Digital printing pigment ink and preparation method thereof

A pigment ink and digital printing technology, applied in ink, dyeing method, application, etc., can solve the problems of limiting the application and promotion of pigment inkjet printing technology, easy to lose color effect, and immature products, etc., and achieve good long-term storage stability Sexuality, meet the requirements of clothing wearing, smooth printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

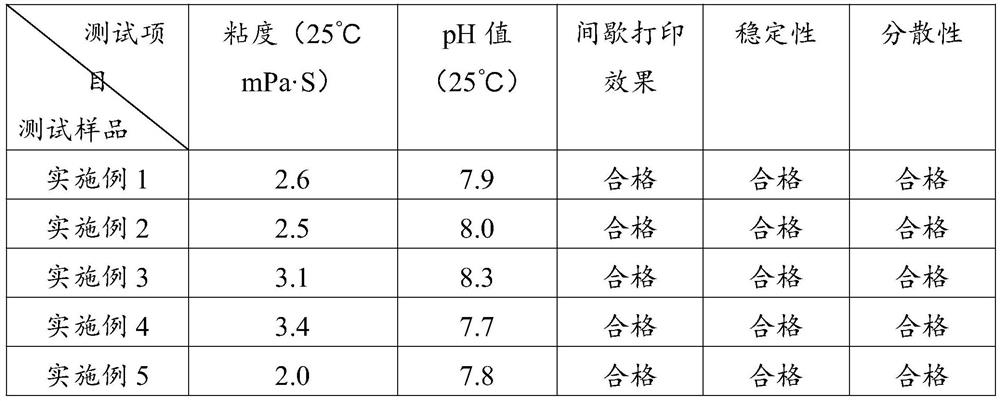

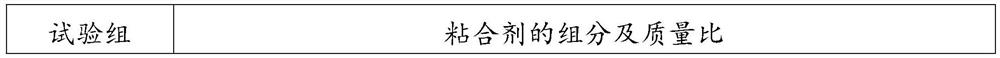

Embodiment 1

[0031] A digital printing pigment ink, which is composed of the following components in weight percentage: 10% of nanoscale organic pigment (golden red), 2% of dispersing wetting agent, 1.2% of adhesive, 10% of moisturizing agent, 0.5% of preservative %, viscosity regulator 7%, pH regulator 0.5% and the balance of deionized water. The dispersing wetting agent is composed of sodium dodecylsulfonate, fatty alcohol polyoxyethylene ether and sodium lignosulfonate, and in terms of mass ratio, sodium dodecylsulfonate: fatty alcohol polyoxyethylene ether: Sodium lignosulfonate = 1:1:0.05. The adhesive is composed of polyacrylate and butadiene copolymer, and by mass ratio, polyacrylate: butadiene copolymer=2:1, and the butadiene copolymer is butadiene and benzene Copolymers of ethylene. The moisturizing agent is composed of sorbitol, potassium tripolyphosphate and diethylene glycol, and in terms of mass ratio, sorbitol:potassium tripolyphosphate:diethylene glycol=1:1:0.3. The prese...

Embodiment 2

[0034] A digital printing pigment ink, which is composed of the following components by weight percentage: 11% of nanoscale organic pigment (golden red), 2.5% of dispersing wetting agent, 1.5% of binder, 12% of moisturizing agent, and 0.5% of preservative %, viscosity regulator 5.2%, pH regulator 0.3% and the balance of deionized water. The dispersing wetting agent is composed of sodium dodecylsulfonate, fatty alcohol polyoxyethylene ether and sodium lignosulfonate, and in terms of mass ratio, sodium dodecylsulfonate: fatty alcohol polyoxyethylene ether: Sodium lignosulfonate = 1:1:0.05. The adhesive is composed of polyacrylate and butadiene copolymer, and by mass ratio, polyacrylate: butadiene copolymer=2:1, and the butadiene copolymer is butadiene and benzene Copolymers of ethylene. The moisturizing agent is composed of sorbitol, potassium tripolyphosphate and diethylene glycol, and in terms of mass ratio, sorbitol:potassium tripolyphosphate:diethylene glycol=1:1:0.3. Des...

Embodiment 3

[0037] A digital printing pigment ink, which is composed of the following components in weight percentage: 9% of nanoscale organic pigment (golden red), 1% of dispersing wetting agent, 0.8% of adhesive, 10% of moisturizing agent, 0.2% of preservative %, viscosity regulator 9%, pH regulator 1% and the balance of deionized water. The dispersing wetting agent is composed of sodium dodecylsulfonate, fatty alcohol polyoxyethylene ether and sodium lignosulfonate, and in terms of mass ratio, sodium dodecylsulfonate: fatty alcohol polyoxyethylene ether: Sodium lignosulfonate = 1:1:0.05. The adhesive is composed of polyacrylate and butadiene copolymer, and by mass ratio, polyacrylate: butadiene copolymer=2:1, and the butadiene copolymer is butadiene and benzene Copolymers of ethylene. The moisturizing agent is composed of sorbitol, potassium tripolyphosphate and diethylene glycol, and in terms of mass ratio, sorbitol:potassium tripolyphosphate:diethylene glycol=1:1:0.3. The preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com