Quick-drying primer for renovating exterior wall tiles and preparation method thereof

A quick-drying, ceramic tile technology, applied in the direction of primer, coating, etc., can solve the problems of unfavorable coating construction, slow coating drying rate, low covering power of coating film, etc., and achieve excellent adhesion and adhesion No change, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

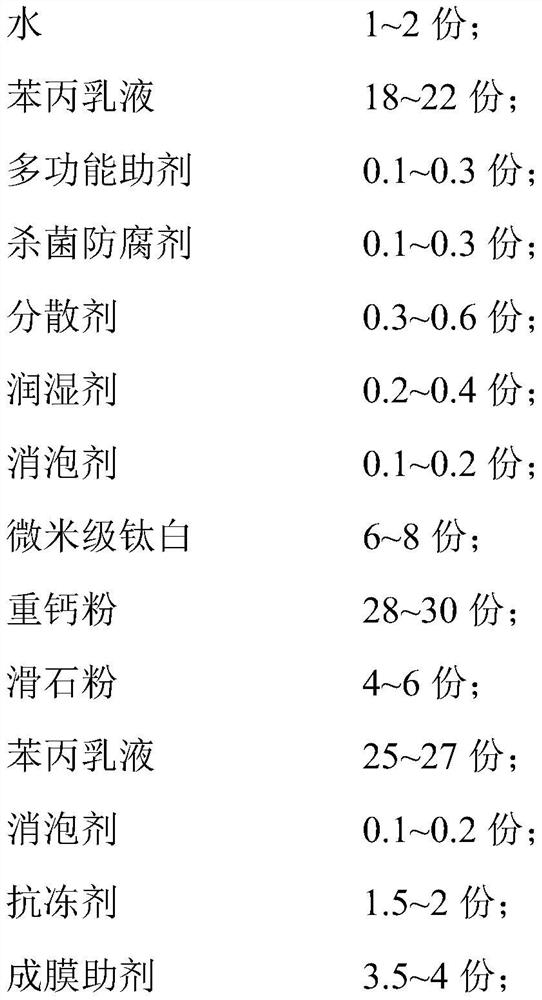

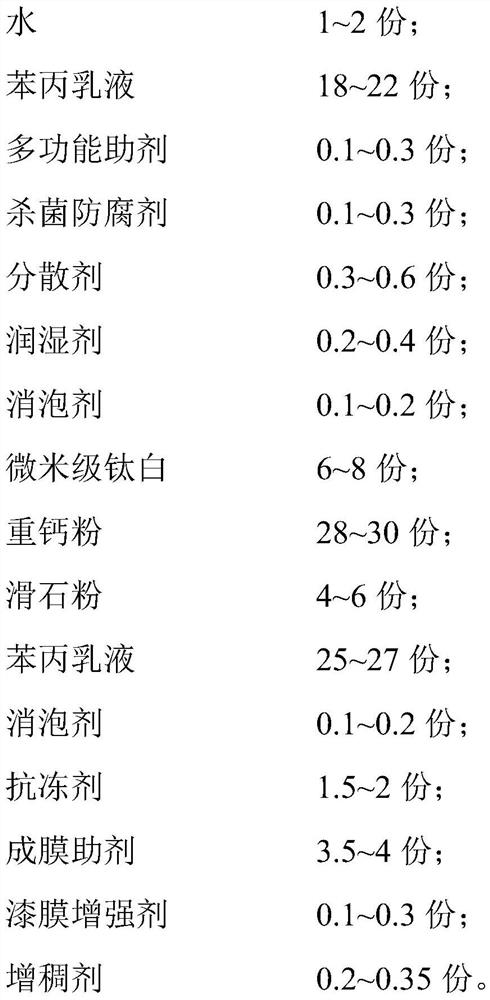

[0036] 1) Add 1 part of water and 18 parts of styrene-acrylic emulsion into the dispersion tank, and add 0.1 parts of multifunctional additives, 0.1 parts of bactericidal preservatives, 0.3 parts of dispersants, and 0.2 parts of wetting agents in sequence at a speed of 400r / min and 0.1 part of defoamer, stirring for 10 minutes;

[0037] 2) Then maintain the above speed and add 6 parts of micron grade titanium dioxide, 28 parts of heavy calcium powder and 4 parts of talcum powder, then increase the speed to 1250r / min, and stir for 15 minutes;

[0038] 3) Finally, reduce the speed to 300r / min, add 25 parts of styrene-acrylic emulsion, 0.1 part of defoamer, 1.5 parts of antifreeze, 3.5 parts of film-forming aid, 0.1 part of paint film enhancer and 0.2 part of thickener in sequence, Stir for 10 minutes to obtain a quick-drying primer.

[0039] Wherein, the antifreezing agent is ethylene glycol; and the film-forming aid is dodecyl alcohol ester.

Embodiment 2

[0041] 1) Add 1.5 parts of water and 20 parts of styrene-acrylic emulsion into the dispersion tank, and then add 0.2 parts of multifunctional additives, 0.2 parts of bactericidal preservatives, 0.4 parts of dispersants, and 0.3 parts of wetting agents at a speed of 300r / min and 0.15 parts of defoamer, stirring for 15 minutes;

[0042] 2) Then keep the above speed and add 7 parts of micron grade titanium dioxide, 29 parts of heavy calcium powder and 5 parts of talcum powder, then increase the speed to 1400r / min, and stir for 15 minutes;

[0043] 3) Finally, reduce the speed to 500r / min, add 26 parts of styrene-acrylic emulsion, 0.15 parts of defoamer, 1.8 parts of antifreeze, 3.7 parts of film-forming aids, 0.2 parts of paint film enhancer and 0.23 parts of thickener, Stir for 12 minutes to obtain a quick-drying primer.

[0044] Wherein, the antifreezing agent is a mixture of 0.8 parts of propylene glycol and 1 part of ethylene glycol; the coalescent is a mixture of 1 part of ...

Embodiment 3

[0046] 1) Add 2 parts of water and 22 parts of styrene-acrylic emulsion into the dispersion tank, and add 0.3 parts of multifunctional additives, 0.3 parts of bactericidal preservatives, 0.6 parts of dispersants, and 0.4 parts of wetting agents in sequence at a speed of 600r / min And 0.2 parts of defoamer, stirring for 15min.

[0047] 2) Then maintain the above speed and add 8 parts of micron grade titanium dioxide, 30 parts of heavy calcium powder and 6 parts of talc powder, then increase the speed to 1500r / min, and stir for 20 minutes;

[0048] 3) Finally, reduce the speed to 600r / min, add 27 parts of styrene-acrylic emulsion, 0.2 parts of defoamer, 2 parts of antifreeze, 4 parts of film-forming aid, 0.3 part of paint film enhancer and 0.35 part of thickener in sequence, Stir for 15 minutes to obtain a quick-drying primer.

[0049] Wherein, the antifreeze agent is polyethylene glycol; the film-forming aid is dipropylene glycol butyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com