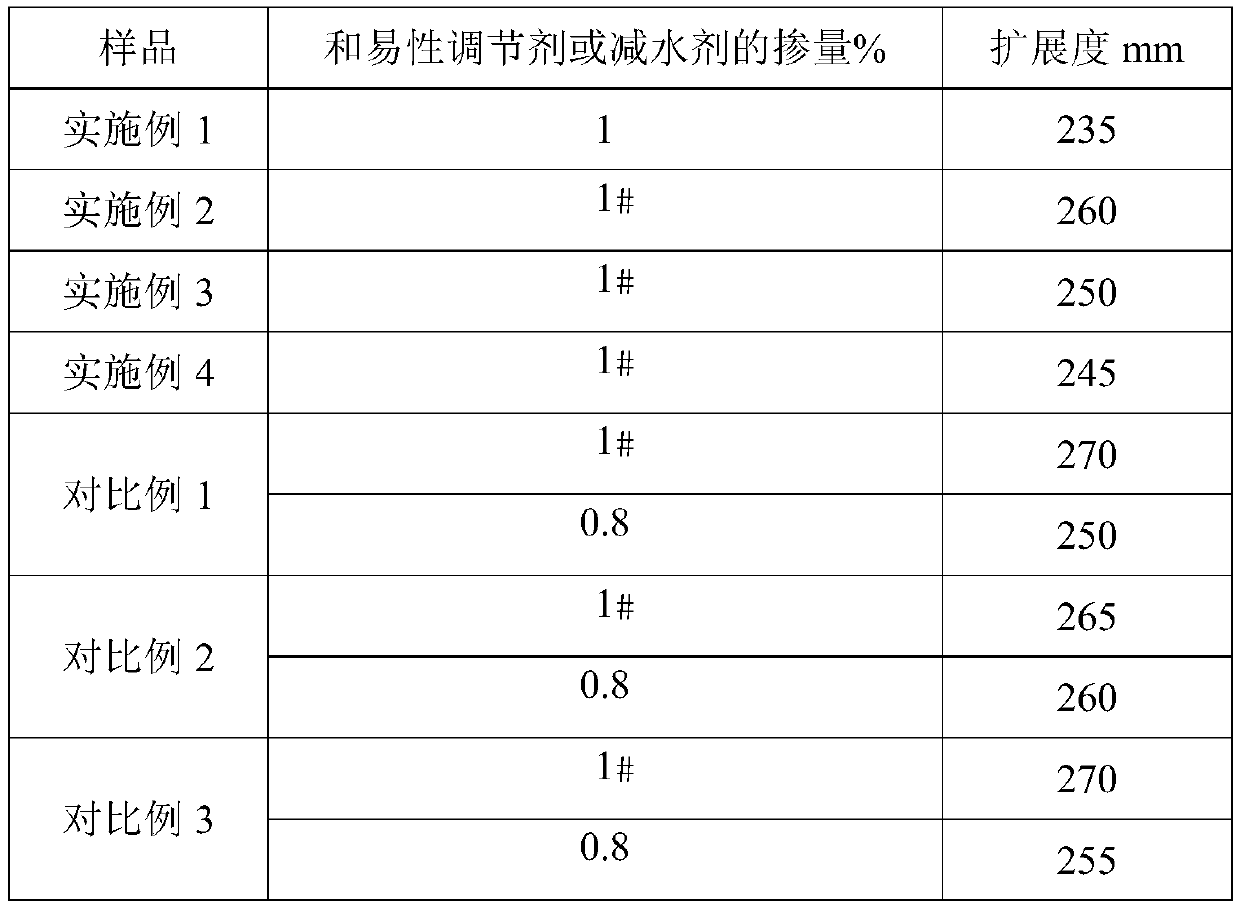

Concrete workability regulator and preparation method thereof

ActiveCN109880020AImprove workabilityWill not cause excessive air contentPotassium dichromateMacromonomer

The invention discloses a concrete workability regulator and a preparation method thereof. The concrete workability regulator comprises the following components: an unsaturated polyether macromonomer,an unsaturated ester monomer, a chain transfer agent, a strong oxidant and a hydrophilic modifier, wherein the molar ratio of the unsaturated polyether macromonomer to the unsaturated ester monomer to the hydrophilic modifier is (0.5-1.5):(0-0.2):(1.65-5.3); the addition amounts of the chain transfer agent and the strong oxidant respectively account for 0.17-0.67% and 0.25-1% of the mass of the unsaturated polyether macromonomer; and the chain transfer agent is a chain transfer agent with reducibility, and the strong oxidant is at least one of potassium permanganate and potassium dichromate.The concrete workability regulator is prepared by polymerizing the chain transfer agent with weak reducibility and the strong oxidant under the condition of no external heat source, the molecular weight of the concrete workability regulator is larger, the concrete workability regulator has thickening and water retention effects, the workability of concrete is improved, and the gas content of the concrete cannot exceed the standard.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Manufacturing method of edible printing ink for ink jet printing and using method thereof

The invention provides a preparation method and application method of edible ink for inkjet printing. This ink can form printed records with good identification and certain water resistance on the surface of various foods (including tablets), food contact materials, food packaging materials, etc. The raw materials of this inkjet ink are approved food additives, including shellac, cellulose resin, ethanol, water and so on. The manufacture method of this ink-jet ink is: a, food coloring is dispersed or dissolved in the aqueous solution that contains cellulose resin to make color base dispersion, contains the water more than 50wt% in this dispersion; B, shellac Dissolve in dehydrated alcohol and make shellac solution, contain the dehydrated alcohol more than 50wt% in this shellac solution; c, color paste dispersion is dispersed in shellac solution again, add a certain amount of conductive salt sodium lactate, pH Regulator ammonium carbonate, humectant, emulsifier, defoamer, etc.; d, filter filling.

Owner:HUBEI KEYIHUA SANDT CO LTD

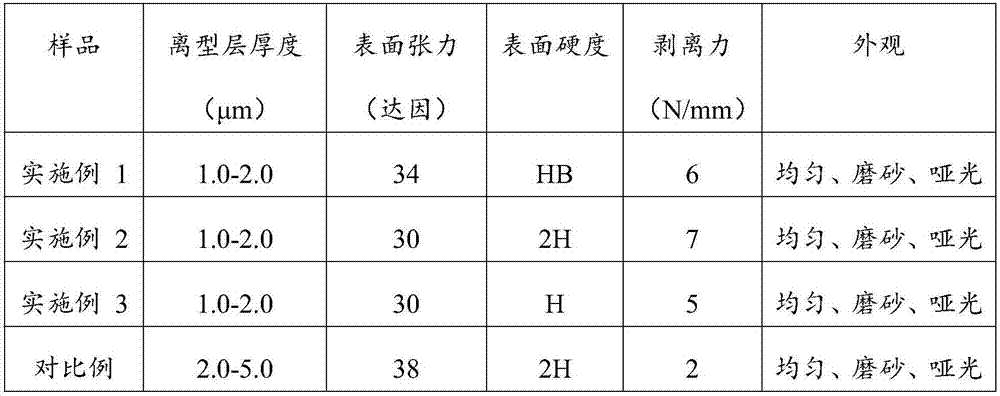

BOPET matte release film

InactiveCN107880298AModerate surface tensionModerate hardnessPolyurea/polyurethane coatingsCyclohexanoneBoPET

The invention relates to a BOPET matte release film, which comprises a polyester base material and a release layer laminated on the surface of one side of the polyester base material. The release layer is characterized by being prepared by painting and curing a coating liquid. The release layer coating liquid comprises the following raw materials in parts by weight: 2.0 to 3.3 parts of fluorine resin, 3.0 to 5.3 parts of polyester polyol resin, 0.5 to 1.7 parts of aldehyde-ketone resin, 1.5 to 3.0 parts of curing agent, 0.2 to 0.6 part of auxiliary agent, 2.1 to 3.5 parts of matting agent, and12.0 to 18.5 parts of mixed solvent, wherein the mixed solvent is prepared by mixing benzene, glycol, 2-heptanone, and cyclohexanone according to a volume ratio of 1:0.7:1.5:0.5; the auxiliary agentis formed by mixing a dispersant and an antistatic agent; and the curing agent is prepared by mixing amino resin and enclosed isocyanate. The provided matte release film has a good peeling property.

Owner:YUNMENG COUNTY DEBANG IND

Anti-sagging polyurethane white finish and main paint thereof

ActiveCN102993938AModerate surface tensionNot easy to hangPolyurea/polyurethane coatingsPolymer scienceSilicon oxide

The invention discloses anti-sagging polyurethane white finish. Main paint of the polyurethane white finish comprises the following components in parts by weight: 35-50 parts of short oil alkyd resin, 40-55 parts of titanium dioxide slurry with mass concentration of 60%, 5-8 parts of talcum powder, 0.1-0.5 part of polyether modified silicone oil leveling agent, 0.5-5 parts of fumed silica and 1-2 parts of solvent. Through the mixing of the components, the polyurethane white finish provided by the invention has proper surface tension and avoids frequent sagging and base exposure; and moreover, under the effect of surface tension, the paint film can be converted from an uneven surface into an even one.

Owner:SHANGHAI CHANGRUNFA PAINT

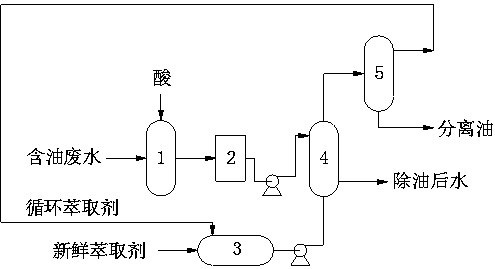

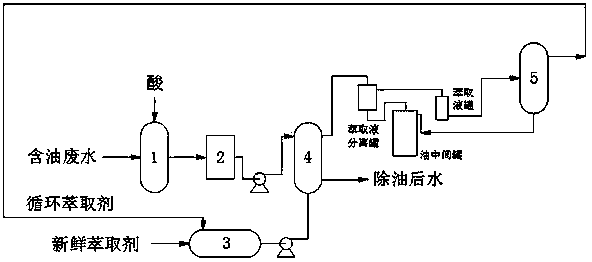

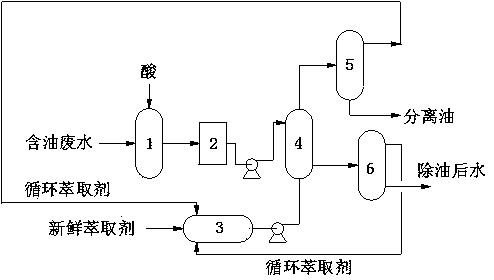

Method for oil removal from wastewater in field of coal chemical industry

InactiveCN103964544ASimplify timeLow costFatty/oily/floating substances removal devicesLiquid separationChemical industryWastewater

The invention discloses a method for oil removal from wastewater in the field of coal chemical industry, which is characterized in that oil contains soluble oil; and the method comprises the following steps: wastewater pretreatment, extraction and oil removal, and extraction agent recovery. Through the method, the oil contained in the wastewater, in particular to the soluble oil can be effectively removed. The invention further provides normal hexane and / or petroleum ether as an extraction agent; and through a practical application experiment, after the method is adopted, the oil contained in the treated wastewater is the soluble oil basically, the removal rate of the oil reaches 95.31-97.91 percent, and the removal rate of the soluble oil reaches 87.08-94.17 percent, so that a good oil removal effect is reached, and particularly, the effect of removing the soluble oil is good.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

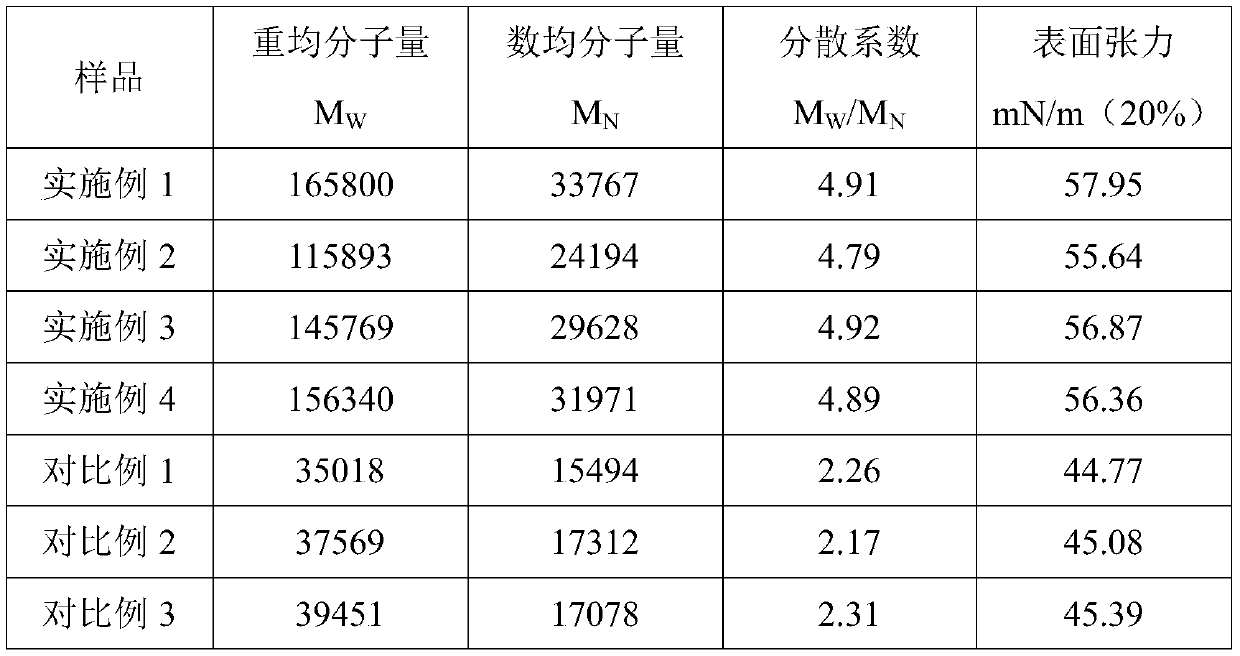

Polymer waterborne polyester and preparation method thereof

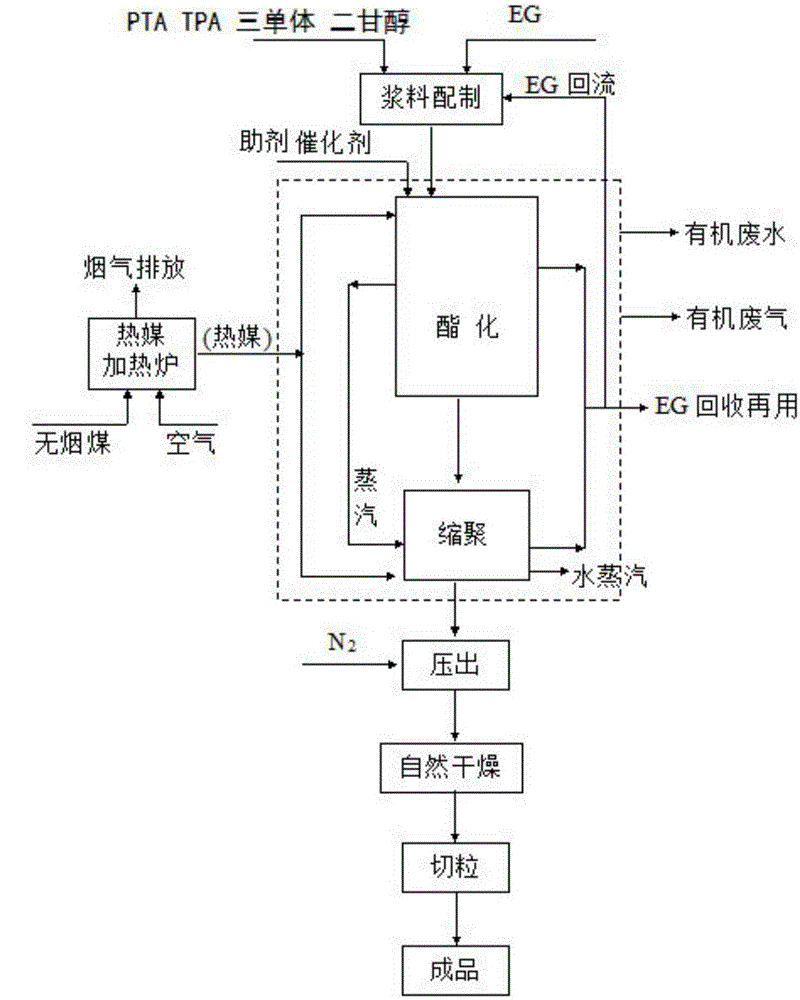

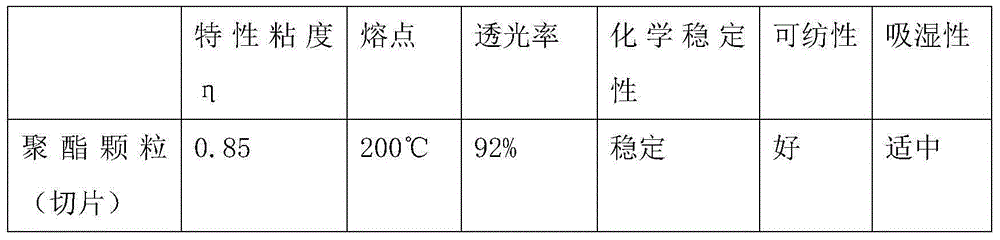

ActiveCN105111423AHigh molecular weightExcellent adhesionFibre treatmentPolymer scienceCarvacryl acetate

The invention discloses polymer waterborne polyester. The polymer waterborne polyester is prepared in the mode that terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol, ternary monomers, a catalyst and other auxiliaries serve as raw materials, and the raw materials and mother liquid are subjected to esterification and condensation polymerization for synthesis. A preparation method of the polymer waterborne polyester includes the steps that firstly, terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol and ternary monomers are made into paste and evenly fed into an esterification kettle through a metering pump, the catalyst is added for an esterification reaction, the auxiliaries are added to monomers generated by the esterification reaction, the mixture is filtered and guided into a condensation polymerization kettle for a condensation polymerization reaction, when a certain process value is reached, the mixture is extruded out through nitrogen, and the transparent polyester product is prepared after cooling, grain-sized dicing, drying and screening. The polymer waterborne polyester replaces traditional acrylic and vinyl acetate products, and urea resin and cyanamide resin which are not environmentally friendly, has a series of advantages of being excellent in adhesive force, high in molecular weight, good in environment friendliness and the like, and can serve as a textile hardening agent to be widely used.

Owner:广州市弘浩纺织助剂有限公司

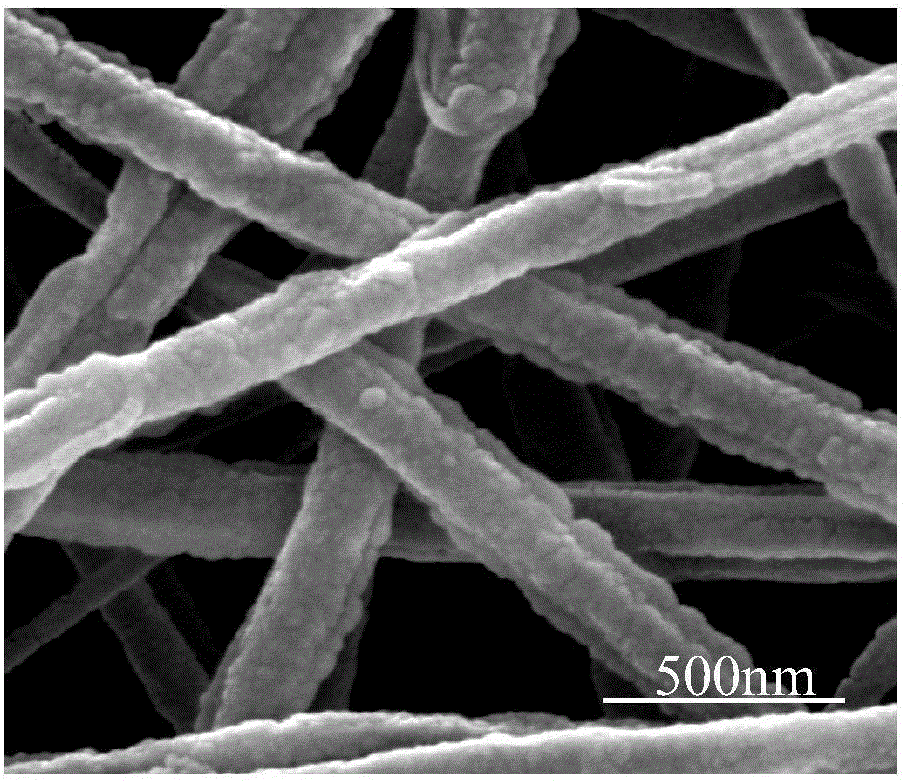

Preparation method of super-hydrophilic polyvinylidene fluoride/polydopamine composite films

ActiveCN106757789AStrong forceHole size effectFibre typesFilament/thread formingCooking & bakingComposite film

The invention discloses a preparation method of super-hydrophilic polyvinylidene fluoride / polydopamine composite films. The preparation method includes the steps: dissolving the polyvinylidene fluoride in mixed solvents of dimethylacetamide and acetone, adding dopamine monomers, and performing electrostatic spinning for polyvinylidene fluoride / dopamine solution to obtain polyvinylidene fluoride / dopamine composite films; performing reaction for the polyvinylidene fluoride / dopamine composite films in a baking oven for 6-30 hours, and taking out to obtain the polyvinylidene fluoride / polydopamine composite films. The polyvinylidene fluoride / polydopamine composite films prepared by the method have high hydrophilic performance and good oil-water separation and adsorption performance.

Owner:SOUTHWEST JIAOTONG UNIV

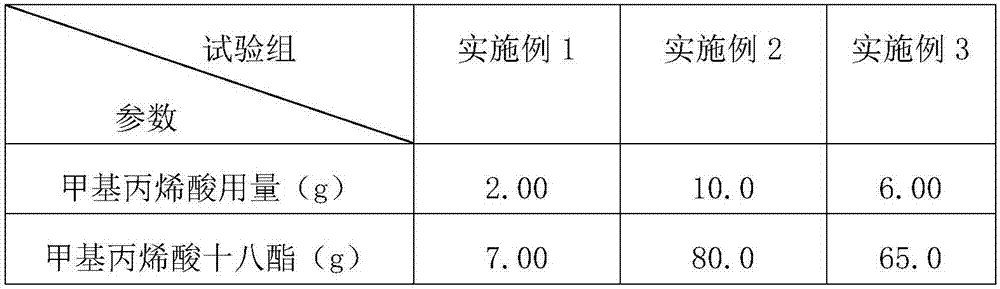

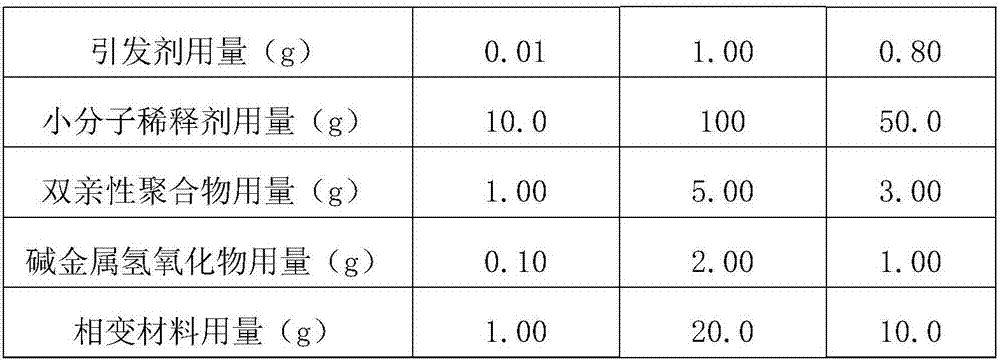

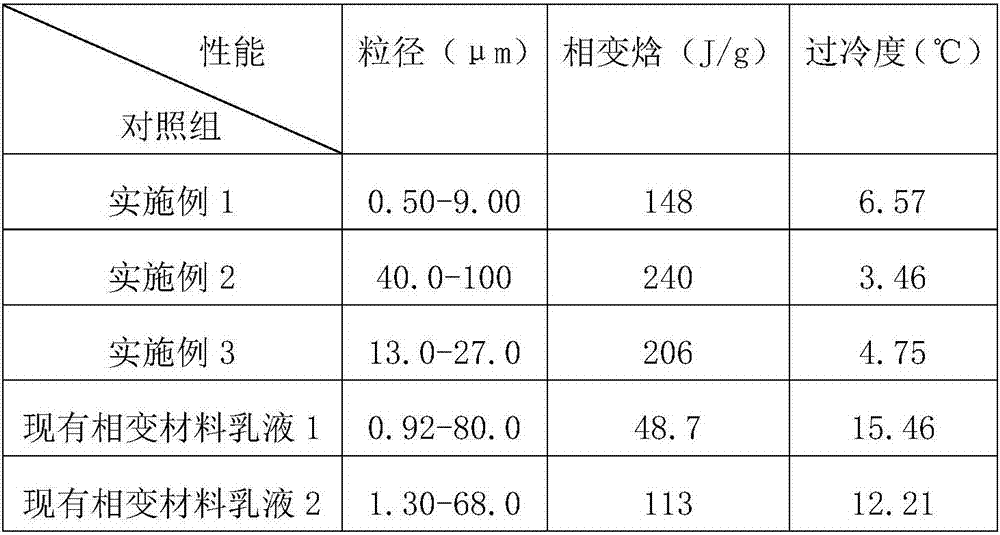

Preparation method of phase-change material emulsion

ActiveCN108003840AImprove performanceUniform particle sizeChemical industryHeat-exchange elementsEmulsionPolymer

The invention relates to the field of preparation of a phase-change material, and particularly discloses a preparation method of a phase-change material emulsion. The preparation method of the phase-change material emulsion comprises the following steps: preparing an amphiphilic polymer and then preparing the phase-change material emulsion by taking the amphiphilic polymer as a surfactant. The preparation method of the phase-change material emulsion is energy-saving and efficient, industrialized implementation is facilitated, and the prepared phase-change material emulsion has stable performance, uniform grain size, high phase-change enthalpy and small supercooling degree and can be widely applied to the fields of heat mediums of functional thermal fluid and refrigeration systems.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

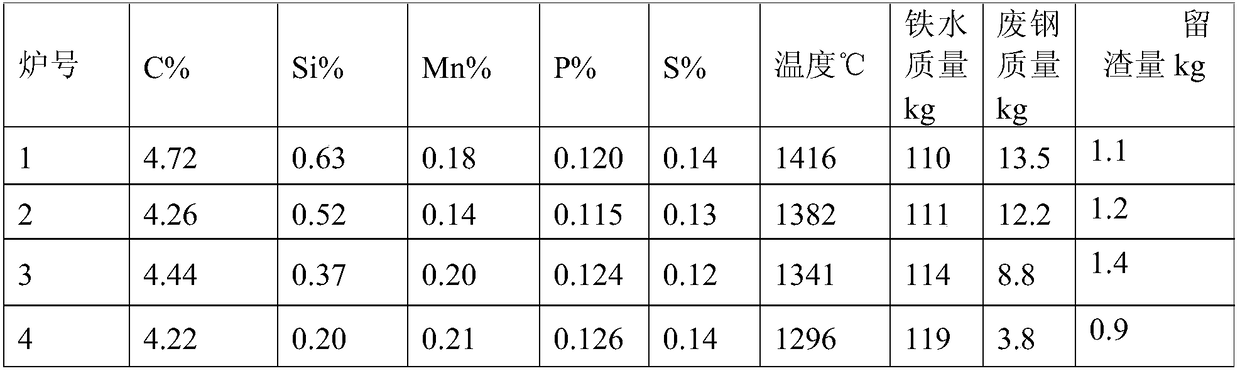

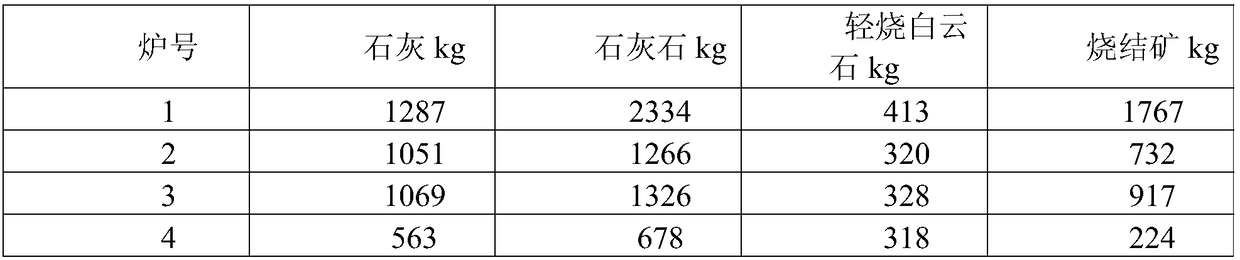

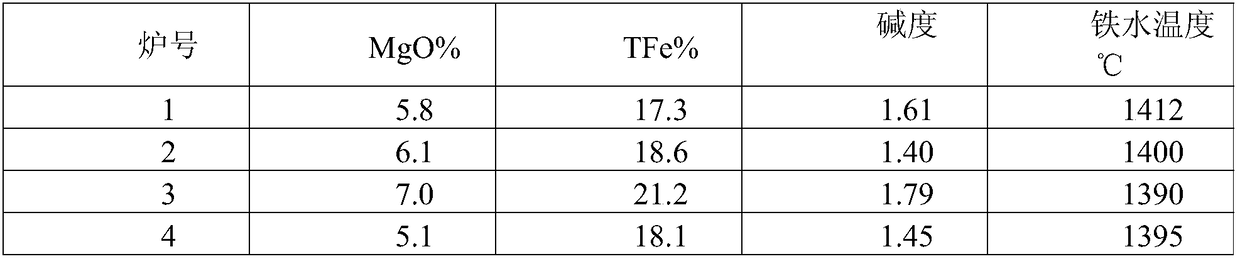

Method for inhibiting splashing in steelmaking process of converter

ActiveCN108486306ASmall splash rateSuitable breathabilityManufacturing convertersProcess efficiency improvementIron oxideMagnesium

The invention relates to a method for inhibiting the splashing in a steelmaking process of a converter, which belongs to the field of converter steelmaking. The method comprises the following steps: determining an appropriate addition amount of waste steel cold material and an addition amount of first batch materials for blowing according to the temperature, components and slag content of molten iron entering the converter as well as the slag residual situation of the previous process, enabling the alkalinity range of the steel slag to be 1.4 to 1.9 when an oxidation period of silicon and manganese is ended, wherein the content of MgO in the slag is 5 to 7 percent, the content of TFe is 18 to 24 percent, and the temperature of the molten iron is 1390 to 1420 DEG C; at a first carbon / phosphorus oxidation reaction selection point, adding a slag making material comprising calcium and magnesium in different batches for multiple times as well as a cold material comprising the iron oxide, wherein at the second carbon / phosphorus oxidation reaction selection point, the alkalinity range of the steel slag is 2.8 to 3.5, the MgO content in the slag is 7 to 10 percent, and the content of TFe is 15 to 20 percent; and in the later period of the blowing, operating by virtue of a pressure gun. By adopting the method, a slag making process is ensured to be adaptive to a reaction process of themolten iron in the blowing of the converter, so that the air permeability and viscosity of the furnace slag in the blowing process can be matched with the reaction rate of carbon removal, silicon removal and manganese removal of the molten steel, and the splashing problem in the steelmaking process of the converter is solved.

Owner:TIANJIN IRON & STEEL GRP

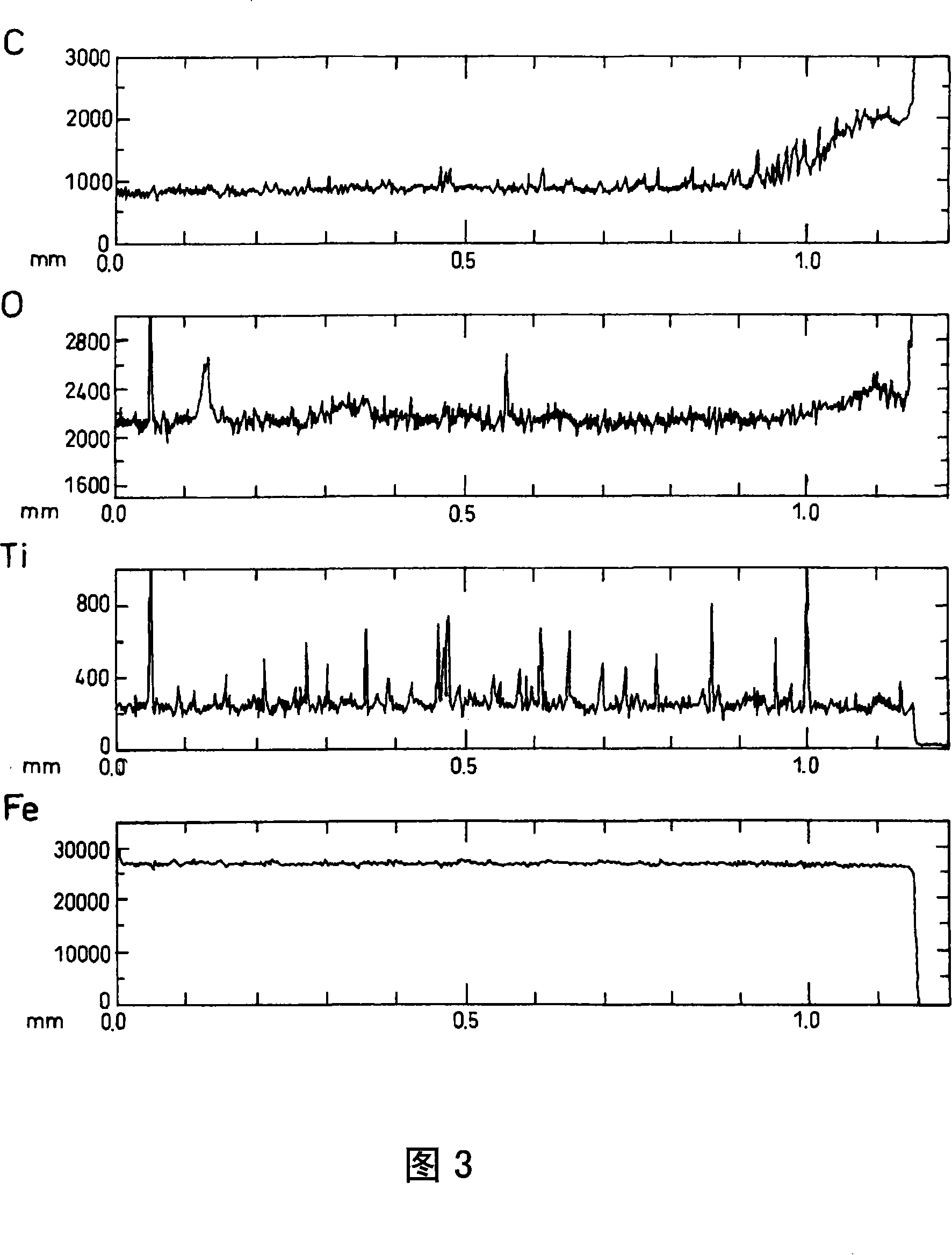

Structure steel welding rod and its production process

InactiveCN1416994ALow viscosityReduce weightWelding/cutting media/materialsSoldering mediaIndustrial gasWhite powder

The present invention relates to a structure steel welding rod and its production process. The welding rod is characterized by that the coating mixture comprises ilmenite 30-38 wt%, rutile 12-15 wt%, titanium white powder 1-4 wt%, white clay 2-4 wt%, sepiolite 8-11 wt%, feldspar 8-11 wt%, mica 5-8 wt%, marble 3-6 wt%, magnesia-calcium powder 4-8 wt%, medium-carbon ferromanganese 7-10 wt%, ferrotitanium 1-4 wt%, wood flour 1-3 wt%, Chinese yam powder 1-4 wt% and microcrystallite 1-2 wt%. Wet welding rod is dried with coal gas produced by industrial gas producer. The welding rod is used widely in steel structure and has high welding efficiency and low production cost.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

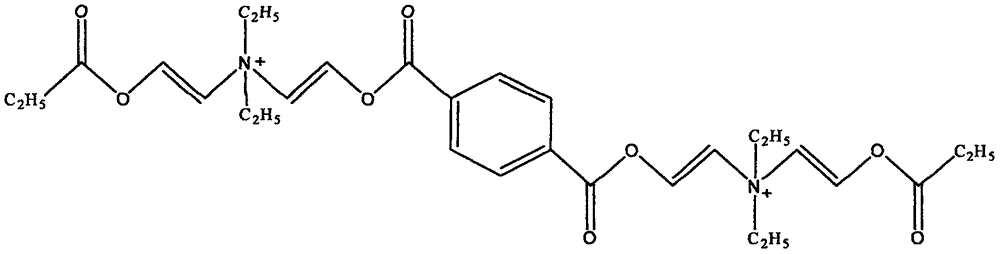

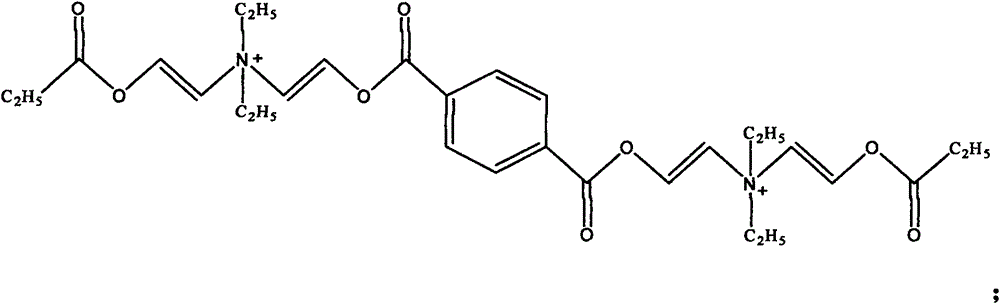

Splash-proof foam agent based on Gemini quaternary ammonium salt surfactant and preparation method for same

ActiveCN105903404AModerate surface tensionModerate tensionOrganic chemistryTransportation and packagingAnti bacterialSewage

The invention discloses a splash-proof foam agent based on a Gemini quaternary ammonium salt surfactant and a preparation method for the same. The splash-proof foam agent includes a surfactant, a foam stabilizer, a thickener, an emulsifier, a pushing agent, a sterilization cleaning agent and deionized water. The invention also discloses preparation methods for the Gemini quaternary ammonium salt surfactant and the splash-proof foam agent. The Gemini quaternary ammonium salt surfactant can stabilize foams and maintain a proper surface tension and certain strength of the foams, and also reduces the use amount of the foaming agent in the splash-proof foam agent without reduction on generation quantity of the foams. The splash-proof foam agent based on the Gemini quaternary ammonium salt surfactant can completely prevent water splashing generated when sewage falls into a collection container, and also has the effects of deodorization and is anti-bacterial. The splash-proof foam agent is suitable for large-scale promotion.

Owner:张放

Solid welding wire

InactiveCN101100022AModerate surface tensionReduced splash generationWelding/cutting media/materialsSoldering mediaOxygenImpurity

The present invention relates to a solid cored welding wire, which is arranged with a cementite layer on the surface. The cementite layer contains 0.005% to 0.10% carbon by weight of the whole welding wire and below 0.010% oxygen by weight of the whole welding wire. Getting rid of the cementite layer, the welding wire contains carbon: 0.005% to 0.150% by weight, Si: 0.4% to 1.2% by weight, Mn: 1.0% to 2.2% by weight, the other components is Fe and inevitable impurity. The solid cored welding wire can ensure the welding dripping be transition stable and reduces splash occurring amount when implementing gas protecting arc welding with high current using CO2 as protecting gas.

Owner:KOBE STEEL LTD

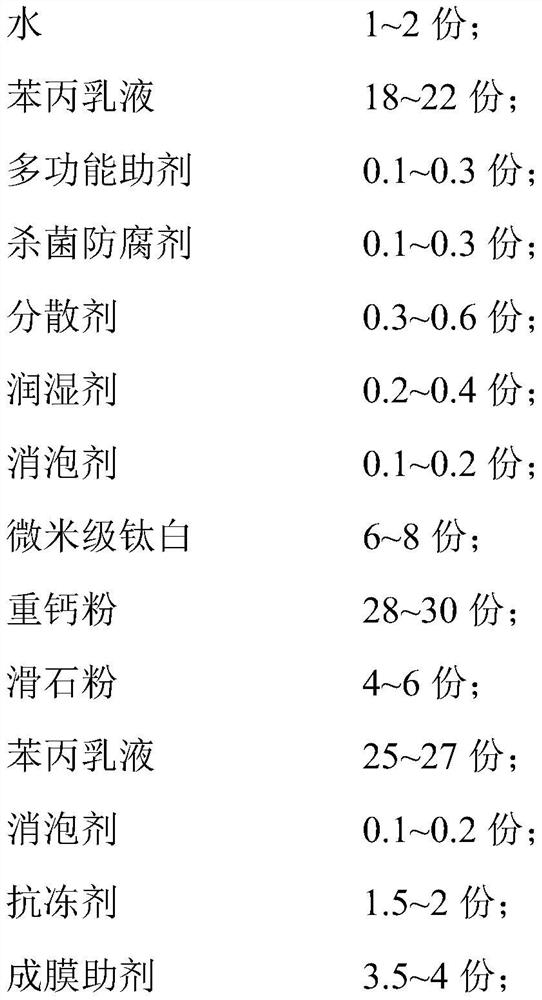

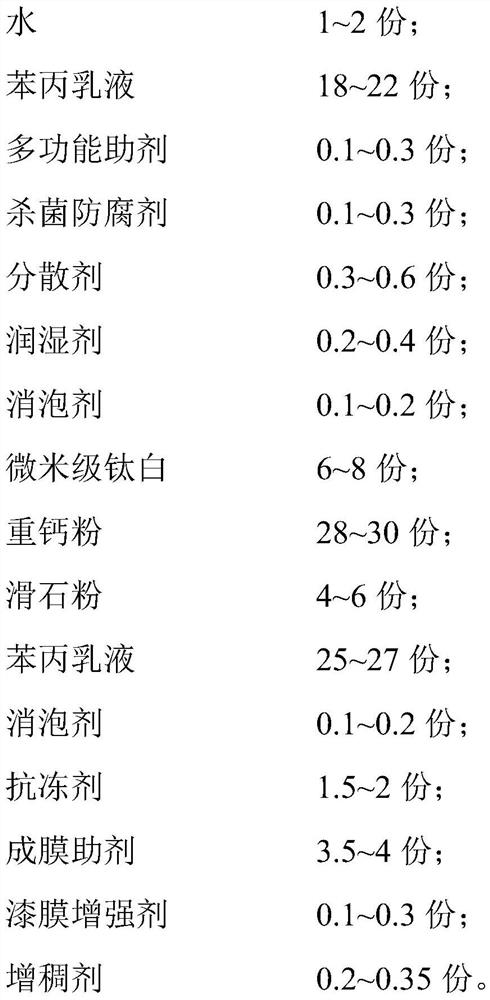

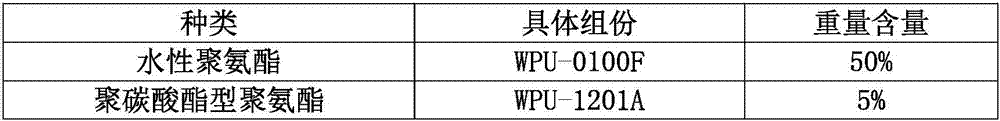

Quick-drying primer for renovating exterior wall tiles and preparation method thereof

InactiveCN112266663AImprove water resistanceImprove adhesionPriming paintsPolymer sciencePreservative

The invention relates to quick-drying primer for renovating exterior wall tiles and a preparation method thereof. The preparation method comprises the following steps of adding water and a styrene-acrylic emulsion into a dispersion cylinder, sequentially adding a multifunctional auxiliary agent, a sterilization preservative, a dispersing agent, a wetting agent and a defoaming agent, and uniformlystirring, adding micron-sized titanium dioxide, coarse whiting powder and talcum powder, increasing the rotating speed and uniformly stirring, reducing the rotating speed, sequentially adding the styrene-acrylic emulsion, the defoaming agent, the antifreeze agent, the coalescing agent, the paint film reinforcing agent and the thickening agent, and uniformly stirring to obtain the quick-drying primer. The quick-drying primer prepared by the invention has excellent adhesive force on the surface of a ceramic tile, and has the characteristics of low cost, covering power, moderate surface tension,quick drying and the like; a paint film is excellent in water resistance, and the adhesive force is not changed after water resistance; the primer is simple and convenient to construct, the primer isa single-component material, and after the surface of the ceramic tile is simply sprayed with the primer, a further surface coating effect, such as stone imitation, embossment, solar heat reflection and self-cleaning, can be achieved instead of simple flat coating.

Owner:YANGZHOU POLYTECHNIC INST

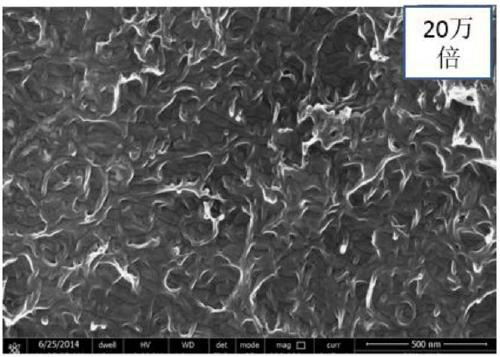

Solid capacitor carbon foil nano conductive carbon paste and preparation method thereof

ActiveCN111105932ARelatively large areaMany surface atomsElectrolytic capacitorsNon-conductive material with dispersed conductive materialCarbon nanotubeAcetamide

The invention relates to solid capacitor carbon foil nano conductive carbon paste and a preparation method thereof. The solid capacitor carbon foil nano conductive carbon paste comprises a polymer carrier and a nano conductive carbon fiber system dispersed in the polymer carrier, wherein the polymer carrier is formed by mixing an adhesive, a polymer solvent and a processing aid; the nano conductive carbon fiber system comprises a carbon nano tube and an acidified carbon nano tube acidified by a mixed solution of concentrated nitric acid and concentrated sulfuric acid; the adhesive is one or more of polyester acrylic resin, waterborne polyurethane resin, epoxy acrylic resin and polyurethane resin; the polymer solvent is several in butyl cellosolve, polyoxyethylene alkyl phenyl ether, methylbenzyl alcohol, N, N-dimethylformamide and terpilenol. The nano conductive carbon fiber system is dispersed in the polymer carrier, so that the microscopic coverage compactness of a carbon layer is improved; and the solid capacitor carbon foil nano conductive carbon paste is suitable for a solid capacitor carbon foil, protects a current collector, prevents the surface of the aluminum foil from being oxidized or corroded, and greatly reduces the ESR of a solid capacitor.

Owner:南通宇华新材料科技有限公司

Color ink-jet printing ink and preparation method thereof

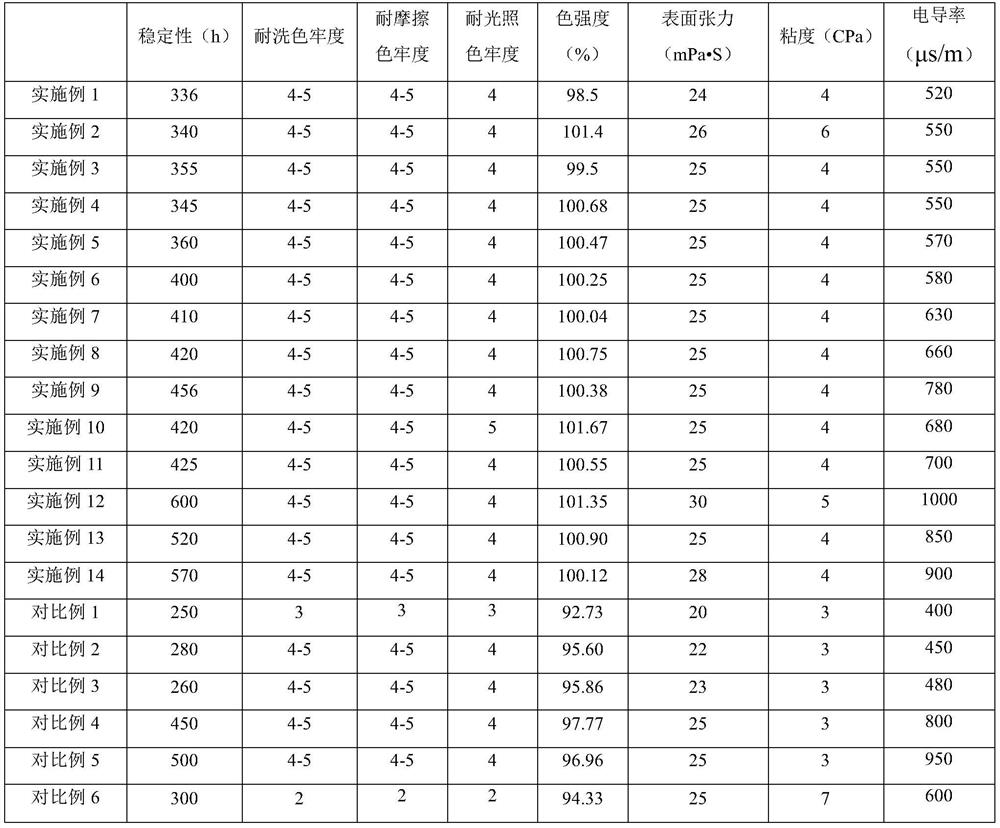

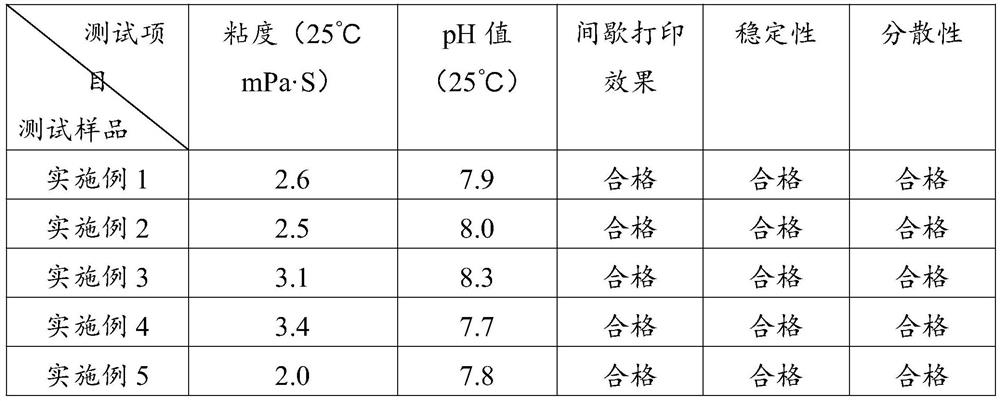

The invention discloses a color ink-jet printing ink and a preparation method thereof. The color ink-jet printing ink comprises the following components in parts by weight: 60-80 parts of deionized water, 8-12 parts of triethanolamine, 5-10 parts of a water-soluble organic wetting agent, 6-8 parts of a wetting binder, 6-8 parts of a cellosolve, 5-7 parts of acrylic resin, 4-6 parts of a colorant, 0.2-0.4 part of a surfactant, 0.1-0.2 part of a preservative and 0.01-0.02 part of a drying agent, wherein the colorant is metal complex dye; the drying agent is selected from ethanol, isopropyl alcohol or 1-cyclohexyl-2-pyrrolidone; the water-soluble organic wetting agent is 1,2-propanediol, glycerine, ethylene glycol, diglycol, triethylene glycol or sorbitol; the wetting binding agent is 2-pyrrolidone, sodium sorbate, polyvinyl pyrrolidone or potassium sorbate. The color ink-jet printing ink is safe, environment-friendly, excellent in definition of a printed image, moderate in surface tension, viscosity and electrical conductivity, capable of clearly imaging on a printing stock medium without a coating, excellent in ink smoothness, unlikely to block an ink-jet printer ink gun, good in water resistance and photostability, and free of corrosion of a printer.

Owner:DONGGUAN PINPAI IND INVESTMENT

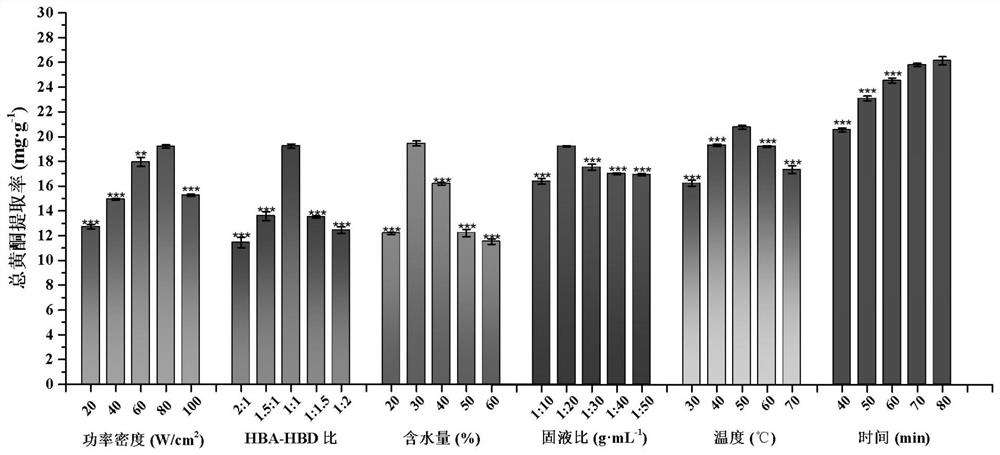

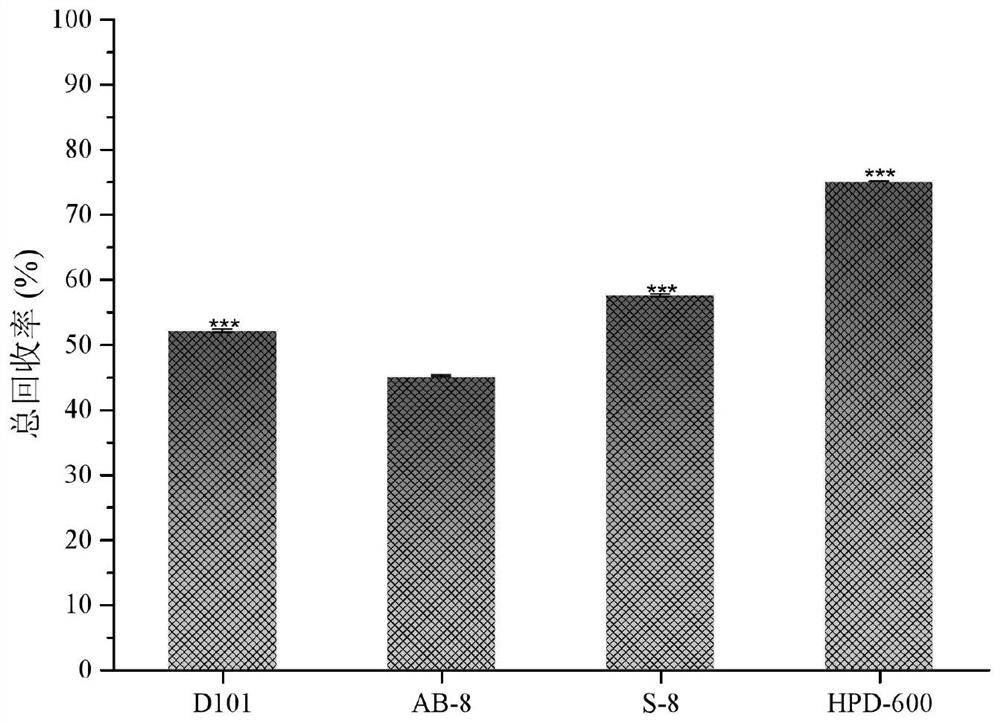

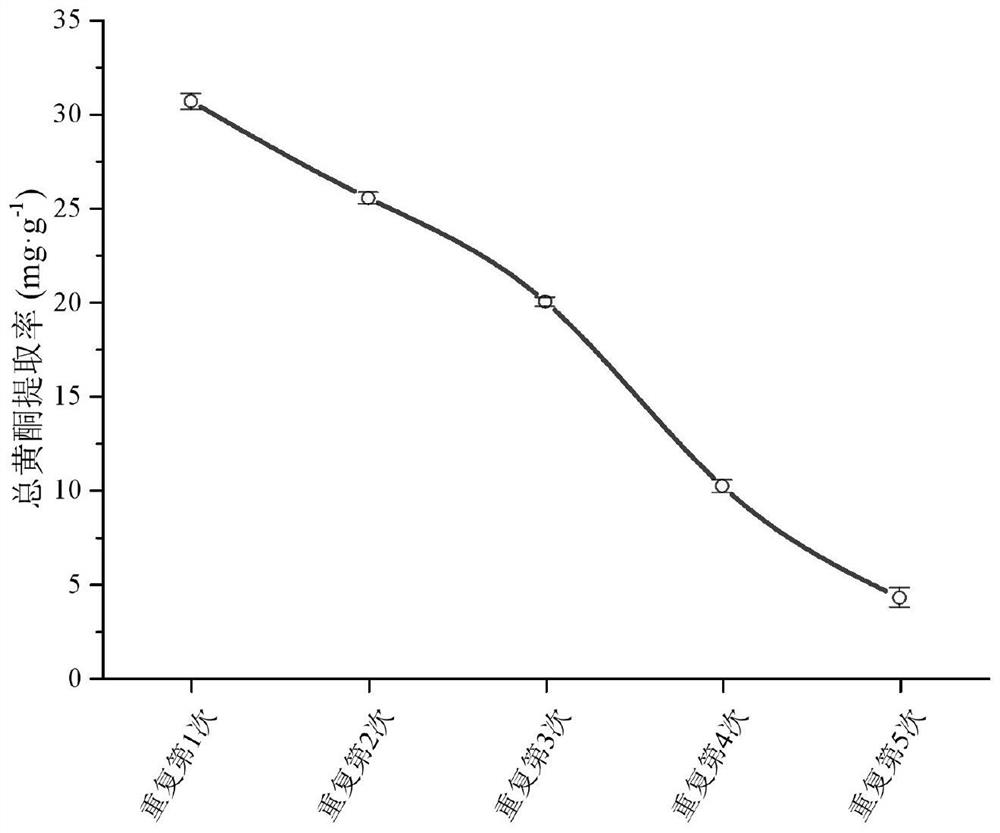

Method for extracting and recovering acanthopanax total flavonoids by using deep eutectic solvent

ActiveCN114010670AModerate viscosityModerate surface tensionDigestive systemAntinoxious agentsXanthonoidOrganosolv

The invention belongs to the technical field of extraction and purification of effective components of traditional Chinese medicines, and particularly discloses a method for extracting and recycling acanthopanax total flavonoids by using a deep eutectic solvent. The method comprises the following steps: by taking powder of acanthopanax roots as a raw material, adding a deep eutectic solvent with a certain water content, extracting acanthopanax total flavonoids under an ultrasonic-assisted condition, and enriching and recovering flavonoid compounds in an extracting solution by using macroporous resin, and meanwhile, after the water in the obtained eutectic recovery liquid is evaporated, extracting the acanthopanax total flavonoids again, wherein the acanthopanax total flavonoids can be repeatedly utilized for at least three times. The invention develops a novel process technology for extracting and enriching the acanthopanax total flavonoid compounds from the acanthopanax roots and stems by combining the eutectic solvent with the macroporous resin, the recycling of the eutectic solvent is realized, and the purposes of greenness, high efficiency and repeatable extraction are achieved. Compared with a traditional extraction method, the method has the advantages of no use of an organic solvent, simplicity and convenience in operation, time saving, safety, low cost and the like, and industrial production can be realized.

Owner:LIAOCHENG UNIV

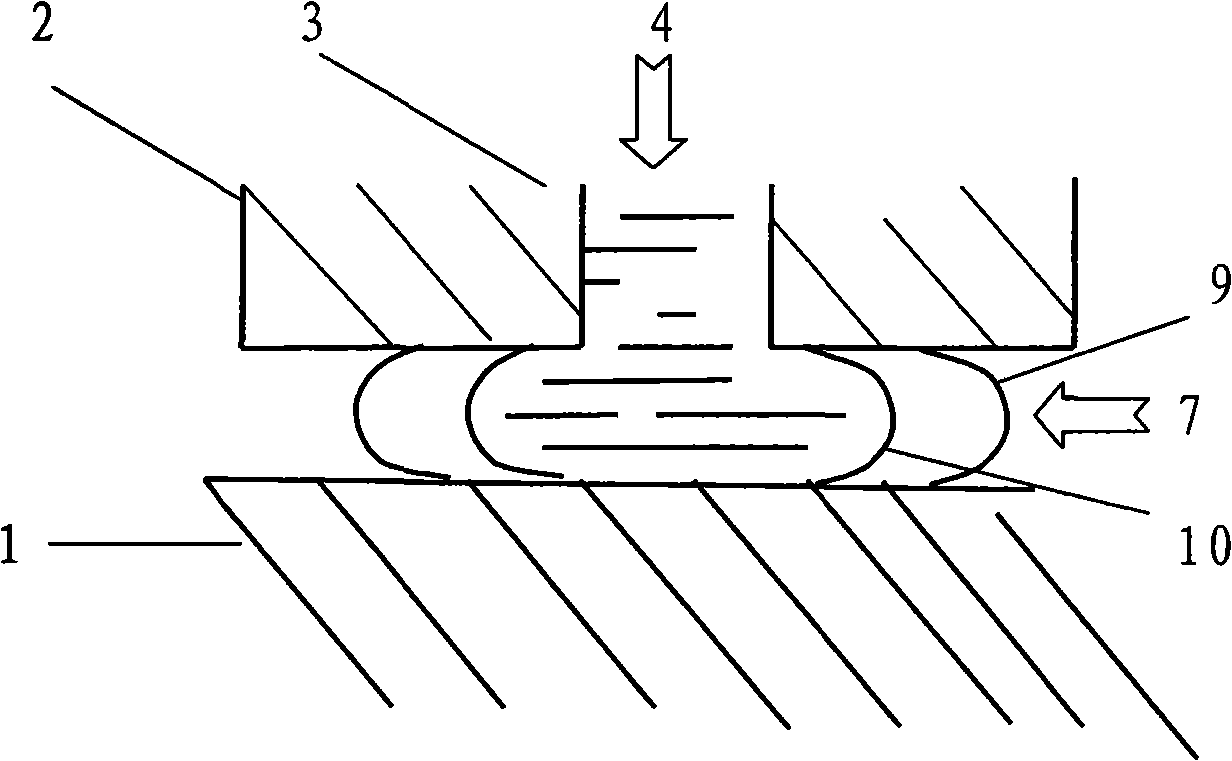

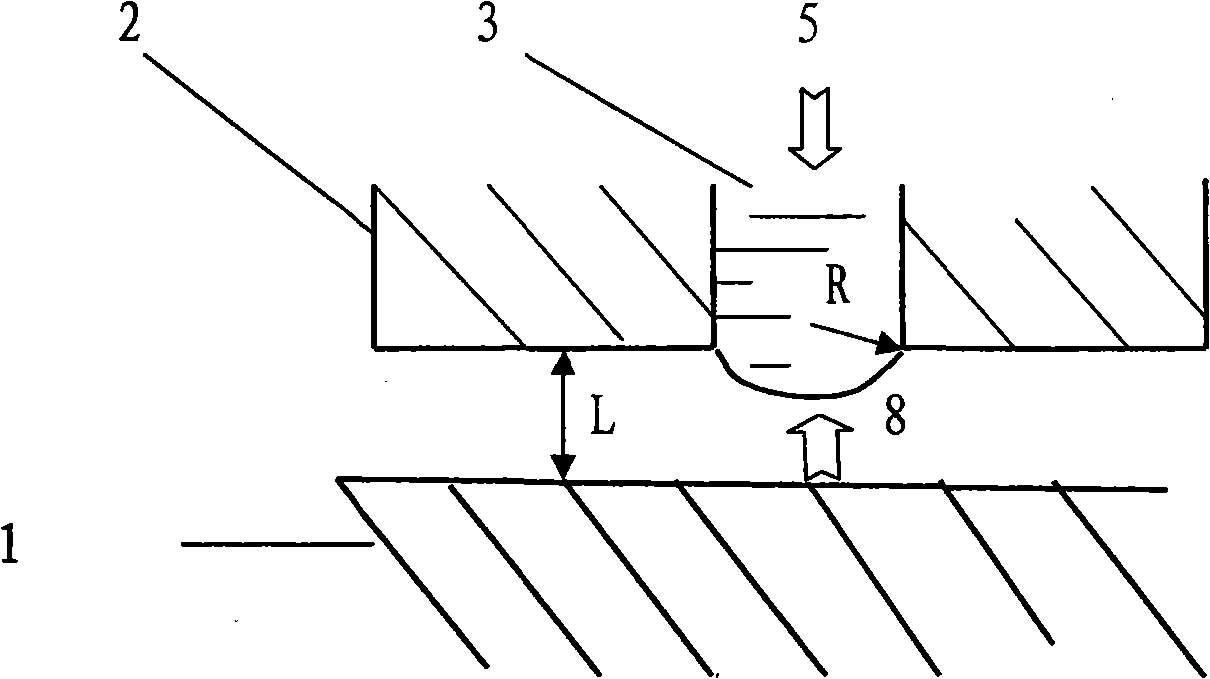

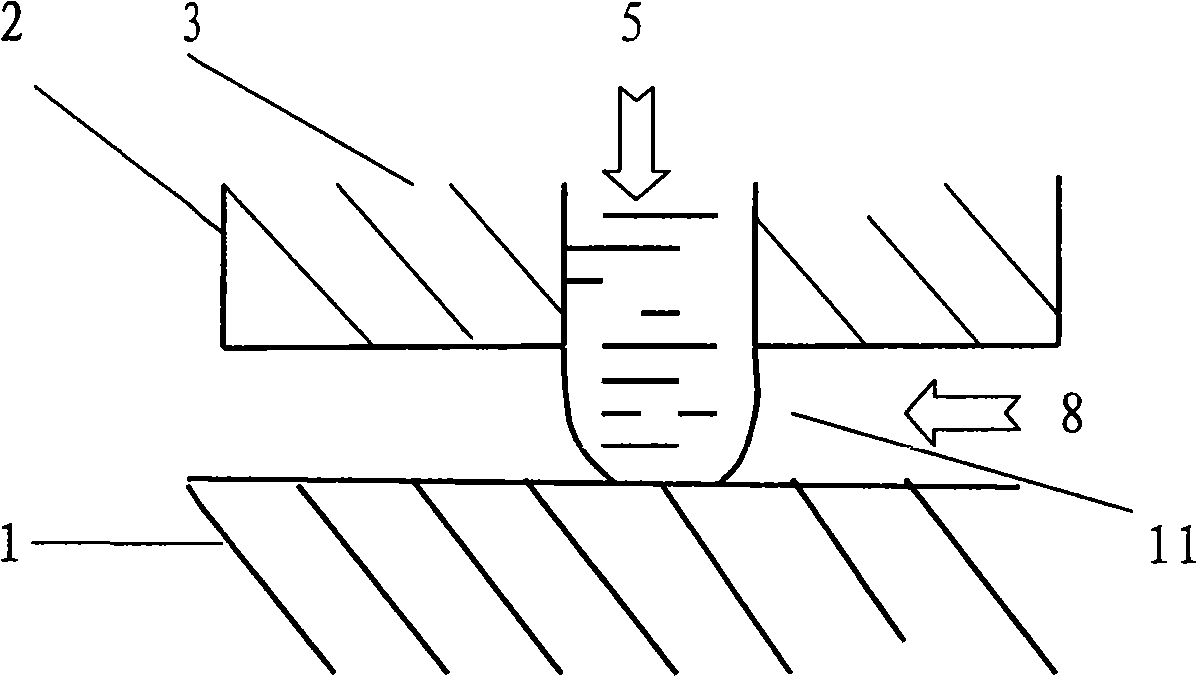

Fast quenching amorphous alloy ribbon and preparation method thereof

This invention belongs to the field of metal material preparation, in particular relates to a fast quenching amorphous alloy ribbon and a preparation method thereof. The preparation method of the fast quenching amorphous alloy ribbon comprises the steps of batching, vacuum melting, secondary melting, ribbon spouting and collecting, and the chemical components are 70 to 85 percent of Fe, 0.001 to 4 percent of Nb, or at least one of Nb, Mo, W, V and Ta, 0.001 to 25 percent of Si, 0.001 to 15 percent of B, 0.001 to 2 percent of Cu, 0.005 to 0.08 percent of at least one of Al and Ti according to the atomic percent. In the ribbon spouting step, a dynamic stable arc weld pool with the both ends protruding outward is formed between a nozzle and a cooling roller, and the temperature of the weld pool is 1180 to 1300 DEG C; the width D of the nozzle gap is 0.1 to 0.4 millimeters, and the space length between the cooling roller and the nozzle is 0.1 to 0.4 millimeters; the thickness of the ribbon is 18 to 24 micrometers, and the roughness Ra is smaller than 2 micrometers. The ribbon has very thin thickness, excellent surface quality and magnetic property, and is suitable for producing high-quality magnet core elements. The ribbon is particularly suitable for being used under high frequency, and has lower high frequency loss and better frequency characteristics.

Owner:AT&M AMORPHOUS TECH CO LTD

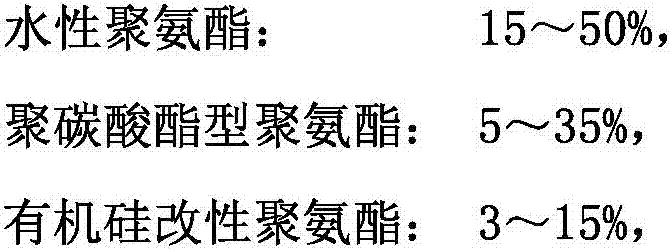

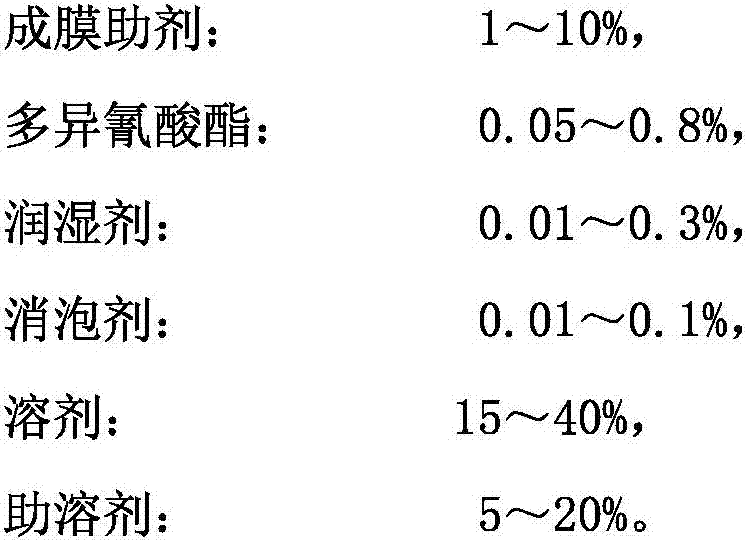

Scratching-resisting waterborne transfer coating

InactiveCN107312436AImprove temperature resistanceThere will be no looseningFireproof paintsPolyurea/polyurethane coatingsHardnessSolvent

The invention discloses a scratching-resisting waterborne transfer coating. The coating comprises the following components in percentage by weight: 15-50% of waterborne polyurethane, 5-35% of polycarbonate polyurethane, 3-15% of silicone-modified polyurethane, 1-10% of a coalescing agent, 0.05-0.8% of polyisocyanate, 0.01-0.3% of a wetting agent, 0.01-0.1% of a defoaming agent, 15-40% of a solvent, and 5-20% of a cosolvent. Compared with the prior art, the scratching-resisting waterborne transfer coating has the advantages of being proper in surface tension which is about 38, free from any adverse influence on later printing performance, high in hardness, and high in high-temperature resistance.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

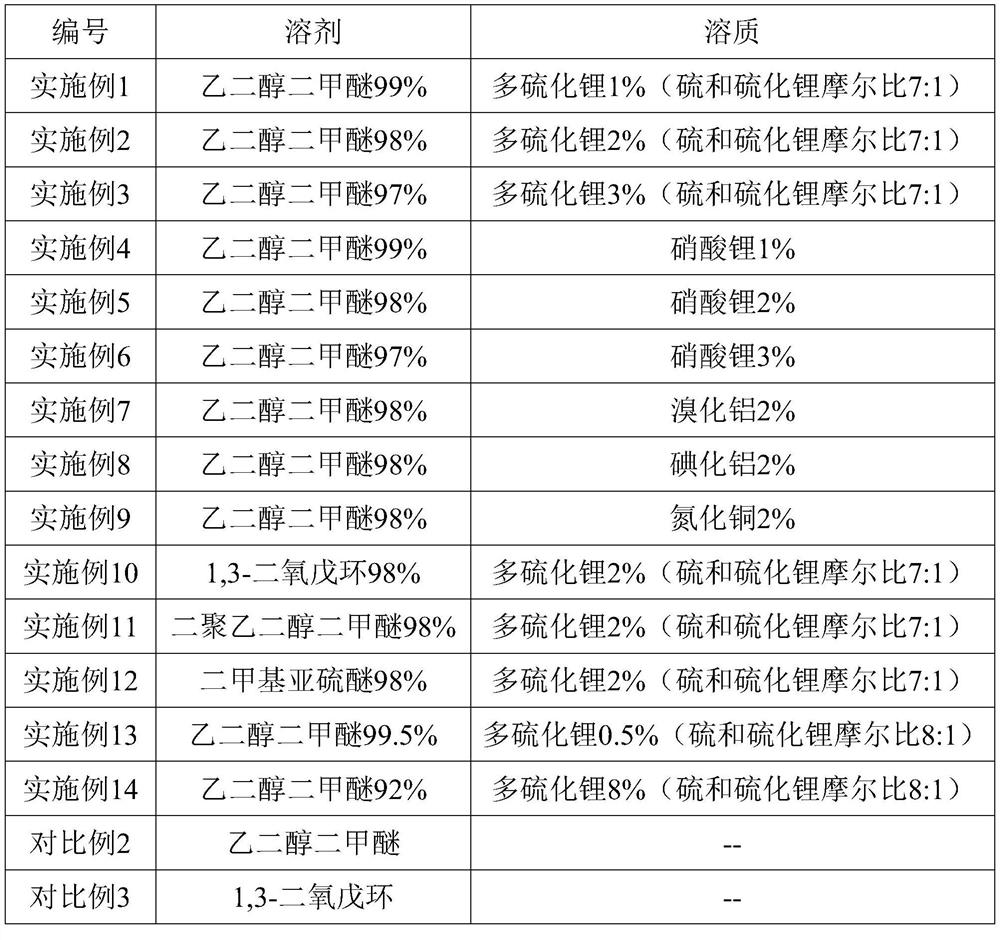

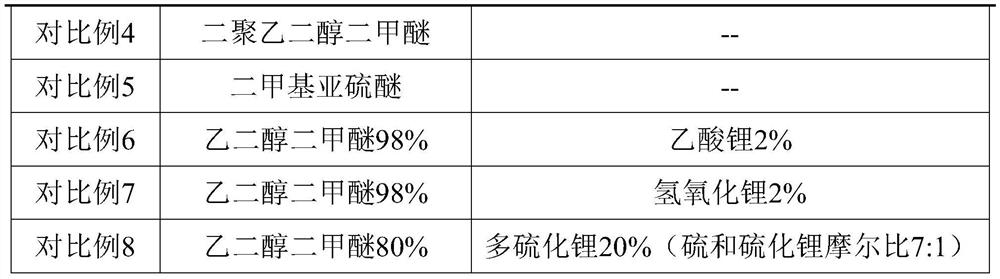

Interface pretreatment liquid for silicon-oxygen pre-lithiation negative electrode as well as preparation method and application of interface pretreatment liquid

InactiveCN113193174AGood chemical stabilityImprove solubilityCell electrodesFinal product manufacturePropanoic acidPolyethylene glycol

The invention relates to an interface pretreatment liquid for a silicon-oxygen pre-lithiation negative electrode as well as a preparation method and application of the interface pretreatment liquid. The interface pretreatment liquid comprises 0.1%-10% of solute and 90%-99.9% of solvent, the solvent is one or more selected from N-methyl pyrrolidone, ethylene carbonate, fluoroethylene carbonate, propylene carbonate, butylene carbonate, dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, gamma-butyrolactone, methyl formate, ethyl formate, methyl acetate, ethyl acetate, ethyl propionate, propyl propionate, ethyl butyrate, propyl butyrate, dimethyl sulfoxide, ethylene glycol dimethyl ether, 1, 3-dioxolane, dipolyethylene glycol dimethyl ether and dimethyl thionyl ether; and the solute is selected from one or more of lithium polysulfide, aluminum iodide, aluminum bromide, lithium nitrate and copper nitride. The solvent can fully infiltrate the internal pores of the lithium-rich negative plate and the surface of the negative active material, and the solute can react with the negative material, so that the stability of the SEI membrane is improved, and the first charge-discharge efficiency and long-term cycle performance of the battery are synergistically improved.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

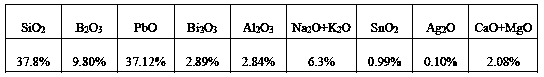

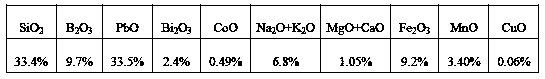

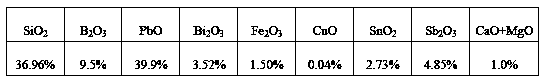

Enamel color material, preparation method thereof, and application in porcelain body painting enamel cultural relic repair

The invention discloses an enamel color material, a preparation method thereof, and an application of the enamel color material in porcelain body painting enamel cultural relic repair. The enamel color material is prepared from the following chemical components in percentage by mass: 33%-51% of silicon dioxide, 0%-3.8% of aluminum oxide, 8%-19% of boron oxide, 31%-53% of lead oxide, 0%-6% of calcium oxide and magnesium oxide, 0%-6.9% of sodium oxide and potassium oxide, 0.5%-6% of bismuth trioxide, 0%-7.2% of tin oxide, 0%-6.5% of antimonous oxide, 0%-13% of ferric oxide, 0%-4.2% of copper oxide, 0%-4% of cobalt oxide, 0%-9% of manganese oxide, 0%-2% of silver oxide and 0%-0.15% of gold oxide. Compared with the traditional enamel painted porcelain, the enamel painted porcelain provided bythe invention has the advantages that the melting point is lower; the colored glaze and an ancient enamel colored pigment layer show a "like-fusion-like" phenomenon at high temperature, can be matchedwith the thermal expansion coefficients of the surface glaze and the pigment layer of the traditional enamel color, has good adhesiveness and good adhesiveness before firing, is easy to disperse, hasmoderate material surface tension in the firing and fusing process, not only meets the fusing property, but also can keep a certain colored drawing three-dimensional shape.

Owner:佛山市天工嘉荟文化科技有限公司 +1

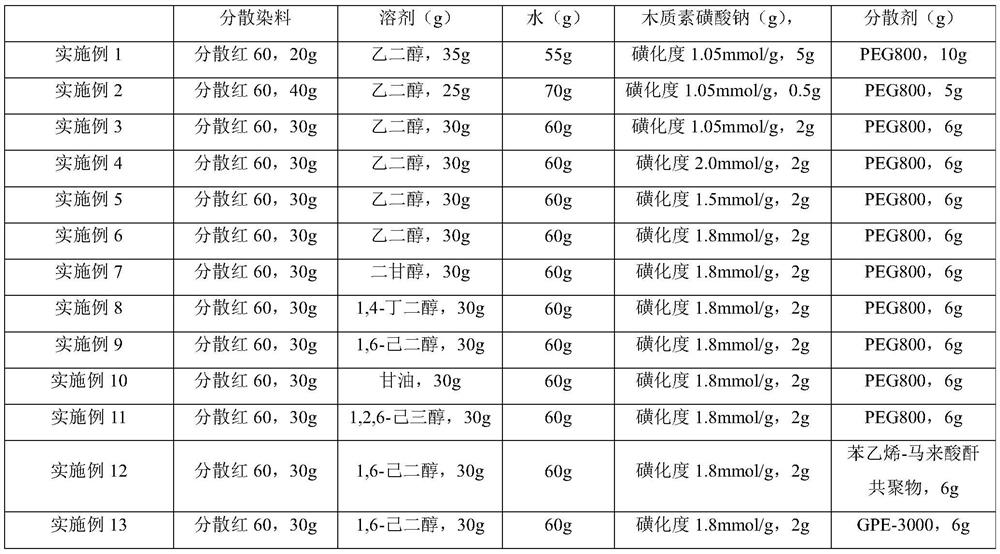

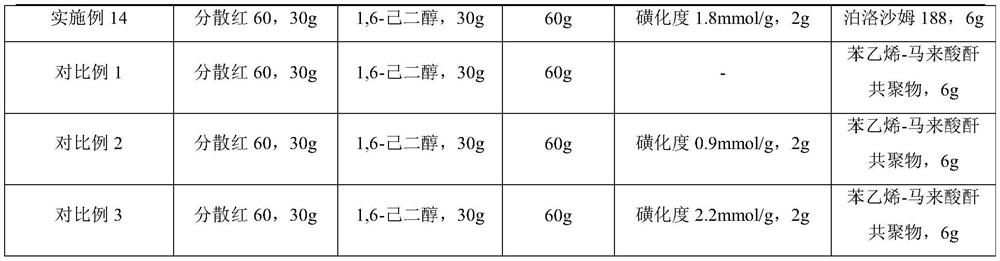

A kind of preparation method of thermal sublimation ink based on disperse dye

The invention relates to a preparation method of dye sublimation ink based on dispersive dye. The preparation method comprises the following steps of (1) sequentially adding water, a disperstant, a solvent and a surfactant into a container, shearing and dispersing; continuing to add the dispersive dye into the container, stirring, and dispersing, so as to obtain a first mixture; (2) using zirconium oxide beads with different particle sizes to grind the first mixture, wherein the particle sizes of the zirconium oxide beads are gradually reduced; (c) adding water into a product in step (b), centrifuging, separating to remove large-particle residues, and filtering, so as to obtain color paste, wherein the mass of water is same as that of the product; (d) mixing the color paste, a wetting agent, a flatting agent, a solvent and water, so as to prepare the dye sublimation ink. The preparation method can meet the use requirements under the conditions of simple technology steps, small amount of raw materials, and lower cost.

Owner:铜陵晖闪数码科技有限公司

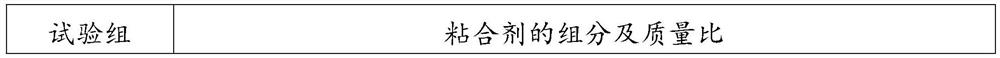

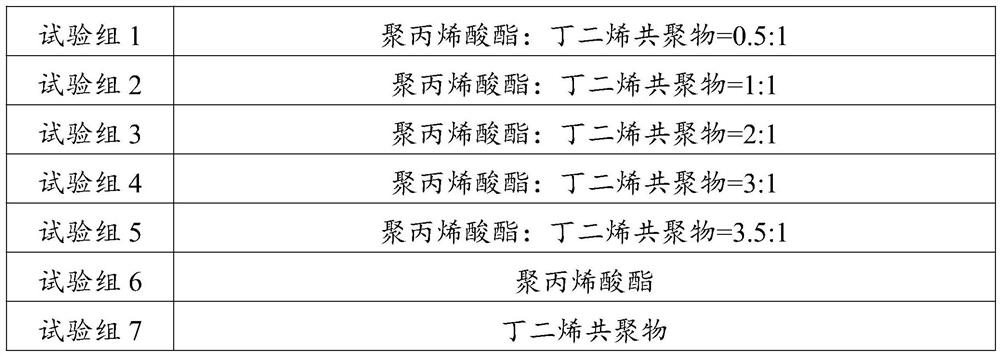

Digital printing pigment ink and preparation method thereof

InactiveCN112375429AReduce manufacturing costExcellent long-term storage stabilityInksDyeing processTextile printerAdhesive

The invention discloses digital printing pigment ink, which is composed of the following components in percentage by weight: 8-12% of nanoscale organic pigment, 0.5-3% of dispersing wetting agent, 0.5-2% of adhesive, 5-15% of humectant, 0.1-1% of preservative, 5-10% of viscosity regulator, 0.1-1% of pH regulator and the balance of deionized water, wherein the particle size of the nanoscale organicpigment is 50-100 nm. According to the invention, the digital printing pigment ink has the advantages of low preparation cost, good long-term storage stability, difficult flocculation, aggregation, precipitation and layering, moderate viscosity and surface tension, good fluidity of the ink in a pipeline, smooth printing, good printing effect, good washing resistance, good dry and wet rubbing fastness of a printed product, and good printing quality, and can meet the clothing wearing requirements of consumers.

Owner:卢洁贞

Radiation curable ink and application thereof

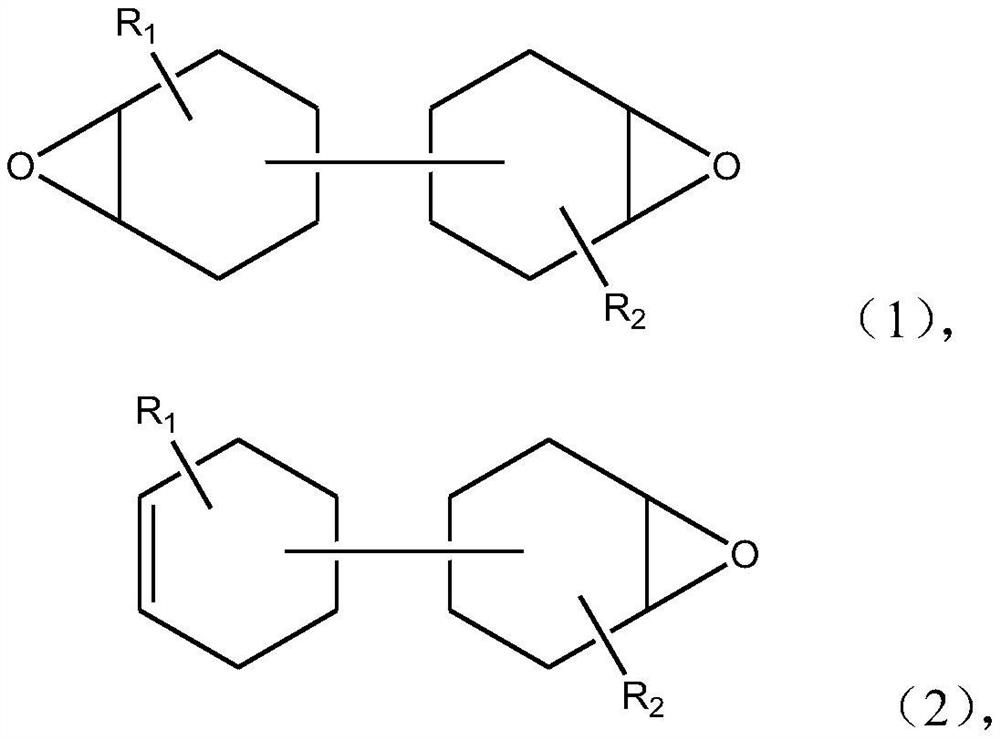

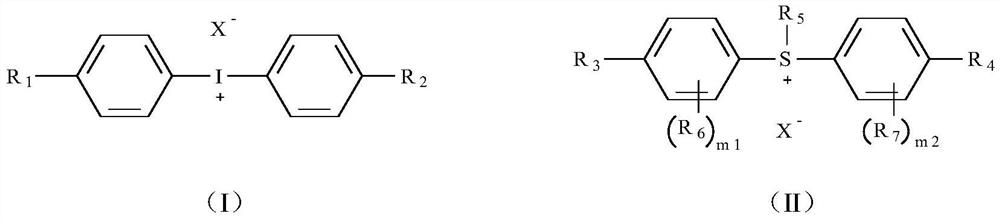

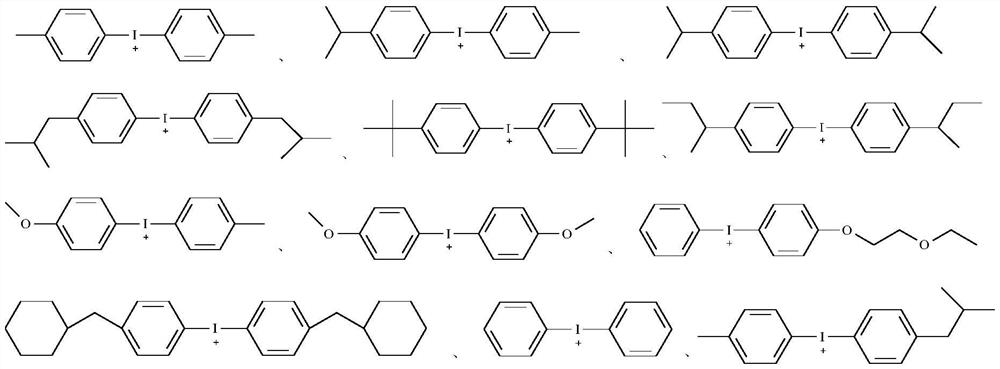

The invention provides radiation curable ink and application thereof. The radiation-curable ink comprises a polymerizable compound, a photoinitiator and a pigment, the polymerizable compound comprisesan epoxy compound, the epoxy compound comprises a first alicyclic epoxy compound, and the first alicyclic epoxy compound contains compounds represented by a formula (1) and a formula (2). In the radiation-curable ink, the polymerizable compound comprises the first alicyclic epoxy compounds shown in the formulas (1) and (2), and the first alicyclic epoxy compounds shown in the formulas (1) and (2)have better compatibility with other components in the composition system by adjusting the contents of epoxy and double bond groups. Therefore, the radiation-curable ink has low viscosity, good processability and productivity, the crosslinking density and surface tension of the whole composition are moderate, and the adhesive force is good during recoating, so that the radiation curable ink is more suitable for recoating.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

A powder 3D printing method based on water-based inorganic binder

Owner:XI AN JIAOTONG UNIV

Fluorine-base type sintered flux used for reducing sulfur and phosphorus contents of welding joint and used in submerged arc hardfacing

InactiveCN102085603BArc stabilizationExcellent high temperature slag removal performanceWelding/cutting media/materialsSoldering mediaCrack resistanceIron(II) oxide

The invention discloses a fluorine-base type sintered flux used for reducing sulfur and phosphorus contents of a welding joint and used in submerged arc hardfacing, relating to the flux technology. The fluorine-base type sintered flux comprises the following components in percent by weight: 30-35 percent of magnesium oxide (MgO), 16-21 percent of calcium fluoride (CaF2), 17-22 percent of aluminium oxide (Al2O3), 14-19 percent of silica (SiO2), 3-5 percent of manganese oxide (MnO), less than 3 percent of ferrous oxide (FeO), 1-3 percent of rare earth fluoride compound additive, 0.3-0.6 percent of sodium oxide (Na2O), 0.15-0.3 percent of potassium oxide (K2O), not more than 0.03 percent of sulphur (S) and not more than 0.04 percent of phosphorus (P).Through controlling the basicity range of the flux and adding the rare earth fluoride compound additive, the oxygen content, the sulfur and phosphorus contents and the impurities in the flux are reduced, and the purity of weld metal is ensured, and higher flexibility and cracking resistance are obtained by hardfacing deposited metal.

Owner:CHINA JINGYE ENG TECH CO LTD +1

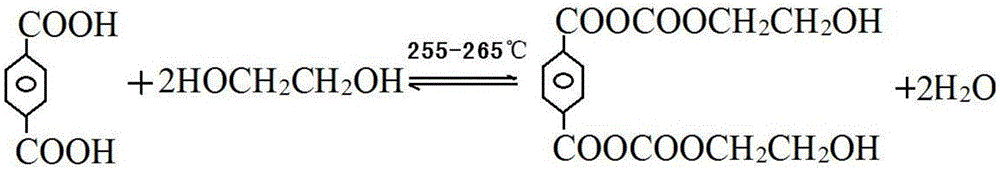

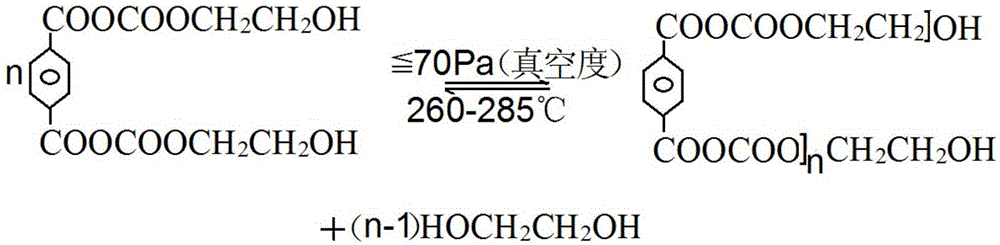

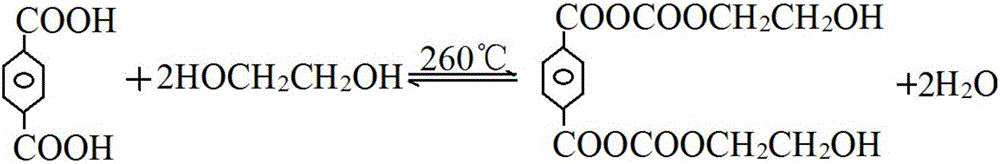

A kind of production method of environment-friendly size polyester for fabric sizing

The invention provides a production method of an environment-friendly polyester slurry. The production method comprises the following steps: (1) putting right amounts of ethylene glycol and terephthalic acid into a slurrying kettle, and stirring into a slurry; (2) carrying out esterification reaction on the slurry in an esterification kettle at 255-265 DEG C, sending the water generated by esterification and volatile ethylene glycol into a fractionating column to perform separation, and controlling the column top temperature by a column top condenser water inlet regulating valve and an external reflux regulating valve, thereby separating out the esterification water; weighing the obtained esterification water, and judging that the esterification reaction is finished when the weighed water is greater than or equal to 95 wt% of the theoretical generated water; (3) polycondensation reaction: carrying out two steps in a vacuum state, and judging the end point of the polycondensation reaction according to the stirring power of the polycondensation reaction kettle; and (4) granulating or slicing. The production method has the advantages of simple technique and stable operation. By adopting the process of judging the end point of the polycondensation reaction according to the stirring power of the polycondensation reaction kettle, the production method is simple, feasible and easy to operate in mass production, and saves the human resources and material resources.

Owner:湖北尚助化学有限公司

A powder 3D printing method based on instant inorganic binder

The invention discloses a powder 3D printing method based on instant inorganic binder. The powder 3D printing method comprises the following steps: firstly, using deionized water as a binder for a 3D printer, and adding a co-volatile agent, a coloring agent and a modifying agent to form a mixed solution as a binder for powder 3D printing; secondly, using instant sodium silicate as a solid binder, mixing the solid binder with 3D printer raw material powder, and then adding flux to form mixed powder as a material for the powder 3D printing; finally, performing the powder 3D printing by using the prepared binder and the mixed powder, wherein the binder prepared from water and the instant sodium silicate are used as the binder for a powder 3D printing process; as for a powder 3D printing nozzle, a solution with the viscosity close to water is only filled, and the solution is stable in performance, easier to store, unlikely to block the nozzle and free of corrosive effect on the nozzle. By the powder 3D printing method, rapid powder 3D printing of a product with complex structure is achieved, and the environment friendliness of the manufacturing process is ensured; by the powder 3D printing method, the production cost is reduced and the product quality is improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com