BOPET matte release film

A release film, matte technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of unfavorable use in the electronics industry, and achieve the effect of moderate surface tension and hardness, and good peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

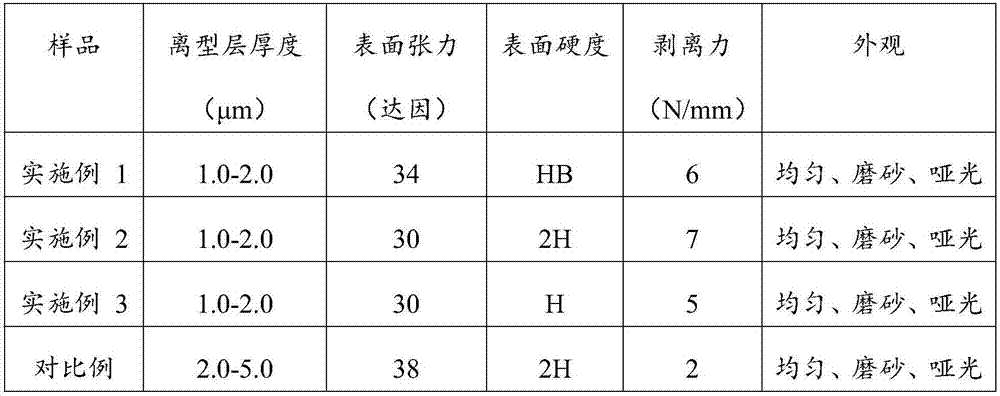

Examples

Embodiment 1

[0023] A BOPET matte release film, comprising a polyester substrate and a release layer laminated on one side of the polyester substrate, the release layer is formed by coating and curing a release layer coating liquid, and the release layer is coated The liquid contains the following raw materials in parts by weight: 2.2 parts of fluorine resin, 3.5 parts of polyester polyol, 0.7 part of aldehyde and ketone resin, 2.5 parts of curing agent, 0.4 part of auxiliary agent, 2.7 parts of matting agent, 15.0 parts of mixed solvent, and the mixed solvent is composed of benzene , ethylene glycol, 2-heptanone, and cyclohexanone are mixed at a volume ratio of 1:0.7:1.5:0.5, and the auxiliary agent is a combination of dispersant and antistatic agent; the curing agent is a mixed system of amino resin and blocked isocyanate;

[0024] Among them, the fluorine-based resin is a binary copolymer of trifluoroethylene-hexafluoropropylene, the hydroxyl value of the fluorine-based resin is 27mgKOH / ...

Embodiment 2

[0026] A BOPET matte release film, comprising a polyester substrate and a release layer laminated on one side of the polyester substrate, the release layer is formed by coating and curing a release layer coating liquid, and the release layer is coated The liquid contains the following raw materials in parts by weight: 2.7 parts of fluorine resin, 4.0 parts of polyester polyol, 1.2 parts of aldehyde and ketone resin, 1.9 parts of curing agent, 0.35 parts of auxiliary agent, 3.1 parts of matting agent, 15.0 parts of mixed solvent, and the mixed solvent is composed of benzene , ethylene glycol, 2-heptanone, and cyclohexanone are mixed at a volume ratio of 1:0.7:1.5:0.5, and the auxiliary agent is a combination of dispersant and antistatic agent; the curing agent is a mixed system of amino resin and blocked isocyanate;

[0027] Among them, the fluorine resin is a binary copolymer of trifluoroethylene-hexafluoropropylene, the hydroxyl value of the fluorine resin is 33mgKOH / g, the ac...

Embodiment 3

[0029] A BOPET matte release film, comprising a polyester substrate and a release layer laminated on one side of the polyester substrate, the release layer is formed by coating and curing a release layer coating liquid, and the release layer is coated The liquid contains the following raw materials in parts by weight: 3.2 parts of fluorine resin, 4.5 parts of polyester polyol, 1.6 parts of aldehyde and ketone resin, 2.9 parts of curing agent, 0.5 parts of auxiliary agent, 3.1 parts of matting agent, 18.4 parts of mixed solvent, and the mixed solvent is composed of benzene , ethylene glycol, 2-heptanone, and cyclohexanone are mixed at a volume ratio of 1:0.7:1.5:0.5, and the auxiliary agent is a combination of dispersant and antistatic agent; the curing agent is a mixed system of amino resin and blocked isocyanate;

[0030] Among them, the fluorine resin is a binary copolymer of trifluoroethylene-hexafluoropropylene, the hydroxyl value of the fluorine resin is 30mgKOH / g, the aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com